Wear testing machines are essential in all industries, from manufacturing to R&D, for checking the durability and performance of materials. However, being conversant with the price range of these machines can oftentimes become overwhelming due to the multitude of factors that influence their costs.

This comprehensive guide puts the pricing structure of wear testing machines in the spotlight by examining factors affecting costs – be it type of machine, capabilities for testing, advanced feature options, or customization. Whether you’re a procurement person, lab manager, or engineer, this resource will give you all the knowledge you need to invest wisely.

Key Factors Influencing Wear Testing Machine Price

1. Type of Machine

The price of wear testing machines is highly influenced by their bearing capacity. Basic models that serve simple abrasion tests will be less expensive. The price will increase for specialized machines that can work on extremely complex simulations, including high-temperature or multidirectional wear.

2. Testing Capabilities

More widely testing machines with diverse ways of simulation wear (e.g., sliding and rolling wear along with impact wear) will also be costly. Higher testing capabilities over load variation by programming and testing for more than one sample will also favor the increase in price.

3. Durability of Materials and Construction

A wear testing machine made out of premium materials and with excellent components assures greater durability and precision. Obviously, sufficient systems are built to withstand long operation times in a day with high-frequency loading, making them costlier because of the longevity in use.

4. Customization and Automation

Upscaling the initial cost are machines that offer customization or automated options to conduct their operation, testing, and data analysis, including real-time data analysis and remote operation. With less need for human interference, these features boost testing productivity, therefore justifying their increased price.

5. Manufacturer and Brand Reputation

Reputable brands charge a higher price, but in return, they offer assurances for reliability, consistent quality, and better after-sale support.

Build Quality and Materials Impact

The quality and materials with which wear testing machines are made certainly have considerable influence on their price. Those machines that are constructed with high-grade alloys, stainless steel, or composite materials earn advantages in terms of:

- Durability: Extended operational life under demanding conditions

- Precision: Consistent and accurate test results

- Resistance: Superior wear and corrosion resistance

- Stability: Long-term operational stability with reduced maintenance

Features and Specifications

Various features and specifications play a crucial role in determining the price of wear testing machines:

- Material Compatibility: Ability to test various substrates and coatings

- Precision Controls: Advanced load application systems

- Environmental Simulation: Temperature and humidity control chambers

- Automation Features: Automated test sequences and data analysis

- Software Integration: Advanced data analysis and reporting capabilities

Price Ranges of Wear Testing Machines

Prices of wear testing machines vary greatly based on functionality, maximum load capacity, level of automation, and included features.

Entry-Level Wear Test Machines

Price Range: $5,000 – $15,000

Entry-level machines focus on basic testing requirements and fit into the standard packaging for educational institutes, small-scale laboratories, or organizations with limited testing needs.

Mid-Range Options

Price Range: $15,000 – $50,000

Mid-range wear test machines include more varieties of testing and higher accuracy, suitable for medium-sized laboratories, research institutions, and organizations with diverse testing requirements. Features include:

- Programmable test parameters

- Advanced data acquisition instrumentation

- Multiple types of wear tests

- Enhanced test flexibility for various applications

High-End Wear Testing Equipment

Price Range: $50,000 – $200,000+

High-end systems are used for challenging industrial applications, advanced research, and specialized testing needs requiring precision and control. They typically feature:

- Fully automated testing procedures

- Advanced data analysis software

- Real-life wear scenario simulation

- Extreme environmental variable testing

Types of Wear Testing Machines

The primary types of wear testing machines include pin-on-disk, ball-on-disk, block-on-ring, reciprocating, abrasion, erosion, and fretting wear testers.

| Type | Process | Material | Load Capacity | Speed | Key Feature |

|---|---|---|---|---|---|

| Pin-on-Disk | Rotating Disk | Metals | Varies | Adjustable | Friction Test |

| Ball-on-Disk | Sliding Ball | Coatings | Varies | High | Precise Wear |

| Block-on-Ring | Rotating Ring | Composites | Varies | Moderate | Low Lubricant |

| Reciprocating | Linear Motion | Polymers | Varies | Variable | Durable Cycle |

| Abrasion | Surface Scuff | All Types | Low | Low-Speed | Rough Surfaces |

| Erosion | Particulate | Ceramics | Medium | N/A | Particle Impact |

| Fretting | Oscillating | Hard Metals | Low | Moderate | Precision Test |

Specialized Testing Equipment

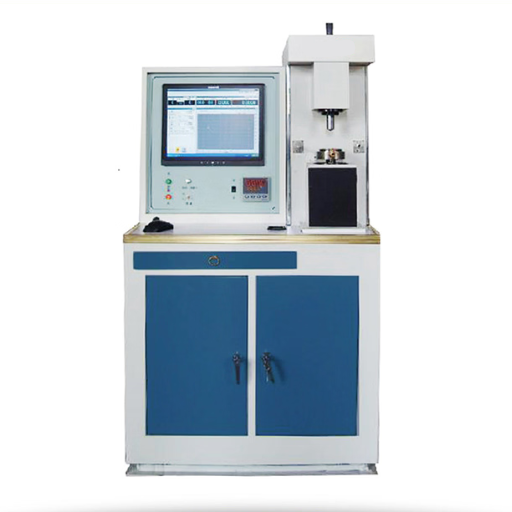

Universal Friction and Wear Testers

Universal Friction and Wear Testing Machines are advanced instruments applied for specifying friction and wear characteristics of materials. These versatile machines can handle:

- Various contact situations (sliding, rolling, reciprocating)

- Multiple material types (metals, polymers, ceramics)

- Variable parameters (load, speed, temperature, lubrication)

- Integrated data acquisition systems

Pin on Disc Wear Testing Machines

Pin on Disc Wear Testing Machines are precision instruments designed to determine wear and frictional characteristics under controlled conditions. They consist of a stationary pin pressed against a rotating disc, measuring coefficient of friction and wear rate.

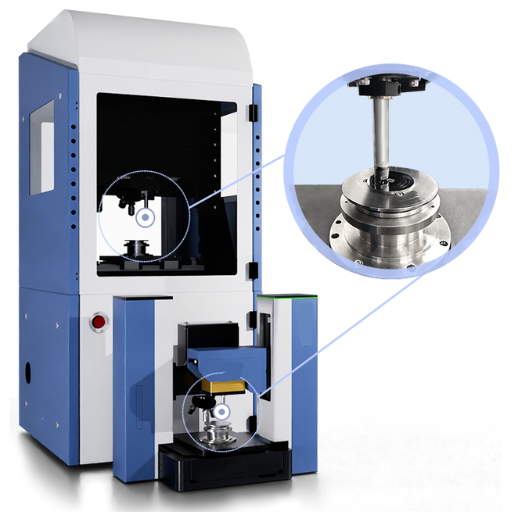

Four Ball Wear Testing Machines

These machines are essential for pressure and friction observations of lubricants and materials. They provide load and rotational forces on steel balls in contact, mimicking real-life tribological scenarios while measuring wear scar diameter and friction coefficient.

How to Select the Right Wear Testing Machine

When selecting a wear testing machine, evaluate these critical factors for optimum performance and suitability:

- Testing Requirements: Specify the kinds of wear tests required (abrasion, adhesion, tribological testing) and ensure compliance with test standards (ASTM, ISO)

- Material Compatibility: Ensure the materials you plan to test, including sample size and geometry, are compatible with the machine

- Load and Speed Range: Verify the maximum and minimum load and rotation or linear speed requirements for your application

- Data Accuracy and Resolution: Assess the machine’s precision and data acquisition system for reliable, repeatable measurements

- Environmental Control: Consider requirements for temperature, humidity, or special fluid testing conditions

- Ease of Operation and Maintenance: Evaluate user-friendliness, automation features, and maintenance requirements

- Budget and Scalability: Match machine features with your budget while considering future scaling needs

Key Considerations

Determining Your Testing Requirements

To effectively determine your testing requirements:

- Assess specific objectives of wear testing

- Identify materials to be evaluated and expected wear mechanisms

- Consider environmental conditions representing real operating applications

- Define operational parameters (load, speed, temperature)

- Establish clear standards for reproducible results

Budget Considerations

When evaluating budget considerations:

- Assess project scope and required financial resources

- Look for cost-effective options meeting reliability and performance standards

- Consider rental vs. purchase options for long-term financial goals

- Ensure budget allocation for strict operational parameter control

- Balance affordability with desired results and consistent performance

Assessing Long-Term Durability and Maintenance

For long-term durability and maintenance assessment:

- Consider material resistance to mechanical stress and environmental conditions

- Implement regular maintenance scheduling for optimal performance

- Calculate lifecycle costs including initial purchase, maintenance, and replacement

- Use performance testing data to estimate wear patterns and maintenance schedules

- Consider predictive analytics for proactive maintenance planning

Applications of Wear Testing Machines

Manufacturing and Material Science

Wear testing machines are essential for evaluating and optimizing materials under friction, wear, and stress conditions. Applications include:

- Automotive: Engine components and braking systems testing

- Aerospace: Turbines, landing gears, and structural components evaluation

- Material Development: High-performance alloys and nanocomposites research

- Quality Assurance: Failure analysis and material formulation refinement

Product Development and Quality Assurance

Wear testing machines enable comprehensive material durability testing under simulated operational conditions, helping to:

- Identify wear mechanisms and predict product life expectancy

- Evaluate material suitability for specific applications

- Ensure products meet performance and safety requirements

- Minimize risks of premature failure

Research and Development in Friction and Wear Studies

In R&D activities, wear testing machines provide precise data for:

- Material behavior analysis under various operational conditions

- Real-life scenario simulation and wear mechanism identification

- Material benchmarking and optimal pairing determination

- Development of safer, efficient, and long-lasting solutions

Frequently Asked Questions (FAQ)

How much does a friction and wear testing machine cost, on average?

The price of a friction and wear testing machine depends on its features and specifications. On average, costs range from a few thousand dollars to tens of thousands of dollars, with computer-controlled or hydraulic universal testing machines at the higher end.

How does a wear resistance test work?

A wear resistance test assesses how well materials stand up to the effects of abrasion and friction over time. A friction testing machine subjects the material to controlled wear conditions while measurements are recorded to describe the wear properties and durability of materials.

What are the applications of universal friction and wear testing machines?

Universal friction and wear testing machines can be used for testing various materials including plastics, metals, and composites. These machines find use in industries concerned with wear resistance, including automotive, aerospace, and manufacturing sectors.

What factors influence the price of wear testing machines?

The price depends on specifications and features such as hydraulic systems, computer control, brand reputation, and the types of testing capabilities (abrasion testing, universal friction testing, etc.).

Why is the coefficient of friction important in wear testing?

The coefficient of friction represents the amount of friction developed between two surfaces. Understanding this coefficient helps determine wear rates, aids in material selection, and supports design improvements for various applications.

What standards are applicable for wear resistant testing?

Many standards govern wear resistant testing, including ASTM and ISO standards. These standards provide guidance on testing methods, equipment specifications, and protocols to ensure comparable results across different testing machines.

How do I select the right abrasion test machine for my needs?

Consider your specific testing requirements, the materials you’re testing, the wear conditions you want to simulate, and the level of precision needed. It’s important to evaluate machine specifications and manufacturer support services.

Conclusion

Understanding wear testing machine pricing requires careful consideration of multiple factors including machine type, testing capabilities, build quality, and brand reputation. By evaluating your specific requirements against available options in entry-level ($5,000-$15,000), mid-range ($15,000-$50,000), and high-end ($50,000-$200,000+) categories, you can make an informed investment decision that balances your technical needs with budget constraints.

Whether you’re in manufacturing, research and development, or quality assurance, the right wear testing machine will provide reliable data essential for material evaluation, product development, and ensuring long-term performance standards.

Reference Sources

-

Universal Testing Machine Cost: 2025 Comprehensive Guide

This guide provides a detailed breakdown of price ranges and factors influencing the cost of testing machines, including loading modes and data acquisition capabilities. -

Wear Testing Machine – All Industrial Manufacturers

A comprehensive resource for exploring wear testing machines, including indicative pricing and sourcing options. -

Price of DIN Abrasion Testing Machine

A marketplace listing that highlights pricing trends and durability considerations for wear testing machines. - Top Wear Testing Machine in China