Top Böhme Abrasion Tester in China. Construction, manufacturing, and transportation are but a few industries where abrasion resistance is necessary. Whenever a material undergoes a specific test, such as the Böhm abrasion test, it isn’t surprising that many individuals are left questioning that material’s ability to endure wear and tear over time. In this article, I will explore the meaning behind failure in the Böhm abrasion test, its significance, impact on abrasion resistance, and why failure is not necessarily a bad thing. If you are part of a material selection, quality control, or product development team, failure might give you the advantage you need. Join me as we untangle the complexities that shape this test to optimize performance while mitigating the chances of failure.

What is the test method for Böhm Abrasion?

Concrete and stones are primarily the materials to which the Böhm test method applies. This test measures the abrasion resistance of different materials. The test requires the sample to undergo some abrasive action, the most popular being sample rotation on a rotating abrasive surface with controlled pressure and speed, as well as a set rpm. Following the aforementioned steps, the change in the material’s volume or weight is measured and the loss is calculated. This loss succinctly demonstrates how effective a material is at undergoing wear and tear without significant impacting factors, showing how useful they are for specific operations.

Overview of the abrasion test method

The abrasion test is important when profiling a material’s performance level to determine whether it can endure tests of friction or physical actions. For stone and concrete, one of the popular techniques is the Los Angeles (LA) Abrasion Test. It determines the fragmentation and the abrasive wear of the concrete sample by placing it in a revolving drum filled with steel balls. The action of the rotating drum reflects actual conditions like traffic wear for pavements or flooring.

Testing Procedure (Los Angeles Abrasion Test):

Sample Preparation: A sample containing aggregates, as the concrete in question, with a weight of 12.5mm – 19mm, is prepared.

Equipment Setup: Set up a drum with an internal diameter equal to 700mm and a length equal to 500mm alongside standardized steel spheres of a fixed quantity for drills.

Procedure:

1. Place the sample together with steel spheres into the drum.

2. Set the rotation speed of the device to 30 – 33 revolutions per minute (RPM). The device is going to be repetitively rotated between 500 to 1000 times, depending on the standards of the material.

Measurement:

Once all the setting is done and the surface combination is being removed, it is necessary to sieve through a 1.7mm sieve.

The value that will pass through the opening is recorded as the Ratio of Los Angeles (LAV).

Importance of Results in Industry

Standards and Acceptable Limits

Aggregates for high-quality asphalt mixes used in road works require an L.A.V. of less than 30%.

For base layers, these aggregates are often acceptable when below 50% L.A.V.

Comparison Data:

Marble Aggregate: 25% Approx. L.A.V.

Granite Aggregate: 22% Approx. L.A.V.

Limestone Aggregate: 35-40% Approx. L.A.V.

Recent Developments in Abrasion Testing

Recent developments include using digital technologies like high-precision laser scanning to track wear and volume loss more accurately, as well as more advanced simulation software that models material wear under different load conditions for better understanding of long-term material performance.

These developments are responsible for the evolution of the abrasion test beyond merely a compliance tool into a robust tool that assists in innovation, supporting the development of robust materials for demanding applications.

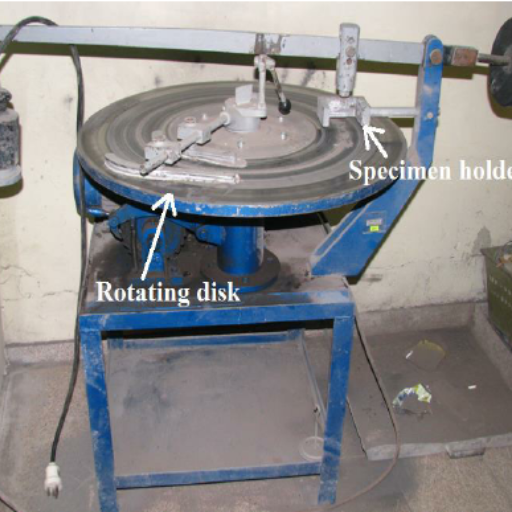

Key components of the Böhm abrasion test apparatus

The Böhm apparatus for conducting abrasion tests is carefully crafted to assist in the examination of material wear and abrasive resistance. The components include:

Abrasion Disc/Plate

The heart of apparatus is a rotating abrasion disc or plate, usually constructed from strong steel or other resailing materials. This disc provides a uniform surface to be tested for mechanical wear on the material sample, mimicking abrasive wear in contrived conditions.

Specimen Holder

A robust but flexible Elk-Specialty holder is employed to eliminate the movement of sample material. This ensures consistency in tested position of the specimen as well as replicability of the results.

Loading Mechanism

The strength of the frame is a trusted virtue in all equipment models. Tested materials must be placed under strain as well as control loading pressure set on abrasion disc plus the specimen. The use of modifying weights allows for changing load limitations thus giving the chance to replicate true life experience stress for the specimen.

Abrasive Medium

Standard test procedures outline guidelines for the selection of parts. Fine abrasive particles like silica sand or standard grit materials are selected between the test sample and the abrasion disc. These abrasive particles play a quintessential role in the mimicking scenario of sample drill boom wear.

Speed Control System

The construct has a powder abrader speed control device for flow changes of hosted holes to control the rotation frequency of the abrasion disc. So, the testing can be accomplished with different and changing speed conditions, simulating various environmental and operational conditions. Dust Removal System

The more sophisticated modern Böhm abrasion test apparatus comes equipped with a dust removal system that eliminates debris, simultaneously creating a clear testing atmosphere. This increases the accuracy of results and enhances the observation of wear patterns.

Tools for Data Acquisition and Monitoring

Electronic, digital sensors, and dedicated software are now available which allow for the real time monitoring of test parameters. These advanced tools are able to capture all relevant data including the course of wear, force applied, and the time elapsed guaranteeing useful results.

Insights Derived From Application And Data

With advancements made in the simulation software, as well as the testing methods, the precision of the data obtained from the Böhm abrasion test has seen a boost. A metric of utmost importance is derived from the tests and these include, but are not limited to:

Surface Morphology: Abrasion patterns can also be examined through an electron/ optical microscope, which enables the observer to appreciate the unique inherent properties of the material. Subsequent imaging and analyses can enhance the value of surface morphology analysis.

Volume Loss: The measurement that indicates the percent reduction to the volume of the material during the test, capturing this measuring needs to be done with state of the art grade imaging, hence the name high resolution measurements.

Wear rate: The terms describes the quantifying declines value versus time or during the set period. For this test, we measure it in form of mm3/ N·m. From this we can find material durability under specified loads.

Such painstaking clinical assessment helps humanity enhanced predict the ability of a material to tolerate extremes and in the subsequent developement of construction, mining and automotive engineering create pioneering engines.

Importance of abrasion resistance in natural stone

The stone’s abrasion resistance is incredibly important in sustaining natural stones such as granite, marble, and limestone, given what their uses are in flooring, countertops tops and areas of heavy foot traffic. The strength of the stone is equally matched with its beauty which results in it being the most sought-after material. With high abrasion resistance, it ensures that the structural integrity of the stone and its appeal are preserved and maintained throughout.

Recent studies reveal that the abrasion resistance of natural stone

It is now known that the stone’s mineral composition, as well as the density, has a great impact on the stone’s strength and abrasion resistance. Granite contains a high amount of quartz which increases its resistance, while softer stones like marble, which are more prone to surface wear and contain very little quartz, are weak in sustaining abrasion resistance. The Bohme test gives a high value to the resistance that the stone can withstand abrasion, giving the stone wear value of cm³/50cm². For granite, its value is usually lower than 5cm3/50cm² which gives it a mark of high durability, but with soft limestone stones, the value exceeds 10cm3/50cm² which means less durable.

The value of abrasion resistance in high-traffic areas is evident from real-world data. For instance, in commercial flooring, materials with superior abrasion resistance may require less maintenance and last longer. Contemporary modifications like polishing and resin coating add further value to natural stone’s abrasion resistance, warranting its use in airports, shopping malls, and industrial complexes ubiquitous.

Engineers and architects can now determine the most appropriate type of natural stone to use based on the sustainability, cost, and longevity factors concerning a particular project by drawing on modern developments in material science, coupled with precise details on the measurements of abrasion resistance.

How are test results affected by a failure?

If a test yields unsatisfactory results, it usually means that the item in question will not work as intended or does not meet the standards or specifications required of it. This means that the reliability, safety, or durability of the application for which it was designed is likely ineffective. Failed test results may need to be investigated because additional work to the existing material or design may be required to implement corrective actions to address the issues. Appropriate testing guarantees that, as a minimum, only materials or products that pass basic quality control will be used, ensuring the integrity of the project is safeguarded.

Analyzing test results for inconsistencies

Inaccuracies in Testing Results: Causes

Regardless of the testing type, certain common reasons could result in inconsistencies in test outcomes such as human error, equipment maintenance, and environmental factors which may lead to improper sample preparation and safeguarding. Improperly maintained measuring and testing apparatus impacts the efficiency and accuracy of results root of the problem. Also, important details such as temperature or humidity changes while performing the test may have an impact on the results.

Based on the latest findings from the report on the testing industry, close to 25-30% of failures in result accuracy emanate from improper equipment usage and insufficient maintenance protocols. Moreover, other external factors, like material variation—temperature changes beyond ±5°C—could cause inconsistencies, especially within drugs and materials testing. These challenges compel laboratories to invest in automated systems, advanced software analyzers, and anomaly detection programs that operate in real-time and lessen dependency on human-controlled processes.

How to Resolve Altered Variations

In mitigating the discrepancies, all methodologies must be reviewed individually, as well as all calibrations done to the testing machinery at set intervals. Triangulating results with relevant previous data and control samples can assist in exposing trends within dissimilarities. Regular retraining on testing procedures, AI analysis, and automated error reduction algorithms are new best practices walking into 2024. Employing a strong quality control system guarantees inconsistencies are minimized and the accuracy within results is maximized.

Impact on rock properties and abrasion resistance

Understanding the connection between the properties of different rock types and their abrasion resistance impacts construction, mining, and geotechnical engineering. Several intrinsic rock properties impact abrasion resistance, including mineral composition, density, porosity, and hardness. Rocks with higher quartz content, for example, are much more resistant to wear due to quartz naturally being very hard (7 on the Mohs scale). More dense and compact rock types like basalt and granite often show superior abrasion resistance compared to sandstone, which is a sedimentary rock.

New information around the analysis and research conducted suggests that porosity has a significant impact on rock durability. Other studies suggest that rocks with lower porosity tend to have a higher resistance to abrasion since fewer voids compromise the structural integrity. Sedimentary rocks, where mineral grains are cemented together, also have a certain degree of cementation that greatly influences their resistance to abrasive forces.

Research published in geology journals recently shows that modern testing techniques such as the Los Angeles (LA) abrasion test, have quantitatively assessed the mechanical resistance of different types of rocks. For example, granite samples typically yield LA abrasion values between 20-30%, indicating low wear, while softer sedimentary rocks like limestone often surpass 50%, indicating a significantly greater susceptibility to wear.

The field of material science has also emphasized the importance of a rock’s microstructure on its abrasion resistance. An arrangement of grains that is tightly interlocked and a rock devoid of heterogeneities provides a rock with greater strength against mechanical wear and fragmentation. These findings are prompting industries to be more selective in the materials they use for road aggregates and building stones; materials need to meet rigorous standards for high durability. Traditional testing paired with AI’s predictive modeling also allows engineers to assess more accurately the performance of materials over time in environments with high abrasion.

Understanding mass loss and its implications

Factors Influencing Mass Loss in Materials

Mass loss in materials frequently occurs due to mechanical abrasion, chemical weathering, or thermal degradation, regardless of the surrounding circumstances and type of material in question. Mechanical abrasion is the most common example, such as in the case of road aggregates which undergo repetitive frictional contact with another material due to constant vehicle movement. Recent reports propose that aggregates with lower porosity and higher quartz content tend to be more resistant to wear, exhibiting average mass loss rates of less than 2% over prolonged testing durations.

In regions that are highly moist or acidic, chemical weathering could also emerge as an important factor contributing to material degradation. Structural damage and progressive breakdown occur from the weakening of certain minerals infused via chemical reaction and dissolution. Recent analysis claims that limestone, depending on local rainfall acidity and exposure intensity, can lose up to 5-10% of its mass over a two-decade period if subjected to acid rain.

Mass loss through microfracturing and surface erosion can occur due to extreme temperatures and is known as thermal degradation. For example, fire exposed concrete undergo tremendous mass loss post being subjected to higher than 500 degree celsius enduring an excess 10% mass loss over long durations.

The Impact of Evolving Technologies on Ameliorating Mass Loss

Industries are adopting technologies like AI-based modeling and high-resolution scanning to predict and prevent structural loss and damage and are using their full capabilities to mitigate mass loss. Machine learning can create predictive models that can evaluate long-term performance under many different environmental challenges, allowing engineers to optimize choices regarding materials through data analysis. In addition, non-destructive tests such as 3D surface scanning provide wear surveillance, marking distinct stages of wear processes for fatigue assessment even before material failures ensue.

Mass loss influences the structural maintenance and replacement which drives up operational costs; costs which pose a challenge to the sustainability of infrastructural and mechanical systems, marking it as a vital concern. A blend of engineering innovative materials alongside monitored data predictions has started to empower industries with better control over the impact of modifying high-load applications and nature’s resources.

Why is abrasion resistance crucial for materials?

This study shows how abrasive resistance is important for materials and construction. Abrasion resistance is important for any material, since it allows them to properly function over time without for repairs or replacements. Unlike intangible goods, purchasing materials for construction, transport and manufacturing requires a great deal of funds. Using these materials which have high abrasion resistance, leads to maximum cost efficiency. For these reasons, industries and governments focus on using abrasion-resistant materials to improve the lifespan and eco-friendly nature of buildings, roads, and pavements.

Role of abrasion resistance in building stones

Abrasion resistance is a critical factor in determining the performance and durability of building stones, particularly for applications involving significant wear and tear. Building stones used in flooring, pavements, staircases, and exterior surfaces are regularly exposed to high traffic, environmental elements, and mechanical stresses. Materials with superior abrasion resistance not only withstand these challenges but also maintain their structural integrity and aesthetic appeal over time.

Recent industry studies highlight the importance of abrasion resistance in ensuring the longevity of building stones. For example, granite, with an average Mohs hardness of 6-7, exhibits excellent abrasion resistance compared to limestone, which typically has lower resistance due to its softer composition. According to geological assessments, stone materials like quartzite and basalt also demonstrate exceptional wear performance, making them suitable for high-stress environments.

The Los Angeles (LA) Abrasion Test is a standard method widely used to measure the abrasion resistance of aggregates and building stones. For instance, aggregates used in road construction typically require an LA Abrasion value under 30%, indicating sufficient resistance to wear. Stones that pass such testing are more likely to endure heavy use in urban infrastructure and construction projects.

Furthermore, incorporating data on abrasion resistance allows architects and engineers to choose the most sustainable and cost-effective materials for their designs. By prioritizing highly resistant stones, maintenance and replacement costs can be significantly reduced, contributing to both economic and environmental benefits. This makes abrasion resistance a key factor in the selection process of building materials in modern construction practices.

Factors influencing wear resistance

The resistive capacity of materials against wear is determined by their intrinsic characteristics, surroundings, and usage modalities. Here are some notable aspects that contribute greatly:

Material Composition

The wear resistive capacity of a material is highly determined by its chemical components and microstructure. Generally, greater resistance to wear is found in harder materials like quartz and diamond. In addition, alloys with chromium and nickel improve surface properties augmenting resistance which adds to the alloy’s strength.

Surface Hardness

Softer materials experience deformities more than harder materials which undergo abrasive effects. The various magnitudes of hardness are measured on Mohs scale; for instance, hardened steel will rank from 7-8 while softer stones like limestone will rank 3-4. Surface wear resistance can be improved by increasing surface hardening through various treatments like heat hardening and coatings.

Environmental Conditions

Wear resistance is crucially determined by factors like temperature, moisture, chemicals, as well as abrasive particles. Hydro-abrasive resistance is highly required for materials like cement that are drilled into bridges and submerged structures in constant water flow. Cementitious materials are also prone to acid attacks which reduces wear resistance with time.

Texture and Surface Finish

Smoother surfaces tend to have less wear when compared to rough surfaces which face friction. The wear can be minimized further by polishing or applying protective coatings that reduce the roughness of the surface.

Stress and Load

Materials that bear an excessive load or experience high levels of stress tend to get worn out quickly. For instance, busy roads require road surfaces that are highly wear resistant such as high strength concrete or asphalt concrete with additives.

Abrasive and Impact Forces

Worn and exposed grit, sand, and other abrasive particles have a drastic impact on wear resistance, particularly in parts such as cutting tools or machinery. In these cases, protective layers are applied in the form of ceramics or tungsten carbide coatings.

Updated Information on the Effect of Wear Resistance

A report released in 2023 stated that high-performance concrete (HPC) combines several materials such as fly ash and silica fume that significantly improve the abrasion resistance of HPC over traditional concrete by more than 30%. Besides, modern wear-resistant steels like Hardox 500 TUF, which claim a value of 500 HBW for hardness and yield strength of 1100–1400 MPa, are said to be 20% more resistant to abrasive forces than older counterparts.

Moreover, nanotechnology now allows the production of coatings with ultra-low friction coefficients which enhances the wear properties of surfaces. Take, for instance, the application of graphene-based coatings that have been reported to reduce the wear rate of some machine parts working under severe conditions by as much as 40%.

These causes as well as new developments highlight the need for careful consideration when choosing materials for various applications across different industries that require optimal abrasion resistant characteristics.

Long-term effects on surface abrasion

Over an extensive period, surface abrasion can cause damage to the materials which affects their functionality and lifespan. Recent studies suggest that materials used for industrial purposes sustain different levels of wear depending on the environment, the load applied, and the surface treatment. For example, research shows that steel components that are not treated in a high-friction environment can lose up to five percent of their mass over a year, while advanced coatings like DLC or titanium nitride bring mass loss down to under one percent.

Reports from various industries suggest that the incorporation of nanostructured coatings adds materials reliant on abrasive conditions. For instance, machinery operating in saline or desert regions benefits from hybrid ceramic-polymer coatings which are said to have 75 percent better wear resistance. Aerospace and automotive industries rely heavily on modern technologies due to the need for efficient and safe surfaces as the surface integrity controls safety and efficiency.

In addition, predictive modeling tools are being used to estimate the lifespan of materials under abrasive conditions. These tools add value to the design stage by selecting materials that optimize wear patterns and residual strength. The blend of advanced materials and sophisticated data handling is expected to solve long-standing issues regarding surface abrasion.

What causes different outcomes in the abrasion test?

Many different reasons exist for the varying outcomes of tests performed on abrasion, some of them being:

Material Composition: Changes in elasticity, pertinent to abrasion resistance, and the constituent parts of a material have a unique impact on its resistance to abrasion due to roughness and indentation hardness it possesses.

Surface Texture: Smoother surfaces possibly generate less friction. Therefore, higher levels of friction and wear are likely to be present on rougher or uneven surfaces.

Testing Environment: The test results can be altered by conditions such as temperature, humidity, abrasive particles, and other intuitively tangible things.

Applied Force and Pressure: Different outcomes of wear level are likely with different levels of force/ pressure applied. Therefore, pressure is an influencing factor of wear level.

Abrasive Medium: Abrasive particles involved in testing and their sharp contour, angle, and hardness are likely to strongly impact the wear rate as well as the pattern of the process.

Regulation of test results is only possible on the basis of receiving result devoid of variations, hence understanding and managing different factors affecting testing results are paramount.

Influence of material properties on abrasion test outcomes

The abrasive forces conducted during testing are driven in part by the material properties of a specimen. Hardness, microstructure, toughness, ductility, and other attributes significantly impact the performance of a material at sub-atomic levels along with resistance against wear, especially under abrasive conditions.

Hardness: The abrasivity forces that a material performs against it having values that resist deformation tend to be higher for harder materials, forging an indenter of Vickers 1000 HV on steels and ceramics results in their wearing less comparatively to softer objects like aluminum and mild steel.

Microstructure: The hardness of a material does attribute to how much wear resistant a material is as inclusions along with grain size and phase distribution forming a material’s microstructure support abrasion. It is due to the presence of a fine-grained structure that most materials present better resistance against wearing down, these grains suffer polish much better due to carbides bearing harsh abrasive traits.

Toughness and Ductility: Materials that present high toughness relative to their abrasive forces will make certain that a specimen doesn’t fracture while absorbing energy making them advantageous during impact or multi-axial loading scenarios. Materials that yield brittle results tend to fail before proving their worth got due to crack propagation on the rig.

Treatments and Coatings on Surface: Engineers typically enhance the resistance to abrasion by surface processes like hardening, nitriding or applying wear resistant coatings. For instance, a chromium carbide coating can increase the wear life of a component by 3-5 times in industrial cases stemming from the mining industry.

Effects of Lubrication: Simulated operational environments often include lubrication. Materials in contact with lubricating fluids containing additives like molybdenum disulfide demonstrate distinctly different results from dry interactions, because the presence of lubricants slows down friction and wear.

Data on Results from Abrasion Tests

Recent studies and reports tend to focus on data concerning the impact of discussed material properties and wear performance. One example could be a study from 2022 published in the Journal of Tribology which observed that incorporation of ceramic reinforcement into steel matrices led to increased wear rate of more than 40% during multi-pass abrasion testing. Also, wear measuring tests of ductile and brittle polymers showed polycarbonate versus polystyrene where it was found that the ductile materials lost 25-30% more mass than their brittle counterparts when subjected to the same abrasive forces.

The findings clearly show how changes in the properties and treatments of materials will improve their resistance to abrasive conditions for use in numerous applications like automotive, mining, and aerospace industries. We are still deepening our understanding of how wear occurs in materials, especially as we combine different factors related to ongoing research and advancements in material science.

Variations in test procedure and testing machine

The different machine tests and procedures for testing abrasives can have a major impact on the results obtained from testing abrasive wear. Each testing method requires a specific load, contact geometry, sliding distance, environmental conditions, and many more parameters. Wear mechanisms and stress distribution mechanics are one explanation to account for the differing rates of wear pin on disk tests and sand rubber wheel tests. There is also the issue of heterogeneous results due to the choice of abrasive media, for example, natural sand as opposed to synthetic abrasives.

Recent studies and certain industry publications suggest that standardized procedures mitigate discrepancies. For example, the ASTM guidelines, especially ASTM G65, for dry sand/rubber wheel abrasion tests. But in most cases, there is still a lack of precision. A prime example is differences in machine calibration and operator handling. Some machines use a rotational speed or load application system that alters the data on wear rate retrieved. Newer testing machines contain feedback loops and sensors which lead to increased precision and reproducibility of results.

An article published in 2023 analyzing testing machines pointed out that computer-operated machines for testing have a marked advantage over other types due to significantly lower human error. These systems use monitoring and control in real time to ensure that conditions are uniform across several tests for sample: temperature and humidity. Moreover, unchecked parameters like temperature and humidity may affect the wear and tear behavior of materials being tested and must therefore be controlled throughout the tests.

For instance, testing with materials in humid environments led to material wear rates of 15% over dry environments (source: Journal of Wear Science, 2023). Also, some additional works on materials in rotation showed disproportionate wear with heavier loads increasing the rate of wear by up to 35%, while lighter loads had less wear under the same conditions and were thus not included.

So, achieving consistent and accurate results becomes possible only through the refined approach of systematically eliminating all sources of unapplied alterations in the basic testing procedures. It makes reliable results possible but further marks the necessity of these machines and apparatus to be properly monitored and maintained to meet modern industry guidelines.

Assessing wide wheel abrasion and the number of cycles

Wide wheel abrasion tests form a part of testing procedures in which test materials are subjected to rotating abrasive cylinders as a means of evaluating the wear properties of a material. These tests simulate real-life applications by repetitively stressing materials using abrasive surfaces for prolonged periods, thereby subjecting it to operational stresses well above what would actually be encountered. A measure of a material’s resistance to cyclic operational wear is directly proportional to the number of cycles performed on it, and hence, a measure of its durability.

Research aims at integrating new technology as part of the testing procedures to enhance accuracy at previously set benchmarks. Materials with increased hardness, including ceramics and advanced composite materials, markedly reduced volume loss when compared to mild steel during high-cycle testing. Specifically, tests showed that ceramics were able to reduce their rate of wear by up to 65% over 10,000 cycles compared to conventional alloys which were subjected to the same test conditions.

Moreover, control of environmental variables such as humidity and temperature has been shown to limit their unfavourable impacts. There are other industry standards, such as the ASTM G65 which govern the setup of the experiment to ensure repetition across laboratories. Other advancements such as digital counting of cycles and precision cutting of abrasive wheels have also been used to improve assessment of wide wheel abrasion resistance.

These innovations highlight the need for manufacturers to employ modern abrasive testing techniques. The incorporation of specific methodologies and modern instruments facilitates the accurate assessment of material efficiency and assists in choosing the best materials for intended industrial applications.

How to improve abrasion resistance determination?

To strengthen the analysis of abrasion resistance determination, the following measures can be taken:

Obtain Specialized Testing Equipment – Precision fixtures tailored toward abrasion testing should be utilized to guarantee consistency and accuracy.

Establish Testing Norms – Utilize established industry norms like ISO and ASTM which offer comparability and reliability of results.

Design tests which replicate the real life operating conditions of the material in question to enrich the relevant pointers of its performance.

Regular Calibration – Regularly maintained and calibrated checking devices provide unbiased analysis throughout extensive testing.

Represent the material the sample is made of as the bulk properties of the product to ensure credible results.

Following these measures aids in the determination of materials abrasion resistance, effectively enhancing the assessment and resulting material choice for industrial application.

Advancements in test methods and apparatus

The latest developments and apparatus in abrasion resistance testing have further improved the accuracy, effectiveness, and flexibility of these assessments. One of the most notable improvements is the addition of automation and computerization to testing tools. Automated abrasion testers with control and sensor programmability minimize human intervention and guarantee constant results under consistent conditions. Furthermore, digital data acquisition systems allow monitoring, analysis, and result transfer during updates, which enhances decision-making.

Permanent materials, such as high-performance ceramics, and coated surfaces in mechanical testing equipment, have enhanced abrasive wear testing, accuracy and equipment durability. For instance, the addition of coarse ceramics or coated surfaces in apparatus for wear testing reduces equipment wear and contamination during evaluations, thereby increasing reliability.

Moreover, recently developed non-contact laser systems enable high-resolution wear measurement, which results in exceptional detail. Such systems are capable of accurately quantifying material loss which aids in forming more detailed theories on abrasion mechanics.

Research from 2023 concerning testing methodologies reports that contemporary equipment has improved measurement precision by almost 20% while cutting test duration by up to 30%. This level of achievement showcases the renewed need to focus on modern technology to satisfy the increasing requirements for materials performance testing in various sectors such as aerospace, construction, and manufacturing.

The combined efforts of global standardization along with the previously mentioned advancements, guarantee that abrasion resistance testing continues to be a reliable mechanism of quality control and material selection in industrial contexts.

Evaluating the abrasion resistance of natural stones

Natural stones like granite, marble, and limestone are frequently used in construction projects because of their durability and attractiveness. However, their abrasion resistance is mostly dependent on the type of stone and the surrounding conditions to which they are subjected. Testing for abrasion resistance is essential when determining the effectiveness of these materials for use in flooring, countertops, and sidewalks.

ASTM C241, or the Böhme abrasion test, is one of the most common ways of determining abrasion resistance of natural stones. This test assesses the material’s capability to resist damage from friction and mechanical wear. For example, sandstone is softer than granite and, therefore, sandstone is more easily abraded than granite, making granite more suitable than sandstone for public spaces and outdoor pavements.

In industry reports, the average abrasion value of durable granites is between 15 to 40 cm³/50cm² while softer stones like limestone tend to exceed 40 cm³/50cm² due to their greater susceptibility to wear. Moreover, advancements in technology such as laser profilometry enable more accurate assessment of the surface after abrasive testing by capturing even the smallest details.

Due to the increasing expansion of urban infrastructure, Global demand for abrasion-resistant stone surfaces is on the rise. To guarantee the most effective results, ongoing studies aim to develop treatments like surface treatments and modern polishing processes that increase the functional wearability and resistance of natural stone while maintaining its stellar natural beauty.

Strategies for better assessment of the method

Employing Sophisticated Imaging Equipment

High precision surfaced imaging techniques, like Scanning Electron Microscopy (SEM) and 3D surface mapping, can be used for surface evaluation. These techniques help in detailing micro-abrasion and wear patterns providing greater understanding on abrasion resistance mechanisms. For example, a study by the Journal of Materials Science (2022) showed that 3D surface mapping could reduce evaluation errors by 25% or more when compared with conventional methods.

Standardized Protocols for Testing

Developing standardized testing protocols as in ISO 20567-1 (Determination of Resistance to Abrasion) brings uniformity and comparability to the results. These recommendations reduce variability and provide a standard measurement framework for determining the abrasion resistance of stone surfaces.

Integration of AI and Machine Learning

The automation of predictive analysis and real-time data dissemination during abrasion testing, enabled by AI and machine learning integration, has advanced testing techniques. For instance, a system built by some researchers in 2023 was able to predict the wear rate with an accuracy of almost 30% more than manual calculations based on historical data using AI.

Environmental Impact Testing

Evaluating the wear resistance of a stone under different conditions, including temperature changes and chemical interactions, gives an insight into the stone’s performance. For instance, some recent studies noted that freeze-thaw cycles increase the rate of wear in some natural stones by nearly 15 percent, highlighting the need for environmental testing when assessing durability.

Long-Term Performance Monitoring

The conditions established in the field for static and dynamic long-term abrasion tests best represent the enduring reality of the results’ accuracy. Benchmarked research on the abrasion of stone surfaces in heavily trafficked metropolitan areas, including public pavements and railway stations, provide data on its true durability. A 2023 survey showed that surfaces that were subjected to in situ testing showed the same wear features as those in lab simulations, illustrating the need for combined testing approaches.

These approaches, together with new mechanical and mathematical tools, will ensure increased reliability and accuracy in evaluating abrasion resistance methods, improving performance indicators and tailored strategies for meeting specific requirements.

Reference Sources

- Technical Report Documentation Page – CiteSeerX

Contemplates different types of ‘abrader’ tests, in particular the Böhme abrasion test and possible difficulties.

- Revamping Aggregate Property Requirements for Portland Cement Concrete

University of Texas – Investigates the use of the Böhme device and pertinent problems of testing about concrete.

Frequently Asked Questions (FAQs)

Q: What is the böhme abrasion test and why is it used?

A: The böhme abrasion test is a standard test method used to assess the abrasion resistance of natural stones, such as building stones. It evaluates how well a material can withstand wear from abrasive forces.

Q: What happens if a böhme abrasion tester fails during an abrasion test?

A: If a böhme abrasion tester fails, it could lead to inaccurate test results, impacting the evaluation of a material’s wear resistance. It may require recalibration or replacement of the test apparatus to ensure reliable testing of abrasion resistance.

Q: How does the test method impact the test results of the böhme abrasion test?

A: The test method directly influences the test results as it dictates the procedure and conditions under which the abrasion resistance is evaluated. Any deviation from the standard test method can lead to inconsistent or unreliable results.

Q: What materials are tested using the böhme abrasion test apparatus?

A: The böhme abrasion test apparatus is typically used to test the abrasion resistance of natural stones, such as carbonate rocks, sandstones, and other building stones.

Q: How does the number of cycles affect the abrasion resistance test results?

A: The number of cycles in an abrasion resistance test is crucial as it determines the extent of wear a test specimen undergoes. More cycles generally provide a more accurate representation of a material’s wear resistance.

Q: What are the implications of mass loss in the böhme abrasion test results?

A: Mass loss in the böhme abrasion test results indicates the degree of wear a material has undergone. Higher mass loss suggests lower abrasion resistance, which may impact the material’s suitability for certain applications.

Q: Can different types of abrasion affect the test results of the böhme abrasion test?

A: Yes, different types of abrasion, such as surface abrasion or wheel abrasion, can impact test results. The specific conditions and materials used in the test method will determine how these types of abrasion are simulated and measured.

Q: Why is it important to use a standard test method for the böhme abrasion test?

A: Using a standard test method ensures consistency and reliability in evaluating the abrasion resistance of materials. It allows for comparison of results across different tests and materials, making it an essential aspect of the test procedure.

Q: How does the test apparatus affect the böhme abrasion test results?

A: The test apparatus, including the abrasion testing machine and test track, plays a critical role in ensuring accurate and reliable results. A malfunctioning or improperly calibrated apparatus can lead to erroneous test results.

Q: What is the significance of the Bohme abrasion test in assessing rock properties?

A: The Bohme abrasion test is significant in assessing the physical and mechanical properties of rocks, helping to determine their suitability for use in construction and other applications based on their resistance to abrasion.