The basic understanding of materials is significant to quality and efficiency, especially in construction, product development, and manufacturing. With this, the comprehending material testing comes in, a substantial and dependent field knowledgeable of the various techniques that undergo evaluations of the behavior of the materials under different circumstances, forces, and effects. This blog post outlines the different kinds of material tests that are essential in understanding the state of a place, as well as the significance each type has to the different fields where they are used. In the mark, this blog also aims to attract different types of people to its content, starting from students, engineers, and, for general information purposes, the person desiring to visit the material sciences.

Introduction to Material Testing

What is Material Testing?

Material research is the examination and validation of materials used in construction. It is an extensive field that involves the physical, mechanical, and chemical research of materials. The main purpose is to check if the material is appropriate for particular applications and conditions such as stress, heat and wear. This ensures that materials are constructed according to specified requirements.

Material research adds value to the products by ensuring that they are compliant, reliable and safe, reducing the probability of financial losses. Manufacturers and engineers are able to confirm and guarantee the suitability of materials by verifying physical properties and durability, as well as flexibility the project or material demands. For example, when it is repeatedly put to use, the material used in the construction and automotive industries should be able to withstand forces that come in contact with it during duty.

Material research serves as a valuable tool in research and development. Engineers and scientists are able to design and develop specialised materials that can be used in various applications. When it is accompanied by an understanding of the capabilities and limitations of a material, research can be undertaken to see if better performance, weights, and sizes can be achieved. Material research frees the heavy burden of product and material checks with regard to standards from production. The information can be used to make informed decisions.

Importance of Material Testing in Modern Industries

Material testing is significant in the current industries as it authenticates the quality, reliability, and function of the materials to be applied wide ranged. It helps in the determination of material strength, persistence, and its reactivity to various environmental factors, which significantly contributes with the compliance to specified industry standards and also in developing with the stronger regulations. The industries, with the thorough testing, can shun the possible material breakdowns, lessen safety threats, and protect the belief of the customer towards the product.

The information concerning the material testing, which is immense, helps in the innovation and product development of the company. Engineers and designers rely on the outcomes of the tests in the selection of the appropriate material for specific applications, and as a result, to optimize the design and functionality. It also influences the achievement of the cost-effectiveness of the company by minimizing the chances of overworking the material, implementing quotas waste of resources, resolving of the enterprise that materials conform with the expected conditions of operation of the designs.

Moreover, sustainability is also promoted, and the development of eco-friendly and waste-reducing materials is supported. Performance of materials is more understandable and so the life of the products can be extended, promoting the effective utilization encil of products, eventually lowering the exploitation of iron ore and all this helps in reducing the environmental impact. To sum up the above, I can say that materials testing can be noted to be sustainable practice, which is fueling the economic growth and is ing the sustainability itself to rise and to move ahead with the assistance of quality and reliability in the construction, automobile, aerospace, and health sector.

Overview of Types of Materials

Materials can largely be grouped into categories according to their characteristics and use. For instance, there are metals, polymers, ceramics, and composites.

Metals:

Steel, aluminum, and copper make it to the list of aluminium types. They are categorized under metals. Due to their stronger and highly conductive characteristics, they are highly categorized alongside electronics and transport and are well-suited for their assembly. The automobiles section and airlines and the car, as well as aeroplanes, have found a soft spot with these substances.

Polymers:

Packaging, medical devices, and consumer products are some of the most rubber and plastics that are lightweight that are resistant to corrosion and are much used in the world. This is because with their flexibility and cost effectiveness, they have been able to infiltrate the market and excel financially. Polymer science advances continue to provide much-needed problem solutions across different fields.

Ceramics:

Inorganic materials are ceramics and they are non-metallic, unrivaled in ease and inorganic materials are ceramics they are non-metallic, unrivaled in ease of use, electromobility, volume resistivity and they are unbreakable. Ceramics are used in engine constructions especially in electronics and medical implants which can be interfaced with the human body and they greatly be improved the batterie life and efficiency.

Composites:

When we talk about composites, it falls in the more extensive categories and is added there as it combines two or more materials that are quite different from each other and are materials of composites. fiberglass and m carbon finde materials and composites are added technology that is construction. along with aeroplanes, and composites can be defined as sports eauipments. aeroplanes.

The advancement in the technology is predominately due to the utilization of, rather, composites from various sectors; and acceptance of the technology that in reality is. To usethe, the enabling of this smart technology also does. It is a defining aspect of the improvement in technology that is reality.

Types of Material Testing Methods

Tensile Testing

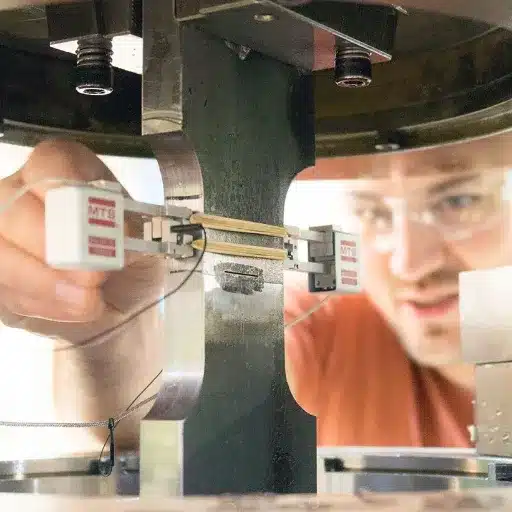

Tensile testing is an experiment that is used for the purpose of getting the mechanical properties of materials by exerting force upon the material. This experiment is important because it helps in knowing the mechanical properties such as strength, ductility, stiffness, and also, the elasticity properties. This facilitates the assessment of how materials can be used in different applications. The sample is elongated under force and the material’s reaction is recorded.

The testing helps in getting the tensile strength, yield strength and also the elongation at the fracture point. Tensile strength can be defined as the maximum stress that a material can take before it breaks. Yield strength is the stress at which the material starts to deform. Elongation at fracture is the maximum stretch that a material can take before deformation. Selection of the material helps in safety of construction, aerospace, and other sports equipment.

The testing is carried out by standard equipment and a universal testing machine is used. The material is clamped, a force is applied, and the material’s stress-strain behaviour is recorded. Assurance of meeting the krequisite standards for the application of the materials is necessary. Testing also makes sure of the being able to meet the standards and to the application of the material.

Hardness Testing

The testing of hardness levels plays an important part in the process used to define a type of materials slashed from unity, a materials ability to resist deformation and or scratching. Doing a materials test also shines a spotlight on a materials reliability and the ease by which it can be damaged during its life, which is imperative to the proper assessment of a materials use. This type of testing has been put within the borders of such industries as construction, aerospace, and engineering to confirm the consistence of materials and its worth.

There are various strategies used to test hardness, such as Brinell, Rockwell, and Vickers testing. All of the methods involve the use of some kind of indenter to the sample that is pushed with a defined force and a measuring the reading of the indentation for analysis. Depending on the type of material and the needed outcome, Brinell and rockwell testing are used mostly for metals; however, for the better resolution of the testing, especially metals, a Vickers test is often preferred.

When the hardness is measured accurately, a manufacturer or an engineer can take the necessary measures to adjust to changes that are crucial to the product’s use. The testing also helps identify the weak points of a material, which in turn aids in maintaining the integrity of a product. Proper hardness testing is guaranteed to yield higher outcomes in terms of quality, and this is maintained in the long term, which assures better outcomes in different applications.

Fatigue Testing

The fatigue test stands out in the sense that it makes use of the machine over and over again, just as systematically assessing the intensity and resilience of materials. This assessment gives us a clearer picture, predicting the time until the materials would be of no use, offering the manufacturers an insight for long-term planning, enabling them to focus on it. The aim is to ascertain the tool’s maximum capacity to bear pressure, which can be repeated for as long as one needs.

In materials testing, the main form of carbon is the wear test, which is done by using a certain type of wear testing material. The wear test is very important for determining the durability and resistance limits of any given material, until it breaks. The wear test can be of any type of material itself, and its main function is to determine if the material can sustain & execute any sort of cyclic loads or forces on it, and the wear test is done until the material. The wear test signals a change in the material; otherwise, it has no value.

Applying fatigue testing methods has proven to be beneficial in several industries, since it provides the manufacturers with knowledge on how to improve the product. The implementation of aerospace parts and medical equipment, along with the carriage of goods, makes it more efficient for transportation. To perfection in all industries, the units are critical in keeping up with the latest technologies, significantly increasing the effectiveness of the applications of the equipment itself.

Key Tools and Equipment in Material Testing

Universal Testing Machines

Universal Testing Machines (UTMs) are an essential bit of gear used to test the quality of materials. These devices are designed to specifically assess and perform tension testing, compression, and shear strength of various materials and materials samples. Testing the materials in this way can help developers determine how well they perform under various types of force within different types of environments. Tension testing, for example, allows the sustainable tension, elastic limit, yield, and ultimate tensile strength (UTS) to be ascertained. These tests coupled with testing viscoelasticity like in plastics and contemporary materials, thermal expansion tests, buckling tests, cyclic tests, and impact can offer a lot of information.

UTMs are regarded as the backbone of the modern industrial revolution for their impact on the ease of mass production, the rapid advancements in material processing and technology, and their impact on the quality of life. Many companies around the world are looking for a material that has as many advantageous properties as possible. This is the reason globally available properties – compliance with useful function and non-abrasive function with low friction – are the most regarded and sought for. Businesses worldwide have made it their goal to find materials that hold all their required features and the support of which is ensured by the outstanding properties which go along with them.

Spectrometers

Utilizing the specific part of the electromagnetic spectrum in which light exists, we can gather a large amount of knowledge with the help of light regarding matter or light interaction matter. One of the applications of spectrometers is to understand the material composition, and chemical composition. A spectrometer can and is effectively used to further analyze and provide information that can be categorized about matter.

There are lots of applications that spectrometers provide. With the help of spectrometers, we are effectively able to study the chemical compositions of matter and understand the light absorption and its subsequent chemical reactions. New subfields such as environmental sciences are scientific disciplines that are globally developing. Technologies such as spectrometers are a crucial aspect in accelerating the development of skills and technologies that can make the world a better place.

It is a known fact that matter is made up of a set of different chemicals, or in shorter terms, is comprised of substances. On the basis of this standpoint, it should be widely understood that in environmental protection spectrometers or science with regard to the environment cannot be overlooked. Even in waste management, the main aim is to process a variety of medical, household, agricultural and other types of waste. The semantics of protecting law and common sense, as a matter of public good, should be understood by adults and by students.

X-Ray Diffraction Tools

Different deltoids are asked about the material. Sample crystals must be ordered, X-rays must be inquired about, measurements of the length of the masking tape with the already polished bits need be taken in some kind of triangle, and more questions need be asked. Those x-rays are asked about and reflected from other samples. The X-ray Powder Diffraction is an essential tool in evaluating the crystalline material. Various aspects of the material such as the atomic arrangement of lattice, crystal structure, residual strain can be evaluated by X-ray methods. In modern times, X-ray powder diffraction methods are suggested for quality check of polymeric materials and its application. In the field of geography, environmental studies, geotechnology, metallurgy and other disciplines, X-ray instruments are helpful in structural dependencies of the control systems.

The use of X-ray Powder Diffraction is extremely important and useful as it prevents the sample from being altered or destroyed. For analysis in the industrial and scientific sectors, this is advantageous. In addition, the method helps calculate lattice characteristics as well as gain judgment sizes and strains in both macroscopic and microscopic respects.

The instruments are irreplaceable for studying the natural environment and many other fields in the world, such as pharmaceuticals, metallurgy, and environmental science. For example, in environmental studies, one can employ X-ray diffraction to identify minerals. Pharmaceutical and health corporations employ X-ray diffraction to assess the purity of water, medicinal fluids, metal doses, and antiretrovirals, therefore allowing them trace lifelong care packages.

Benefits of Material Testing

Improved Reliability of Materials

Quality and safety compliance are the main benefits of testing materials. Detecting issues is of the essence in both materials in the raw state and finished products. This information might amount in changes in the design or the manufacturing process. With testing, it is now possible to reliably predict performance of the materials under various conditions. This maximises the life of the materials and reduces downtime from product failures.

For instance, by doing a fatigue test together with the hardness and tensile testing, it’s possible to more closely check to see how well the combination of the material can be pushed under stress. Critics can claim that this is an extra cost, but in the long run it eliminates the delays and costs of failed products and provides a product with better performance on the market and a longer service life.

Moreover, health and safety regulations and the harmonisation of standards—products are now forced to comply with several standards with traceability to the tested material, ensuring consistency. Businesses investing to ensure that their products are in compliance will save funds across the board. At the end of the day, the brand of such companies, as well as their goodwill, will flourish through different value-added services.

Compliance with Industry Standards

Companies must be able to verify that their materials match specific standards to deliver. This issue is resolved by performing material testing, which examines the physical, mechanical and chemical material properties and their application to guarantee reliability and safety.

The reason material testing is done is to establish that the specific material meets the accepted global standards and laws. Global standards and laws are beneficial to nearly all industries, such as construction, manufacturing, cars, or airplanes, to ensure uniformity and fabrications, and most important, safety. It is possible to impose material regulations including the presence of chillers and heaters through united nations, advocating for low corporate prices.

Companies benefit from material testing as it helps in preventing future problems and enables some level of risk management, in addition to helping some of the companies to improve quality.131 businesses can make the necessary changes to the material and designs by finding the problems quicker. This means they can avoid the equivalent of a catastrophe, which also means that credibility, reputation, and ethics is acquired for the organisations.

Cost Efficiency in Production

Materials testing is a technique through which materials of any kind, including metals, plastics, ceramics, gels, adhesives, fibres, and even pure chemical,s are evaluated and analysed. The testing also includes determination of the mechanical, chemical, and electrical properties of the materials to know their strength, reactivity, conductivity, and many more of the material. This kind of testing also includes evaluations which also take a look at the materials stored and how they are going to be used, including the stress, temperature, and environmental nature as well. This helps companies and different parties to choose the right materials, which suits the needs and requirements of the products and processes they would like to institute.

At the front end, material testing helps in getting rid of the waste in the production process and reduction of delays during production, leading to the reduction of costs. In any stage of production, any defects are eliminated when materials are tested early, which is beneficial as during the production process, the cost of rework is much lower. This approach encourages the use of high-quality material which is cost-effective. it also improves the use of resources when it comes to production.

In addition, material testing leads to the reduction of costs when it comes to the operations and to the additional resources used, as it helps in extending the life of the products and improves performance. The need for expensive replacements and the repairs is reduced. During material testing, both the production and the materials testing is enhanced as it helps a lot in making better, simpler decisions; it helps in reducing the risks and this leads to very cost-effective and easy production process.

Emerging Trends in Material Testing

Integration of Automation in Testing

Automated material testing offers the industry a range of massive benefits like reduced human error, enhanced repeat testing efficiency, and improved accuracy. Automated systems assist by reducing time-consuming tasks and costly errors, which can be expensive but are cheaply automated. More samples can be tested in a shorter amount of time and improved results can be guaranteed, which is important to maintain supervisors’ standards of high-quality product control.

Lately, the most advantageous benefit of incorporating automated testing of materials is in the handling of repetitive tasks. Automated machines can now run tensile, compression, and fatigue tests with little to no human intervention. This does not only cut down on labor fees but also allows engineers to manage more challenging and laborious jobs, thereby improving overall productivity in the testing environment.

Automation also plays a vital role in the exhaustive capturing and analysis of data. Current automated systems come with sensors and software that oversee the testing of the different variables. They can move through processes, which they are good at, and produce fine, up-to-the-minute reports. This kind of precision and insight, in conjunction, assists in adjusting methods of production and as a result, helps to produce better materials.

AI-Powered Analysis Techniques

Technologies in material science are greatly influenced by the emergence of machines that can provide significant and precise data and insights. These rely majorly on the diverse and advanced processing algorithms, which makes it easier to assess material properties and possible defects. Through data-based forecasts and pattern recognition, machines make material testing faster and virtually eliminate the inaccuracies of manual assessment.

Certainly, the ability to make performance predictions under different conditions is a powerful advantage in material testing. Equipment training based on AI algorithms printed on AI chips pairs with modeling material reaction to stress, temperature, and pressure variations using said equipment. This greatly accelerates the creation of new materials, ensuring the quality and full scale production of the item along with the corresponding cut and any available materials and equipment, eliminating the trial-and-error process.

Moreover, AI supported tools are of help with material testing by controlling monitoring needs in real-time. For these systems, the centralized sensor data is perpetually analyzed and any even slight changes or anomalies indicating a fault in the material’s structure or fabric are detected. This framework approach strengthens safety and ensures all material produced is in compliance with strict standards. The use of AI has made material testing more credible and flexible in that it is attuned to the new needs of industry.

Sustainability-Focused Testing Practices

Sustainability and the environment are the primary focus and things are no different in the material testing industry. These practices ensure quality, quality and safety in the material. Additionally, the waste and resource conservation alongside testing processes is crucial in the testing industry. It is better to continue using materials and carrying out non-destructive testing methods like ultrasonic and x-ray methods alongside other methods for reduced emissions and constant wastewater avoidance and reduced use of new materials.

What is more, growing concerns in the world has also made it possible to use renewables and recyclable materials in the testing industry. Advanced systems are already in the market for cutting down emissions and to check energy overconsumption. AI and data-driven methods of working are already in place to improve efficiency of testing, hence cutting down need for unwarranted repetitive testing work. This not only lowers the overall operations expenses but it also cuts down the need for the resources.

Frequently Asked Questions (FAQ)

Q: What does material testing?

A: Material testing involves a process to check of the physical and model properties of materials. It uses different techniques to put materials under certain conditions and loads to make sure such materials meet the standards and specifications of their applications.

Q: Tensile testing, compression tests, bend tests, and corrosion testing – what are the other types of material testing?

A: There are various other types of material testing like tensile testing, compression tests, bend tests, and corrosion testing. Each method is used to test, check, and examine a specific property like strength, ductility and resistance for a material to environmental factors that helps in ensuring the meeting of the required product standards and quality of materials and components.

Q: A tensile testing machine is used in material testing? How?

A: A tensile testing machine is used to measure the tensile strength of a material. Such a machine helps in measuring the amount of load that the material can bear while being stretched until it breaks. This will help in getting information on the material’s stretching and in addition to that, mechanical property.

Q: What is the purpose of compression together with the compression tests in material testing?

A: Compression tests are carried out to assess materials in response to compressive loads. They are specifically carried out to assess the building’s compressive rocks and with the qualification to see if they can do the construction work and in addition to that to check on the materials that are there for the compressive rocks to see if they do meet the criteria of the construction which is in use.

Q: In the processing of quality control, how does testing of materials come into play?

A: Since it provides manufacturers of goods the tools they needs to test specific properties of raw materials, material testing is a key part of quality control. The use of the said machines allow a straight-forward and objective assessment of whether products can work as intended, which is of utmost importance for consumer products.

Q: Material testing, how do testing standards affect it?

A: Testing standards are the guidelines that govern how material tests are conducted. They are vital because they ensure the same procedures are followed across multiple test sites. This leads to the accurate comparison of material properties. It is thus imperative for the development of new materials and quality oversight to follow those standards.

Q: Can a brief explanation be provided on what testing is on a material failure point?

A: The occasion in material testing when a material undergoes the phase where it fractures, deforms, and breaks itself due to the load is referred to as a failure point. It’s important to note that there is a specific type of testing used to determine the material’s failure point. Adjusting a material’s mechanical characteristics is important in addressing the material engineers want for a particular engineering process.

Q: What are the tests carried out to evaluate the mechanical and physical properties in materials and What are the outcomes to be assessed?

A: When materials are under testing, the mechanical, and physical properties are examined and yield tensile strength, compressive strength, elasticity, ductility, and hardness. A crucial matter when choosing a material is its ability to respond to a range of stimuli, and its effectiveness in meeting the specific material requirement of an application.

References

- Materials Testing | Strength, Durability & Quality – Britannica – Defines materials testing as the measurement of characteristics and behavior of substances like metals, ceramics, and plastics under various conditions.

- 21 Different Types of Material Testing – Xometry – Explains material testing as a process to understand a material’s properties and behaviors in specific environments and under specific loads.

- What is Material Testing – Ametek Test – Describes material testing as a technique to determine the physical and mechanical properties of raw materials and components.