For professionals and researchers working with geotextiles, understanding their mechanical performance is critical to ensuring their effectiveness and reliability in various engineering applications. This article provides a comprehensive overview of the standard test methods, including ASTM standards, used to evaluate the puncture and tensile properties of geotextiles. These properties are essential for determining the material’s durability, resistance to stress, and suitability for use in demanding environments such as road construction, erosion control, and landfill lining. By exploring these standardized methods in detail, this piece aims to equip readers with the technical knowledge needed to interpret test results and make informed decisions about material selection and application. Top Test Fixtures in China

What Is the Astm Standard for Geotextiles?

The ASTM standard for geotextiles is a set of guidelines established by the American Society for Testing and Materials (ASTM) to ensure the quality and performance of geotextile materials. The most commonly referenced standard is ASTM D4439, which provides terminology and classifications for geotextiles. Additionally, ASTM D4595 outlines test methods for tensile properties, while ASTM D4751 defines procedures for determining the apparent opening size of geotextiles. These standards are designed to ensure consistency, reliability, and suitability of geotextiles in various engineering applications.

Overview of ASTM Standards in Geotextile Testing

Key ASTM Standards for Geotextile Testing

ASTM standards serve as critical benchmarks in the evaluation and utilization of geotextiles across engineering applications. Below is an overview of some key ASTM standards frequently used to ensure performance and durability:

- ASTM D4439 – Terminology and Classifications: This standard provides a comprehensive framework for defining and classifying geotextiles, ensuring a clear and consistent language for manufacturers, engineers, and researchers. It delineates key properties such as tensile strength, permeability, and elongation.

- ASTM D4595 – Tensile Properties Using Wide-Width Strip: This test method evaluates the tensile strength of geotextiles under controlled conditions, offering insights into their ability to withstand tensile stresses in both machine and cross-machine directions. The results ensure the material meets strength requirements for specific applications.

- ASTM D4751 – Apparent Opening Size (AOS): This standard determines the effective pore size of geotextiles through sieve analysis, which is critical for assessing filtration capabilities and soil compatibility. By understanding the AOS, engineers can select the appropriate fabric to prevent soil migration while maintaining fluid permeability.

These standards collectively establish a scientifically rigorous approach to evaluating the mechanical, physical, and filtration properties of geotextiles, enabling their reliable use in construction, drainage, and erosion control projects.

Importance of Geotextile Standards in Construction

Geotextile standards play a critical role in ensuring the longevity, performance, and safety of infrastructure projects. These standards establish uniform criteria for material properties, such as tensile strength, permeability, and durability, which are essential for maintaining structural integrity under various environmental conditions. By adhering to these specifications, engineers can mitigate risks such as soil erosion, material degradation, and improper drainage. Reliable geotextile standards also enable consistent quality control, ensuring compatibility with specific project requirements like filtration, reinforcement, or separation. Furthermore, they promote sustainability by optimizing resource usage and reducing environmental impact. Ultimately, geotextile standards provide a scientifically-backed framework that supports efficient project design, minimizes failure rates, and ensures the long-term success of construction and environmental engineering applications.

How to Access and Implement ASTM Standards

To access and implement ASTM standards effectively, I typically begin by visiting the ASTM International official website. Here, I can explore their standards catalog or use the search function to locate specific documents relevant to my project. Subscriptions or individual standard purchases are often required, which provides me with accurate and up-to-date information.

Once I have access, I carefully review the scope, guidelines, and technical specifications outlined in the standard to ensure they align with my project needs. To implement these standards, I integrate their requirements into my project planning and conduct any necessary testing or quality checks as prescribed. Additionally, I stay informed by referring to educational resources, webinars, or support tools offered by ASTM International to ensure compliance and proper application of the standards. This systematic approach helps me achieve precision and reliability in my work.

How Is the Tensile Test Conducted on Geotextiles?

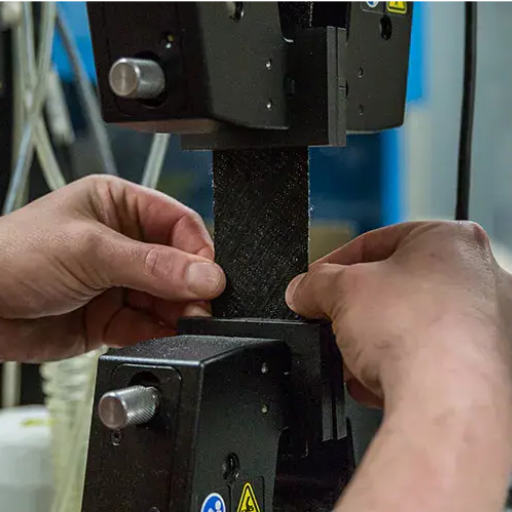

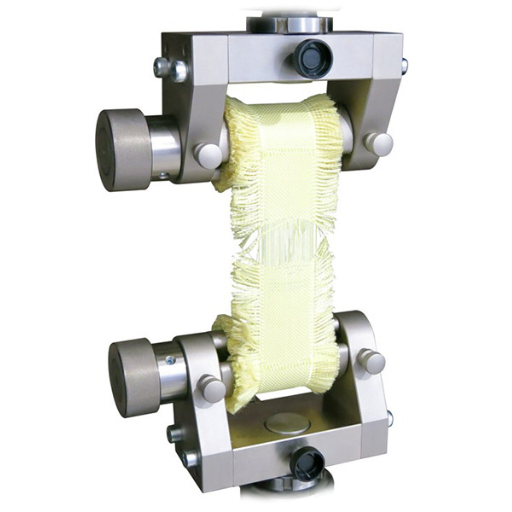

The tensile test on geotextiles is conducted to evaluate their strength and elongation properties under applied stress. The procedure typically follows standardized methods, such as ASTM D4595 for wide-width strip tensile testing. The test involves securing a specimen of the geotextile in a tensile testing machine, ensuring uniform alignment to prevent skewing. A constant rate of elongation is applied to the specimen until failure occurs, and during this process, both the force and elongation are recorded. Key parameters such as ultimate tensile strength and breaking elongation are derived from the data, providing critical insights into the material’s performance for engineering applications.

Understanding the Tensile Test Method

Key Insights from Tensile Testing Procedures

The tensile test is essential for evaluating the mechanical properties of materials, particularly strength and deformation characteristics. During testing, a material sample is subjected to uniaxial tension until failure, ensuring precise measurements of force and elongation. This method reveals key material behaviors such as yield strength, ultimate tensile strength, and elongation at break, providing data critical for structural and engineering design.

From leading resources on tensile testing, three consistent principles emerge:

- Sample Preparation – Proper specimen preparation is vital to ensure reproducibility. Samples should conform to standardized dimensions, often defined by ASTM or ISO guidelines, and any imperfections like scratches should be avoided as they can affect results.

- Testing Parameters – The controlled application of stress, based on a constant strain or stress rate, is integral to obtaining reliable data. The gauge length, cross-sectional area, and rate of elongation directly influence the accuracy of the results.

- Data Analysis and Applications – The stress-strain curve generated from tensile testing provides valuable insights into elasticity, plasticity, and fracture behavior. This data informs material selection and performance evaluation in industries like construction, aviation, and manufacturing.

The method’s precision and alignment with global standards make tensile testing a foundation for understanding material integrity and ensuring safety across engineering applications.

Preparing the Geotextile Specimen for Testing

To prepare the geotextile specimen for testing, I follow a standardized procedure to ensure accuracy and repeatability. First, I cut the sample to the required dimensions specified by the relevant testing standard, such as ASTM D4595 or ISO 10319, while ensuring clean and precise edges to prevent stress concentration. Next, I pre-condition the specimen in a controlled environment with standardized temperature and humidity levels to eliminate any impact of external factors. Proper alignment during mounting is critical to guarantee uniform load distribution across the sample during testing. These steps ensure that the specimen’s behavior accurately represents its performance under real-world conditions.

Interpreting Tensile Strength and Elongation Results

Tensile strength represents the maximum stress that a material can withstand while being stretched or pulled before failure. It is a critical metric used to assess the mechanical robustness of materials in various engineering applications. The results are typically reported as the ultimate tensile strength (UTS), calculated by dividing the maximum force applied by the cross-sectional area of the specimen. High tensile strength materials are often preferred for demanding applications, such as in aerospace or construction, where structural integrity is paramount.

Elongation, on the other hand, measures a material’s ability to stretch or deform under tensile stress before breaking. Expressed as a percentage of the original gauge length, elongation provides insights into the material’s ductility. Higher elongation indicates greater deformability, which is desirable for applications requiring flexibility or energy absorption, such as in automotive crash components.

Interpreting these results requires understanding the interplay between these properties. For instance, materials with high tensile strength and low elongation are often brittle, making them strong but susceptible to sudden failure without significant deformation. Conversely, materials with moderate tensile strength and high elongation exhibit ductility, allowing them to absorb energy and deform significantly before failure. By analyzing these metrics collectively, engineers can match material properties to specific performance requirements, ensuring optimal functionality and safety in the intended application.

What Is the Puncture Test Method for Geotextiles?

The puncture test method for geotextiles is a standardized procedure used to evaluate the resistance of a geotextile material to penetration by a pointed object. This test simulates conditions where the material may be subjected to concentrated loads or sharp objects during installation or use. Typically conducted using ASTM D6241 or ISO standards, the test involves applying force to a specimen using a probe until puncture occurs, while the force required is recorded. The results help determine the material’s strength, durability, and suitability for specific engineering applications, such as soil reinforcement or erosion control.

Introduction to Puncture Test and ASTM D4833

Puncture Test and ASTM D4833: Significance and Application

The puncture test described by ASTM D4833 is a critical evaluation procedure for measuring the puncture resistance of geosynthetic materials, such as geomembranes and geotextiles. It involves the application of force to a standard-sized specimen using a specified probe until failure occurs. This allows for the accurate quantification of material performance under concentrated stress conditions. According to the latest technical evaluations and reported usage data, ASTM D4833 has become a standard for industries that require precise measurement of a material’s durability under localized pressure.

This test is particularly instrumental in applications where geosynthetics are deployed in environments involving sharp objects, heavy loads, or potential mechanical damage, such as landfill liners, transportation infrastructure, and containment systems. By determining a material’s ability to withstand punctures, ASTM D4833 assists engineers and designers in selecting materials that meet the mechanical performance criteria necessary for prolonged functionality and safety under specific operating conditions.

Procedure for Conducting the Puncture Resistance Test

- Preparation of the Specimen

First, I ensure the test specimen is cut to the required size, typically 150 mm x 150 mm, and free from wrinkles or defects that might influence the results. The specimen is conditioned in a controlled environment at 23°C ± 2°C and 50% ± 5% relative humidity for at least 24 hours before testing.

- Mounting in Testing Apparatus

I securely position the specimen in the clamp assembly of the puncture resistance testing machine, ensuring that it lies flat and that the material remains taut to avoid inaccurate readings.

- Testing Setup

The testing apparatus consists of a steel puncture probe with a conical point having a diameter of 1.0 mm ± 0.1 mm at the tip and an angle of 45°. The probe is attached to a calibrated load cell capable of measuring forces up to 1,000 N or higher, depending on the expected material strength.

- Application of Force

I initiate the testing machine at a controlled rate of 300 mm/min (±10%), bringing the steel probe into contact with the specimen. The force is gradually applied until the probe punctures through the material.

- Data Recording

During the test, I record the maximum force (in Newtons) required to puncture the specimen. This value represents the material’s puncture resistance.

- Repeat Testing

I repeat the procedure on a minimum of five different specimens from the same material sample to account for variability. The average puncture resistance is calculated and reported.

7. Technical Parameters to Report

-

- Maximum puncture force (N)

- Probe dimensions (angle and tip diameter)

- Displacement rate (mm/min)

- Test temperature and relative humidity

- Average puncture force and standard deviation

Careful adherence to these steps ensures that the puncture resistance test yields reliable and reproducible results in compliance with ASTM D4833 specifications.

Significance of Puncture Resistance in Geotextile Performance

Puncture resistance is a critical parameter in assessing the durability and functionality of geotextiles in various engineering applications. Geotextiles are frequently exposed to sharp objects or angular aggregates during installation and service, which can compromise their integrity if insufficient puncture resistance is present. This property directly impacts the material’s ability to function as a barrier, filter, or reinforcement without undergoing mechanical damage.

Key technical parameters influencing puncture resistance include the following:

1. Material Composition

-

- Fiber type (e.g., polypropylene, polyester)

- Fabric manufacturing method (woven, non-woven, or knitted)

- Mechanical Properties

- Tensile strength (N or kN/m)

- Elongation at break (%)

- Thickness (mm)

- Test Conditions

- Puncture force at failure (N)

- Test apparatus specifications (probe dimensions, test setup)

- Environmental conditions (temperature, humidity)

Engineering projects that utilize geotextiles with optimized puncture resistance are better protected against mechanical wear and retain their functional efficacy over time. Ensuring that such properties align with ASTM or ISO standards is essential for maintaining performance reliability.

How Does the ISO Standard Compare with ASTM for Geotextiles?

The ISO and ASTM standards for geotextiles share a common goal of ensuring consistent performance and reliability, but they differ in methodology, test procedures, and regional adoption. ISO standards, such as ISO 10319 for geotextile wide-width tensile testing, emphasize international applicability and uniformity across global markets. ASTM standards, like ASTM D4595, provide detailed protocols tailored to specific technical and operational conditions, catering primarily to North American practices. While both standards assess key properties such as strength, puncture resistance, and durability, variations in apparatus design, specimen preparation, and acceptable tolerances often necessitate cross-referencing for compliance in international projects. A thorough understanding of both standards is critical for engineers to select appropriate specifications based on project requirements and geographic considerations.

Comparison of ISO and ASTM Standards

ISO and ASTM standards differ primarily in their scope, geographic application, testing methodologies, and material specifications, necessitating context-based application.

|

Parameter |

ISO |

ASTM |

|---|---|---|

|

Scope |

Global |

Regional (US) |

|

Focus |

Broad sectors |

Materials-focused |

|

Testing |

Metric units |

Imperial units |

|

Accreditation |

ISO-certified |

ASTM membership |

|

Terminology |

Universal terms |

US-specific terms |

|

Adaptability |

International |

Domestic use |

|

Updates |

Less frequent |

Frequent |

|

Specimens |

Higher precision |

Moderate detail |

Adapting International Standards for Local Geotextile Testing

To adapt international standards like ISO for local geotextile testing, I ensure the methods align with regional conditions and requirements, such as soil types and climate variations. I cross-reference ASTM standards to bridge gaps where ISO guidelines may lack localized applicability, particularly for U.S.-specific projects. This involves carefully calibrating equipment to match imperial units while maintaining the precision and universal terminology inherent to ISO protocols. By doing this, I uphold global quality benchmarks while ensuring practical relevance in local testing environments.

Benefits of Following Both ISO and ASTM Guidelines

- Enhanced Global Compatibility: Adhering to both standards ensures that testing systems and results are universally recognized and accepted, facilitating collaboration and trade across international borders.

- Improved Accuracy and Consistency: By integrating ISO’s precise procedural frameworks with ASTM’s rigor in practical applications, testing outcomes are both reliable and reproducible.

- Comprehensive Evaluation: Leveraging insights from both guidelines allows for a more thorough assessment of materials, accounting for diverse environmental and operational conditions.

- Streamlined Regulatory Compliance: Using both standards ensures alignment with varied regional and global regulatory requirements, minimizing potential disputes and non-compliance risks.

- Innovation in Testing Methodologies: Combining these guidelines promotes advancements in testing techniques, fostering innovation while maintaining adherence to established best practices.

What are the Key Properties of Geotextiles in Testing Systems?

Geotextiles exhibit several critical properties that are evaluated during testing to ensure their performance and suitability for specific applications:

- Tensile Strength: Determines the resistance of geotextiles to stretching forces, critical for load-bearing applications.

- Permeability: Measures the ability of the material to allow fluids to pass through, essential for drainage and filtration functions.

- Puncture Resistance: Evaluates the material’s durability against sharp objects and localized pressures.

- UV Resistance: Assesses the geotextile’s ability to withstand prolonged exposure to ultraviolet radiation without degradation.

- Elongation at Break: Indicates the material’s flexibility by measuring stretch capacity before failure.

- Apparent Opening Size (AOS): Reflects the pore size for controlling soil particle retention in filtration systems.

- Abrasion Resistance: Ensures the geotextile maintains integrity under mechanical wear and friction.

Each of these properties plays a pivotal role in defining the performance of geotextiles under various environmental and operational scenarios.

Critical Test Systems for Evaluating Geotextiles

To ensure geotextiles meet required performance benchmarks, standardized test systems are employed to evaluate their mechanical, hydraulic, and durability properties under controlled conditions. These test methods address key functional characteristics and allow for consistent comparison across products. The following are critical test systems commonly used:

- Tensile Strength and Elongation Tests

Tensile tests determine the maximum force a geotextile can withstand before failure, along with its elongation behavior. ASTM D4632 (grab test) and ASTM D4595 (wide-width strip test) are widely adopted standards for this purpose. These tests simulate conditions of mechanical loading encountered in real-world applications, such as soil reinforcement and subgrade stabilization.

- Puncture Resistance Testing

Evaluating the material’s ability to resist puncture is vital for applications involving sharp objects or uneven surfaces. ASTM D6241 (CBR puncture test) is extensively used to assess puncture strength by simulating field stress conditions. This test is critical for projects such as landfill liners and roadway construction.

- Permittivity and Filtration Tests

Hydraulic properties, including permeability, are assessed to ensure proper water flow while preventing soil particle loss in filtration systems. ASTM D4491 is commonly utilized to determine permittivity, which measures the water flow rate through the geotextile. This property is crucial in drainage systems and erosion control projects.

Comprehensive evaluation through these and other standardized tests ensures that geotextiles are appropriately designed and reliable for diverse engineering applications.

Role of Test Specimens and Preparation in Accurate Results

Importance of Test Specimens and Preparation in Accurate Results

Accurate test results heavily depend on the quality and preparation of test specimens. Ensuring consistency in specimen dimensions, cutting methods, and handling practices is critical to maintaining standardized conditions during testing. Variations in these factors can introduce errors, leading to misinterpretation of material performance. Specimens must be representative of the larger material batch, with no defects or irregularities that could skew results. Additionally, environmental conditions such as temperature and humidity during preparation must align with specific test standards, as these factors can influence material properties like tensile strength, elongation, and permeability. Proper preparation not only ensures adherence to ASTM or ISO testing protocols but also facilitates reliable comparisons across different materials and applications.

Common Challenges and Solutions in Geotextile Testing

Challenge 1: Ensuring Uniformity in Sample Preparation

Description: Variability in sample preparation, such as uneven cutting or inconsistent specimen dimensions, can lead to inaccurate results.

Solution: Employ precision cutting tools and strictly adhere to dimensional tolerances specified by standards such as ASTM D5035 for strip or grab tests. For tensile testing, sample width and length tolerances are critical, typically ±1 mm, to ensure accuracy.

Challenge 2: Controlling Environmental Conditions

Description: Fluctuations in temperature and humidity can significantly impact the mechanical properties of geotextiles, such as tensile strength and elongation.

Solution: Conduct testing in a controlled lab environment within standard conditions (e.g., 21 ± 2°C temperature and 65 ± 5% relative humidity, as outlined by ASTM D1776 or ISO 139). Allow test specimens to condition in this environment for at least 24 hours prior to testing.

Challenge 3: Calibration of Testing Equipment

Description: Improperly calibrated equipment can yield erroneous or non-repeatable results, especially in parameters like tensile force or elongation measurements.

Solution: Ensure regular calibration of testing machines according to manufacturer guidelines and verification standards like ASTM D7269. Load cells should be calibrated for both maximum capacity and sensitivity to low-force readings.

Challenge 4: Achieving Accurate Permeability Measurements

Description: Determining water flow rate through geotextiles can be inaccurate if clogs or improper sealings occur during testing.

Solution: Utilize ASTM D4491 (permittivity testing) guidelines, ensuring all clamps and seals prevent leakage. Recommended head loss ranges of 50-150 mm should be maintained for consistent flow results.

Challenge 5: Avoiding Specimen Slippage During Tests

Description: Slippage or improper grip alignment in tensile tests compromises result integrity.

Solution: Apply pneumatic or hydraulic grips with textured or serrated surfaces to enhance friction. Ensure even clamping pressure and alignment of specimens within ±1° to the load axis.

By addressing these challenges with precise methodologies and adherence to standards, geotextile testing results can achieve high levels of accuracy and repeatability, enabling reliable evaluations for engineering and construction applications.

Reference Sources

-

ASTM D4595 – Standard Test Method for Tensile Properties of Geotextiles: This source provides detailed information on testing geotextiles for tensile properties.

-

ASTM D6241 – Standard Test Method for Measuring Static Puncture Strength of Geotextiles: This method measures the force required to puncture geotextiles, offering insights into their puncture resistance.

-

Evaluation of the Tensile and Puncture Properties of Geotextiles: A research article discussing tensile and puncture properties under various conditions.

- Top Test Fixtures in China

Frequently Asked Questions (FAQs)

Q: What is the purpose of the ASTM standard for geotextiles?

A: The ASTM standard for geotextiles provides a method for determining the mechanical and physical properties of geotextiles, such as puncture and tensile properties. It is used for acceptance testing of commercial shipments to ensure quality and performance standards are met.

Q: How does the wide-width strip method work in testing geotextiles?

A: The wide-width strip method is used to determine the tensile properties of geotextiles by applying a tensile force to a specimen with a specific width. This method is used to evaluate the strength and elongation of geotextiles by the wide-width strip technique, ensuring consistent and reliable results.

Q: What is the significance of the d4595 in geotextile testing?

A: The d4595 is a specific ASTM test method used to determine the tensile properties of geotextiles by the wide-width strip method. It is widely recognized in the industry for its accuracy and reliability in assessing the mechanical properties of geotextiles.

Q: Why is the mass per unit area important in geotextile testing?

A: The mass per unit area is a critical property that influences the performance and application of geotextiles. It helps in determining the weight and density of the material, which affects its strength, durability, and suitability for specific applications.

Q: How are test specimens prepared for geotextile testing?

A: The test specimens are prepared according to specific guidelines outlined in the relevant ASTM publication. This involves cutting the geotextiles to a specified width and length, aligning the fibers, and ensuring uniformity across the group of test specimens as described in the standard.

Q: What is the importance of puncture resistance in geotextiles?

A: Puncture resistance of geotextiles is a crucial property that determines the material’s ability to withstand sharp objects and pressure. It is vital for applications where the geotextile will be exposed to potential damage, ensuring the longevity and effectiveness of the material.

Q: How does the test method cover both woven and nonwoven geotextiles?

A: The test method covers both woven and nonwoven geotextiles by providing procedures that account for their unique structural properties. It includes different parameters and adjustments in testing to accurately assess the performance of each type of fabric.

Q: Can the test method be used for acceptance testing of commercial shipments?

A: Yes, the test method may be used for acceptance testing of commercial shipments. It ensures that the geotextiles meet the specified standards and are suitable for their intended applications, providing assurance to manufacturers and consumers.

Q: What role does elongation play in the tensile properties of geotextiles?

A: Elongation is a measure of how much a geotextile can stretch before breaking. It is an essential factor in tensile testing as it indicates the flexibility and elasticity of the material, which are important for its performance in various applications.