Tensile testing machines serve a pivotal role in material science and engineering, offering invaluable insights into the mechanical properties of materials. These machines are specifically designed to evaluate how materials respond when subjected to controlled tension forces, providing critical data such as tensile strength, elongation, and yield strength. Whether developing new alloys, assessing polymer durability, or ensuring construction-grade steel meets safety standards, tensile testing machines are at the heart of ensuring material reliability and performance. This article explores the fundamental principles underlying these devices, their core components, and their diverse applications across industries. By the end, you will gain a comprehensive understanding of what makes tensile testing indispensable and how it drives innovation in manufacturing, design, and quality control.

What Is a Tensile Testing Machine and How Does It Work?

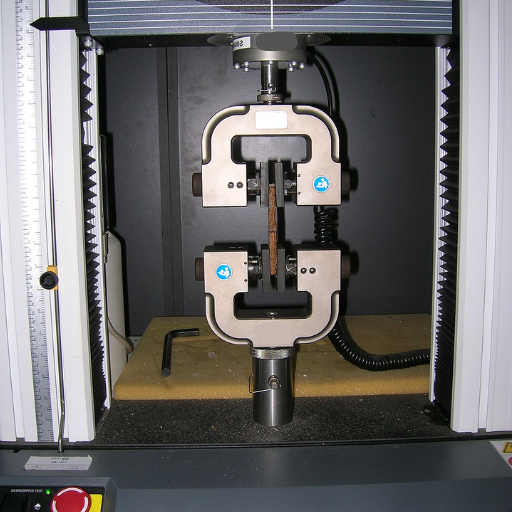

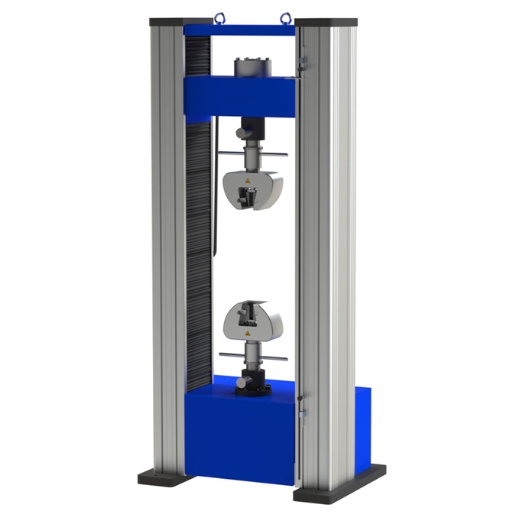

A tensile testing machine is a device used to measure the mechanical properties of materials, particularly their strength and elongation under tension. It works by applying a controlled tensile force to a specimen, gradually stretching it until failure occurs. The machine typically consists of a load frame, a crosshead to hold the specimen, and a load cell to measure the applied force. During testing, data on force and displacement are recorded, providing crucial information such as tensile strength, yield strength, and elasticity. These insights help assess material performance in real-world applications and ensure compliance with industry standards.

Components of a Tensile Testing Machine

- Load Frame

The load frame is the primary structure of the tensile testing machine. It provides the structural rigidity required to apply and measure loads accurately during testing. The frame is typically constructed from high-strength steel or aluminum to minimize deformation under load.

- Crosshead

The crosshead moves vertically to apply tension or compression to the specimen. It is motorized and often driven by servo mechanisms or hydraulic systems to ensure precise control over speed and displacement. Crosshead speeds usually range from 0.001 mm/min to 500 mm/min, depending on testing requirements.

- Grips and Fixtures

Grips securely hold the specimen in place during testing. Common grip types include wedge grips, pneumatic grips, and hydraulic grips. Specialized fixtures, such as extensometers or adapters, may also be used for certain materials to ensure accurate alignment and stress distribution.

- Load Cell

The load cell is a highly sensitive component used to measure the applied force. Typical load cell capacities range from 100 N to 300 kN, depending on the machine’s application. High-precision load cells ensure measurement accuracy within ±0.5% or better.

- Extensometer

Extensometers are optional but critical for measuring strain directly on the specimen. They commonly have a strain measurement range of ±0.05 mm to ±50 mm, with an accuracy of ±0.2%. Non-contact extensometers, like laser or video-based systems, may also be employed for advanced applications.

- Control System and Software

The control system regulates the operation of the machine, including crosshead movement and data acquisition. Integrated software is used to configure test parameters, record data, and generate stress-strain curves. Systems often include real-time monitoring features and comply with ISO 6892 or ASTM E8 standards.

Each of these components works in unison to ensure consistent and accurate material testing, making them critical in evaluating the mechanical properties of tested materials.

The Testing System and Its Mechanism

The operation of material testing systems relies on a combination of mechanical precision and advanced software to ensure accurate and standardized results. The central mechanism includes a load frame, which houses the actuator and crosshead system, designed to apply precise mechanical forces, such as tension, compression, or bending, to the specimen. Load cells, calibrated to strict standards, measure the applied force with high accuracy, while extensometers or displacement sensors track the deformation of the material.

The functionality of the testing system is heavily dependent on the control software, which enables users to configure test protocols, ensure compliance with standards like ISO 6892, ASTM E8, and ASTM D638, and monitor real-time data during testing. Depending on the system, data acquisition integrates seamlessly with computing platforms to generate detailed reports, including stress-strain curves and yield point metrics, which are critical for analyzing material behavior under varying conditions.

To maintain high precision and reliability, testing systems often incorporate feedback loops and automated corrections, ensuring consistent performance even during extended usage. Calibration to industry standards is a fundamental process to guarantee data validity, supporting their application across diverse industries, including automotive, aerospace, and construction. These systems, therefore, play a pivotal role in material property evaluation, product development, and quality assurance.

Understanding Load Cells and Their Importance

Load cells are precision instruments designed to measure force or weight by converting mechanical force into an electrical signal. They are widely used in various industries due to their accuracy, reliability, and versatility in measurements. Load cells operate based on several core principles, including strain gauge technology, piezoelectric effects, or hydraulic mechanisms, depending on the intended application.

Key Technical Parameters of Load Cells:

- Rated Capacity: The maximum load a load cell can accurately measure, typically specified in kilograms or tons.

- Accuracy Class: Represents the precision level, defined by parameters such as sensitivity, non-linearity, hysteresis, and repeatability.

- Sensitivity (mV/V): Indicates the output signal per unit of excitation voltage under full-rated load.

- Non-linearity: The maximum deviation of the load cell’s output from the ideal straight line, expressed as a percentage of full scale.

- Temperature Compensation Range: Specifies the operational range in which the load cell maintains accuracy, typically in degrees Celsius (e.g., −10°C to +50°C).

- IP Rating (Ingress Protection): Indicates resistance to environmental factors such as dust, water, or humidity (e.g., IP67 for industrial applications).

Understanding these parameters and selecting a load cell tailored to specific operational requirements ensures accurate force measurement, which is critical to achieving quality control and operational efficiency across numerous applications.

How to Conduct a Tensile Test?

To conduct a tensile test effectively, follow these steps:

- Specimen Preparation: Ensure the test specimen is prepared according to applicable standards (e.g., ASTM or ISO), with precise dimensions and surfaces free from defects.

- Machine Setup: Calibrate the tensile testing machine to the required specifications and install the appropriate grips or fixtures to securely hold the specimen.

- Mounting the Specimen: Place the specimen in the machine’s grips, ensuring it is aligned properly to avoid uneven stress distribution during the test.

- Test Parameters Configuration: Configure the machine with the required settings, including loading rate, gauge length, and environmental conditions, based on the testing standard.

- Execution of the Test: Start the test, allowing the machine to apply tensile force to the specimen at a controlled rate until failure or the predefined endpoint.

- Data Collection: Record critical data such as load, elongation, and stress-strain behavior throughout the test for further analysis.

- Post-Test Analysis: Examine the fracture surfaces and analyze the collected data to evaluate material properties, including tensile strength, yield strength, and ductility.

Adhering to these steps ensures consistent, accurate, and reliable test results, critical for material performance evaluation.

Preparing the Specimen for Testing

To prepare the specimen for testing, I would first ensure that it meets the standard dimensions and geometry specified by relevant testing protocols, such as ASTM or ISO standards. This preparation includes machining the specimen accurately to the required size to avoid introducing stress concentrations or irregularities that could influence test results. Additionally, I would thoroughly inspect the specimen for surface defects, like scratches or imperfections, as these might compromise the integrity of the test. Finally, ensuring the specimen is clean and free of contaminants, such as oil or debris, is essential to achieve reliable and repeatable measurements.

Step-by-Step Test Procedure

- Specimen Preparation

Ensure the test specimen is machined accurately to the specified dimensions, minimizing surface irregularities or stress concentrations. Inspect the specimen for defects like scratches or cracks and clean it thoroughly to remove contaminants such as oil, debris, or moisture.

- Equipment Calibration

Verify that all testing equipment, including load frames, sensors, and measurement devices, are properly calibrated according to the relevant standards to ensure accurate and reliable data.

- Mounting the Specimen

Securely mount the specimen in the testing apparatus, ensuring precise alignment to avoid eccentric loading or misalignment during the test.

- Pre-Test Inspection

Conduct a final check of the entire setup, including the specimen and instrumentation, to confirm proper installation, functionality, and preparation.

- Initiating the Test

Start the test procedure as specified by the experimental protocol. Apply the required loads or stresses incrementally, or at a constant rate as defined, while monitoring the behavior of the specimen.

- Data Recording

Continuously record relevant data such as applied loads, displacements, deformation, and strain through automation or manual entry, ensuring high fidelity of the output.

- Monitoring for Anomalies

Observe the test progression closely and identify any unexpected behavior or equipment malfunctions for corrective action or documentation.

- Terminating the Test

Stop the test once the failure criterion, maximum load, or specified endpoint is reached, following the procedural guidelines.

- Post-Test Inspection

Carefully remove the specimen and inspect it for visible signs of deformation or failure. Document observations with photographs, sketches, or additional measurements as applicable.

- Data Analysis and Reporting

Process and analyze the recorded data to derive the required test metrics. Cross-verify results with theoretical or expected values, and compile a comprehensive test report summarizing all findings and observations.

Role of Testing Software in Tensile Testing

Testing software plays a pivotal role in tensile testing by automating data collection, ensuring accuracy, and facilitating comprehensive analysis. Modern testing software interfaces with tensile testing machines to control parameters such as load rate, extension, and strain measurement. It enables real-time monitoring and provides precise, repeatable results by minimizing human error. Advanced software features include graph generation for stress-strain curves, data storage for traceability, and compliance with international testing standards like ASTM and ISO. Additionally, integrated analysis tools allow for the calculation of critical mechanical properties such as tensile strength, yield strength, and elongation at break. These capabilities improve efficiency, maintain consistency in testing, and streamline the creation of detailed test reports. Consequently, testing software is indispensable in ensuring the reliability and reproducibility of tensile testing outcomes.

What Are the Key Material Properties Measured by a Tensile Testing Machine?

A tensile testing machine is designed to evaluate several critical material properties that define the mechanical performance of a material. These key properties include:

- Tensile Strength: The maximum stress a material can withstand while being stretched before breaking.

- Yield Strength: The stress at which a material begins to deform plastically, marking the transition from elastic to permanent deformation.

- Elongation at Break: The percentage increase in length of a material at the point of fracture, indicating ductility.

- Young’s Modulus: A measure of a material’s stiffness, calculated as the ratio of stress to strain in the elastic deformation region.

- Toughness: The total energy a material can absorb before failure, combining strength and ductility.

These properties are essential for understanding the suitability of materials for various applications, ensuring safety, reliability, and performance in real-world conditions.

Determining Tensile Strength

To determine tensile strength, I would conduct a tensile test using a universal testing machine. This involves preparing a standardized specimen of the material, securely clamping it in the machine, and applying a controlled uniaxial force until the material fractures. The tensile strength is then calculated by dividing the maximum load sustained by the material by its original cross-sectional area. This process provides a precise measurement, which is critical for evaluating performance under load and ensuring the material meets the required specifications.

Calculating Yield Strength and Ultimate Tensile Strength

To calculate yield strength, I would start by identifying the point on the stress-strain curve where the material begins to deform plastically. This is typically done using the 0.2% offset method, which involves drawing a line parallel to the elastic portion of the curve at 0.2% strain and determining the stress value at the intersection. This value represents the yield strength and is essential for understanding the material’s behavior under load.

For ultimate tensile strength (UTS), I would locate the maximum stress value on the stress-strain curve, which corresponds to the highest force the material can sustain before necking begins. The UTS is calculated by dividing this maximum load by the original cross-sectional area of the specimen. Both yield strength and UTS are critical parameters in evaluating material properties and determining suitability for specific engineering applications.

Assessing Modulus of Elasticity

To assess the Modulus of Elasticity (E), I would measure the slope of the linear region of the stress-strain curve, as this represents the material’s elastic behavior. By dividing the stress by the corresponding strain in this proportionality range, the modulus can be calculated. This value is pivotal as it quantifies a material’s stiffness and determines its ability to deform elastically under stress. Accurate measurement requires precise instrumentation to ensure the stress-strain relationship remains within the elastic limit of the material.

Why is Universal Testing Important in Material Testing?

Universal testing is critical in material testing as it provides comprehensive data on a material’s mechanical properties, including tensile strength, compressive strength, and elasticity. By subjecting materials to controlled conditions, universal testing machines ensure accurate and repeatable results that are essential for evaluating material performance. This testing helps engineers and manufacturers determine whether a material meets specific strength and durability requirements, guiding design decisions and ensuring safety and reliability in applications across industries.

Evaluating Mechanical Properties of Materials

To evaluate the mechanical properties of materials, several technical parameters must be considered. These parameters include, but are not limited to:

- Tensile Strength – This measures the maximum stress a material can withstand while being stretched or pulled before breaking. It is typically expressed in units such as megapascals (MPa).

- Compressive Strength – This defines the capacity of a material to resist compressive forces without failure. Like tensile strength, it is expressed in MPa.

- Young’s Modulus (Elastic Modulus) – This parameter quantifies the stiffness of a material and is represented as the ratio of stress to strain in the linear elastic deformation region, measured in gigapascals (GPa).

- Elongation at Break – This indicates the strain a material experiences before rupture, typically represented as a percentage (%).

- Flexural Strength – Relevant for materials subjected to bending forces, this measures its capacity to resist deformation under load, expressed in MPa.

- Hardness – Hardness tests (e.g., Brinell, Rockwell, or Vickers methods) measure a material’s resistance to localized plastic deformation.

- Impact Strength – This quantifies the material’s ability to absorb energy and resist fracture under sudden loading, measured in joules (J).

By systematically assessing these parameters, engineers can characterize materials accurately and determine their suitability for specific applications. Each parameter aligns with industry standards to ensure precision and reliability in outcomes.

Importance of Testing Standards

Testing standards are critical for ensuring quality, consistency, and reliability in material performance evaluations. Standardized tests provide a unified methodology for assessing key properties such as hardness, tensile strength, and impact resistance, enabling comparison across materials and industries. By adhering to established standards developed by organizations like ASTM, ISO, or DIN, manufacturers can ensure that their materials meet regulatory requirements and customer expectations. These standards also facilitate reproducibility, allowing results to be verified and replicated across different laboratories globally. Furthermore, they play a crucial role in product safety and innovation, offering a benchmark for compliance while driving advancements in material science.

Applications in Quality Control and Product Development

- Material Consistency Testing: Standards ensure that materials used in production meet predefined specifications, minimizing batch-to-batch variability and ensuring uniformity in final products.

- Defect Detection: Advanced testing techniques can identify potential flaws or weaknesses in materials, allowing manufacturers to address issues before products reach the market.

- Compliance Verification: Adhering to standardized protocols aids in verifying that products meet regulatory and industrial requirements, reducing the risk of non-compliance penalties.

- Process Optimization: Data obtained from standardized testing can be used to refine manufacturing processes, improving efficiency and reducing waste while ensuring product reliability.

- Prototype Evaluation: During product development, standardized testing methods are utilized to evaluate prototype performance under simulated real-world conditions, guiding iterative improvements.

What Are the Different Types of Testing Machines?

Testing machines can be broadly categorized into universal testing machines, tensile testing machines, compression testing machines, fatigue testing machines, impact testing machines, hardness testing machines, and dynamic testing machines.

|

Type |

Purpose |

Material |

Test Type |

Key Feature |

|---|---|---|---|---|

|

Universal |

Versatile tests |

Metals, etc. |

Multiple |

All-in-one |

|

Tensile |

Pull strength |

Polymers, etc. |

Tensile |

Force-specific |

|

Compression |

Stress limits |

Concrete, etc. |

Compressive |

Stress testing |

|

Fatigue |

Durability test |

All materials |

Cyclic Loads |

High precision |

|

Impact |

Shock energy |

Metals, etc. |

Impact |

Quick stress |

|

Hardness |

Surface tests |

Metals, etc. |

Hardness |

Intrusion eval. |

|

Dynamic |

Motion tests |

Complex mats. |

Dynamic loads |

High velocity |

Difference Between Electromechanical and Hydraulic Systems

Electromechanical systems rely on electric power and mechanical components to generate motion, offering precision and energy efficiency, while hydraulic systems utilize fluid pressure to produce force, enabling high power density and consistent force output.

|

Parameter |

Electromechanical |

Hydraulic |

|---|---|---|

|

Power Source |

Electricity |

Fluid Pressure |

|

Energy Efficiency |

High |

Moderate |

|

Precision |

Excellent |

Lower |

|

Force Output |

Limited |

High |

|

Maintenance |

Less frequent |

Frequent |

|

Load Handling |

Moderate |

Heavy loads |

|

Speed Control |

Easy |

Moderate |

|

Environmental Impact |

Cleaner |

Risk of leaks |

|

Noise Levels |

Low |

High |

Specialized Material Testing Machines

Overview of Specialized Material Testing Machines

Material testing machines are critical tools used for evaluating the mechanical properties of materials under various conditions. Common tests conducted include tensile, compression, flexure, and fatigue testing, helping industries ensure product quality and conformance to standards. Below is a concise breakdown of key types and their applications:

- Universal Testing Machines (UTMs)

Universal testing machines are versatile systems capable of conducting tensile, compression, and bending tests. They accommodate a wide range of materials, from metals and polymers to ceramics, and are equipped with precise load cells for accuracy. Common applications include determining tensile strength, elastic modulus, and elongation properties under controlled loading conditions.

- Hardness Testing Machines

These machines measure a material’s resistance to deformation, typically using methods such as Brinell, Rockwell, or Vickers hardness tests. Hardness testing is essential for applications like determining wear resistance and suitability for load-bearing components.

- Dynamic and Fatigue Testers

Fatigue testing equipment evaluates material performance under cyclic loading, estimating the durability and lifespan of a component, particularly in critical sectors like aerospace and automotive. Dynamic testers often simulate real-world stress conditions to uncover potential failure points.

These specialized machines integrate key technologies such as electromechanical or hydraulic systems, each tailored for specific testing scenarios. Advances in data acquisition software further enhance precision, reproducibility, and reporting capabilities in materials research and quality control.

Choosing the Right Testing Machine for Your Needs

When selecting a testing machine, I focus on three main criteria—application requirements, system functionality, and budget constraints. First, I assess the specific materials and testing standards I need to meet, such as tensile, compression, or fatigue testing. This ensures that the machine aligns with my industry’s standards, whether it’s ASTM, ISO, or another specification. Second, I evaluate the core technologies of the system, such as whether an electromechanical system would suit my needs for precision at lower loads or if a hydraulic system is better for high-force applications. I also consider advanced features like data acquisition software for analysis and automation capabilities. Lastly, I balance these needs with my budget, ensuring that the chosen equipment provides optimal performance without unnecessary cost. This structured approach helps me select a testing machine that is efficient, reliable, and tailored to my requirements.

Reference Sources

-

Tensile testing of metallic materials: A review – A comprehensive review discussing tensile data and the design of tensile testing machines.

-

Design and development of a miniaturised tensile testing machine – Focuses on the design of a miniature tensile testing machine for educational purposes.

-

Open-Source Flexible Material Tensile Testing Apparatus – Discusses an open-source tensile testing machine and its applications.

-

High rate tensile tests–Measuring equipment and evaluation – Explores high-rate tensile testing and the reliability of mechanical properties measured.

-

Top Tensile Testing Machine in China

Frequently Asked Questions (FAQs)

Q: What is a tensile testing machine?

A: A tensile testing machine, often referred to as a universal testing machine, is used to determine the tensile strength and other properties of materials, such as tensile behavior and tensile load when a force is applied.

Q: How does a tensile testing machine work?

A: A tensile testing machine works by applying a tensile force to a material specimen. The machine measures the change in length and the force applied to determine the tensile stress and other mechanical properties.

Q: What materials can be tested with a tensile testing machine?

A: Tensile testing machines can test a variety of materials, including metals, plastics, and composites. They are versatile and can assess the tensile and compressive properties of different materials.

Q: What is the purpose of using a tensile grip in testing?

A: Tensile grips are used to securely hold the material specimen in place during testing. They ensure that the tensile force is applied evenly across the specimen’s original length to obtain accurate results.

Q: What is the significance of the stress-strain curve in tensile testing?

A: The stress-strain curve is crucial for understanding the material’s response to tensile stress. It shows the elastic region, where the material returns to its original length, and the plastic region, where permanent deformation occurs.

Q: How do Instron universal testing machines differ from other tensile testers?

A: Instron universal testing machines are renowned for their precision and reliability. They offer advanced features for accurate measurement and analysis of tensile behavior under various testing conditions.

Q: What is the role of hydraulic universal testing machines in tensile testing?

A: Hydraulic universal testing machines use hydraulic power to apply a tensile force. They are often used for testing larger specimens or when higher force is required for testing the tensile strength.

Q: Can tensile testing machines measure shear properties?

A: While tensile testing machines primarily test tensile properties, some universal testing systems are equipped with additional fixtures to measure shear properties, allowing for a comprehensive analysis of material strength.

Q: Why is it important to test the tensile strength of materials?

A: Testing the tensile strength of materials is essential for quality control and ensuring material performance in applications. It helps predict how materials will behave under tensile and compressive forces in real-world conditions.