The importance of manhole covers in the urbanization system is fundamental to safety management, accessibility, and protection inflicted on the systems beneath the streets. Although, the structural soundness of these manhole covers is something that should never be taken lightly, as failing during testing can signal serious operational risks along with safety hazards and a multitude of expensive consequences. This article focuses on the public safety concerns and the compliance to industry standards with the manhole cover testing protocols failure and safety procedures in place to deal with these noncompliance failures. Recognizing the impacts and reasons of failure allows essential social parties to address the structural insecurity, systems restrictions, and enhance preemptive actions to maintain key infrastructure reliability.

What Are the Common Reasons for Manhole Cover Testing Failures?

Manhole cover testing failures commonly originate from a few critical causes:

- Material Deficiencies – Failure in materials such as low-grade cast iron and improperly mixed composites, result in a lack of strength and durability needed.

- Manufacturing Defects – Low quality control standards result in loose quality control during production causing issues such as poor control over casting leading to unbalanced weight distribution causing structural degradation.

- Overloading – Covers that are not designed for specific classes of loads face failure when subjected to over-vehicular or even industrial weight surpassing set limits.

- Environmental Factors – The environment’s impact due to harsh chemicals and corrosion as well as temperature changes can reduce material integrity, which will lead to failure under stress situations.

- Improper Testing Procedures – Through neglecting standardized test methods, operators risk inaccurate results with undetected weaknesses, therefore, oversights on vulnerabilities on the manhole cover goes unchecked.

All of these problems can be linked to poor quality control practices, non-compliance to the regulations of the relevant governing body, or inappropriate choice of materials made with regard to environmental conditions and loading factors.

Understanding the Inspection Process of Manhole Covers

To achieve the necessary requirements for the performance and function of manhole covers, thorough documentation from a step-by-step inspection is claimed to preserve the manhole components structurally while observing set instructions from the relevant authorities. Important processes include visual inspection, non-destructive testing (NDT), and assessment of the cover’s load-bearing capacities.

- Visual Assessments – They document relevant phenomena like fractures or physical changes such as bending which can result as corrosion. These inspectors as well gather paperwork of these records will help over time in identifying patterns of deterioration.

- Non-Destructive Testing (NDT) – Ultrasonic and radiographic tests are among the advanced techniques employed to reveal the cover’s underlying defects without damaging its surface. These methods make it possible to detect invisible stress fractures, voids, or inconsistencies in the material that go undetected without the aid of these devices.

- Load-Bearing Evaluations – Ensuring the cover’s load resistance intersects with its intended weight capacity involves a check measuring how much weight it can carry. This procedure usually involves applying incremental weight until a preset figurative ceiling is reached while ensuring the safeguard under both static and dynamic loads.

Environmental factors come into play, such as exposure to chemical agents, temperature extremes, and moisture that contribute to material degradation faster than normal should be noted as well. Applying these exhaustive methodologies enables proactive maintenance measures that strategically manage risks of critical infrastructure failures, enhance the operational lifespan of manhole covers, and reduce the likelihood of operational failures.

Common Structural Issues Leading to Failure

The structural failure of a manhole cover is often a mix of multiple design errors, combined with a periodic lapse in a material’s structural resilience, additional firefighting or other external factors having more stress enduring equipment. Overrating load is a major issue, this encompasses the scenario where a manhole is supposed to be load bearing but it does not have the requisite support to deal with the traffic of commuters, be it vehicles or foot traffic. This cover eventually bends or fissures, further weakening the section of the cover where the material was compromised. Weathering extremes coupled with sustained high or low loads, combined with poor manufacturing processes of subpar alloy mix during the fabrication, can damage weather-resilient parts of the structure, culminating in deeper fractures and faster breakage.

Corrosion is also critical, especially for cast iron or steel manhole covers. Moisture, de-icing salts, and industrial chemicals accelerate oxidative reactions and weaken the material over time. Moreover, poor installation like improper sealing or uneven bedding increases structural failure risk. Moderate temperature changes contribute additional thermal stress due to contraction and expansion, which gradually breaks down the manhole cover and its frame.

The Role of Material Condition in Manhole Cover Testing

Condition of the material impacts the integrity and performance of the manhole cover, especially during impacts, therefore, requires careful attention. Inspection and maintenance of internal defects, such as cracks and weaknesses, are done more often using non-destructive testing (NDT) methods like ultrasonic and X-ray because they don’t accelerate material degradation. Ductile manhole covers are constructed from modern composite materials and, therefore, are offered greater strength-to-weight ratios and resistance to corrosion.

Recent studies show that adding wear-resistant coatings and corrosion inhibitors increases the lifespan of manhole covers even in aggressive chemical environments. Moreover, stress distribution and deformation calculations under different loading conditions are done using finite element analysis (FEA) simulations, thus improving the selection and optimization of the material and its thickness during the design stage. These improvements put into focus the testing and the condition of the materials used so strict measures must be taken to ensure the safety and the functionality in every possible scenario.

What Are the Consequences of a Failed Manhole Cover Test?

A failure in testing a manhole cover can lead to safety risks, operational halts, and monetary losses. This can be looked at from a safety angle. A manhole cover that is either faulty or out of alignment structurally endangers people, vehicles, and even workers. This may cause injuries or accidents. From an operational perspective, this type of failure hinders vital utility facilities, postponing important maintenance or repair work, and affecting the region. From a financial perspective, defective covers and other damages or liabilities add to the spending stubs. Compliance with standards and thorough testing are quite important for preventing these outcomes.

Potential Risks to Public Safety and Infrastructure

Utility covers are critical for any city as they directly impact public safety and the operational effectiveness of vital infrastructure systems. Inadequate selection of materials or poor manufacturing processes out of lack of adherence to the quality control guidelines lead to poorly maintained covers increasing the risk for fatigue failures or complete collapses. If such failures occur in dense traffic regions, there are serious risks to pedestrians and vehicles that can result in injuries or deaths.

Infrastructure integrity is another area of concern with malfunctioning utility covers. Utility covers have the potential to disrupt systems such as electrical grids, water pipelines, or even telecommunications systems, as they may abruptly collapse. These disruptions may cause service interruptions, water contamination, or even large-scale operational delays. Research suggests badly designed or corroded utility covers also result in higher service interruption risks which in turn causes longer recovery times and higher costs.

In order to mitigate these issues, quality control is needed during the production phase including thorough inspections after the installation is complete. Utility covers are increasingly being made from advanced materials such as ductile iron alloys which are more mechanically robust under dynamic loads. Utility covers also need to comply with the appropriate safety requirements by ASTM or EN standards which sets minimum safety thresholds and required efficiency for their design and performance.

Costs Associated with Repairing a Failed Manhole Cover

Working on a failed manhole cover encompasses a balance of direct and indirect expenses, which for more serious problems can increase rapidly. Materials, including replacement covers and supporting frames, along with the labor cost for excavation, removal, and installation, are all direct costs. For materials, concreted covers are fabricated as units and in parts, meaning they can cost anywhere between $300 to $700. Add in the additional $500 to $1500 for labor costs, depending on how regionally competitive and intricate the project is.

Indirect costs are of greater significance, but often taken for granted. For example, trodden fuel and increased intake of stationary fuel pumps due to temporary road closures and construction of traffic in both directions provide local businesses with heightened attention. Furthermore, routine maintenance check-ups provide greater benefits as emergency repairs are always needed instead of scheduled maintenance during peak seasons due to rush procurement of fewer materials but greater labor.

How Can a Failed Manhole Cover Be Repaired?

The following steps should be conducted when fixing a malfunctioning manhole cover:

- Inspection and Assessment

Step one is begin by closely inspecting the edges of the manhole cover to see how deep the issue goes. This has aided an individual recognize whether the damage is surface deep or complicated, assisting in choosing if they require blunt or careful methods to fix it.

- Cleaning and Preparation

Remove debris, if there is any, and dirt along loose materials around the manhole so as to make sure of providing a fresh working terrain. Faultless preparation increases the chances of the repair being effective.

- Replacement or Realignment

Should the manhole cover be irreparably damaged, it must be substituted with a new one that adheres to local regulations. For loose or misaligned covers, proper fit realignment of the frame is often possible.

- Reinstallation and Sealing

Position the repaired or newly issued cover firmly within the frame. Fill gaps between the frame and surrounding pavement with properly graded asphalt or concrete to reduce future movement, as well as water ingress risks.

- Testing and Final Inspection

Conduct a last inspection to ascertain that the cover is situated flush with the road surface and confirm that it is securely fixed in place. Also confirm that it has been positioned to sustain and evenly distribute the anticipated loads and traffic.

These added measures seek to enhance functionality and safety the least disruptive way possible relative to the surrounding area.

Choosing the Right Materials for Repairing Manhole Covers

|

Material Type |

Key Features |

Advantages |

Limitations |

Applications |

|---|---|---|---|---|

|

Ductile Iron |

High strength, corrosion-resistant |

Durable, supports heavy loads |

Higher cost than cast iron |

High-traffic urban areas |

|

Cast Iron |

Strong, traditional material |

Cost-effective, widely available |

Prone to corrosion, brittle |

Low to moderate traffic zones |

|

Composite Materials |

Lightweight, non-corrosive |

Easy to handle, non-metallic |

Can be less durable than metals |

Residential and pedestrian areas |

|

Reinforced Concrete |

High compressive strength |

Affordable, customizable |

Heavy, susceptible to cracking |

Low-speed and low-traffic areas |

|

Stainless Steel |

Excellent corrosion resistance |

Aesthetic, high tensile strength |

Expensive, requires precise fabrication |

Specialized applications |

|

Fiber-Reinforced Plastic |

Lightweight, non-conductive |

Corrosion-resistant, easy to install |

Limited load capacity |

Electric or telecommunications zones |

|

Polyurethane |

Durable synthetic material |

Weather-resistant, shock-absorbing |

Limited heat resistance |

Temporary or low-traffic installations |

When to Consider Full Replacement vs. Repair

The consideration of whether to restore a cover or have a full replacement done is influenced by several elements like the extent of the damage, the overall condition of the structure, and the anticipated usage scenarios. Covers with deformations, surface cracks, or some degree of damage can be repaired through patching with epoxy or polyurethane-based materials which is less expensive comparatively and eliminates downtime.

On the other hand, fully replacing the manhole cover is the most suitable decision to take, especially when the protective structural envelope of the manhole cover is weakened by extensive corrosion, large fractures, severe deformation, or anything that heavily reduces its ability to carry loads. Covers that do not comply with the updated building codes should also be replaced as soon as possible, especially if they are located in high traffic areas where safety concerns arise. Also, in cases where multiple patch repairs had already been done, only to have the same performance failure occur afterward, replacing the cover would save money in the long run.

What Testing Methods Are Used for Manhole Covers?

A combination of load testing, material analysis, and dimensional inspections serves to evaluate manhole covers’ safety and performance. Each cover’s manufactuer warranty is guided by criteria which must include rigorously tested materials, consistent with industry standards for load bearing integrity as well as no deformation or wear lowering its valued lifespan. Composition Integrity assurance confirms that the material cover complies with a strict standard like Ductile composites, to ensure it is both corrosion resistant and wear resilient, alongside extending an impaired lifespan. Reporting on storm damage provides an allowance framework where failsafe hinges compromise risk-accidents, aligned with stability bolstering. These methods are standardized by organizations like ASTM or EN, which ensures all installations done worldwide have consistent benchmarks set for performance and reliability.

Overview of Vacuum Testing for Manhole Integrity

Vacuum testing is a widely-recognized non-destructive method utilized to assess the structural integrity and watertightness of manhole systems. This procedure involves sealing all inlet and outlet pipes of the manhole before applying a vacuum pressure inside the structure. Monitoring pressure reveals whether the sealed vacuum space is hypothetically turned into a timed challenge where counters start at set thresholds. Drainage for venting baloon budget dwindling past a certain point indicates drains opening too fast pose a tag risk alongside low thresholds for opposing urgency for exceeding structural limits.

This approach works well because it precisely identifies even the smallest defects, making it useful for compliance checks. Vacuum testing is usually regulated by ASTM C1244, which sets specific requirements for the testing pressure, duration, and current industry equipment requirements. This ensures consistent inspection for installations ranging from precast concrete manholes to field-assembled systems.

Utilizing Dye Testing to Identify Leaks

For plumbing, roofing, and water systems, dye testing is an accurate and dependable technique for locating and identifying system leaks. This evaluation method consists of non-toxic, water-soluble dye being injected into a system or structure under assessment. The dye is applied to suspected breach areas where, with time, the movement or appearance of the dye indicates breaches and their corresponding magnitudes.

Improvements in formulation have enhanced the operational efficacy of various dyes both in detection and their environmental testing conditions. Dyes these days are specifically designed to be measurable even in poor lighting and other difficult environments which ensures thorough evaluations. Moreover, the compliance of dye testing with industry regulations such as ASTM practices which governs the appropriate use of tracing dyes, showcases its application in contemporary practices. This methodical strategy effectively controls the chances for false positive results and ensures consistency which makes dye testing a popular choice for diagnosing leaks in both residential and industrial frameworks.

How Often Should Manhole Covers Be Inspected?

Remote or inaccessible manhole covers must be examined at least once every year, and this includes people’s safety and mechanical functionality. These areas may also be subject to frequent inspection such as every three months due to increased traffic and equipment use. Focus areas for inspections should include any signs of decay, damage, or misalignment that could lead to loss of precious access or pose grave risks to safety. Approaching local municipal instructions or relevant guidelines ensures compliance and, thereby, maintenance checklist are better adhered to.

Recommended Inspection Frequency Based on Infrastructure Age

For infrastructure less than a decade old, annual inspections are generally adequate to maintain structural health assuming no severe environmental conditions or usage patterns that accelerate wear and tear. However, the infrastructure aging progressive requires more frequent inspections.

For structures aged between 10 and 20 years, a semi-annual inspection is advised to capture early indications of material fatigue, weathering, or stress from use. After 20 years, the infrastructure should be inspected quarterly to evaluate aging materials, potential corrosion, and adherence to safety regulations, including changes in requirements. Critical risk systems or agile failure systems, especially those that are load-bearing or under high pressures, require tighter scrutiny due to their potential for sudden failure if not closely examined.

These proposed intervals are consistent with minimum benchmarks for engineering and maintenance standards, and are supported with evidence on material ages, structural stress thresholds, and performance benchmarks over time. These customized intervals mitigate risk while simultaneously extending infrastructure use.

Factors Influencing the Need for More Frequent Inspections

- Environmental Conditions

Extremes of environment, such as high humidity, salinity, and temperature especially accelerate degradation of material. Take the example of metal structures located at coastal areas. Such structures are subject to higher rate of corosion (20%-30%) as compared to structure located away from the coast due to the moisture saturated air. Furthermore, extreme heat of cold temperatures cause contraction and expansion stresses which impact structural integrity. These and similar environments require regular monitoring to preemptively identify critical signs of failure.

- Load and Operational Demands

Systems and components operating under irregular load patterns encounter high stress and require closer attention for inspection. Evidence suggests that operation at more than 70% load increases failure rates significantly (1.5x) which high exceed nominal ranges of operation. Close attention is also essential to avoid unexpected downtimes through avoidance of high-cycle fatigue and stress-related wear.

- Age of the Structure or Equipment

All aged structures naturally incur damage over time, regardless of the regular schedule of maintenance. Such structures are more prone to critical failures—up to 40%—beyond 75% of the expected lifespan. Trouble spots require almost continuous attention in order to arrest problems in aged systems.

- Historical Failure Data

Previously malfunctioning or underperforming systems are predisposed to encounter further issues. For instance, if a certain equipment series experiences persistent bearing failures within a two-year timeframe, the need for proactive inspections should be implemented to mitigate future issues. Furthermore, employing predictive maintenance methods like vibration analysis enhances optimization of inspection intervals.

These factors are essential when attempting to formulate an inspection schedule. Intersecting these parameters systematically brings the operational paradigm to enhanced resilience, efficiency, and safety.

What Codes and Standards Govern Manhole Cover Testing?

Compliance regarding the reliability, performance, and safety anatomy of manhole covers and construction site access point lids is framed by a number of standards, lying in the domain of safety, durability, and manhole cover compliance. Some relevant standards are highlighted as follows.

- ASTM A48/A48M – This standard outlines criteria of strength classification for gray iron castings which meets the requirements for manhole covers.

- EN 124 – This standard covers a European classification of manhole covers and frames considering their loading capacity starting from pedestrian zones to heavy-duty traffic areas.

- AASHTO M306 – This standard was developed by the American Association of State Highway and Transportation Officials (AASHTO) and deals with the manhole covers structural integrity and performance under the roadway conditions.

Compliance with these standards is required for the installation of manhole covers with rigorous safety, performance benchmarks, and compliance with public infrastructure reliability.

Understanding OSHA Guidelines for Manhole Safety

The Occupational Safety and Health Administration (OSHA) regulations concerning zone 2 in the vicinity of manholes are especially important for utility and construction workers who confront the danger of confined spaces. OSHA defines manholes as permit-required confined spaces, which require specific access procedures to be followed. Moreover, hazard evaluation and ventilation protocols must be carried out. As per these rules, employers need to ensure atmospheric testing for oxygen deficiency, toxic gases, or explosive conditions prior to any entry. In addition, there must be a reliable ventilation system capable of sustaining safe air quality.

In addition to the issues outlined above, OSHA also requires that protective equipment such as harnesses for fall protection and retrieval systems be used to eliminate the risk of entrapment or injury. There must also be an attendant trained for the situation who stands outside the manhole to monitor the conditions and respond to possible emergencies. Signage and barriers must also be put in place to indicate the area is restricted while warning oncoming persons of potential risks. Compliance to all the steps outlined is imperative, as deviation from them can result in serious injuries or death.

Key Industry Standards for Manhole Cover Inspection and Repair

The inspection and maintenance of manhole covers are regulated by relevant safety, effectiveness, and operational standards. One such key industrial standard is ASTM A48, which outlines the grading iron casting and manhole cover’s material and tensile strength requirements. Compliance with such material specifications alleviates potential damages due to heavy loading on the structure.

Moreover, the Manual on Uniform Traffic Control Devices (MUTCD) has specifications on signage and barriers to be used during the inspection and repair of traffic intersections. Based on the Traffic Safety at Roadworks Procedures, proper signs, fences, and lights must be utilized in order to safeguard both workers and pedestrians in places with high volume of people. In addition, NASSCO prepares specific criteria for the assessment of the structural flaws and for the application of rehabilitation techniques which can include reinforced concrete liners, polymeric coatings, or modern methods aimed at sealing weak points to block water ingress and structural deterioration.

Reference Sources

-

Testing, Analysis, and Classification of No-Dig Manhole Rehabilitation Materials: This study highlights the catastrophic consequences of manhole failures, such as sinkholes and wastewater blockages.

-

Defect-and Component-Based Assessment Model for Manholes: The study developed a systematic condition assessment model for manholes, identifying critical components prone to failure. It emphasizes the importance of proactive maintenance to prevent sudden collapses.

-

The Pothole Patrol: Using a Mobile Sensor Network for Road Surface Monitoring: While focused on road surface monitoring, this study indirectly addresses manhole-related issues by identifying surface anomalies like potholes, which can result from manhole failures.

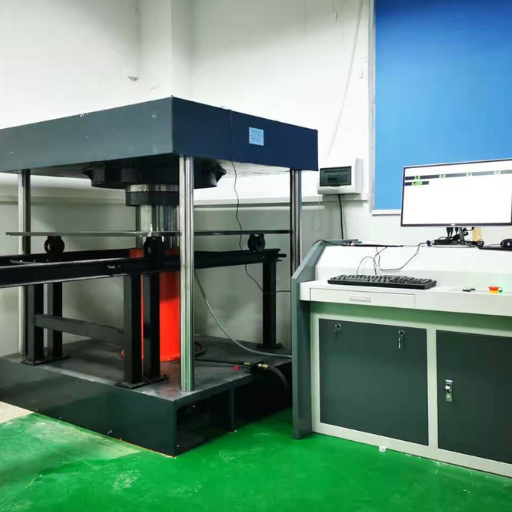

- Top Manhole Cover Testing Machine in China

Frequently Asked Questions (FAQs)

Q: What are the possible consequences of a damaged manhole during testing?

A: If a manhole testing fails due to a damaged manhole, it can lead to issues such as infiltration of soil and water into the sewer system, potential overflow, and compromised manhole conditions that may affect the overall sewer system integrity.

Q: How is the requirement for manhole testing determined?

A: The requirement for manhole testing is determined based on the local regulations, the age of the sewer lines, previous maintenance records, and the overall condition of the manhole sections themselves.

Q: What is the procedure if a manhole fails the testing?

A: If a manhole fails the testing, an investigation is typically carried out to assess the extent of the damage. This may include CCTV inspections and visual assessments to determine the necessary repairs or replacements needed to ensure proper functionality.

Q: Can a damaged manhole lead to fatalities?

A: Yes, a damaged manhole can potentially lead to fatalities if it causes hazardous conditions, such as sudden collapses or toxic gas release, especially if people are entering the manholes without proper safety measures.

Q: What role do soil conditions play in manhole testing?

A: Soil conditions can significantly affect manhole testing outcomes. Poor soil conditions may lead to instability in the manhole structure, which can result in infiltration or other issues that compromise the sewer system’s functionality.

Q: What equipment is commonly used to test manholes?

A: Common equipment used for manhole testing includes vacuum pumps to create a vacuum of 10 inches of mercury and pressure gauges to measure the integrity of the manhole against specified requirements.

Q: How can manhole conditions affect the flow in the sewer system?

A: Poor manhole conditions can disrupt the flow in the sewer system by causing blockages, reducing capacity, or leading to overflow situations, which can ultimately impact the entire sewer system’s operation.

Q: What is the significance of the backfill in manhole installations?

A: Proper backfill is crucial for manhole installations as it supports the structure, prevents soil erosion, and helps maintain the integrity of the manhole against external pressures and infiltration.

Q: How often should manhole inspections be conducted?

A: The frequency of manhole inspections can vary based on local requirements, but it is generally recommended to conduct inspections at least annually or more frequently in areas with known issues or adverse manhole conditions.