When evaluating the integrity and performance of welded joints, precision and reliability are paramount. The weld bend test machine serves as a critical tool in assessing a weld’s ductility and strength under stress, making it an indispensable asset in industries where safety and durability are non-negotiable. This article will provide a comprehensive overview of the weld bend test machine, exploring its functionality, significance, and how it aids in maintaining quality standards across various applications. Whether you’re an industry professional, a quality control specialist, or someone looking to deepen their understanding of welding technology, this guide will equip you with the essential knowledge to appreciate the critical role of this testing equipment.

What Is a Welding Bend Test Machine?

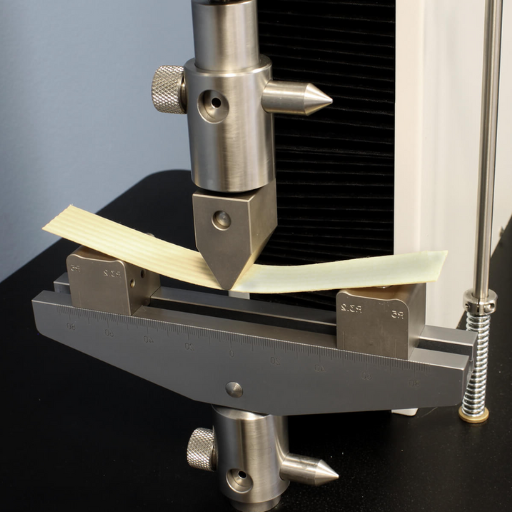

A welding bend test machine is a specialized device used to evaluate the ductility and soundness of welded joints. By applying controlled force to bend a welded specimen, the machine identifies defects such as cracks, voids, or incomplete fusion that may compromise the weld’s integrity. This testing method ensures that welded components meet established quality and safety standards for their intended applications.

Purpose of Bend Testing

The primary purpose of bend testing is to assess the ductility, strength, and overall integrity of a welded joint under stress. This test provides crucial information about a weld’s ability to withstand mechanical deformation during real-world applications without exhibiting critical defects. By bending a sample to specific angles, it becomes possible to identify internal flaws such as lack of fusion, porosity, or inclusions that might not be visible on the surface.

Bend testing is widely used in industries such as construction, automotive, aerospace, and manufacturing, where the reliability of welded joints is paramount. For example, standard tests such as guided bend tests often require the sample to be bent to a specified angle (commonly 180 degrees), with results evaluated against strict criteria outlined by standards like AWS D1.1 or ISO 5173. Data collected during these tests, such as the elongation before failure or the presence of surface cracks exceeding permissible thresholds, aids in determining whether a weld meets the mechanical property specifications for its application.

By ensuring welded joints conform to established performance benchmarks, bend testing minimizes the risk of structural failures, enhances safety, and assures compliance with quality certifications.

Components of a Bend Test Machine

A bend test machine comprises several critical components that collectively ensure accurate and reliable evaluation of material or weld performance under bending stress. These components include:

- Loading Mechanism: Responsible for applying forces to the test specimen, the loading mechanism typically includes hydraulic or mechanical actuators. The loading force should be calibrated accurately and capable of achieving forces typically ranging from 0.5 kN to 500 kN or greater, depending on the material and testing requirements.

- Support Rollers: Positioned beneath the specimen, support rollers maintain stability and provide consistent support during testing. These rollers often have adjustable spacing to adapt to various specimen sizes and are typically made of hardened steel to prevent deformation under load.

- Mandrel (or Punch): The mandrel exerts force on the specimen to induce bending. Its diameter is a critical specification, as it must conform to the test standard (e.g., ASTM E290 or ISO 5173). For ductile metals, mandrel diameters typically range from 2 to 4 times the specimen thickness.

- Frame Assembly: A rigid frame provides structural stability during operation, ensuring that deformation occurs in the specimen rather than the machine. Frames are engineered to withstand high forces without any compromise to alignment or rigidity.

- Measurement System: This system includes displacement sensors and force transducers to monitor bending angles and applied loads with precision. Load measurement devices often comply with standards such as ISO 7500-1 for accuracy.

- Control System: Advanced machines feature automated control systems, including user interfaces or software for programming test parameters such as bend angle, deflection rate, and test speed. Typical bending speeds range from 1 mm/min to 10 mm/min, ensuring compliance with testing protocols.

By integrating these components, a bend test machine ensures high precision, repeatability, and adherence to technical standards, making it indispensable for mechanical testing applications.

How a Bend Test Machine Works

A bend test machine operates by applying a controlled force to a specimen, typically in the form of a beam or sheet, to evaluate its ductility, toughness, and resistance to fracture. The test typically involves positioning the specimen on supports while a load is applied in the center, bending it into a specific angle or until failure occurs. Key components, such as the loading nose and supporting anvils, are designed to ensure consistent force distribution and minimize distortions. Advanced machines integrate sensors to measure force, displacement, and stress-strain data in real-time, allowing detailed analysis of the material’s mechanical properties. By employing precision alignment and force control, the process determines compliance with standards such as ASTM E290 or ISO 7438, ensuring reliable and repeatable results.

How Does a Weld Bend Test Work?

The weld bend test works by subjecting a welded specimen to a bending force to evaluate its ductility and soundness. The test involves placing the specimen on a bending fixture and applying force, typically through a plunger or roller, until a specified angle or deformation is achieved. This process highlights any cracks, voids, or imperfections in the weld, ensuring the weld’s integrity and compliance with applicable standards.

Types of Weld Testing

The main types of weld testing are destructive testing and non-destructive testing, encompassing methods such as bend tests, tensile tests, ultrasonic testing, radiographic testing, magnetic particle testing, and dye penetrant testing.

|

Test Type |

Category |

Purpose |

Key Method |

|---|---|---|---|

|

Bend Test |

Destructive |

Check ductility |

Specimen bending |

|

Tensile Test |

Destructive |

Assess strength |

Tensile machine |

|

Ultrasonic Test |

Non-Destructive |

Detect defects |

Sound waves |

|

Radiographic Test |

Non-Destructive |

Find voids/cracks |

X-ray inspection |

|

Magnetic Test |

Non-Destructive |

Spot fissures |

Magnetic field |

Steps in Conducting a Bend Test

- Specimen Preparation: Obtain a standardized test specimen, ensuring it meets the required dimensions and surface finish as per applicable standards (e.g., ASTM, ISO).

- Inspection and Cleaning: Inspect the specimen for any visible defects such as scratches or burrs and clean its surface to prevent interference during testing.

- Equipment Setup: Configure the bending equipment, including the loading fixture and supports, according to the specific test parameters, such as specimen thickness and desired bend angle.

- Positioning the Specimen: Place the specimen securely on the supports, ensuring proper alignment and stability to prevent undesirable movement or uneven loading.

- Applying the Load: Gradually apply the load through a bending punch or roller at a controlled rate to achieve consistent deformation.

- Monitoring the Test: Observe the bending process, noting any irregularities, such as cracking, which may indicate low ductility or material defects.

- Measuring Results: Measure the bend angle or radius, as well as any induced cracks or fractures, using precision measuring tools or visual inspection.

- Recording and Analysis: Document the results and compare them with specification standards to evaluate the material’s ductility and performance.

Common Defects Detected by Bend Testers

Bend testers are instrumental in identifying numerous defects that can compromise material integrity and performance. Common defects include:

- Cracking: Visible cracks on the surface of the material during or after bending suggest insufficient ductility or underlying imperfections within the material’s structure.

- Fractures: Complete separation of the material under stress often indicates brittleness or flaws at a microstructural level, which can render the material unsuitable for demanding applications.

- Surface Deformation: Issues such as wrinkling, rippling, or uneven surfaces may occur, signifying inconsistent material properties or improper processing methods.

- Springback: This defect occurs when the material attempts to return to its original shape after bending, highlighting issues with elasticity or improper material choice for the intended purpose.

By systematically analyzing these defects, bend testers provide critical data that aid manufacturers in assessing compliance with design and performance standards. This ensures both the reliability and durability of the final product.

Choosing the Right Bend Test Fixture

Selecting the appropriate bend test fixture requires consideration of several key factors to ensure accurate results. First, identify the material type and thickness, as these will dictate the fixture’s design and capacity. Second, evaluate the bending radius and angle required for the test, ensuring the fixture can accommodate these specifications. Lastly, consider the loading mechanism, whether it involves three-point or four-point bending, as it directly impacts the stress distribution and testing outcomes. Choosing a fixture that aligns with these criteria is crucial for obtaining reliable and replicable results.

Key Features of Bend Test Fixtures

- Adjustable Support Spans: Bend test fixtures are equipped with adjustable spans to accommodate specimens of varying lengths and testing requirements, ensuring versatility across applications.

- High-Strength Materials: Fixtures are constructed from durable materials, such as hardened steel or aluminum alloys, to resist deformation and maintain precision under high loading conditions.

- Precision Alignment: Built-in alignment mechanisms ensure accurate positioning of the test specimen, minimizing errors in stress application and measurement.

- Compatibility with Testing Machines: Bend test fixtures are designed to integrate seamlessly with universal testing machines, offering compatibility with standard testing protocols and settings.

- Load Measurement Accuracy: Many fixtures are equipped with integrated sensors or load cells to monitor applied forces with high precision, contributing to the accuracy of results.

Importance of Fixture Selection

Selecting the appropriate fixture is critical to ensuring accurate and reliable testing outcomes in materials and mechanical testing. The fixture must be designed to handle the specific dimensions, material properties, and test conditions of the specimen to eliminate variability in results. An improperly chosen fixture can lead to misalignment, uneven force distribution, or specimen damage, compromising test precision.

Additionally, the fixture’s compatibility with the testing machine is essential to prevent calibration errors and operational inefficiencies. Standardized fixtures ensure the integration of test parameters and measurement systems, simplifying setup and ensuring repeatability across tests. Factors such as load capacity, gripping mechanism, and rigidity must also be evaluated to align with testing requirements.

Ultimately, proper fixture selection enhances the accuracy, consistency, and reproducibility of data, facilitating a deeper understanding of material behavior under specified conditions. It is a pivotal aspect of experimental design, ensuring that results meet both technical and regulatory standards.

What Are the Benefits of a Tensile Test?

Tensile testing offers critical insights into the mechanical properties of materials, such as tensile strength, elongation, elastic modulus, and yield strength. These parameters are essential for evaluating material performance under stress, ensuring reliability in applications ranging from construction to aerospace engineering. Additionally, tensile tests aid in quality control by identifying defects, ensuring compliance with industry standards, and supporting material selection processes for specific design requirements.

Understanding Tensile Testers

Tensile testers, also referred to as universal testing machines (UTMs), are precision instruments designed to measure the mechanical properties of materials under uniaxial tension. They evaluate key parameters such as tensile strength, elongation at break, yield strength, and elastic modulus, providing detailed insights into a material’s behavior under stress. Tensile testers typically consist of a load frame, force sensor, grips or fixtures to hold the material, and software for data acquisition and analysis.

These machines operate by applying a controlled, uniaxial tensile force to a sample until deformation or fracture occurs. The resulting stress-strain data is critical for applications in material development, quality control, and ensuring compliance with industry standards such as ASTM E8 and ISO 6892. Tensile testers are employed across industries including construction, automotive, aerospace, and biomedical engineering to validate material performance under various loading conditions and facilitate informed design decisions.

Applications of Tensile Testing

- Material Selection and Development: Tensile testing is used to evaluate the mechanical properties of new materials or alloys, aiding in the selection of materials for specific engineering applications.

- Quality Assurance and Compliance: Industries rely on tensile testing to ensure that materials meet predefined specifications and comply with international standards such as ASTM and ISO, ensuring safety and reliability.

- Product Design and Optimization: By understanding a material’s tensile strength, yield point, and elongation, engineers can optimize product designs to enhance performance and durability under operational stresses.

- Failure Analysis: Tensile tests help in identifying the root cause of material failure by providing insights into how a material behaves under stress and determining its breaking point.

- Educational and Research Applications: Tensile testing is widely used in academic and research environments for studying material science principles and investigating the behavior of novel materials under stress.

Comparing Bend and Tensile Testing

Bend testing evaluates the material’s ductility and resistance to deformation under bending stress, while tensile testing determines the material’s strength, ductility, and behavior under uniaxial tensile stress.

|

Aspect |

Bend Test |

Tensile Test |

|---|---|---|

|

Purpose |

Ductility |

Strength |

|

Stress Type |

Bending |

Tensile |

|

Load Applied |

Flexural |

Axial |

|

Results |

Deformation |

Elongation |

|

Fail Point |

Crack Start |

Break Point |

|

Application |

Shape Forming |

Load Bearing |

|

Specimen |

Fixed Beam |

Uniform Rod |

|

Equipment |

Bend Tester |

Tensile Machine |

How to Maintain a Weld Bend Tester?

To maintain a weld bend tester effectively, ensure regular cleaning of all components to prevent debris buildup that could impact test accuracy. Lubricate movable parts as per the manufacturer’s recommendations to minimize wear and friction. Inspect the device periodically for signs of mechanical damage, such as wear on rollers or cracks in fixtures, and replace any defective parts. Calibrate the equipment at regular intervals to maintain precision and compliance with industry standards. Finally, store the tester in a dry, controlled environment to avoid corrosion or environmental damage. Proper maintenance ensures reliable performance and extended equipment lifespan.

Regular Inspection and Maintenance

I ensure regular inspection and maintenance of test equipment by following a structured process. First, I check for any physical damage, such as cracks or loose connections, and promptly address these issues. I also clean all components using appropriate cleaning agents to prevent the accumulation of dust or residue that may affect performance. Calibration is performed at recommended intervals, using industry-grade standards, to ensure measurement accuracy and compliance. Additionally, I document all maintenance activities in a detailed log to track the condition and performance of the equipment over time. This disciplined approach minimizes the risk of failure and extends the operational lifespan of the device.

Common Issues and Troubleshooting Tactics

When addressing device performance issues, it is essential to adopt a systematic approach to identify root causes and implement precise solutions. Based on insights from leading resources, the following are common technical issues and corresponding troubleshooting tactics:

1. Issue: Calibration Drift

-

- Cause: Environmental factors such as temperature fluctuations or prolonged use can cause measurement inaccuracies.

- Tactic: Regularly calibrate the device using certified reference standards. Ensure the surrounding environment is stable and meets the device’s operating temperature range, commonly specified in the equipment manual (e.g., 10°C-30°C for many systems). Record calibration results to detect patterns or recurrent deviations.

- Issue: Erratic Readings

- Cause: Presence of dust, residue, or internal component wear may affect sensor reliability.

- Tactic: Perform regular cleaning according to manufacturer specifications, using recommended cleaning agents or tools. Inspect connectors and sensors for damage or wear, replacing components if needed. Ensure proper grounding of electronic devices to prevent electrical noise interference.

- Issue: Device Failure to Execute Functions

- Cause: Software bugs or firmware incompatibility can disrupt functionality.

- Tactic: Verify that the firmware and software versions are up-to-date as per the manufacturer’s official releases. Conduct a full device reset to restore default settings if issues persist and systematically test functions post-reset. If unresolved, consult specific error codes in the user manual or contact technical support with detailed error logs.

By aligning these practices with technical parameters specified in user documentation, operational performance can be optimized effectively.

Extending the Lifespan of Test Equipment

To effectively extend the lifespan of test equipment, I ensure regular maintenance and calibration in accordance with the manufacturer’s recommendations. Proper handling and storage, including protecting devices from extreme temperatures, moisture, and physical impacts, are essential. I verify that firmware and software are consistently updated to prevent compatibility issues. Additionally, careful adherence to usage guidelines, such as avoiding overloading or misuse of instruments, reduces wear and tear. By implementing these measures, I can sustain optimal performance and reliability of my equipment over time.

Reference Sources

-

Understanding Bending in Welding Inspections – A detailed blog on the principles and applications of welding bend tests.

-

55 Ton Tensile Tester | Destructive Weld Testing – Information on durable and reliable welding test equipment.

-

Bend Test Welding: A Guide to Testing Metal Welds – A guide to ensuring consistent and accurate weld testing.

-

Homemade Bend Tester Discussion – A forum thread discussing practical insights into bend testing.

-

Weld Testing Equipment – A collection of tools and equipment for weld testing.

Frequently Asked Questions (FAQs)

Q: What is a Weld Bend Test Machine?

A: A Weld Bend Test Machine is an essential piece of machinery used to test the ductility and strength of welded joints. It helps determine the quality and performance of welds by applying stress to a metal coupon and observing its response.

Q: How does a 55 ton bend and tensile tester work?

A: A 55 ton bend and tensile tester works by applying up to 55 tons of force to a welded joint using a combination of die and plunger sets to bend or stretch the coupon. This helps assess the material’s strength and ductility according to industry standards such as ASME and API 1104.

Q: What are the main components of a ton bend and tensile tester?

A: The main components of a ton bend and tensile tester include the pump, plunger, die and plunger sets, and the jaws that hold the metal coupon in place. The machine may be powered by electric or pneumatic systems depending on its design and application.

Q: Why is a pump important in a Weld Bend Test Machine?

A: The pump is crucial in a Weld Bend Test Machine as it generates the hydraulic or pneumatic force necessary to operate the machinery. It enables the application of controlled pressure to the metal coupon during testing.

Q: What role does a bender play in the testing process?

A: A bender in the testing process is used to apply bending stress to the metal coupon. It helps evaluate the weld’s ability to withstand deformation without cracking or breaking, which is key for ensuring the weld’s reliability.

Q: How is a welding lab equipped for bend tests?

A: A welding lab equipped for bend tests typically includes a ton bend and tensile tester, various die and plunger sets, electric or pneumatic systems, and other accessories to facilitate testing. This setup ensures accurate evaluation of weld quality and compliance with standards.

Q: What is the significance of using a guided 55 ton bend and tensile tester?

A: Using a guided 55 ton bend and tensile tester ensures precise control over the testing process, allowing for consistent and repeatable results. This is important for meeting industry qualifications and standards such as ASME and API 1104.

Q: What is the procedure for conducting a weld bend test?

A: The procedure for conducting a weld bend test involves placing a metal coupon in the jaws of the tester, selecting the appropriate die and plunger sets, and then applying pressure using the pump. The test observes the coupon’s ability to bend without failure, assessing its ductility and strength.

Q: What factors determine the suitable test setup for a specific weld?

A: Factors that determine the suitable test setup include the type and thickness of the metal, the width of the coupon, and the maximum force required. The choice of accessories such as die and plunger sets and the type of pump (electric or pneumatic) also play a role in the setup.

Q: Can a Weld Bend Test Machine be used for industrial applications?

A: Yes, a Weld Bend Test Machine is suitable for industrial applications, including fabrication and welding equipment qualification. It ensures that welds meet the necessary strength and ductility requirements for safe and reliable performance in various industrial settings.