Test fixtures are the foundation of effective and reliable testing processes, serving as the crucial link between a well-designed test strategy and actionable results. However, their performance and functionality can be influenced by a multitude of factors, ranging from environmental conditions and material durability to operational design and usage patterns. This blog post dives into a detailed exploration of the key elements that directly impact the efficacy and reliability of test fixtures. Whether you’re refining your current test setups or designing new systems from scratch, this guide will provide you with the technical insights needed to identify potential vulnerabilities and optimize fixture performance. Stay tuned as we dissect these influential variables and present strategies to mitigate their effects, ensuring consistent and accurate testing outcomes.

How Does Fixture Design Impact Test Results?

The Influence of Fixture Design on Test Results

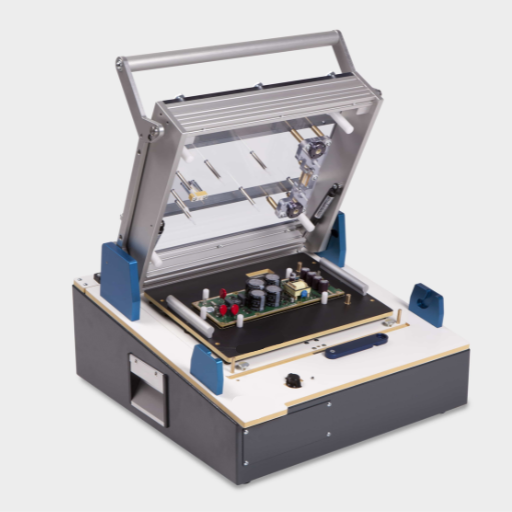

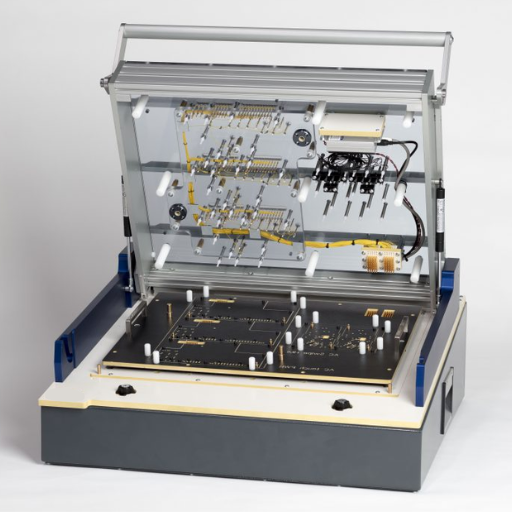

Fixture design directly impacts the accuracy, repeatability, and reliability of test results. A well-designed fixture ensures proper alignment, stability, and consistent positioning of components during testing, reducing the likelihood of measurement errors. Conversely, poor fixture design can introduce variables such as improper load distribution, misalignment, or movement, which can compromise the integrity of the results. By prioritizing precision and stability in fixture design, engineers can minimize discrepancies and ensure that test outputs reliably reflect real-world performance.

Understanding the Basics of Fixture Design

Key Principles of Fixture Design

Fixture design involves the creation of precision tools to securely hold, support, and locate components during manufacturing or testing processes. An effective fixture must ensure stability, repeatability, and ease of use while accommodating the desired operations. Key principles of fixture design include:

- Accuracy and Alignment

Fixtures must accurately align components to ensure consistency in machining, assembly, or testing processes. Misalignment can lead to manufacturing defects or inaccurate test data.

- Stability and Rigidity

Providing a stable and rigid foundation is critical to prevent movement or vibration during operations, which can affect precision and compromise results.

- Flexibility and Adaptability

Modern fixtures often incorporate modular or adjustable designs to accommodate multiple part geometries or process requirements, enhancing versatility across different applications.

- Ease of Loading and Unloading

Fixtures should facilitate ergonomic and efficient loading and unloading of parts to reduce downtime and operator fatigue while maintaining precision.

- Material Selection

The choice of materials for fixtures significantly impacts durability and performance. Commonly used materials include steel, cast iron, and aluminum, selected based on load requirements, wear resistance, and thermal stability.

By adhering to these principles, engineers can design fixtures that improve the efficiency and accuracy of production or testing workflows, resulting in higher-quality outcomes.

Common Mistakes That Affect Test Results

- Improper Calibration of Equipment

I have often found that failing to calibrate testing equipment accurately leads to errors in results. Calibration must be performed regularly to ensure consistency and alignment with established standards.

- Environmental Factors Overlooked

Another key observation is that environmental variables, such as temperature, humidity, or vibrations, are sometimes ignored during testing. These factors can significantly alter outcomes and must be controlled to maintain reliability.

- Neglecting Material or Fixture Compatibility

I have seen cases where materials or fixtures used in testing are not compatible with the expected parameters, resulting in skewed data or equipment damage. Careful selection and verification of materials can mitigate this issue effectively.

By addressing these common oversights, I ensure the validity and reproducibility of test results in professional and controlled settings.

Strategies for Improving Fixture Design

To improve fixture design effectively, I focus on three key strategies:

- Prioritizing Precision and Stability

I ensure that all fixtures offer precision alignment and remain stable under operating conditions. This involves using robust materials and designs tailored to the specific application to minimize deviations and maintain reliability.

- Adapting for Versatility

Flexibility in fixture design is critical for accommodating various test scenarios. I incorporate adjustable components and modular systems wherever possible, allowing for easier adaptation to different setups without compromising structural integrity.

- Enhancing Usability and Maintenance

Incorporating user-friendly features such as ergonomic adjustments and quick-release mechanisms is essential. Additionally, I design fixtures with maintenance in mind, ensuring straightforward access to critical parts for cleaning, repairs, or replacement to reduce downtime.

By adhering to these strategies, I address common challenges and optimize fixture performance to achieve accurate and repeatable results.

What Role Does Test Pressure Play in a Leak Test?

Test pressure is a critical parameter in a leak test as it directly influences the reliability and accuracy of the results. Properly calibrated test pressure ensures that the conditions during the test replicate actual operating scenarios, effectively identifying any potential points of leakage. If the pressure is too low, leaks may go undetected, resulting in faulty parts passing the test. Conversely, excessive pressure can cause damage to the component or produce false positives. Therefore, precise control and monitoring of test pressure are essential to balance sensitivity, avoid over-stressing the test object, and achieve consistent, repeatable outcomes.

The Importance of Test Pressure in Leak Testing

- Leak Detection Sensitivity: Proper test pressure is critical for ensuring the test setup can detect even minor leaks. Insufficient pressure may fail to expose small defects, compromising the integrity and reliability of the tested component.

- Component Safety: Applying excessive pressure during leak testing can overstress the component, causing physical damage or deformation that might render the part unusable. Controlled pressure prevents such risks and maintains the part’s functionality.

- Test Accuracy: Accurately regulated test pressure minimizes the chances of false positives or negatives, which can occur when the pressure applied deviates from specified parameters. This ensures a reliable assessment of the component.

- Process Consistency: Maintaining consistent test pressure across multiple tests ensures repeatable results. This is essential for quality assurance processes, where uniformity is a critical requirement for batch testing.

- Compliance with Standards: Many industries have specific standards and regulations governing test pressures for leak testing. Adhering to these requirements not only ensures technical compliance but also enhances credibility and customer trust in the testing procedures.

How to Ensure Accurate Test Pressure?

To ensure accurate test pressure, I follow a structured approach that prioritizes precision and adherence to technical guidelines. First, I verify the calibration of all pressure measurement instruments, ensuring they meet the required accuracy standards. Regular calibration against certified reference devices is essential. Second, I confirm that the test environment, including temperature and humidity, is controlled within acceptable parameters to avoid environmental influences on pressure readings. Third, I use appropriate test media—typically air, nitrogen, or water—matching the specifications of the system under test to prevent variability. Lastly, I carefully monitor the pressurization rate to achieve a steady and uniform increase, avoiding sudden spikes that could compromise accuracy.

Key Parameters to Consider:

- Pressure Gauge Accuracy: ±0.5% of full-scale or better.

- Environmental Conditions: Temperature range of 15°C to 25°C, humidity below 70% RH.

- Pressurization Rate: Maintain a rate not exceeding 10% of the maximum test pressure per second.

- Calibration Intervals: Instrument recalibration every 6 to 12 months, as per usage intensity.

These steps ensure reliable and repeatable test pressure results, aligning with industry best practices and regulatory requirements.

Consequences of Incorrect Test Pressure

Incorrect test pressure can have several significant and potentially hazardous consequences. Over-pressurizing a system may result in mechanical failure or permanent damage to components such as seals, valves, and pipe fittings, leading to costly repairs or replacement. For instance, pipe ruptures often occur beyond the material’s designed yield strength, which can happen when pressures significantly exceed the maximum allowable working pressure (MAWP). Conversely, under-pressurizing can result in an inadequate assessment of the system’s integrity and reliability, leading to undetected weaknesses that may fail under operational conditions.

Additionally, deviations from specified test pressure parameters compromise compliance with industry standards such as ASME or ISO, which can lead to regulatory penalties or invalidated certifications. Excessive or insufficient pressure during hydrostatic or pneumatic testing can also distort test data, undermining the accuracy of results. For optimal testing outcomes and system safety, it is vital to adhere to guidelines such as maintaining pressurization within ±2% of MAWP and ensuring pressure increments align with the design standards for the specific materials and equipment in use.

Why Are Environmental Tests Crucial for Test Fixtures?

Environmental tests are crucial for test fixtures because they simulate real-world conditions, ensuring that the fixtures can withstand factors such as temperature fluctuations, humidity, vibration, and corrosion. These tests validate the durability, performance, and reliability of the fixtures under operational stress. Without these assessments, fixtures may fail prematurely during usage, leading to inaccurate test results and potential system failures. By accounting for environmental influences, these tests ensure compliance with standards and enhance the integrity of both the fixtures and the systems they support.

Key Elements of an Environmental Test

- Temperature Testing

This involves exposing fixtures to extreme temperatures to evaluate performance under both high and low thermal stress. Common parameters include:

– High-temperature range: +85°C to +125°C

– Low-temperature range: -40°C to -60°C

These tests ensure materials and components maintain functionality within specified temperature limits.

- Humidity Testing

Fixtures are subjected to high levels of moisture to simulate real-world conditions involving condensation or prolonged exposure to humid environments.

– Typical humidity levels tested: 85% to 95% relative humidity at varying temperatures.

This helps assess resistance to corrosion, mold growth, and degradation.

- Vibration and Shock Testing

Replicating mechanical stresses such as vibrations or acceleration forces ensures structural and functional reliability.

– Vibration frequency range: 5 Hz to 2000 Hz.

– Shock levels: 10 g to 30 g acceleration.

These tests verify robustness to mechanical disturbances during operation or transit.

- Corrosion Testing

Salt spray and environmental exposure tests are conducted to determine resistance to corrosive atmospheres, especially for fixtures used in coastal or industrial applications.

– Salt spray exposure duration: 24 to 1,000 hours.

This assessment ensures longevity where corrosion risks are high.

- Operational Durability under Combined Stress

Often, multiple environmental factors are tested simultaneously, such as temperature cycling with vibration.

– Sample test parameter (temperature cycling): -40°C to +85°C, at a rate of 10°C/min with concurrent vibrational forces at 10 to 500 Hz.

This approach evaluates the cumulative impact of environmental stressors acting together.

By addressing these key testing parameters systematically, environmental tests provide a comprehensive validation framework to ascertain fixture reliability and compliance with operational standards.

Impact of Temperature and Humidity on Test Results

Temperature and humidity critically influence the performance, durability, and accuracy of test results across various materials and electronic components. Elevated temperatures can accelerate material degradation, thermal expansion, and shifts in electronic properties, potentially leading to test inaccuracies or premature failure predictions. Conversely, low temperatures can induce brittleness in materials and decrease battery performance, skewing reliability assessments.

Humidity introduces additional complexity as moisture intrusion can lead to corrosion, insulation degradation, and the creation of conductive pathways within electrical systems. Variations in relative humidity also alter the physical properties of materials such as adhesives, polymers, and coatings, impacting their mechanical performance under stress conditions. Together, these environmental factors demand controlled testing environments to simulate worst-case operational scenarios accurately. By accounting for the interplay between temperature and humidity, testing protocols can ensure comprehensive evaluation of product resilience and compliance with stringent industry standards.

Maintaining Consistent Test Results in Varying Environmental Conditions

To maintain consistent test results in varying environmental conditions, it is essential to control and monitor key parameters during testing processes. The primary factors influencing test reliability include temperature, humidity, pressure, and exposure time. These parameters should be set within standardized ranges to minimize variability:

- Temperature Control: Conduct testing within a predefined temperature range, typically ±2°C of the set point, to ensure uniformity. For example, standard testing for certain industrial products is often performed between 20°C and 25°C.

- Humidity Regulation: Maintain relative humidity (RH) levels within ±5% of the target. Common practice in controlled environments ranges between 40% and 60% RH, depending on the product’s sensitivity to moisture.

- Pressure Stability (if applicable): For pressure-sensitive evaluations, ensure that chamber pressure remains within ±1% of the established baseline value to prevent data inconsistencies.

- Exposure Time Accuracy: Use calibrated timers to enforce consistent exposure durations, with a tolerance of ±0.1% to minimize discrepancies.

To achieve these outcomes, utilize advanced monitoring systems such as data loggers, automated environmental control units, and recalibrated instruments. These technological implementations enable precise regulation of conditions, actively mitigating external environmental fluctuations and ensuring reproducibility in test results. Ensuring thorough compliance with industry standards such as ISO 17025 and ASTM protocols further enhances reliability and validity in varying operational environments.

How Do Types of Test Influence the Testing Process?

The types of tests significantly influence the testing process by determining the methodologies, equipment, and parameters required. For instance, destructive tests like tensile strength evaluations necessitate the permanent alteration of materials, requiring specialized machinery and precise calibration. Conversely, non-destructive tests, such as ultrasonic or radiographic testing, demand advanced, sensitive equipment to assess properties without causing damage. Additionally, the choice of test impacts data collection methods, reproducibility standards, and compliance with specific industry protocols, ensuring the results align with the intended application and regulatory requirements.

Different Testing Equipment and Their Uses

Different testing equipment, such as tensile testers, ultrasonic flaw detectors, hardness testers, spectrometers, and thermal cameras, are used for material strength evaluation, non-destructive inspections, hardness measurement, chemical composition analysis, and thermal imaging, respectively. Below is a detailed summary of their uses in a concise tabular format:

|

Equipment |

Key Use |

Parameter |

Method |

|---|---|---|---|

|

Tensile Tester |

Strength Testing |

Stress, Strain |

Tensile Load |

|

Ultrasonic |

Flaw Detection |

Sound Waves |

Reflection |

|

Hardness Tester |

Hardness Testing |

Indentation |

Surface Test |

|

Spectrometer |

Chemical Analysis |

Composition |

Spectrum Read |

|

Thermal Camera |

Heat Mapping |

Temperature |

Infrared |

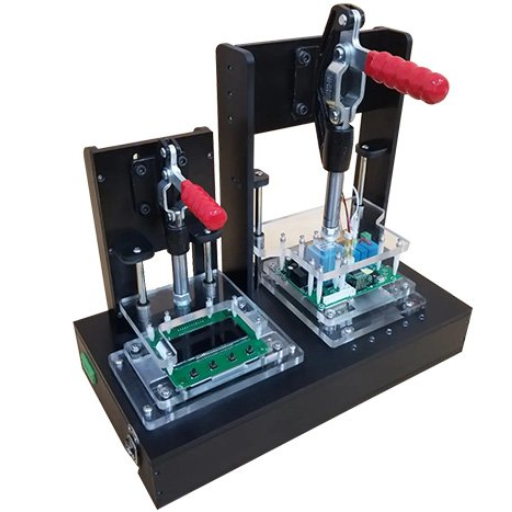

Comparison Between Automated Test Fixtures and Manual Testing

Automated test fixtures leverage technology to execute tests repeatedly and consistently, while manual testing relies on human execution for flexibility and exploratory assessment.

|

Parameter |

Automated |

Manual |

|---|---|---|

|

Speed |

High |

Low |

|

Accuracy |

Consistent |

Variable |

|

Cost |

Higher Setup |

Lower Initial |

|

Scalability |

Excellent |

Limited |

|

Flexibility |

Limited |

Adaptive |

|

Maintenance |

Required |

Minimal |

|

Errors |

Low |

Higher |

|

Learning Curve |

Steep |

Simple |

Ensuring Reliable Test Results Across Various Testing Processes

Ensuring reliable test results across various testing processes requires a strong focus on key factors such as consistency, accuracy, scalability, and adaptability within the testing framework. Automated testing provides unparalleled consistency and repeatability, ensuring that tests are executed precisely as designed, which reduces human errors. This method is particularly advantageous for large-scale projects given its ability to handle complex scenarios and vast amounts of data with high accuracy.

On the other hand, manual testing allows for greater adaptability and is suited for exploratory testing where human intuition and experience are essential. While it may involve a higher error margin and variability, its simplicity makes it ideal for smaller projects or situations requiring nuanced judgment. Employing hybrid approaches that combine automated precision with the flexibility of manual oversight often ensures optimal results.

To maximize reliability, it is crucial to establish clear testing objectives, employ rigorous validation mechanisms, and continuously monitor and update testing protocols. Aligning the testing methodology to the specific requirements of the project and ensuring proper resource allocation will further strengthen the reliability of test outcomes.

What Are the Key Factors That Affect the Test Outcome?

Several key factors influence the test outcome, ranging from the quality of the testing environment to the accuracy of the methodologies employed. Firstly, environmental consistency is critical; variations in conditions such as temperature, humidity, or external interference can skew results. Secondly, the precision of the tools and technologies utilized directly affects data reliability. Poorly calibrated instruments or outdated software can introduce errors. Thirdly, the skill and expertise of the personnel conducting the tests play a significant role, as improper handling or interpretation can compromise outcomes. Lastly, the adequacy of test design, including the definition of parameters and control groups, ensures that results are both meaningful and replicable.

Identifying Factors Affecting Test Accuracy

Test accuracy is influenced by several critical factors that determine the reliability and validity of results. Firstly, the integrity of the testing environment must be maintained, including controlled variables such as temperature, humidity, and the elimination of external interferences. This ensures that results are consistent and reproducible under standardized conditions. Secondly, equipment calibration and software configuration are paramount—unmaintained tools or misconfigured systems can produce significant deviations, skewing data collection and analysis. Thirdly, the qualifications and proficiency of personnel are essential, as operators with insufficient training increase the risk of operational errors or misinterpretations of test outcomes. Furthermore, the structure and comprehensiveness of the test design, particularly the inclusion of well-defined parameters, sufficient sample sizes, and appropriately selected control groups, underpin the statistical validity of the resulting data. Collectively, optimizing these factors is critical to achieving high-fidelity, actionable test outcomes.

The Role of Calibration in Achieving Accurate Test Results

- Standardization of Measurement Tools – Calibration ensures that all instruments used in testing adhere to standardized measurement criteria, reducing variability and enhancing consistency across test results.

- Reduction of Systematic Errors – Regular calibration identifies and eliminates systematic errors in measurement systems, improving the overall accuracy and reliability of the data collected.

- Compliance with Regulatory Standards – Many industries require adherence to stringent regulatory and quality standards, and calibration ensures that instruments meet those specifications, minimizing compliance risks.

- Prolonged Equipment Longevity – Proper calibration can help identify potential issues in test equipment early, allowing for timely maintenance and extending the operational lifespan of the instruments.

- Enhanced Data Precision – By aligning measurement tools to a known reference, calibration enhances the precision of data, which is critical for making informed decisions and conducting repeatable experiments.

How Inaccurate Test Results Can Derail the Testing Process

Inaccurate test results can have a cascading effect on the reliability and success of a testing process, jeopardizing both the outcomes and operational objectives.

- Compromised Product Quality – Unreliable test measurements can lead to incorrect evaluations of product performance, potentially allowing defective or non-compliant products to proceed. For instance, deviations in tolerance parameters such as voltage (±1%) or measurement accuracy in micrometers (±0.5 μm) can result in flawed components.

- Regulatory Non-Compliance – Many industries, such as aerospace or medical devices, require adherence to strict standards (e.g., ISO/IEC 17025 or FDA requirements). Erroneous test results can lead to non-compliance penalties or costly recalls.

- Ineffective Decision-Making – Data-driven decision-making relies heavily on the integrity of test results. Misinformation stemming from inaccuracies in variables like thermal stability (e.g., ±0.2°C in laboratory experiments) can misguide project directions or resource allocation.

- Wasted Resources – Faulty results necessitate repeated tests, causing delays, increased labor hours, and unnecessary expenditures. For example, discrepancies in calibration tolerances for pressure sensors (e.g., ±0.1 psi) can multiply time and material wastage during troubleshooting efforts.

- Customer Dissatisfaction – Ultimately, the inability to deliver reliable results impacts the end-user experience, eroding trust and damaging reputations. Errors in critical metrics, such as dimensional consistency in manufacturing (±5 μm), can result in subpar client outcomes.

Addressing these risks requires meticulous calibration, regular validation of test equipment, and rigorous adherence to technical standards to maintain the integrity of the testing process.

Reference Sources

-

The Role of Test Fixture Design for Manufacturing Electronics – Discusses factors like production volume, product size, and quality in test fixture design.

-

Common Problems in Vibration Test Fixture Design – Highlights common pitfalls and solutions in vibration test fixture design.

-

Test Fixtures Benefits (and misconceptions) | RTI Article – Covers the benefits and misconceptions of test fixtures, along with key considerations.

-

What is Test Fixture – Provides an overview of test fixtures and their role in creating a controlled testing environment.

-

Top Test Fixtures in China

Frequently Asked Questions (FAQs)

Q: What is the role of test fixture design in ensuring accurate test results?

A: Test fixture design is crucial in ensuring accurate test results as it provides a stable and repeatable setup for the test execution. Properly designed test fixtures contribute significantly to minimizing variability and external factors that can affect the outcomes.

Q: How do test chambers include factors like temperature and humidity levels?

A: Test chambers include precise control over temperature and humidity levels, which are critical test conditions. These factors can significantly impact the performance of the device under test, and controlling them helps ensure that the test results are consistent and reliable.

Q: What factors can affect the performance of mechanical test fixtures?

A: Several factors can affect the performance of mechanical test fixtures, including the material properties, environmental conditions within the test chamber, and the alignment of fixture components. These factors must be carefully managed to avoid inaccurate results.

Q: Why is test time important in designing test fixtures?

A: Test time is important in designing test fixtures because it influences the efficiency and throughput of the testing process. Optimizing test time without compromising the quality of test conditions ensures that the test station operates effectively.

Q: How do automated fixtures enhance test execution?

A: Automated fixtures enhance test execution by reducing human error, increasing repeatability, and speeding up the testing process. They ensure that the test results are consistent by automating repetitive tasks and maintaining precise control over the test conditions.

Q: What are the benefits of using test fixtures tailored to specific applications?

A: Test fixtures tailored to specific applications offer precise alignment and support for the device under test, ensuring accurate test results. They are designed to handle the unique requirements and constraints of the specific test, leading to more reliable and valid outcomes.

Q: How do test fixtures provide support during functional testing?

A: Test fixtures provide essential support during functional testing by securely holding the device under test in place and facilitating the application of test conditions. This support is crucial for testing the functionality of the device accurately and reliably.

Q: In what ways can external factors impact leak testing results?

A: External factors such as temperature fluctuations, humidity, and vibration within the test chamber can impact leak testing results. Ensuring stable environmental conditions and proper fixture design helps mitigate these effects and maintain the integrity of the test results.

Q: Why is it important that test fixtures offer flexibility in their design?

A: It is important for test fixtures to offer flexibility in their design to accommodate a wide range of test conditions and device configurations. This flexibility ensures that the test fixture serves multiple testing scenarios, enhancing its utility and cost-effectiveness.