Low cylinder compression is a critical issue that can drastically impact engine performance, efficiency, and reliability. For both seasoned automotive enthusiasts and everyday vehicle owners, understanding the signs and root causes of low cylinder compression is essential to maintaining a healthy engine. This blog post dives deep into the topic, offering a detailed examination of the symptoms that can signal this problem and exploring the underlying factors that lead to compression loss. Whether you’re experiencing engine misfires, poor acceleration, or trouble starting your vehicle, this guide will equip you with the knowledge to diagnose and address low cylinder compression effectively. Read on to uncover the mechanics behind this common issue and discover actionable steps to protect your engine’s performance.

What Are the Common Symptoms of Low Engine Compression?

Common Symptoms of Low Engine Compression

- Engine Misfires – A reduction in compression can disrupt the combustion process, leading to inconsistent power delivery and noticeable engine misfires.

- Reduced Power and Acceleration – Low compression diminishes the engine’s ability to generate sufficient power, resulting in sluggish acceleration and poor overall performance.

- Difficulty Starting the Engine – Insufficient compression can make it harder for the engine to start, often requiring extended cranking before ignition occurs.

- Excessive Exhaust Smoke – Faulty compression can contribute to incomplete combustion, sometimes leading to increased or unusually colored exhaust smoke.

- Unstable Idle – The engine may struggle to maintain a steady idle, often running rough or stalling unexpectedly.

If you notice one or more of these issues, it’s crucial to diagnose the problem promptly to minimize potential damage to your engine.

How Does Loss of Compression Affect Engine Performance?

Loss of compression has a significant and detrimental impact on engine performance. Compression is essential for generating the pressure required to ignite the air-fuel mixture within the combustion chamber. When compression decreases, it results in reduced power output, making the engine less effective at producing the force needed to propel a vehicle. Fuel efficiency is another area that suffers, as incomplete combustion caused by low compression leads to wasted fuel. Additionally, there may be difficulty starting the engine, as insufficient pressure prevents proper ignition. Over time, a loss of compression can cause further mechanical issues, including increased stress on internal components, heightened emissions due to unburnt fuel, and potential damage to parts like piston rings, valves, or cylinder walls. Addressing and resolving compression issues promptly is crucial to maintaining optimal engine performance and longevity.

What Are the Signs of Low Engine Compression?

- Difficulty Starting the Engine – The engine may crank but fail to start, as insufficient compression prevents proper ignition of the air-fuel mixture.

- Loss of Power – A noticeable decrease in engine power and performance, particularly during acceleration, can indicate that one or more cylinders are unable to generate adequate compression.

- Misfiring Cylinders – Frequent misfires during operation, especially under load, are often linked to low compression in the affected cylinders.

- Unusual Exhaust Smoke – Excessive or unusual smoke from the exhaust, often white or bluish in color, can result from unburnt fuel or oil entering the combustion chamber due to compression issues.

- Poor Fuel Economy – A decline in fuel efficiency occurs when unoptimized combustion caused by low compression leads to wasted energy and increased fuel consumption.

Can Low Engine Compression Cause a Misfire?

Yes, low engine compression can directly cause a misfire. Engine compression is vital for the combustion process, as it ensures the air-fuel mixture is properly compressed for efficient ignition. When the compression in one or more cylinders drops below the required threshold, it disrupts the balance of combustion, resulting in incomplete or inconsistent firing of the affected cylinders. Common causes of low compression leading to a misfire include worn piston rings, damaged valves, blown head gaskets, or cracks in the cylinder walls. Diagnosing and addressing the root cause promptly is critical to preventing further damage to the engine and ensuring smooth operation.

What Causes Low Compression in Engine Cylinders?

Low compression in engine cylinders can be attributed to several mechanical issues. Worn or damaged piston rings can create gaps, allowing combustion gases to escape into the crankcase. Similarly, faulty intake or exhaust valves, such as those that are burnt, bent, or improperly seated, may fail to seal the combustion chamber effectively. A blown head gasket can result in compression loss by allowing gases to leak between cylinders or into the cooling system. Cracks in the cylinder walls or cylinder head are another potential cause, as they compromise the integrity of the compression chamber. Regular maintenance and thorough diagnostic procedures are essential to identify and rectify these issues before they lead to further engine damage.

How Do Worn Piston Rings Affect Compression?

Worn piston rings significantly impact engine compression by failing to maintain a proper seal between the piston and the cylinder wall. This loss of seal causes a reduction in cylinder pressure, leading to decreased engine efficiency, power loss, increased blow-by gases, and elevated oil consumption. When the piston rings are worn, exhaust gases can escape into the crankcase (blow-by), and oil may enter the combustion chamber, resulting in visible smoke from the exhaust.

Technical Parameters Affected by Worn Piston Rings:

1. Compression Pressure:

-

- Normal range for most gasoline engines: 120-200 psi per cylinder.

- Readings below 100 psi generally indicate significant wear or damage.

- Blow-By Rate:

- Acceptable levels typically measure under 20% of total cylinder pressure loss.

- Excessive blow-by directly correlates to worn or damaged rings.

- Oil Consumption:

- Unusual oil consumption exceeding 1 quart per 1,000 miles can suggest piston ring failure.

- Hydrocarbon (HC) Levels in Exhaust:

- Elevated HC emissions due to incomplete combustion are often a sign of oil bypassing the rings.

Prompt diagnosis and replacement of worn piston rings are crucial to restore optimal engine performance and prevent further mechanical degradation.

Can a Blown Head Gasket Lead to Compression Issues?

Yes, a blown head gasket can directly cause compression issues within an engine. The head gasket serves as a critical seal between the engine block and cylinder head, ensuring proper containment of combustion pressure. When it fails, the seal is compromised, allowing combustion gases to escape. This results in lower compression in one or more cylinders, often leading to symptoms like misfires, reduced engine power, or difficulty starting.

Additionally, a blown head gasket can allow coolant or oil to leak into the combustion chambers. This not only worsens the compression problem but can also cause further damage to internal components due to improper lubrication or overheating. Diagnosing a blown head gasket typically involves a compression test, a cylinder leak-down test, or chemical testing of the coolant for combustion gases. Early identification and repair are essential to avoid severe engine damage and ensure proper performance.

What Role Do Valves Play in Maintaining Compression?

- Sealing the Combustion Chamber – Valves create a tight seal within the combustion chamber, preventing air-fuel mixture or exhaust gases from escaping during the compression and power strokes.

- Regulating Airflow – Intake valves control the amount of air or air-fuel mixture entering the combustion chamber, ensuring proper compression ratios for optimal engine performance.

- Maintaining Exhaust Flow – Exhaust valves facilitate the efficient expulsion of burnt gases, preventing backpressure that could interfere with engine compression.

- Heat Management – Properly functioning valves help dissipate heat from the combustion process, reducing the risk of warping or damage that could compromise compression seals.

- Timing Synchronization – Precise opening and closing of valves, governed by the camshaft, ensure that compression is maintained by allowing airflow and sealing at the correct intervals in the engine cycle.

How to Diagnose Low Compression in a Car Engine?

Steps to Diagnose Low Compression in a Car Engine

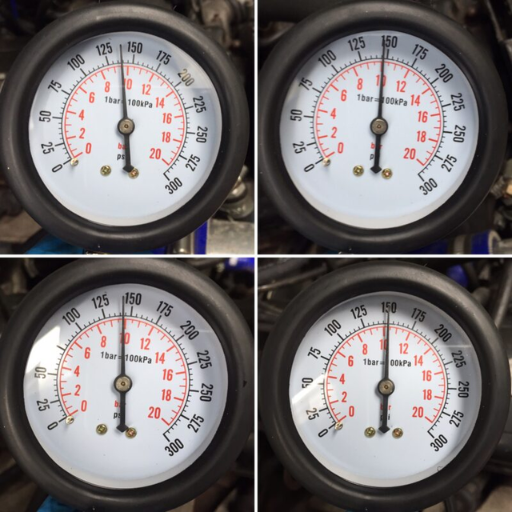

- Perform a Compression Test

Use a compression gauge to measure the pressure in each cylinder. Remove the spark plugs, insert the gauge, and crank the engine. Compare the readings to the manufacturer’s specifications to identify any discrepancies.

- Inspect for Leak Sources

Conduct a leak-down test to pinpoint the exact cause of low compression. This test introduces compressed air into the cylinder and helps identify whether the issue is due to worn piston rings, damaged valves, or a faulty head gasket.

- Examine Spark Plugs and Cylinders

Check the spark plugs for oil or unusual deposits, which could indicate internal damage. Use a borescope to visually inspect the cylinders for signs of scoring, cracks, or excessive wear.

- Check Valve Operation

Verify that the valves are opening and closing at the correct intervals. Inspect for signs of damage, sticking, or improper clearances, which can prevent proper sealing and lead to compression loss.

- Evaluate Head Gasket Integrity

Look for external and internal signs of a blown head gasket, such as coolant leaks, oil mixing with coolant, or excessive white smoke from the exhaust.

By following these steps, you can diagnose the underlying cause of low compression and take the necessary steps to address the issue.

What Is a Compression Test and How Is It Performed?

A compression test is a diagnostic procedure used to evaluate the health of an internal combustion engine by measuring the pressure generated within each cylinder during the compression stroke. It provides critical insights into the condition of the piston rings, cylinder walls, and the sealing of the intake and exhaust valves. By identifying variations or low compression values, the test helps pinpoint issues such as worn piston rings, valve leaks, or a blown head gasket.

To perform a compression test, first, ensure the engine is at operating temperature for accurate results. Disable the ignition and fuel systems to prevent the engine from starting during the test. Remove the spark plugs to gain access to the cylinders and connect a compression gauge to one cylinder at a time. Crank the engine several times (typically 4–6 revolutions) while observing the gauge’s reading. Record the compression value for each cylinder and compare it to the manufacturer’s specifications. Any significant deviations between cylinders typically indicate mechanical issues that warrant further inspection. Using advanced tools and adhering to proper procedures ensures reliable and precise results from the compression test.

How to Interpret Compression Test Results?

To interpret compression test results effectively, I first compare the recorded compression values of each cylinder to the specifications provided by the manufacturer. A compression reading that deviates significantly—usually by more than 10-15%—from the average of the other cylinders may indicate an issue such as worn piston rings, a damaged valve, or a blown head gasket. Consistently low readings across all cylinders could point to a timing issue or widespread engine wear. Additionally, I look for uniformity; large differences between cylinder readings can signify localized problems needing detailed diagnostic checks. Proper interpretation is essential for identifying the source of engine performance issues accurately.

What Tools Are Needed to Test Compression?

To test compression accurately, I use a compression tester, which includes a pressure gauge and an adapter that fits into the spark plug hole. A basic set usually covers most vehicle types, but for specific engines, I ensure I have the correct thread size and sealing type for the adapter. Additionally, I require a ratchet and spark plug socket to remove the spark plugs, as well as a remote starter switch or an assistant to crank the engine. When performing the test, I ensure the engine is at operating temperature, the throttle is fully open, and all spark plugs are removed to achieve consistent and valid results. Compression readings typically range from 120 PSI to 200 PSI for most gasoline engines, with minimal variance between cylinders being critical (usually within 10-15%).

How Can You Fix Low Engine Compression?

Low engine compression can be addressed depending on the underlying cause. Begin by identifying the source of the issue, which may include worn piston rings, leaking valves, or a damaged head gasket. For worn piston rings, an engine rebuild or ring replacement is necessary. Leaking valves often require a valve job, involving regrinding or replacing the affected valves and valve seats. If a damaged head gasket is the culprit, it must be replaced, ensuring the cylinder head is inspected for warping or cracks beforehand. Regular maintenance and proper diagnostics are essential to prevent compression-related issues and extend engine lifespan.

Is It Possible to Repair Piston or Cylinder Wall Damage?

Repairing piston or cylinder wall damage is highly situational and depends on the extent and type of damage. Minor piston damage, such as small scratches or scuff marks, can sometimes be resolved by polishing or light machining. Severe damage, including cracks or broken piston skirts, typically requires piston replacement as repairs are not reliable for long-term performance. Similarly, minor cylinder wall damage, such as glazing, can often be addressed through honing, which restores the surface finish and ensures proper piston ring seating. However, deeper scratches or scoring may necessitate reboring the cylinder and installing oversized pistons to restore engine functionality.

Whether repairing or replacing, precise measurement and inspection are critical. A comprehensive evaluation including testing for tolerances, material wear, and underlying causes—such as improper lubrication or overheating—ensures optimal results. Proper tooling and expertise are also required, highlighting the importance of consulting with an experienced technician for these types of repairs.

How to Replace a Blown Head Gasket?

Replacing a blown head gasket is a complex process that demands precision and attention to detail. First, I begin by disconnecting the battery and draining the engine coolant to ensure a safe workspace. Next, I remove components such as the intake manifold, exhaust manifold, and cylinder head, carefully labeling parts to ensure reassembly accuracy. Once the cylinder head is accessible, I inspect it for warping or damage, as resurfacing or replacement may be required. I then clean the engine block surface thoroughly to ensure no residue remains that could prevent a proper seal. After positioning the new head gasket—ensuring alignment with the manufacturer’s specifications—I reinstall the cylinder head and torque it to the proper sequence and specification using a calibrated torque wrench. Finally, I reassemble the removed components, refill the engine with coolant, and perform a thorough test to verify the repair has resolved the issue. It is critical to follow the vehicle’s service manual and utilize high-quality replacement parts to guarantee the longevity and reliability of the repair.

When Should Valves Be Repaired or Replaced?

Valves should be repaired or replaced when they show signs of wear, damage, or failure, such as leaking, sticking, or loss of compression. I typically inspect valves during routine maintenance or when there are symptoms like misfires, rough idling, or poor engine performance. If I observe burnt, bent, or pitted valves, they are replaced to prevent further engine damage. Following manufacturer guidelines ensures the engine operates efficiently and reliably.

What Are the Long-Term Effects of Low Compression?

Low compression in an engine can lead to several long-term effects that compromise overall performance and reliability. Reduced compression decreases power output, resulting in sluggish acceleration and reduced efficiency. Prolonged low compression can cause excessive fuel consumption, incomplete combustion, and increased emissions. Over time, it may lead to additional component wear, such as damage to pistons, piston rings, or cylinder walls, further exacerbating the issue. Additionally, persistent low compression increases the risk of engine overheating and potential failure if left unaddressed. Regular diagnostics and timely repairs are essential to mitigate these effects and maintain engine health.

How Does Low Cylinder Compression Impact Fuel Efficiency?

Low cylinder compression significantly reduces fuel efficiency by disrupting the combustion process within the engine. When compression levels drop, the air-fuel mixture fails to ignite as efficiently, leading to incomplete combustion. This results in the engine requiring more fuel to produce the same level of power, ultimately increasing fuel consumption. Furthermore, low compression often causes a loss of power output and forces the engine to work harder, compounding the decrease in efficiency. Addressing low compression promptly ensures better combustion performance and helps restore optimal fuel economy.

Can Compression Issues Lead to More Serious Engine Problems?

Yes, compression issues can lead to more serious engine problems if left unresolved. Low compression reduces combustion efficiency and can place additional stress on other engine components. Over time, this can result in overheating, excessive fuel consumption, and even catastrophic engine failure.

Key Technical Parameters to Monitor:

- Compression Pressure: Normal compression pressure typically ranges between 120-180 psi for most gasoline engines, with variations depending on the make and model.

- Cylinder Leak Down Rate: Healthy engines should exhibit a leak-down rate of less than 10-15%. Higher rates indicate significant leakage from valves, piston rings, or cylinder walls.

- Fuel-to-Air Ratio: Optimal ratios are around 14.7:1 for stoichiometric combustion. Deviations due to poor combustion from low compression can harm performance and cause engine knocking.

- Exhaust Gas Temperature (EGT): Persistent low compression may elevate EGTs beyond normal operating ranges (approximately 1200°F-1600°F, depending on engine type), risking damage to the exhaust valves and turbocharger components in forced induction systems.

Regular diagnostics and repairs, such as conducting compression tests and inspecting head gaskets, pistons, and valves, are critical for preventing cascading damage from compression-related issues.

Reference Sources

- Top Causes of Low Engine Compression and How to Fix Them – Rislone

- Low Compression Symptoms, Plus FAQ – CarParts

- Common Causes of Loss of Compression – Reddit Discussion

- Low Compression Symptoms: Diagnosing Engine Cylinders – YouTube Video

- Top Compression Testing Machine in China

Frequently Asked Questions (FAQs)

Q: What are the symptoms of low compression in an engine?

A: Symptoms of low compression often include a hard to start engine, misfiring, loss of power, and rough idling. If the compression is low in one or multiple cylinders, it can lead to decreased engine performance and efficiency.

Q: What are common causes of low compression in a low compression engine?

A: Common causes of low compression include worn piston rings, burned valves, a damaged head gasket, and a broken camshaft. These issues can lead to low engine pressure by allowing air to escape from the combustion chamber.

Q: How can a timing belt lead to low compression?

A: A timing belt that is out of alignment or has broken can lead to low compression by causing the engine’s valves and pistons to be out of sync, preventing proper sealing and creating combustion issues.

Q: Why might compression be low in only one cylinder?

A: Low compression in one cylinder can be caused by a specific problem in that cylinder such as a burned valve, cracked cylinder head, or a piston with burn holes that allow air to escape.

Q: How do air and fuel issues contribute to low compression?

A: If the air intake system is faulty or the fuel mixture is incorrect, it can lead to improper combustion, which may result in low compression. Ensuring proper air and fuel delivery is essential for maintaining engine pressure.

Q: What happens if two cylinders lose compression at the same time?

A: If two cylinders lose compression simultaneously, the engine is running inefficently which can lead to significant power loss, increased fuel consumption, and potentially further damage to the engine components.

Q: Can a broken camshaft cause low compression?

A: Yes, a broken camshaft can cause low compression by preventing the valves from opening and closing at the correct times, disrupting the engine’s ability to create combustion efficiently.

Q: How does a running engine with low compression affect vehicle performance?

A: A running engine with low compression can result in poor acceleration, reduced power, and overall decreased vehicle performance, as the engine cannot generate the necessary force to propel the vehicle effectively.

Q: What role does the top of the engine play in maintaining compression?

A: The top of the engine, including the cylinder head, valves, and head gasket, plays a critical role in maintaining compression by ensuring the combustion chamber is sealed properly to contain the air and fuel mixture during combustion.

Q: Can higher compression in other cylinders compensate for one with low compression?

A: Higher compression in other cylinders cannot fully compensate for one with low compression, as the imbalance can cause the engine to run unevenly, leading to additional stress and potential damage over time.