The pull test is an invaluable testing technique employed by a wide array of industries to ascertain those materials whose utmost properties and strength are necessary: adequate durability and safety. The test could be used to assess adhesives that retain their wallpapers or bear their tensile strength; metals may pass the pull test in terms of tensile strength; and fasteners prove their credentials for use through performance pull tests, all to ascertain specific data considered necessary for a standard on quality and safety. This blog explores the concepts of pull testing and proof testing, examining their applications, methodologies, and key differences. Post completion of this article, you ought to develop an understanding of how these tests play a role in ornamental and structural construction of products and systems in many disciplines.

Introduction to Pull Tests

Pull tests are mechanical methods for testing materials, components, or assemblies by applying tensile force until a particular result occurs, which may be anything such as deformation or failure. Pull tests are critical in assessing load capacity, ensuring structural integrity, and meeting safety standards. These tests serve their purpose across various industries, including construction, aerospace, and manufacturing, to evaluate how promising products perform under real-world stress. They provide measured data to identify weaknesses, justify designs, and carry out quality control.

Definition of a Pull Test

The pull test is an evaluation procedure applied to determine the tensile strength, bonding ability, or durability specification of a component or assembly under controlled conditions. The pull test involves subjecting the specimen to an axial tensile force that is increased until one of several pre-established results occurs: either some deformation of the material is visible, a failure at the adhesive interface is evident, or the specimen fractures completely. Results from such tests form the basis for understanding stress and strain relationships, studying various test materials to determine load-bearing capabilities, or establishing safety standards for the industry under respective protocols, such as ISO or ASTM.

Recent Developments: Recent insights offer that pull tests have undergone tremendous upgrades in methodology due to advancements in testing Engineering equipment and simulating tools. For instance, automatic pull-testing machines ensure greater precision, while real-time data acquisition improves accuracy in failure-point data analysis. Additionally, with the emergence of sectors such as renewable energy and advanced composites manufacturing, scientists in these fields are increasingly using pull testing to characterize materials for withstanding tough environmental and mechanical stresses. Hence, such upgradation ensures that products meet a reasonably higher expectation regarding performance and quality standards, which keep evolving.

Purpose and Significance

It is basically an extension of determining tensile strength, holding power, and adhesion of materials, the pull test in controlled conditions. It is when a known force is applied through the mechanism until the material or bond breaks and when the maximum load capacity, the elongation before failure, load behavior, or durability of the product is recorded. These qualities are used to assess the reliability of the product, ensure compliance with industry standards, and identify shortcomings in material composition or design.

Pull testing has significance in areas such as aerospace, construction, medical devices, and automotive manufacturing. The Pull Test ensures structural integrity in critical applications, the quality of products during production, and research and development for establishing new materials. Pull Testing is most crucial for safety-critical elements where failure under stress would result in an unthinkable consequence. Thus, it enhances confidence in product performance and its acceptance by regulatory authorities, promoting the realization of safer and efficient technologies.

Importance of Understanding Pull Tests

Pull tests and their workings deserve utmost importance, as they help determine the exact tensile strength of a specific material and its adhesive abilities under a given set of conditions. The engineers and manufacturers use this method to verify that the product exhibits its attributes according to the set property standards and industry-specific legal regulations. Pull tests enable the identification of weak links in materials or bonds, which in turn facilitates further improvement in product design based on finer details in mechanical behavior. Additionally, pull testing reduces risks in failures by confirming the ability of a product to perform and withstand real-time conditions. Its utmost importance lies in aerospace, construction, and medical device applications, where strength, ability, and reliability are ingrained into each fabric of the material.

Types of Pull Tests

Pull tests encompass tensile pull tests, adhesive pull tests, bond pull tests, shear pull tests, and wire pull tests.

| Test Type | Purpose | Key Parameters | Industries | Outcome |

|---|---|---|---|---|

| Tensile Pull Test | Measure strength | Load, Elongation | Construction | Material Limits |

| Adhesive Pull Test | Assess adhesion | Force, Surface | Manufacturing | Bond Integrity |

| Bond Pull Test | Evaluate bonds | Force, Thickness | Electronics | Bond Strength |

| Shear Pull Test | Test shear force | Stress, Yield | Aerospace | Joint Durability |

| Wire Pull Test | Test wire bonds | Force, Diameter | Medical Devices | Bond Stability |

Tensile Pull Tests

Tensile pull tests are done primarily to measure the mechanical strength of a material and/or component when axial tensile stress is applied. The specimen is loaded to failure while keeping control of the loading. This provided essential data on tensile strength, elongation, and the failure point of the specimen. There is an increasing emphasis on considering tensile pull testing implementations in emerging industries, including renewable energy, advanced manufacturing, and sustainable construction materials.

Innovation Focus: One common question posed is: “How do tensile pull tests contribute to material innovation, especially for sustainable applications?” This test could be pivotal in determining the mechanical properties of eco-friendly materials, such as bioplastics or recycled composites. By providing a reliable measurement of their stress-strain behavior, the researcher or engineer can develop formulations for high-performance applications that retain their environmental significance. This approach maintains regulatory standards while advancing sustainable technology, making tensile pull testing crucial in material development.

Adhesion Pull Tests

Adhesion pull testing also tends to be a necessary procedure to evaluate the fastening power between coatings, adhesives, or surface treatments, and their substrates. A controlled tensile force is exerted perpendicularly on the surface until the bond fails, thereby allowing an engineer to measure the strength of the adhesive power. A typical pull-off monitor utilizes special dollies; however, the results are subject to variations, including surface preparations, adhesive formulations, and environmental conditions. Industries such as construction, automobile, and airplane find this test as a part of their procedures ensuring their materials’ dependability and specification checks, such as ASTM D4541 and ISO 4624.

Destructive vs. Non-Destructive Testing Methods

Destructive testing methods include tensile tests, impact tests, hardness tests, and adhesion pull tests. Non-destructive methods, on the other hand, include ultrasonic testing, radiographic testing, magnetic particle testing, and dye penetrant testing.

| Aspect | Destructive | Non-Destructive |

|---|---|---|

| Purpose | Failure analysis | Defect detection |

| Material Impact | Permanent damage | No damage |

| Examples | Tensile, Impact | Ultrasonic, Radiography |

| Time | Longer | Shorter |

| Cost | Higher | Lower |

| Application | Final product tests | Real-time inspections |

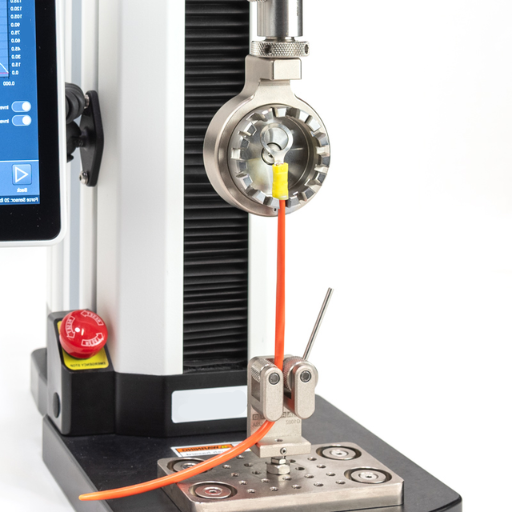

Tools and Equipment for Pull Testing

Pulling tests require a specialized suite of equipment that subjects materials or components to axial tensile forces, thereby ascertaining their strength and durability. Some of the more general tools and equipment that may be used in pull testing include:

- Universal Testing Machines (UTMs): These machines feature load cells, grips, and extensometers for precise measurement of tensile strength, elongation, and breaking points of specimens.

- Load Cells: These are highly accurate sensors that measure the force applied during tests.

- Gripping Mechanisms: Grips or fixtures designed to secure the test sample, ensuring reliable test results that prevent any slipping.

- Extensometers: Measuring deformation or strain of the material under stress.

- Control Systems and Software: Computerized systems for real-time data acquisition, test control, and result analysis.

- Calibration equipment: Used to keep testing machines accurate and ensure they comply with industry standards and regulations.

These tools, when combined, provide a dependable framework for testing material properties across various industrial and research fields.

Common Pull Testers and Dynamometers

Pull testers and dynamometers find their place in a plethora of industrial applications to measure tensile force, load, and the mechanical properties of materials. Modern pull testers typically feature high load cell accuracies, grips configured in various ways, and control systems that can be programmed to test multiple materials and components. The commonly used ones are motorized tabletop models charged with testing smaller samples and large-capacity floor model testers for industrial applications. Most of these machines are designed to meet ASTM and ISO testing standards, ensuring the most accurate and reliable results.

Force measurement dynamometers can be mechanical or digital. A mechanical dynamometer is rudimentary and based on spring mechanisms, whereas digital versions are more precise, utilizing electronic load cells and offering improved displays and data-logging features. Both dynamometers find applications in wire crimp testing, adhesive bond testing, material strength testing, and quality assurance. Handheld digital dynamometers are a typical example used in ergonomic measurements, and inline types are used for production systems.

Ultimately, the choice depends on whether the standards of testing require capacity and precision, as well as the system’s ability to integrate with control systems for automated operation.

Force Gauges and Their Applications

Force gauges are primary tools used in measuring compressive and tensile forces in various industries and laboratories. They are extensively utilized for testing materials, verifying product quality, and evaluating mechanical performance. Typically, there are two broad categories of force measurement devices: mechanical and digital. Both setups confer special advantages based on the testing scenario and the precision required.

A mechanical force gauge is a simple device that is robust and can be used for straightforward force measurements. Such a force gauge is best suited for environments with rugged applications. Digital force gauges, in contrast, possess higher accuracy and data can be logged in real time, along with interfacing with advanced computer-controlled test systems.

Force gauges have applications in various industries, including manufacturing, automotive, construction, and medical device production. They determine break strength, confirm assembly fitment, and register force during repetitive operations. Force gauges of the present day typically feature modular design characteristics that provide compatibility with various grips, fixtures, and testing stands, enabling specific-use functionality tailored to the testing protocols involved. Choosing the right force gauge depends on the range of measurements required, the need for accuracy, and adherence to industry-specific regulations.

Calibration and Setup for Accurate Results

To achieve accurate results, proper calibration and setup of the force gauge are my top priorities before beginning testing. Firstly, I ensure that the device has been calibrated against the manufacturer’s criteria or one of the recognized standards, including ISO or ASTM, using certified calibration weights. This procedure prevents measurement drift and aids in repeatability. Secondly, I must ensure that the force gauge is securely attached to the test stand and not subject to any outside movement, which could compromise accuracy. Thorough positioning and alignment of the operating axis of the gauge to the direction of force also guard against errors during operation. Lastly, I configured the device parameters, including measurement units and thresholds, for the specific application. Periodic calibration ensures that calibration has not been compromised, as do considerations regarding environmental conditions, such as temperature and relative humidity.

Best Practices for Implementing Pull Tests

To produce the accurate and reliable test data, specific standard operating procedures are followed during pull testing. These include calibration verification of testing equipment to ensure that the standards are met. The installation of the fixture or attachment point must be secure to prevent unintended movement. Force must be applied gradually and in line with the axis in question so as not to set up any sort of uneven stress distribution. The test environment should be controlled with respect to temperature and vibrations, which may affect the readings. Well-document all results, and re-test whenever necessary to confirm consistency and accuracy.

Selecting the Right Testing Method

The most suitable testing technique will depend mainly on many critical deciding factors, such as material properties, the testing purpose, and the particular requirements of the field of application. When one wishes to investigate breaking points and a structural integrity of materials, destructive tests are preferred, such as tensile tests or impact tests. NDTs would be the preferred approach when the test must be carried out by preserving the sample and applying a method to detect internal flaws or discontinuities, such as ultrasonic or radiographic testing. Furthermore, the techniques used should conform to industrial and legal standards to ensure the accuracy and reliability of the results. Other deciding factors include the cost of the application, the availability of equipment, and the skill required for carrying out the test.

Maintaining Consistent Testing Procedures

Testing procedures must be consistent, which is why I prioritize working according to the standard methods recognized under any industry regulation; thus, the accuracy and reliability of the tests are ensured. I routinely calibrate test equipment to avoid Errors that could result from mechanical or operating inconsistencies. Additionally, I maintain a detailed record of the methodology, from sample preparation to final analysis, ensuring that my procedures are reproducible and transparent. Furthermore, faculty training and staying current with developments in testing technologies are vital aspects for maintaining expertise and best practices. By following these protocols, I assure quality and dependable results in every evaluation.

Training Staff and Interpreting Results

Clear protocols are laid, and constant education on standards of test and analysis and new methods is promoted to train the staff. The course of training will concentrate on testing in the use of equipment; quality control, and proper guidelines in the use of test equipment. Regular workshops and demonstrations should follow to reinforce practice and ensure the concepts are retained, thereby enhancing worker competency in the field. Result interpretation must emphasize statistical analysis, the importance of deviation, and documentation practices that guarantee reliability and the accuracy of the final findings. This should then be supported by a peer-review process in which the team constantly verifies data to enhance the robustness of data interpretations. The implementation of these measures yields a well-trained squad capable of delivering consistent, high-quality results.

The Role of Pull Tests in Various Industries

Pull tests hold importance in several industries, as they verify the mechanical integrity and strength of materials, components, or assemblies. They are implemented in manufacturing, construction, aerospace, and telecommunications to ensure compliance with safety standards or performance specifications. Pull tests impart tensile forces in disassembling or detaching components or units to bring out weaknesses in the material or design; they may further check durability of the product while holding quality control so that reliability and operational efficacy are maintained.

Construction Applications

By assessing materials for strength and adhesion, pull tests ensure that structural members remain intact and are safe within the construction industry. Typically, these tests are applied to check the anchors, bolts, and fasteners of concrete, masonry, or steel structures to ensure they can hold a particular load. For instance, pull-out tests evaluate rebar embedment strength or ascertain adhesive anchors’ ability to resist given tensile forces. Pull testing is conducted on materials used for cladding, curtain wall systems, and roofing membranes to verify that they perform and respond as expected under design and environmental conditions. Providing an early detection of weaknesses in the construction procedure, pull tests support durability, safety, and compliance with industry standards.

Manufacturing and Engineering Applications

Pull testing holds significant applications in manufacturing and engineering dictated by the load it displays: the mechanical integrity and bonding strength of substances and components. Welds, fasteners, adhesives, and crimps are tested during pull testing to ensure the highest standards have been maintained. For example, in metal fabrication, pull testing assesses the strength of welded joints, while in cable manufacturing, it checks the tensile strength of crimped connectors. Then, pull testing is used in stress analysis in aerospace and automotive sectors so that the materials will resist operational loads and adverse conditions. Pull testing provides usable and precise measurement data, enabling manufacturers to detect defective products, optimize production processes, and comply with regulatory standards. This method of testing is how engineering ensures safety.

Aerospace Industry Uses

Pull testing holds vital significance in the aerospace industry for certifying the structural integrity and reliability of components under extreme conditions. Organically experienced tensile stresses are of greater magnitude in aerospace applications, where materials and their connections are supposed to absorb tensile load without failure. Pull tests are used to evaluate the strength and durability of key components, including fasteners, wiring harnesses, and composite materials, in the construction of aircraft and spacecraft. These tests expose the weaknesses in components under test and ensure compliance with prosecutions governing safety, such as those of FAA and EASA.

The aerospace industry has developed better pull test methods with the more recent automation and high precision measurement systems. Test data is crucial during the implementation of predictive maintenance, enabling engineers to proactively address failures and thereby extend the lifespan of expensive, mission-critical systems. Pull testing enhances material performance and reliability, optimizing design standards and manufacturing processes to build a highly innovative and safe aerospace industry to date.