When evaluating the durability and strength of materials, particularly in geotechnical and engineering applications, selecting the appropriate testing method is critical. Two widely recognized approaches are the Puncture Resistance Test Fixture and the CBR Static Puncture Test Fixture. While both are designed to assess a material’s capacity to withstand puncture forces, their objectives, methodologies, and applications differ significantly. This article will serve as a detailed guide to help you understand the distinctions between these two test fixtures. By clarifying their purposes, operational techniques, and specific use cases, we aim to empower engineers, researchers, and industry professionals to make informed decisions tailored to their testing requirements.

What Is a Puncture Resistance Test and How Does It Work?

A puncture resistance test measures a material’s ability to withstand forces that could penetrate its surface. This is achieved by using a standardized testing apparatus, where a pointed probe or fixture is pressed against the material at a controlled speed until penetration occurs. The primary objective is to determine the material’s strength and durability under such conditions. This test is widely used in industries like packaging, textiles, and construction to evaluate product performance and ensure safety and reliability. Results from puncture resistance tests provide critical data to help select materials suited for specific applications.

Exploring Puncture Test Methods for Geotextiles

Puncture test methods for geotextiles are designed to evaluate their ability to withstand localized forces, such as those caused by sharp objects, which is critical in ensuring long-term performance in construction and environmental applications. The most commonly utilized test standards are ASTM D6241 (Static Puncture Test), ASTM D4833 (Pin Puncture Test), and ISO 12236.

- ASTM D6241 involves applying vertical pressure using a standardized plunger on a geotextile specimen clamped securely, measuring the force required to puncture it. This test is frequently used in ground reinforcement and landfill applications due to its focus on evaluating suitability under heavy loads.

- ASTM D4833, on the other hand, employs a smaller, pointed probe to assess penetration resistance, simulating conditions with sharp, localized stresses. This method is widely applicable for lightweight geotextiles used in less demanding applications.

- ISO 12236, similar to ASTM D6241, emphasizes evaluating puncture resistance under a defined pressure but is more commonly adopted for international projects due to its global recognition.

Each method focuses on specific aspects of performance and material behavior, making it essential to select the appropriate standard based on the intended application and environmental conditions. Combining test data provides a comprehensive performance profile for geotextiles, ensuring they meet structural, environmental, and safety requirements effectively.

The Role of ASTM Standards in Puncture Testing

- ASTM D4833 – Standard Test Method for Index Puncture Resistance of Geomembranes and Related Products

This standard evaluates the puncture resistance of geomembranes by utilizing a puncture probe and measuring the force required to penetrate the material.

- ASTM D6241 – Standard Test Method for Static Puncture Strength of Geotextiles and Geotextile-Related Products

This method determines the static puncture resistance using a steel plunger to simulate the force exerted by sharp objects under static loading conditions.

- ASTM D3787 – Standard Test Method for Bursting Strength of Textiles – Diaphragm Bursting Strength Tester Method

While not exclusively for geotextiles, this standard assesses the resistance of fabrics to bursting, which is closely related to puncture performance under pressure.

- ASTM D5514 – Standard Test Method for Large-Scale Hydrostatic Puncture Testing of Geomembranes

This standard enables the evaluation of puncture resistance by subjecting geomembranes to hydrostatic pressure over large-scale samples, simulating real-world stresses.

- ASTM F1306 – Standard Test Method for Slow Rate Penetration Resistance of Flexible Barrier Films and Laminates

This test addresses the slow-rate penetration resistance, which is critical for understanding puncture behavior in barrier films and laminates within geotechnical applications.

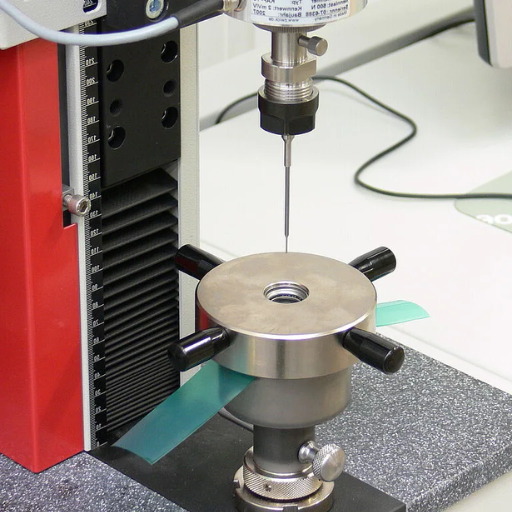

Equipment Used in Puncture Resistance Testing

1. Universal Testing Machine (UTM)

-

- Purpose: Measures the force required to puncture geomembranes and barrier materials.

- Key Parameters:

- Load cell capacity (typical range 1 kN to 50 kN depending on the material being tested).

- Crosshead speed for slow-rate penetration (commonly 50 mm/min as per ASTM standards).

- Recording precision (down to ±0.5% of the load applied).

- Puncture Probe or Indenter

- Purpose: Simulates the real-world concentrated stress applied by sharp objects.

- Key Parameters:

- Probe material (steel or hardened alloy for consistency).

- Standardized shape and diameter (e.g., 3.18 mm hemispherical tip for films).

- Hydrostatic Pressure Test Apparatus

- Purpose: Evaluates puncture resistance under uniform static pressure for large sample areas.

- Key Parameters:

- Water pressure application range (up to 200 kPa or as specified by standards).

- Sample chamber dimensions (dependent on the test specifications).

- Clamping and Fixture Systems

- Purpose: Ensures the test material remains securely fixed without slippage during testing.

- Key Parameters:

- Firm grip without inducing artificial stress concentrations.

- Compatibility with varying sample sizes and thicknesses (flexible adjustments to accommodate materials up to 3 mm thickness).

- Data Acquisition System

- Purpose: Records penetration force, displacement, and time with high accuracy.

- Key Parameters:

- Sampling rate (preferably ≥10 Hz to capture detailed force-displacement curves).

- Digital interface for data visualization and analysis.

These tools, when used under controlled laboratory conditions, enable accurate and repeatable measurement of puncture resistance, ensuring compliance with specified standards and providing critical insights into material performance.

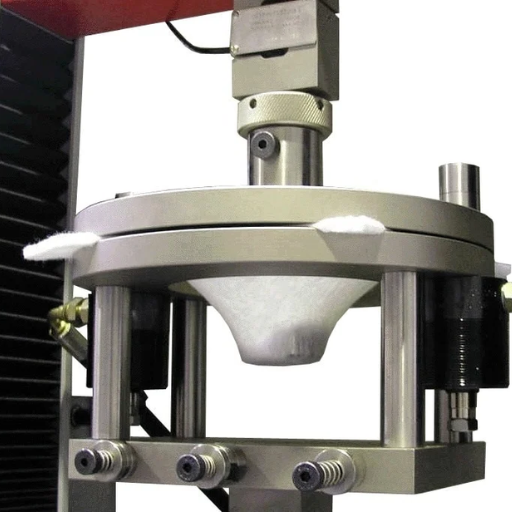

Understanding the CBR Static Puncture Test

The CBR (California Bearing Ratio) static puncture test is a procedure designed to evaluate the resistance of geotextiles and related products against penetration under static conditions. This test simulates a concentrated force applied to the material, thereby measuring its puncture resistance and helping to determine its suitability for specific applications.

Key Parameters of the CBR Static Puncture Test:

1. Sample Preparation: The material is clamped securely to ensure uniform tension during testing.

- Test Apparatus: The setup includes a metal plunger of standardized diameter, which applies force perpendicular to the material’s surface.

- Testing Procedure:

- The plunger moves at a constant rate of displacement (e.g., 50 mm/min) to prevent rate-dependent variations.

- Force and displacement data are recorded continuously using high-accuracy sensors.

- Performance Metrics:

- Maximum force at rupture provides key data on material strength.

- Total energy absorption reflects the material’s ability to distribute applied forces.

By controlling these parameters and analyzing the results, the test offers a reliable way to compare material performance and verify compliance with engineering design requirements.

Key Aspects of the CBR Puncture Test

The California Bearing Ratio (CBR) Puncture Test is a critical method for evaluating the strength and load-bearing capacity of compacted soil samples, subgrades, and similar materials used in construction. The key aspects of this test can be summarized as follows:

1. Purpose of the Test:

-

- The test assesses the resistance of materials against penetration under standardized loading conditions. This data is essential for designing infrastructure like pavements, roads, and airfield runways.

- Test Procedure:

- A cylindrical plunger applies a uniform penetration rate of 1.25 mm/min to the prepared material sample.

- The resistance to penetration is measured and compared to that of a standard crushed rock material, yielding the CBR value as a percentage.

- Interpretation of Results:

- Higher CBR values indicate stronger, more load-resistant materials.

- Typical CBR values range from 2%-10% for clay, 20%-80% for well-graded sandy gravel, and up to 100% or more for crushed stone.

- Applications:

- The data supports pavement thickness design, subgrade evaluation, and material compliance checks with established engineering criteria.

By synthesizing these aspects, engineers and researchers obtain a comprehensive understanding of material performance under applied loads, contributing to safe and efficient construction designs.

How ASTM D6241 Influences CBR Test Procedures

ASTM D6241, which focuses on testing the static puncture strength of geotextiles and related products, plays a pivotal role in enhancing the accuracy and reliability of California Bearing Ratio (CBR) test procedures. This standard ensures that geotextiles used in soil stabilization and reinforcement are evaluated for their resistance to puncture forces, a critical parameter when designing layers subjected to heavy loads. By incorporating ASTM D6241, engineers can select materials that contribute to increased bearing capacity and longevity of subgrades.

Key Technical Parameters:

1. Puncture Strength:

-

- ASTM D6241 measures the tensile strength required to rupture a geotextile when punctured. Values typically range from 500 N to over 10,000 N, depending on material specifications.

- Displacement Rate:

- The puncture test under ASTM D6241 specifies a constant displacement rate, commonly around 50 mm/min, ensuring consistency across tests.

- Geotextile Composition:

- Material types (e.g., woven, non-woven) directly affect puncture resistance and their integration in improving CBR results.

Influence on CBR:

- By evaluating puncture strength, ASTM D6241 facilitates the selection of high-performance geotextiles that mitigate soil deformation under load, leading to higher CBR values.

- The use of compliant geotextiles enhances subgrade stability, distributes applied loads more evenly, and reduces the risk of rutting, all critical for proper CBR testing and field performance.

By aligning CBR test procedures with ASTM D6241 standards, a deeper understanding of geotextile-soil interaction can be achieved, promoting design structures that meet rigorous engineering demands.

Types of Geotextiles Tested with CBR Method

The primary types of geotextiles tested using the CBR method include woven, non-woven, knitted, and hybrid geotextiles, each of which is evaluated based on its performance in load distribution and subgrade reinforcement.

|

Type |

Material |

Structure |

Uses |

CBR Benefit |

|---|---|---|---|---|

|

Woven |

Polypropylene |

Interlaced |

Roads |

High strength |

|

Non-Woven |

Polyethylene |

Random fibers |

Drainage |

Load spread |

|

Knitted |

Synthetic |

Knitted loops |

Reinforcement |

Flexibility |

|

Hybrid |

Mixed fibers |

Combined |

Versatile |

Broad utility |

Comparing Puncture Resistance and CBR Static Puncture Tests

Puncture Resistance Tests focus on measuring the resistance of a material to penetration under load, while CBR Static Puncture Tests evaluate a material’s strength and stiffness when subjected to static pressure.

|

Parameter |

Puncture Resistance |

CBR Static Puncture |

|---|---|---|

|

Objective |

Resist load |

Stiffness measure |

|

Load Type |

Dynamic |

Static |

|

Material Tested |

Flexible fabrics |

Geotextiles, geomembranes |

|

Standard Used |

ASTM D4833 |

ASTM D6241 |

|

Key Results |

Puncture force |

Penetration resistance |

|

Use Case |

Durability checks |

Structural design |

|

Device |

Cone or puncture tip |

CBR plate |

|

Test Speed |

High speed |

Slow speed |

Differences in Test Equipment

The primary difference between test equipment lies in the apparatus and testing procedures used for dynamic and static puncture resistance evaluation. For dynamic tests like ASTM D4833, a cone or puncture tip is employed at high speed to measure the force required to penetrate flexible fabrics. This setup replicates the rapid application of force seen in real-world impacts. Conversely, static puncture tests such as ASTM D6241 utilize a CBR (California Bearing Ratio) plate and exert slow, controlled force. This methodology assesses the material’s resistance to sustained pressure and deformation under static load conditions. These distinctions reflect the need to tailor test equipment to match anticipated field conditions, thereby ensuring the accuracy and relevance of durability and structural design evaluations.

Varying Testing Standards and Protocols

To address the outlined questions effectively, it is essential to compare the technical parameters and objectives of various testing standards. For dynamic puncture resistance, as governed by EN ISO 12236, the drop height, mass of the probe, and probe geometry are tightly controlled, typically involving a steel probe weighing 500 grams dropped from a height of 500 millimeters. These parameters aim to emulate real-world impact scenarios, such as falling debris or machinery loads.

On the other hand, static puncture tests like ASTM D6241 focus on sustained loading conditions. This involves utilizing a circular plate with a diameter of approximately 50 millimeters, applying a compressive force at a specified rate, often 50 millimeters per minute, until peak resistance or failure is observed. This test is designed to simulate long-term pressure conditions experienced under landfill, road, or foundation applications.

By outlining these technical parameters, practitioners can choose the appropriate testing protocol depending on project-specific demands, ensuring structural integrity and field performance are accurately validated. Both methodologies emphasize the importance of standardized procedures to benchmark material performance consistently across varying use cases.

Applications in Geotextile and Geomembrane Testing

- Filtration Efficiency Testing: Testing geotextiles to determine their ability to retain soil and simultaneously allow water to pass through, hence ensuring proper filtration in drainage systems.

- Tensile Strength Analysis: Determining the tensile strength of geotextiles and geomembranes in regards to their ability to endure stress and deformation under load.

- Puncture Resistance Testing: Assessing protective membranes to sharp penetration for them to withstand damaging impacts while ensuring effective geomembrane protection at the lining applications.

- Permeability Testing: Analyzing the flow rate of water through geotextiles to determine their suitability for use in water diversion and erosion control systems.

- UV Resistance Evaluation: Assessing the effect of solar radiation on the strength of geotextiles and geomembranes to estimate potential exposure to sunlight and their durability in exterior applications.

How to Choose the Right Puncture Test Fixture for Your Needs

Choosing an appropriate puncture test fixture requires assessing multiple factors to ensure it aligns with the specific requirements of your application. Begin by evaluating the type of material to be tested, considering its thickness, flexibility, and intended use. Ensure the fixture is compatible with the testing standard appropriate for your industry, such as ASTM D4833 for geotextiles, to guarantee reliable and comparable results. Additionally, consider the fixture’s load capacity and its compatibility with your testing equipment, as well as any customization options available to accommodate unique sample geometries. Durability and ease of use are also vital factors, as they contribute to consistent results and efficient operations. By thoroughly analyzing these criteria, you can select a puncture test fixture that optimally satisfies your operational and material testing needs.

Factors to Consider: Static Puncture Strength and More

When evaluating static puncture strength and related factors, I prioritize several key aspects to ensure precise testing and reliable results. First, I verify the load capacity of the puncture test fixture to confirm it aligns with the maximum force requirements of my materials. Next, I assess the fixture’s compatibility with my testing apparatus, ensuring seamless integration without modifications. If my samples have unique geometries, I explore customization options that enable accurate and repeatable testing. Additionally, I emphasize the durability of the fixture, selecting materials and designs that resist wear under prolonged use. Lastly, ease of use remains critical—features such as straightforward setup and user-friendly adjustments significantly contribute to operational efficiency and consistency in obtaining test data.

When to Use ASTM D4833 vs. ASTM D6241

When deciding between ASTM D4833 and ASTM D6241, I consider the specific application and the relevant technical parameters of the materials being tested. ASTM D4833 is primarily used for puncture resistance testing of geotextiles and related products, employing a small diameter probe (8 mm) to simulate localized puncture forces. This method is particularly effective for lighter geotextiles or when testing scenarios involve point loads. On the other hand, ASTM D6241 evaluates the puncture strength of geotextiles through a much larger, 50 mm diameter plunger, making it suitable for heavier geotextiles or nonwoven materials that must withstand more distributed load scenarios.

Key technical parameters:

- ASTM D4833:

- Probe diameter: 8 mm

- Applicable for lighter or thin geotextiles

- Test measures concentrated puncture resistance

- ASTM D6241:

- Plunger diameter: 50 mm

- Designed for heavy-duty or thick geotextiles

- Simulates distributed puncture loads across a larger contact area

By aligning these parameters with the functional requirements of the material, I ensure proper standard selection to obtain meaningful, application-specific data.

Understanding ISO and International Testing Standards

The International Organization for Standardization (ISO) establishes global benchmarks for testing materials such as geotextiles, ensuring consistency, reliability, and reproducibility of results across different regions and industries. ISO standards like ISO 10319, which assesses geotextile tensile properties, and ISO 12236, for static puncture resistance, are widely utilized. These standards are meticulously developed through a consensus-driven process involving experts from various countries, promoting compatibility in methods and data interpretation.

By standardizing methodologies, ISO ensures that materials tested under their protocols perform as expected in specific applications, enabling seamless trade and engineering practices across borders. Additionally, international standards harmonize with other frameworks, such as ASTM, to address regional requirements while maintaining global applicability. For professionals working with geotextiles or related materials, understanding and adhering to these guidelines is critical to achieve precise, comparable, and scientifically validated results.

The Importance of Puncture Testing in Geotextiles Industry

Puncture testing is a fundamental procedure in the geotextiles industry, designed to evaluate the material’s resistance to penetration under applied force. This is particularly significant as geotextiles are often used in environments where sharp objects, such as rocks or debris, may impose mechanical stress. By measuring puncture strength through standardized methods such as ASTM D6241, engineers can ensure the durability and performance of geotextiles under real-world conditions. The data obtained from puncture testing supports material selection, quality control, and compliance with regulatory requirements, thereby securing the structural integrity and longevity of projects utilizing geotextile materials.

Ensuring Puncture Resistance in Woven Geotextiles

It is imperative to ensure the puncture resistance of woven geotextiles through precise testing methods and careful material selection. To achieve this, I focus on performing standardized tests, such as ASTM D6241, which evaluate the materials’ ability to withstand mechanical stresses like punctures caused by sharp objects or uneven substrates. By analyzing these results, I can determine the suitability of a geotextile for specific applications, ensuring that it meets both project requirements and regulatory standards. Additionally, I prioritize sourcing high-quality woven geotextiles that offer an optimal balance of tensile strength and durability, providing reliable performance in demanding conditions.

The Impact on Geosynthetics and Related Products

The impact of geosynthetics and related products is multifaceted, influencing both the structural stability and design efficiency in engineering applications. Key effects are observed in areas such as load distribution, erosion control, and filtration, where geosynthetics provide essential functionality. For instance, their tensile strength enhances soil reinforcement, enabling the construction of steeper slopes or retaining walls without compromising safety. Typical tensile strength values for woven geotextiles range from 25 kN/m to 200 kN/m, ensuring adaptability across varying project demands.

Additionally, permeability is a crucial parameter in drainage and filtration applications. Geotextiles are designed with a permeability coefficient (k) typically between 10^-1 m/s to 10^-4 m/s, depending on the required flow rate and soil characteristics. These values are integral in preventing clogging while maintaining adequate drainage.

Abrasion resistance and puncture resistance also significantly contribute to the longevity of geosynthetics in high-stress environments. Corresponding values for puncture resistance may range from 500 N to 2000 N, ensuring robust performance under sharp or uneven conditions.

Considering thermal behavior, thermal stability becomes essential when geosynthetics are exposed to extreme temperatures, with materials being capable of functioning within a range of -30°C to 80°C depending on polymer composition. Ensuring these technical parameters align with project specifications promotes reliability and extends product lifecycle in diverse applications.

Future Trends in Puncture Testing Technologies

The evolution of puncture testing technologies is driven by advancements in materials science, automation, and data analysis. Emerging trends include the integration of automated testing systems that ensure higher precision and repeatability in results. These systems leverage robotics and AI to standardize testing procedures, minimizing human error and increasing throughput in industrial applications.

Additionally, there is growing adoption of advanced sensors and real-time monitoring capabilities, which enable detailed analysis of material responses under puncture forces. Such systems can capture micro-level data on deformation, rupture, and energy absorption, providing comprehensive insights for material optimization.

Another significant development is the use of eco-friendly testing protocols. Researchers are focusing on reducing the environmental impact of testing, including the use of sustainable or recyclable test materials and energy-efficient testing equipment. Furthermore, digital simulation tools, such as finite element analysis (FEA), are increasingly being used to complement physical testing. These tools allow for predictive modeling of puncture resistance, reducing the dependency on extensive physical trials while maintaining accuracy.

By combining these trends, future puncture testing will become more efficient, sustainable, and capable of addressing the material challenges posed by next-generation applications.

Reference Sources

-

Static Puncture Strength Test Fixture for Geotextiles – This source provides details on static puncture strength test fixtures, including their application in geotextiles and the ASTM D6241 standard.

-

Comparison of CBR and Pin Puncture Strength Testing – A research paper discussing the correlation between CBR and pin puncture strengths for woven geotextiles.

-

Test Methods – Typar – This page explains various test methods, including puncture resistance tests like ASTM D4833 and their relation to static puncture tests.

-

ASTM D4833 Test Fixture | GD4833-145 – Information on a test fixture designed to comply with ASTM D4833, which is used for determining puncture resistance in geotextiles.

- Top Test Fixtures in China

Frequently Asked Questions (FAQs)

Q: What is the primary purpose of a puncture resistance test fixture?

A: The primary purpose of a puncture resistance test fixture is to measure the force needed to puncture a material, ensuring its durability and suitability for specific applications. This test is crucial in evaluating product quality in various industries.

Q: How does a CBR static puncture test fixture differ from a puncture resistance test fixture?

A: A CBR static puncture test fixture is specifically designed to assess the puncture resistance of materials like nonwoven geotextiles using a static force. In contrast, a general puncture resistance test fixture may be used for dynamic testing machines and can accommodate a broader range of materials and testing conditions.

Q: Why is it important to secure the sample during testing?

A: Securing the sample during testing is crucial to ensure accurate and consistent results. It prevents movement or slippage that can affect the test outcome, especially in tensile testers and compression tests.

Q: What role does the test controller play in these tests?

A: The test controller manages the test machine, ensuring precise application of forces and accurate measurement of results. It is essential for maintaining consistency and reliability in both puncture resistance and CBR static puncture tests.

Q: How does the strength and elongation of a material affect its puncture resistance?

A: The strength and elongation of a material significantly impact its puncture resistance. Higher strength and elongation typically indicate better resistance to puncture, as the material can absorb more energy before failure.

Q: What is the significance of mass per unit area in puncture tests?

A: Mass per unit area is a critical factor in determining a material’s puncture resistance. Heavier materials generally offer better resistance, making mass per unit area an essential parameter in product quality assessment and civil engineering applications.

Q: Are grips and fixtures important in puncture tests?

A: Yes, grips and fixtures are vital in puncture tests as they ensure the sample is held securely in place, allowing for accurate force application and measurement. They prevent sample slippage and contribute to reliable test results.

Q: Can these test fixtures be used for both tensile and compression tests?

A: While puncture resistance and CBR static puncture test fixtures are primarily designed for puncture tests, some dynamic testing machines can be adapted for tensile and compression tests, depending on the grips and fixtures used.

Q: What industries benefit from using puncture resistance and CBR static puncture test fixtures?

A: Various industries, including civil engineering, geotextile manufacturing, and packaging, benefit from these test fixtures. They help ensure materials meet specific puncture resistance standards, contributing to product quality and performance.