Introduction to Rubber Testing

Testing of rubber is a series of processes that measure the physical, mechanical, and chemical characteristics of rubber materials in order to meet specific standards of performance required for any given application. The primary tests perform checks on tensile strength, elasticity, hardness, aging resistance, etc. These tests tell a lot about durability and suitability of particular rubbers in various conditions. Thus, rubber testing is done for quality control, product development, and regulatory purposes that put rubber components to situations better reflective of real-life applications to guarantee their utmost reliability and safety.

What is Rubber Testing?

Rubber testing is a universal term that refers to a series of operations that measure the physical, mechanical, and chemical characteristics of rubber materials to ensure that they meet set specifications for the intended use. Modern rubber testing utilizes new methods: tensile strength, elongation at break, compression set, resistance to degradation by the environment, and so on, with methodologies including dynamic mechanical analysis (DMA), thermogravimetric analysis (TGA), and Fourier-transform infrared spectroscopy (FTIR) among others. Adding to that list are tests for specific applications such as how the rubber performs when exposed to heat, ozone, or certain chemicals, which essentially try to mimic real-life operating conditions. These technologies do not only secure reliability and safety of products but also ensure adherence to strict industrial regulations and the enhancement of product life cycles. Rubber testing becomes more of a necessity when we talk about automotive seals, medical devices, or conveyor belts as a way to keep quality control and quality improvement in materials networking.

Importance of Rubber Testing in Various Industries

Rubber testing has an appurtenant role in the success of almost any industry, as it guarantees the materials so tested would meet performance, durability, and safety standards expected for any given application. In areas such as automotive industries, rubber testing is of utmost importance to verify that rubber materials that form component parts like tires, belts, and seals resist extreme temperatures, abrasion, and pressures, and in so doing, aid in safeguarding the users and improving the efficiency of vehicles. Whereas in the medical industry, rubber testing guarantees that the elastomeric materials used in gloves, tubing, and seals are biocompatible, are sterile, and can undergo the sterilization process without losing their physical integrity. Rubber testing also finds application in the construction industry to ascertain that the materials for vibration isolation, waterproofing, and sealing systems will perform well under varying environmental conditions. In general, rubber testing assures the basis for compliant materials with international standards like ASTM and ISO while pushing the forefront of advances toward new materials designed for high-performance applications.

Overview of ASTM Standards in Rubber Testing

ASTM standards are well known to provide essential requirements on which quality, safety, and performance of rubber materials are based in the various industries. Some of the most important standards include ASTM D2000, generally specified for elastomer compounds, based on stringent physical property requirements and performance criteria under various operating and environmental conditions; ASTM D412 describes methods for determining tensile strength, elongation, and stress-strain properties of materials and thus provides useful information on the mechanical behavior of a material under test; ASTM D2240 generally describes the test method for the measurement of hardness of rubber materials using a durometer, which is an important parameter for applications where hardness requirements are very stringent. Thus, this standard ensures the reproducibility and reliability of test results, thereby promoting international trade by assuring conformity with accepted test methods used worldwide.

Common Rubber Testing Methods

Tensile testing measures the mechanical properties of rubber vis-à-vis tensile strength, limit of elongation at break, and stress-strain behavior. The specimen is gripped at both ends and pulled until it fractures, thus providing useful data for the evaluation of durability and performance during stress. ASTM D412 is widely used as one of the standards.

Hardness testing, on the other hand, measures a rubber’s resistance to deformation. This property is measured as per ASTM D2240 using a device called “durometer.” Hardness is an important parameter, considering specific rigidities that different applications require, and hence forming the basis of performance specifications.

It determines the retention capacity of rubber material to restore to its original thickness after a compression force has been applied at a specific load and temperature within a given time. This test is important for seals and gaskets.

Abrasion resistance testing determines how rubber materials undergo the process of erosion from friction between a substrate and rubber under different conditions. One instance where the method given in ISO 4649 is crucial is an environment of high friction involving tires and conveyor belts.

Aging and heat resistance tests examine how rubber materials will endure under conditions of prolonged heat, oxygen, and other environmental factors. This in turn allows predicting of lifespan and performance degradation so that the material can be optimized for use under very tough operating conditions.

Each of these testing methods provides information vital to the characterization of rubber properties, which allows materials to qualify for application-based functional and safety requirements of different industries.

Tensile Strength and Elongation Testing

Taking into account the mechanical properties of rubber materials when they are stressed, tensile strength and elongation tests must be carried out. It is the tensile strength measurement of test material subjected to forces until it fails or the maximum tensile forces applied to it until breaking; elongation is the test that measures the extent to which it can be stretched and deformed before all transformation into a percentage of the original length. These tests are done generally by means of a Universal Testing Machine (UTM). The rubber specimen is clamped in these machines, tension is applied, and testing is carried out until failure.

Modulus (stress at a defined strain), breaking point, and elongation at break are among the course parameters studied during these tests. Many aspects will affect the results, including those of material composition, curing, and temperature during testing. Information on tensile and elongation properties is very useful for determining durability, flexibility, and quality for the specific application, applying industrial standards such as ASTM D412 or ISO 37 accordingly. This would be essential to industries like automotive, aerospace, and manufacturing, where the functions of rubber components must be realized under various mechanical loads.

Hardness Testing: Techniques and Instruments

Rubber hardness tests consider resisting any deformation by applying a known force to a given area. Usually, Shore hardness is applied; it measures an indentation’s depth with respect to fixed pressure and time. Shore A or Shore D units are mainly utilized depending on the degree of elasticity or stiffness of rubber involved. Shore A is used for soft rubbers, while test hard rubbers are best tested with Shore D. Then there is the IRHD test, which provides somewhat higher precision and is also supported by international standards like ISO 48. These assessments are valuable in satisfying industry requirements and help manufacturers decide whether the rubber components they produce are suitable for a variety of applications-from sealing to vibration damping.

Compression Set Testing and Its Significance

The compression set test is an important method that is designed to assess a material’s ability to hold its elastic properties when subjected to prolonged compression under special temperature and time limitations. This test measures the residual deformation of a rubber or elastomeric material after it is compressed between two rigid plates to a defined thickness for a specified amount of time. The most important reason for these tests is for looking into the long-term performance of materials used in situations where it is very important that they maintain the efficiency of the seal or the structural integrity under stress.

Specialized Equipment for Rubber Testing

Various specialized equipment is provided to account for the entirety of testing requirements when rubber testing is carried out; each instrument has a different specification of the materials to be tested. Examples of some of the most important include:

1. Compression Set Testers

A measure of the ability of an elastomer to sustain permanent deformation when subjected to prolonged compression. Such testers are necessary for materials used as seals and gaskets.

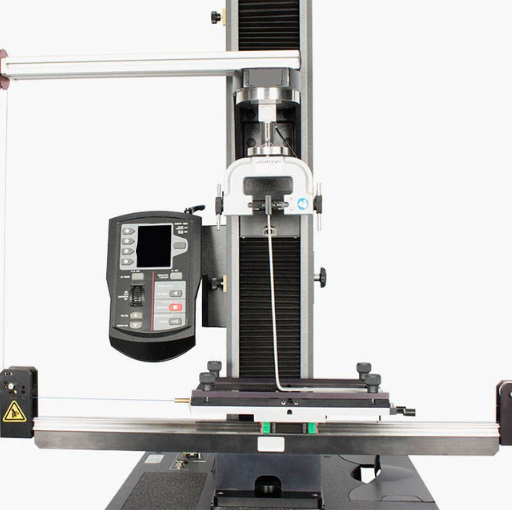

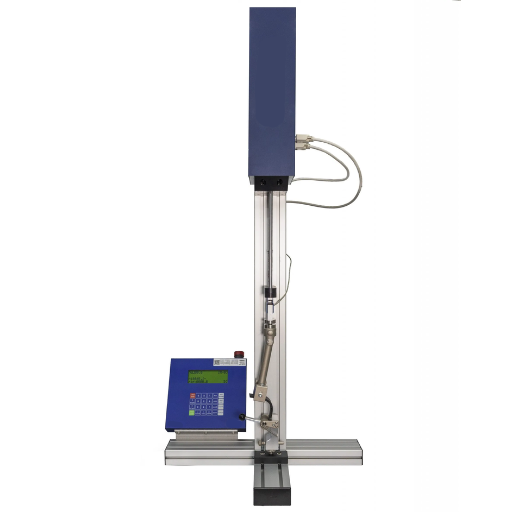

2. Tensile Testing Machines

These machines are capable of testing the tensile strength, elongation, and modulus of rubber, which emotion the need for the material in environment requiring durability and flexibility.

3. Hardness Testers (Shore Durometers)

These are the key instruments used to test the hardness of rubber and to provide data on the resistance of the material to deformation.

4. Abrasion Resistance Testers

These testers test the wear resistance of rubber subjected to friction, simulating situations encountered in such other high usefulness situations like tires and conveyor belts.

5. Dynamic Mechanical Analyzers (DMA)

These instruments provide information about the viscoelastic behavior and performance of rubber materials when dealing with different temperatures and frequencies.

6. Aging Test Chambers

These chambers allow simulation of accelerated environmental exposure to heat, ozone, or UV irradiation to test material stability and performance over time.

When combined, these instruments can fully describe the rubber material, confirming their conformity to a certain industry requirement and assuring expected reliability in their applications.

Overview of Rubber Testing Instruments

Rubber testing instruments are used to assess the mechanical, chemical, and thermal properties of rubber materials so as to verify the suitability for one or the other application. Instruments most commonly used are:

| Instrument | Primary Function | Key Applications |

|---|---|---|

| Universal Testing Machines (UTMs) | Measure tensile strength, elongation, and compression characteristics | Mechanical performance evaluation |

| Hardness Testers | Test rubber hardness with standard scales such as Shore A | Material structural attribute determination |

| Rheometers | Determine viscoelastic and curing properties | Processing and final rubber properties |

| Abrasion Resistance Testers | Simulate wear conditions | Performance and durability under stress |

| Aging Test Chambers | Simulate environmental factors | Accelerated aging analysis |

These instruments help to control and test the quality of rubber materials and products in accordance with industrial standards such as ASTM and ISO, as a guarantee of the durability and reliability of rubber products.

Using Durometers for Hardness Measurements

Rubber hardness testing by durometers is conducted by measuring the resistance offered by the rubber to indentation under a specified force. The commonest scales utilized for rubber materials are Shore A and Shore D, standing for relatively softer and harder compounds, respectively. The normal procedure is to apply the calibrated indenter to the rubber surface according to standards like ASTM D2240, and an accurate reading is obtained after a few seconds as the value will stabilize. To achieve reliable results, it is worth noting that it is important to select the right scale, carry out the tests under consistent conditions, and correctly calibrate several devices regularly.

Tensile Testers and Their Applications

Tensile testers, also known as Universal Testing Machines (UTMs), are the sole instrument for measuring the fundamental mechanical behavior of materials under tensile, compressive, or flexural loads. Primarily, they serve one function: measuring the tensile strength of materials, elongation, yield strength, and modulus of elasticity. Tensile testers are used by manufacturers, aerospace, and construction sectors to test metals, polymers, and composites to ensure that their work remains structurally reliable and durable. A specimen is first placed under a holder, to which a controlled amount of force is exerted, after which the opposition of the specimen to force until either breaking or deformation is recorded, the standard test method is followed, such as ASTM or ISO. Procedural calibrations, the alignment of the instrument, and sample preparation are very important to have exact results of tests that will be repeated.

Industry Standards Governing Rubber Testing

Rubber testing is governed by key industry standards to ensure uniformity, reliability, and quality of testing procedures. Among the famous standards are ASTM D412 for tensile strength and elongation, ASTM D2240 to measure hardness using a durometer, and ISO 37 to cover the tensile testing of vulcanized or thermoplastic rubbers. These standards specify the conditions to prepare specimens, conditions for tests, and techniques of measurement to enable consistent evaluation of rubber, both mechanically and into several applications and industries.

ASTM Standards: A Guide to Compliance

Adhering to ASTM standards in rubber testing guarantees reliability, accuracy, and repeatability in the evaluation of material properties. The standards provide a stringent framework for the preparation, testing, and analysis of rubber products, whereby all test results meet the preset requirements and hence usefulness for manufacturers and consumers alike. For example, ASTM D412 outlines the procedure for tensile strength and elongation tests, which are crucial in determining how rubber will stand up to mechanical stresses in terms of durability and flexibility. ASTM D573 determines heat treatment of rubbers and their materials, being pertinent test methods for analyzing aging processes of rubbers capable of yielding information on the expected property performance of materials in high-temperature ambient temperature conditions.

ISO Guidelines for Rubber Testing

Key ISO Standards

- ISO 37: Determines tensile strength, elongation and stress at break of materials

- ISO 188: Analyzes heat resistance through accelerated aging tests of vulcanized or thermoplastic rubber

- ISO 815: Deals with compression set testing that assesses material recovery ability after compression

- ISO 4649: Covers abrasion resistance testing methods

ISO standards cover testing and evaluation of rubber materials and ensure consistency and reliability applicable to industries throughout the world. The maintenance of standardization of rubber products is thereby supported on an international level by these guidelines.

The Impact of Standards on Testing Processes

Basically, standards influence rubber testing processes by giving an explicit protocol and methodology, leading to standards with consistent reproducible, reliability-based results. For example, ISO 37 determines tensile stress-strain properties with procedures that ensure uniformity in material strength and elasticity evaluation. ISO 4649, on the other hand, may be informative concerning critical tops wear performance through abrasion resistance. ASTM standards such as ASTM D2000 are used extensively to specify rubber in engineering; thus, an engineer can classify and select rubber according to physical and chemical properties needed for a specific application. Some manufacturers functionally reduce variations within production, can better predict material performance, and enhance world trade through adherence to these standards accepted globally.

Advancements in Rubber Testing Techniques

The recent development of rubber testing analysis methods is oriented toward maximum precision, efficiency, and reproducibility in the evaluation of materials. The latest technologies, such as dynamic mechanical analysis, provide an understanding of viscoelastic properties with respect to temperature and frequency. Thermal analysis is crucial for providing information regarding thermal stability and characteristics of decomposition, such as thermogravimetric analysis and differential scanning calorimetry. Nondestructive testing methods like ultrasonic testing and X-ray tomography have been introduced for evaluating any interior defects without affecting the sample, while the innovations highly improve the reliability of the prediction of rubber performance and development of high-performance materials.

Innovations in Rubber Process Analyser Technology

Recent developments in rubber process analyzer technology have brought revolutionary change in evaluation techniques to observe rubber dynamic and static properties under different simulated processing conditions. Owing to the developments in sensitivity and measurement range, modern RPAs can be employed for an accurate analysis of viscoelastic properties of rubber materials, namely storage modulus, loss modulus, and tan delta. Advanced software integration techniques with features such as real-time data processing and multi-parameter optimization are implemented, improving accuracy in predicting processability and hence end-use performance. Automatic sample-loading devices and temperature control systems, among others, considerably improve the reproducibility and efficiency of testing, enhancing workflows in both quality control and research within rubber manufacturing.

The Future of Rubber Testing Services

From my viewpoint, the future of rubber-testing services will revolve around automation, machine learning, and phenomena of sustainability. Advanced automated testing systems will be implemented, minimizing human erection and maximizing efficiency in obtaining real-time data collection and analysis. Machine learning algorithms will be applied for predictive modeling in order to foresee material behaviors under various conditions even before the commencement of the tests. There will also be an urgent pursuit toward sustainable testing methods, wherein testing engages on environmentally friendly practices and materials congruent with global environmental goals. Such innovations will bring in improvements in testing accuracy aside from hastening production processes while keeping pace with industry demands for innovation and sustainability.

Importance of Compliance with Test Standards

Importance of complying with test standards in rubber testing could be discussed in view that such compliance ensures uniformity, reliability, and safety in application. The way I see it, given that materials comply with these standards, it follows that in any specific industry, rubber materials will exhibit favorable performance and durability as dictated by their particular operative conditions. It further promotes international trade by certifying that these products satisfy an internationally recognized standard such as ASTM or ISO. Moreover, non-compliance will bring with it increased chances of failure in service, promote conflicts with regulations, and cast doubt on the credibility of the associating parties who should have otherwise proved their commitment to quality and exactitude in production.

Reference Sources

-

Understanding Rubber Testing Methods

This guide covers 7 major areas of rubber testing, including 30 individual test methods and procedures. -

How to Test the Quality of Rubber

A detailed blog post discussing various rubber tests such as hardness, compression set, rheology, and more. -

Rubber Testing 101

An overview of physical and analytical testing methods for rubber materials. -

A Guide to Rubber – An Overview

This article provides insights into rubber materials, their properties, and their applications.