Tensile strength is one of the most critical properties in material science, serving as a key indicator of a material’s ability to withstand stretching forces before failure. Whether considering the structural integrity of metals, polymers, or composites, understanding the factors that influence tensile test outcomes is vital for applications across industries such as construction, aerospace, and manufacturing. This article dives deeply into the intricate details behind tensile testing, examining how external environmental variables, material composition, and testing methodologies can impact results. By the end of this guide, you will have a comprehensive understanding of the complexities surrounding tensile strength and the tools to interpret testing data with precision. Prepare to uncover the science that drives material performance.

What Is Tensile Strength?

Tensile strength refers to the maximum stress a material can withstand without failure when being pulled apart. As a fundamental aspect of a material, it reveals how a material is able to resist tensile forces and bear loads. Usually assessed through a tensile test, this attribute offers valuable information regarding a material’s reliability and appropriateness for given projects.

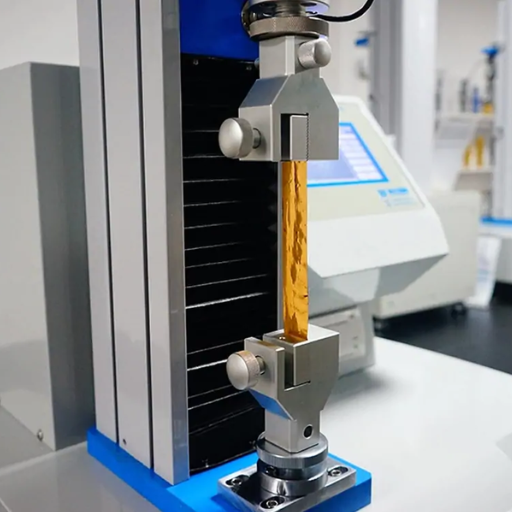

How Is Tensile Strength Measured?

Tensile strength is measured through a standardized tensile test. In this process, I would use a tensile testing machine to apply uniaxial force to a material sample with a consistent cross-sectional area. The sample is stretched until it fractures, and throughout the test, I record the force and elongation. By dividing the maximum force applied before breaking by the original cross-sectional area of the sample, I calculate the tensile strength. This controlled procedure ensures repeatability and accurate determination of the material’s mechanical properties.

Why Is Tensile Strength Important?

Tensile strength is a critical mechanical property that defines a material’s ability to withstand the maximum amount of tensile force without failure. It is essential for determining the durability and safety of materials under load, particularly in structural, aerospace, automotive, and manufacturing applications. By evaluating tensile strength, engineers can select materials that ensure reliable performance and prevent catastrophic failures. Furthermore, tensile strength data is vital in optimizing designs, reducing material waste, and achieving cost-efficient engineering solutions.

What Role Does Tensile Force Play in Testing?

- Material Characterization: Tensile force is fundamental in identifying the mechanical properties of materials, such as yield strength, ultimate tensile strength, and elongation, which are critical for defining material behavior under stress.

- Quality Control: Tensile testing using controlled tensile force ensures that materials meet manufacturing specifications and industry standards, guaranteeing consistent performance and safety.

- Failure Analysis: Applying tensile force aids in understanding material failure mechanisms, allowing engineers to determine stress thresholds and design components to prevent such failures.

- Product Development: Tensile force testing informs the design and optimization of materials and products by providing key performance metrics, ensuring that new innovations meet their intended mechanical requirements.

- Structural Integrity Assessment: Assessing materials under tensile force helps verify that structural components can handle expected loads and stresses, ensuring durability and reliability in real-world applications.

What Are the Factors Affecting Tensile Strength?

Several factors influence tensile strength, including:

- Material Composition: The molecular structure and chemical composition of a material directly impact its ability to resist tensile forces. For example, the presence of alloying elements in metals can enhance strength.

- Microstructure: The grain size, phase distribution, and defects within a material’s microstructure play a crucial role in determining its tensile strength. Fine-grained materials typically exhibit higher strength.

- Temperature: Elevated temperatures can weaken material bonds, reducing tensile strength, while lower temperatures may increase brittleness.

- Manufacturing Process: Techniques such as heat treatment, forging, and rolling can alter the internal structure and mechanical properties of a material, thus affecting its tensile strength.

- Load Conditions: The rate of applied stress, as well as the direction and magnitude of loading, can influence how a material behaves under tensile force.

Each of these factors must be carefully considered during material selection and design to ensure optimal performance under tensile stress.

How Does Material Composition Affect the Outcome?

Material composition plays a critical role in determining a material’s mechanical properties, including its behavior under tensile stress. The presence and proportion of elements within an alloy significantly influence characteristics such as strength, ductility, and resistance to fracture or fatigue. For instance, higher carbon content in steel increases tensile strength but reduces ductility, while the addition of elements like chromium and nickel can improve corrosion resistance and toughness. Non-metallic materials, such as polymers, depend on their molecular structure, with factors like chain length, cross-linking, and crystallinity sharply affecting their tensile performance. Ultimately, understanding and controlling these compositional variables enables engineers to tailor materials for specific applications, ensuring optimal performance and reliability.

What Impact Does Temperature Have on Results?

Temperature has a profound impact on material performance and can significantly alter results across various applications. For metallic materials, increases in temperature typically reduce yield strength, tensile strength, and hardness while enhancing ductility. Conversely, lower temperatures may increase brittleness, particularly in materials with body-centered cubic (BCC) structures. Thermal expansion becomes a key parameter, as changes in dimensions due to temperature can induce stress or misalignment in assemblies.

For polymers, elevated temperatures can lead to softening or melting, governed by the glass transition temperature (Tg) and melting temperature (Tm). Below Tg, polymers are rigid and brittle, while above Tg, they exhibit increased flexibility. High temperatures can also accelerate degradation, especially in thermoplastics. For non-metals like ceramics, performance tends to remain stable at high temperatures, but extreme thermal gradients might induce cracks due to thermal shock.

Key parameters to consider include:

- Thermal expansion coefficient (α): Quantifies dimensional changes per degree of temperature change.

- Glass transition temperature (Tg) and melting temperature (Tm) for polymers.

- Yield strength and tensile strength at various temperature ranges (e.g., -50°F to 1500°F for metals).

- Fracture toughness (KIC): Affected by low-temperature brittleness in metals and ceramics.

Accurate monitoring and control of temperature conditions are essential in mitigating adverse effects and ensuring reliable material performance.

Why Does Test Speed Matter?

Test speed is a critical factor in material testing as it directly impacts the behavior of materials under stress and the accuracy of test results. The rate at which a load or stress is applied can influence the mechanical properties being measured, including yield strength, tensile strength, and fracture toughness. For instance, slower test speeds generally allow materials to deform plastically over a longer period, providing a more realistic assessment of ductile materials. Conversely, higher test speeds can produce strain-rate-dependent effects such as increased brittleness, particularly in polymers and metals. Furthermore, certain materials exhibit viscoelastic or time-dependent behavior, meaning their properties change significantly under varying test speeds. Standardizing and carefully controlling test speeds are therefore crucial to ensuring repeatable, comparable, and application-representative test data. This is especially important when simulating real-world operational conditions where dynamic or impact loads may be involved.

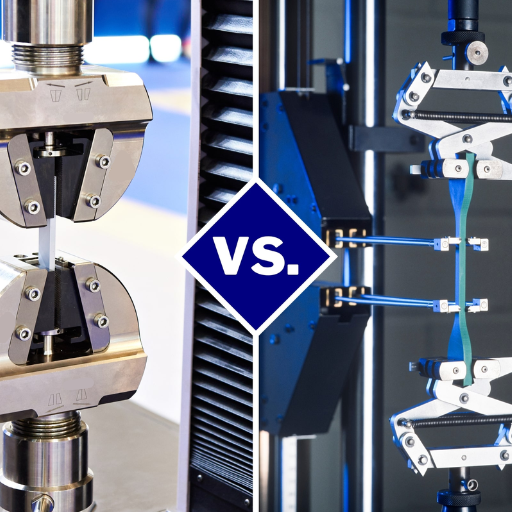

How Do Different Types of Tensile Test Methods Compare?

Several tensile test methods are commonly employed, each offering distinct advantages and application-specific insights. The standard tensile test, performed under constant loading conditions, provides fundamental properties like ultimate tensile strength, yield strength, and elongation. However, tests such as strain-rate controlled tensile tests allow for the evaluation of material behavior under dynamic loading conditions, crucial for applications involving high-speed impacts or fluctuating stresses. Non-ambient tensile testing, conducted at varying temperatures, enables the assessment of material performance in extreme environments, such as cryogenic or high-temperature operations. Lastly, micro-tensile tests focus on small-scale specimens, pivotal for characterizing thin films or materials in microelectronics. By matching the test method to the intended application and operational conditions, engineers can derive the most relevant material data effectively.

What Is the Standard Test Method?

The standard test method for tensile testing of materials is outlined by ASTM (American Society for Testing and Materials) standards, primarily ASTM E8/E8M for metals and ASTM D638 for plastics. ASTM E8/E8M specifies the procedures for conducting tension tests on metallic materials, providing detailed guidance on specimen preparation, test machine calibration, and data reporting. For plastics, ASTM D638 addresses unique considerations such as the influence of polymer elasticity and specimen dimensions. These standards ensure consistency, reliability, and comparability of results across laboratories and industries. Additionally, advancements in computational analysis and the integration of digital extensometers are enhancing the precision of standard tensile testing methodologies globally.

How Do Alternative Methods Affect Results?

Alternative methods of tensile testing can significantly influence results by introducing variations in critical parameters such as strain measurement accuracy, loading rate control, and specimen geometry. For example, using non-standard specimen shapes or sizes may lead to deviations in stress and strain calculations due to altered stress distribution. Similarly, adopting different strain measurement techniques, such as video-based extensometers instead of clip-on types, may affect precision, with video extensometers offering non-contact advantages but potentially lower resolution.

Key Technical Parameters to Consider:

1. Strain Measurement Method:

-

- Clip-on Extensometer Precision: ±0.01 mm

- Video Extensometer Precision: ±0.05 mm

- Loading Rate:

- Standard Rate per ASTM D638 or ISO 527 guidelines (e.g., 5 mm/min for specific materials).

- Specimen Geometry:

- Standard dimensions (e.g., 50 mm gauge length for plastics) versus custom geometries, which may alter stress distribution.

- Environmental Conditions:

- Controlled temperature and humidity (e.g., 23°C ± 2°C, 50% ± 5% RH) versus variable conditions, which may impact material behavior.

To ensure consistency, adhering to recognized standards while accounting for the limitations of alternative methods is crucial in minimizing result discrepancies and maintaining data comparability.

What Are Common Test Methods Used in Industry?

From my perspective, the most common material testing methods in the industry include tensile testing, hardness testing, and impact testing, each with specific technical parameters that ensure reliable and repeatable results.

1. Tensile Testing

-

- This method evaluates a material’s strength and ductility by measuring its response to uniaxial tension.

- Key Parameters:

- Strain rate (e.g., 0.001–0.1 s⁻¹ depending on test requirements)

- Gauge length (e.g., 50 mm for standard specimens per ASTM E8)

- Test speed based on material type and standards (e.g., 5 mm/min for metals).

- Hardness Testing

- Hardness tests (e.g., Brinell, Rockwell, or Vickers) measure a material’s resistance to deformation under a controlled force using a specific indenter.

- Key Parameters:

- Force applied (e.g., 10–3000 kgf for Brinell Hardness Test per ASTM E10)

- Indenter type (e.g., steel or tungsten ball, diamond cone)

- Dwell time (standardized, often 10-15 seconds).

- Impact Testing

- This test determines a material’s toughness by evaluating energy absorption during fracture under sudden impact (e.g., Charpy or Izod methods).

- Key Parameters:

- Test temperature (e.g., -40°C to room temperature, monitored with precision)

- Specimen size and notch type (e.g., 10 mm × 10 mm with a V-notch per ASTM E23)

- Impact energy measurement (e.g., Joules).

Each of these testing methods contributes valuable data toward understanding material performance under specific conditions, enabling precise evaluation tailored to industrial requirements.

How to Use a Tensile Test Machine Effectively?

To use a tensile test machine effectively, it is essential to follow a precise and systematic approach:

1. Prepare the Specimen:

-

- Ensure the specimen is fabricated to standard dimensions (e.g., ASTM E8/E8M for metals).

- Measure and document the specimen’s initial dimensions accurately (gage length, width, and thickness).

- Set Up the Machine:

- Verify the calibration of the tensile test machine to ensure accurate force and displacement measurements.

- Install the appropriate grips or fixtures for the specimen’s geometry and material type.

- Perform the Test:

- Secure the specimen in the machine’s grips, ensuring it is properly aligned to prevent bending forces.

- Input test parameters (e.g., strain rate, load limits) into the machine’s control system.

- Gradually apply load or displacement as per the testing standard, monitoring real-time data.

- Record and Analyze Data:

- Capture key results such as yield strength, ultimate tensile strength, elongation, and reduction in area.

- Ensure data is stored and analyzed appropriately for reporting and material evaluation.

- Post-Test Inspection:

- Examine the fractured specimen to confirm failure mode and alignment accuracy.

- Record relevant visual observations for a comprehensive analysis.

Adopting these detailed steps ensures accuracy, repeatability, and compliance with testing standards, ultimately facilitating reliable material characterization.

What Are the Components of a Tensile Test Machine?

A tensile test machine, also known as a universal testing machine (UTM), consists of several critical components designed to ensure precise measurement and evaluation of material properties under tensile loads. Key components include:

1. Load Frame:

-

- Provides the structural support for the machine and holds other components in alignment.

- Often made of rigid materials like steel to minimize deformation during testing.

- Crosshead:

- A movable component that applies tensile force to the specimen.

- Can be adjusted to control the speed and direction of the applied load, typically within the range of 0.01 mm/min to 500 mm/min, depending on material and testing requirements.

- Load Cell:

- Measures the applied force with high sensitivity and accuracy.

- Load cells typically operate within defined capacity ranges, such as 10 kN, 50 kN, or 100 kN, depending on machine specifications.

- Grips/Fixtures:

- Secure the specimen firmly at both ends to prevent slipping during testing.

- Common types include wedge grips, hydraulic grips, and pneumatic grips, selected based on specimen geometry and material type.

- Extensometer:

- Measures the elongation or strain of the specimen during testing.

- Extensometers are often classified by their gauge length (e.g., 10 mm, 25 mm) and precision, with some achieving accuracy up to ±0.5% of the measured strain.

- Controller and Software:

- Regulates machine operation, including load application, speed control, and data acquisition.

- Modern systems include advanced software for real-time data visualization, stress-strain curve generation, and compliance with ASTM and ISO testing standards.

- Power Unit:

- Supplies the required power for the machine’s hydraulic or mechanical operation.

- Hydraulic systems typically operate at pressures ranging from 2000 to 3000 psi.

- Safety Features:

- Includes protective guards, overload sensors, and emergency stop systems to ensure operator safety and equipment integrity during testing.

Each of these components functions cohesively to provide accurate, repeatable measurements of a material’s mechanical properties, such as tensile strength, yield strength, and modulus of elasticity.

How to Prepare a Test Specimen?

To prepare a test specimen, I ensure it is machined or fabricated according to the applicable testing standards, such as ASTM or ISO. First, I select the material and confirm its dimensions and geometry comply with the testing specifications. Next, I use precision cutting or machining tools to shape the specimen carefully, maintaining uniformity to avoid any anomalies during testing. Once shaped, I inspect the specimen for surface defects or irregularities that could compromise the results and polish or clean it as needed. Finally, I label the specimen to track its identity and store it in controlled conditions to prevent contamination or damage before testing.

How to Interpret the Results?

To interpret the results, I first compare the data obtained from the specimen tests against the predefined standards or benchmarks specific to the material or application. I focus on key parameters such as strength, durability, and any deviations from expected performance metrics. Patterns or anomalies in the results are analyzed to identify potential causes, such as material inconsistencies or testing errors. Where applicable, I use statistical methods to validate the data’s reliability and ensure that the findings align with theoretical predictions or industry norms. This systematic evaluation enables me to draw accurate, actionable conclusions.

What Is the Relationship Between Tensile Stress and Ultimate Tensile Strength?

Tensile stress represents the force per unit area applied to a material, causing it to stretch. Ultimate tensile strength (UTS), on the other hand, is the maximum tensile stress that a material can withstand before failing. The relationship between the two lies in the fact that tensile stress is measured during testing, and as the applied stress increases, it eventually reaches the ultimate tensile strength at the material’s breaking point. UTS thus defines the maximum capacity of the material under tensile loading conditions.

How to Calculate Ultimate Tensile Strength?

To calculate ultimate tensile strength (UTS), you need the maximum load applied during a tensile test and the original cross-sectional area of the material being tested. The formula for UTS is:

UTS = Fmax / A0

Where:

- Fmax is the maximum force (load) applied to the specimen during the tensile test (measured in Newtons or pounds-force).

- A0 is the original cross-sectional area of the specimen (measured in square meters or square inches).

The tensile test is typically performed using a universal testing machine. A specimen with a known geometry is subjected to controlled tensile force until it fractures. The data recorded during the test is used to calculate UTS, providing critical insight into the material’s mechanical performance under tensile loading.

What Is the Difference Between Yield Strength and Ultimate Strength?

Yield strength and ultimate strength differ in that yield strength signifies the stress at which a material begins to deform plastically, while ultimate strength indicates the maximum stress a material can withstand before breaking.

|

Parameter |

Yield Strength |

Ultimate Strength |

|---|---|---|

|

Definition |

Stress for plasticity |

Max stress before break |

|

Point on Curve |

Elastic limit |

Peak of stress curve |

|

Deformation |

Reversible to permanent |

Permanent deformation |

|

Load Capacity |

Start of plastic flow |

Maximum load capacity |

|

Failure |

No fracture |

Fracture occurs |

How Does Tensile Stress Influence Material Performance?

Tensile stress directly impacts material performance by determining how a material deforms and ultimately fails under applied forces. When tensile stress is applied to a material, it causes elongation along the direction of the force. The performance can vary based on the material properties, such as yield strength and ultimate strength, as seen in the stress-strain curve. Key parameters influencing material performance under tensile stress include:

- Yield Strength: Indicates the stress level at which the material transitions from elastic deformation (reversible) to plastic deformation (permanent). Materials with higher yield strength can resist permanent deformation under larger loads.

- Ultimate Tensile Strength (UTS): Represents the maximum stress a material can endure before fracture. It sets a definitive upper limit to the load-bearing capacity of the material.

- Elongation at Break (%EL): A measure of the material’s ductility, showing how much strain a material can withstand before it fails. Higher elongation indicates better ability to deform plastically without immediate fracture.

Tensile stress tests are crucial for evaluating the mechanical properties of materials and determining their suitability for applications requiring high durability and reliability under load.

Reference Sources

- Everything You Need to Know About Tensile Strength – Xometry

- Tensile Strength – Instron

- Four Factors Affecting the Metal Tensile Test – LinkedIn

- Understanding Tensile Strength, Elongation, and More – Maeden

- Top Tensile Testing Machine in China

Frequently Asked Questions (FAQs)

Q: What is tensile strength and why is it important in material testing?

A: Tensile strength refers to the maximum load a specimen can sustain without fracture when being stretched or pulled. It is important in material testing because it measures the endurance limits and mechanical efficiency of materials when subjected to forces attempting to pull them apart.

Q: What factors affect the tensile strength of a material?

A: Every material has its own composition, temperature, rate of strain, and the presence of any flaws or impurities which are factors affecting tensile strength. Predicting material performance under stress requires knowledge of these factors.

Q: How does the tensile strength of materials vary between different types of materials?

A: The tensile strength of materials varies significantly; for example, metals like copper typically have a higher tensile strength compared to plastics, which often have lower tensile strength. These variations are due to differences in molecular structure and bonding.

Q: What is the significance of conducting tensile tests on materials?

A: Conducting tensile tests is significant as it helps in determining the tensile properties of materials, ensuring they meet specific standards for safety and performance in their intended applications.

Q: How are tensile tests performed, and what do they measure?

A: A tensile test is performed by applying a controlled tension to a specimen and measuring its response until it breaks. This test measures the tensile strength, elongation, and other mechanical properties of the material.

Q: What are the types of tensile strength relevant to material testing?

A: Types of tensile strength include yield strength, ultimate tensile strength, and breaking strength. Each type provides insight into different aspects of a material’s durability and performance under stress.

Q: How do the tensile properties of plastics differ from metals?

A: The tensile properties of plastics generally include lower tensile strength and greater elongation compared to metals. Plastics deform more easily, which can be advantageous or disadvantageous depending on the application.

Q: Why is understanding tensile strength critical in engineering and construction?

A: Understanding tensile strength is critical because it helps engineers and constructors select suitable materials that can withstand expected loads and stresses, ensuring the safety and longevity of structures and products.

Q: What are some common applications that require high tensile strength materials?

A: Common applications requiring high tensile strength materials include bridges, aircraft, automotive components, and cables. These applications demand materials that can endure significant stress without failing.

Q: How can tensile strength be improved in materials?

A: Tensile strength can be improved through methods such as alloying, heat treatment, and work hardening. These processes alter the material’s internal structure to enhance its ability to withstand tensile forces.