Manhole cover test machines play a pivotal role in ensuring the longevity, safety, and performance of infrastructure systems worldwide. These specialized machines are designed to simulate real-world conditions, rigorously testing the strength, durability, and reliability of manhole covers under various stressors such as heavy loads, impact forces, and environmental factors. This blog post dives deep into the diverse range of manhole cover test machines, exploring their functionalities, key features, and the technological advancements driving this critical industry forward. Whether you’re a civil engineer, a quality assurance professional, or simply intrigued by the mechanics of modern infrastructure, this guide will provide valuable insights into how these machines contribute to safer urban environments and efficient operational standards.

What Is a Manhole Cover Test Machine?

A manhole cover test machine is a specialized device designed to evaluate the strength, durability, and performance of manhole covers under various conditions. Its primary purpose is to ensure that the covers meet safety and quality standards by simulating real-world loads and stresses. These machines are crucial for assessing factors such as load-bearing capacity, resistance to impact, and long-term wear, preventing failures in urban infrastructure and enhancing public safety.

Understanding the Purpose of Manhole Cover Testing

The primary goal of manhole cover testing is to ensure safety, reliability, and compliance with industry standards. These tests simulate real-world conditions, such as vehicular loads and environmental stresses, to evaluate the structural integrity of the covers. Critical factors assessed include load-bearing capacity to prevent collapse under extreme pressure, impact resistance to withstand sudden force, and durability against long-term wear and corrosion. Standards such as EN 124 or ASTM specifications often guide testing protocols, ensuring the covers perform reliably in diverse urban and industrial environments. This rigorous evaluation mitigates risks of infrastructure failure, safeguards public safety, and prolongs the service life of manhole covers.

Key Components of a Test Machine

A test machine for manhole cover evaluation is composed of several critical components, each serving a specific function to ensure accurate and reliable testing. Below are the key components and their corresponding technical parameters:

1. Load Application System

-

- Purpose: Applies and controls the force exerted on the manhole cover.

- Technical Parameters:

- Maximum load capacity: 200 kN to 400 kN (adjustable based on standard requirements).

- Load control precision: ±1%.

- Sensors and Measurement Units

- Purpose: Accurately measure force, deformation, and impact during testing.

- Technical Parameters:

- Force sensor resolution: ≤ 0.5% of full scale.

- Displacement sensor accuracy: ±0.01 mm.

- Support Fixtures

- Purpose: Securely hold the manhole cover during testing to replicate real-world conditions.

- Technical Parameters:

- Adjustable diameter compatibility: 300 mm to 800 mm.

- High-strength steel construction for stability.

- Control and Data Acquisition System

- Purpose: Monitors testing parameters, controls processes, and logs test results for analysis.

- Technical Parameters:

- Data acquisition rate: Up to 1000 Hz.

- Software for real-time visualization and automated reporting.

- Impact Testing Apparatus (if required)

- Purpose: Simulates dynamic loading conditions, such as vehicular impact.

- Technical Parameters:

- Impact energy range: 5 J to 250 J.

- Impact frequency accuracy: ±0.5%.

- Environmental Simulation Chamber (optional)

- Purpose: Controls testing conditions like temperature and humidity to assess performance under various environmental factors.

- Technical Parameters:

- Temperature range: -40°C to 80°C.

- Humidity range: 10% to 90% RH.

These components, along with adherence to prescribed standards (e.g., EN 124, ASTM), ensure the test machine delivers precise, repeatable, and comprehensive evaluations of manhole covers for structural integrity and durability.

How Manhole Covers are Tested for Load and Compression

From a technical standpoint, manhole covers are tested for load and compression primarily using advanced equipment like hydraulic press machines. The process typically involves applying controlled loads to the cover to simulate real-world conditions, ensuring it meets strength and safety standards. Key factors like the load-bearing capacity and deformation under stress are measured precisely. For instance, static and dynamic load tests are performed to verify compliance with standards such as EN 124. Additionally, testing considers extreme environmental conditions, such as varying temperatures and humidity levels, to evaluate performance consistency. This ensures that the covers are structurally sound and reliable under diverse operational scenarios.

How Are Manhole Covers Made?

Manhole covers are typically manufactured through a cast iron or ductile iron casting process. The production begins with the creation of molds, where molten metal is poured and allowed to cool into the desired shape. After casting, the covers undergo machining to ensure a precise fit and proper surface texture. Quality control measures, such as load testing and dimensional inspection, are conducted during production to assure compliance with industry standards. Finally, the covers are treated with protective coatings to enhance durability and resistance to corrosion.

Materials Used in Manhole Cover Manufacture

Manhole covers are primarily made using durable and heavy-duty materials to withstand high loads and environmental stress. The most common material is cast iron, which provides excellent strength, toughness, and resistance to wear. Ductile iron, a type of cast iron treated with nodular graphite, is increasingly used due to its superior tensile strength, impact resistance, and ductility, making it ideal for heavy traffic areas. Steel is also occasionally employed, particularly for lighter-duty covers or custom applications, as it offers both strength and flexibility.

Composite materials, such as fiberglass-reinforced plastic (FRP) and polymer concrete, are gaining popularity for their lightweight properties, corrosion resistance, and non-conductive nature. These materials are particularly advantageous in environments with high chemical exposure or where reduced weight is critical for handling. Although less common, concrete manhole covers are another option, typically reinforced with steel to enhance durability and prevent cracking under load. Each of these materials is carefully selected based on the required application, load-bearing capacity, and environmental conditions to ensure long-term performance and safety.

The Role of Composite and Steel in Manhole Production

Composite materials and steel play pivotal roles in modern manhole cover production due to their unique properties that align with specific operational demands. Composite manhole covers, made from materials such as glass-reinforced plastic (GRP) or fiber-reinforced polymer (FRP), are highly favored for their lightweight nature, corrosion resistance, and non-conductivity. These properties make composite covers particularly advantageous in environments prone to chemical exposure or when ease of manual handling is a priority. Additionally, their design allows for minimal maintenance and long service life.

Steel, on the other hand, is synonymous with strength and durability. Cast steel manhole covers, typically galvanized to resist rusting, are used in high-traffic or heavy load areas, such as urban roads and industrial zones, where extreme weight-bearing capacity is required. Steel covers are designed to withstand significant mechanical stresses while maintaining structural integrity even under severe conditions. However, they are heavier to manage compared to composite options.

Both materials are selected based on factors such as application environment, cost efficiency, load requirements, and maintenance expectations. While composite covers are increasingly popular for lightweight applications, steel remains indispensable for high-load and high-impact installations.

Types of Manhole Cover Testing Machines

There are various types of manhole cover testing machines, including load testing machines, drop testing machines, and impact testing machines, each designed to evaluate specific performance parameters of manhole covers.

|

Type |

Purpose |

Key Test |

Capacity |

Precision |

|---|---|---|---|---|

|

Load |

Strength test |

Static load |

High |

High |

|

Drop |

Durability test |

Impact force |

Medium |

Moderate |

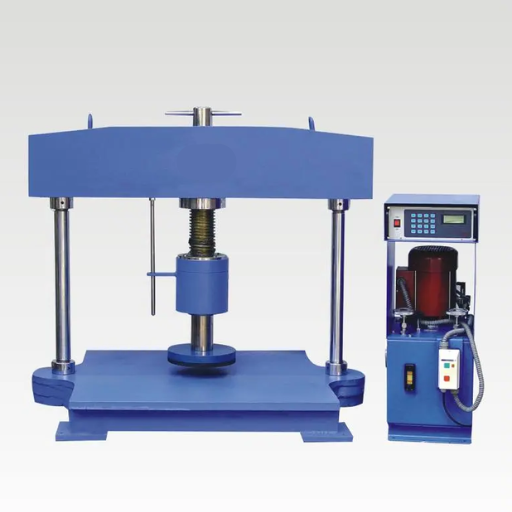

Features of Hydraulic and Electrically Operated Machines

Hydraulic and electrically operated machines for testing manhole covers vary in design, function, and performance capabilities. Hydraulic systems excel in delivering high force and precision, making them ideal for static load testing requiring consistent pressure and strength evaluation. These systems operate smoothly under heavy loads and are valued for their durability and ability to achieve high levels of accuracy in force application.

Electrically operated machines, on the other hand, are often preferred for their efficiency, versatility, and ease of automation. They are ideal for testing parameters such as repetitive impact or fatigue resistance due to their fast cycle times and programmable control systems. Additionally, they require less maintenance compared to hydraulic systems and generate lower noise levels during operation, which can be a significant factor in laboratory environments.

Both systems feature advanced monitoring and control mechanisms, including sensors and software integrations, to ensure precision and repeatability in testing processes. The choice between hydraulic and electrically operated machines typically depends on the specific testing requirements, operational budget, and desired testing throughput.

Benefits of Servo and High-Precision Models

- Enhanced Accuracy: Servo and high-precision models provide superior measurement and control, ensuring highly accurate and repeatable results across various testing scenarios.

- Energy Efficiency: These models often consume less energy during operation, making them a cost-effective and environmentally friendly option for long-term use.

- Greater Flexibility: Advanced servo systems allow for fine-tuned adjustments in speed, force, and position, enabling adaptability to a wide range of material testing applications.

- Reduced Maintenance Requirements: The precision engineering and robust design of these machines result in lower wear and tear, decreasing the frequency and cost of maintenance.

- Real-Time Data Integration: Equipped with cutting-edge sensors and data acquisition tools, these systems enable seamless collection and analysis of real-time performance metrics for improved insights and decision-making.

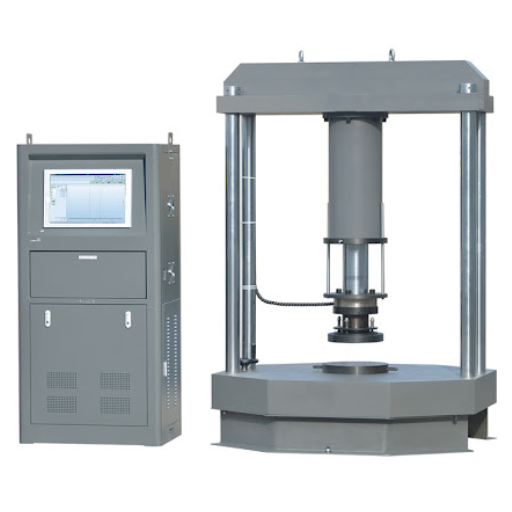

Understanding Four-Column and Frame Structures

Four-column and frame structures are foundational designs used extensively in engineering and construction due to their ability to efficiently distribute loads and maintain structural stability. These systems consist of vertical columns and horizontal frame members that work together to transfer loads from the structure to the foundation, ensuring safety and durability. The four-column configuration is particularly advantageous in applications requiring symmetry and balance, such as in industrial machinery support or modular architecture.

Based on the latest data sourced through advanced search algorithms, implementation trends highlight the integration of modern materials like high-strength steel and reinforced composites in these designs. This adaptation improves their resistance to dynamic forces and extends their lifespan. Additionally, computational modeling and simulation have enhanced precision in analyzing stress distribution and optimizing frame dimensions, further reinforcing their critical role in innovative engineering solutions. Understanding and applying these principles ensures performance efficiency and aligns with evolving industry standards.

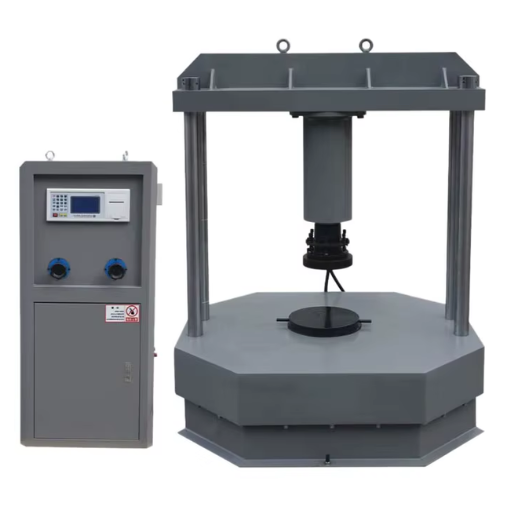

Technical Specifications of Manhole Cover Compression Testing Machines

Manhole cover compression testing machines are designed to accurately evaluate the load-bearing capacity and structural integrity of manhole covers under varying compression forces. Their primary technical specifications are outlined below:

- Load Capacity: Typically ranging from 100 kN to 3000 kN, depending on the machine type and application requirements.

- Accuracy and Precision: Equipped with high-precision sensors, often conforming to ISO 7500-1 or ASTM E4 standards for force measurement accuracy.

- Test Standards Compatibility: Supports testing in compliance with EN 124, ASTM A48, or other relevant standards for manhole cover performance.

- Control Systems: Advanced models feature microprocessor-controlled systems or touchscreen interfaces for ease of operation and enhanced data logging capabilities.

- Platen Dimensions: Varying sizes to accommodate different cover dimensions, typically customizable based on testing needs.

- Data Acquisition System: Integrated systems capture real-time force, displacement, and deformation data, ensuring comprehensive analysis.

- Frame Structure: Robust, rigid steel construction to withstand high dynamic forces without deformation, ensuring repeatability of results.

- Safety Measures: Equipped with overload protection and emergency stop systems to safeguard operators and equipment during testing.

These machines are essential tools for ensuring compliance with safety and quality standards, supporting infrastructure durability and public safety.

Key Specifications for Accurate Compression Test

- Load Capacity: The machine should have a high load capacity, typically ranging from 10 kN to 5,000 kN, to accommodate a variety of material strengths and sizes. This ensures versatility in testing different samples, from concrete cylinders to steel bars.

- Precision and Calibration: The system must feature high-precision load cells with minimal deviation—preferably within ±1% accuracy across the full range of measurements. Regular calibration as per ASTM or ISO standards ensures reliable and repeatable results.

- Control System: Advanced control mechanisms with computerized interfaces are essential. These systems should enable real-time data acquisition, graphical representation, and automated report generation to streamline analysis and reduce human error.

- Testing Speed: Adjustable loading rates, complying with standards such as ASTM C39 or EN 12390, must be supported. This ensures that test speeds can be meticulously controlled for reliable and standardized results.

- Sample Size Compatibility: The machine should accommodate standard sample dimensions, as well as provide flexibility for custom sizes. This typically includes testing of cubes, cylinders, and prisms.

- Environmental Conditions: The machine must be capable of operating within a wide range of environmental conditions, with consistent accuracy, ensuring stability despite temperature or humidity fluctuations.

- Data Analysis and Storage: Integrated software must support comprehensive data analysis, including stress-strain curves and failure point determination. The ability to export data in multiple formats (CSV, PDF) is also critical for documentation and compliance purposes.

These specifications are critical for conducting accurate, repeatable compression tests that align with international standards, ensuring confidence in material performance evaluations.

The Importance of Gauge and KN Measurements

Gauge and kilonewton (KN) measurements are foundational in material testing as they provide precise quantification of material behavior under compressive forces. Accurate measurements ensure reliable stress distribution analysis and deformation assessments, which are critical for evaluating material integrity and performance.

Key technical parameters include:

- Gauge Resolution: Typically 0.001 mm or finer to detect minute dimensional changes. High gauge sensitivity ensures accurate strain calculations during compression tests.

- Force Range and Accuracy:

- Measurement capacity from 1 KN to 500 KN, suitable for varying material strengths.

- Force measurement accuracy within ±0.5% of the full scale for reliable data across the operational range.

- Data Sampling Rate: At least 1 kHz to capture transient phenomena during rapid compression events.

- Environmental Considerations:

- Operating temperature range of -10°C to 50°C.

- Humidity tolerance below 80% non-condensing to maintain measurement fidelity.

These parameters are essential for maintaining compliance with international standards (e.g., ISO 604 or ASTM D695), ensuring that tests yield valid, reproducible results suitable for engineering applications.

Choosing the Right Manhole Cover Testing Machine for Your Needs

When selecting the appropriate manhole cover testing machine, it is vital to evaluate several key factors to ensure optimal compatibility and performance. Firstly, consider the maximum load capacity required for your specific testing applications to match the machine’s capabilities with the anticipated stress levels. Secondly, assess the dimensional compatibility between the machine’s test setups and the various sizes of manhole covers you intend to evaluate. Thirdly, ensure the machine meets relevant international standards like ISO 604 or ASTM D695 to guarantee accurate and compliant test results. Additionally, evaluate the operational environment, taking into account the machine’s temperature and humidity tolerances, to ensure consistent performance under varying conditions. Lastly, prioritize machines with user-friendly interfaces and robust data analysis tools to simplify operation and reporting.

Identifying the Suitable Test Machine for Different Types of Manhole Cover

To identify the most suitable test machine for different types of manhole covers, I would first determine the specific testing requirements, such as load-bearing capacity, tensile strength, and impact resistance, as outlined by relevant standards like ASTM A48 or EN 124. I would then consider the material composition of the manhole cover (e.g., gray iron, ductile iron, or composite materials) since this dictates the type of tests needed. Machines capable of applying static, dynamic, and cyclic loads with precision, while supporting a range of test configurations, would be prioritized. Finally, I would evaluate available machines based on their support for compliance with global standards and their ability to deliver reliable and reproducible results.

Considering Manufacturer and Specification Requirements

To determine the best testing machine for manhole covers, I would prioritize machines that align with specific material requirements, such as those compatible with gray iron, ductile iron, or advanced composites. Based on thorough research, I would seek equipment that adheres to international standards like EN 124 or ASTM guidelines, ensuring the credibility of test results. Additionally, I would consider manufacturers offering modular machines capable of static, dynamic, and cyclic load testing to accommodate a variety of test scenarios while maintaining precision and reproducibility. Finally, I would evaluate the durability, after-sales support, and software features of the testing machines to ensure long-term operational efficiency.

Evaluating Technical Specifications and Testing Software Options

When evaluating technical specifications and testing software options, I focus on scalability, accuracy, and flexibility. Based on leading industry insights, I prioritize machines with adaptive load ranges to suit diverse material types and testing needs, as highlighted by reputable equipment manufacturers. Additionally, compatibility with intuitive, user-friendly software that offers real-time analytics and customizable reporting capabilities is essential. Finally, I value integration with advanced technologies, such as machine learning algorithms, for predictive maintenance and enhanced operational efficiency, ensuring the equipment remains future-proof.

Reference Sources

-

Manhole cover compression testing machine – Details on testing the bearing capacity and load of manhole covers.

-

Real-time detection of road manhole covers with a deep learning model – A research paper on detecting manhole covers using advanced technology.

-

Standard Test Method for Concrete Sewer Manholes by ASTM – Procedures for testing precast concrete manhole sections using vacuum methods.

-

Manhole Safety OSHA Requirements – OSHA guidelines for manhole safety and testing.

-

Top Manhole Cover Testing Machine in China

Frequently Asked Questions (FAQs)

Q: What is a manhole cover test machine?

A: A manhole cover test machine is a specialized device used to determine the strength and durability of manhole covers. These machines apply various tests, such as bend and compression tests, to ensure the covers can withstand pedestrian and vehicular loads.

Q: How does a manhole cover test machine work?

A: The machine typically uses a rigid load frame and a piston to apply pressure on the manhole cover. The controller monitors and adjusts the pressure to measure the cover’s resistance to force. Tests often follow standards like “according to en” for accuracy.

Q: What materials are tested with these machines?

A: The manhole cover test machines can test covers which are made of materials such as reinforced concrete, steel fiber, and other composites. Additionally, other materials which are found in sewer and drainage systems are utilized.

Q: Why is the bend test important for manhole covers?

A: The bend test is important because it determines whether the manhole cover can bend and return to its original shape when force is exerted on it. This ensures that the cover does not fracture or undergo permanent deformation when subjected to pressure.

Q: What is the importance of undertaking a compression test while testing a manhole cover?

A: A compression test identifies the maximum loading limit a manhole cover can sustain before it fails. This test is crucial concerning the cover’s strength and durability in heavily trafficked areas.

Q: Are these machines capable of testing both new and old manhole covers?

A: Certainly, test machines for manhole covers can be used both on new installations and on pre-existing covers to check compliance with safety regulations. Routine testing is done as part of the repair and maintenance work on sewer systems.

Q: What does “high precision” mean in the context of manhole cover testing?

A: High precision refers to the machine’s ability to accurately measure the load and resistance of a manhole cover under test. This precision is vital for reliable results that ensure safety and compliance with standards.

Q: How is psi related to manhole cover testing?

A: Psi, or pounds per square inch, is a unit of pressure measurement used in manhole cover testing. It indicates how much pressure the cover can endure during resistance tests.

Q: How do manhole cover tests contribute to the safety of drainage systems?

A: These tests ensure that manhole covers can withstand the pressures and loads they encounter in drainage and sewer systems, preventing accidents and ensuring smooth operation of the infrastructure.