Top Material Testing Machine in China. Choosing the correct machine for testing the mechanical properties of materials plays a significant role in getting trustworthy outcomes. The Universal Test Machine and the Compression Testing Machine are examples of two widely utilized devices in the material testing sector. At first glance, they may appear similar, but their unique functions, capabilities, and applications set them apart. My goal is to highlight the differences between these two machines so that you are better suited to make decisions regarding your material testing requirements. You do not need to be a scientist or an engineer to appreciate the world of material science because this article discusses the invaluable features of both machines regarding material testing. Join me in identifying the differences and breaking down the uses of both machines.

What is a Universal Test Machine?

A Universal Test Machine (UTM) is used to test the different mechanical properties of materials, for example, their tensile strength, flexural strength, and compressive strength. It measures the response of the sample while applying certain forces, hence providing relevant information on its reaction to different changes. They are used extensively in the construction, manufacturing, and material development industries because they can perform a wide array of tests.

How does a UTM work?

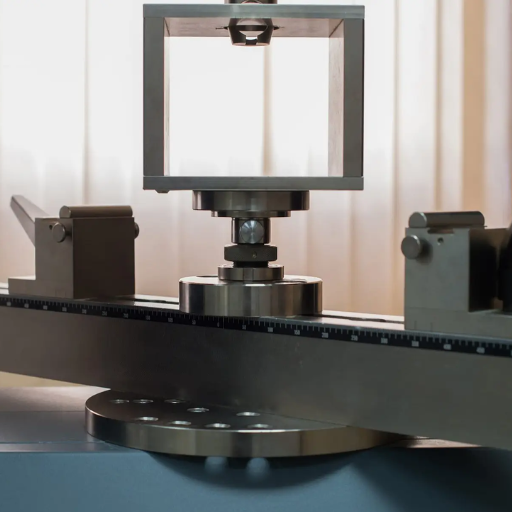

To analyze the mechanical properties of various materials, a Universal Testing Machine (UTM) applies a force to a sample in a controlled manner. The UTM has various components which include a load frame, a crosshead, load cells, fixtures and automation control systems. I explain the applications of each component below:

Load Frame – This is a rigid frame that provides and maintains mechanical support to the parts of the test system. The Frame guarantees stiffness and accuracy during the force application.

Load Cell – This measures the respective force or load that a sample experiences. UTMs have state of the art load cells that allow for precision measurement of forces in grams up to a few kilonewtons depending on the machine’s capability.

Crosshead and actuators – Crosshead, as a part that moves, applies force on the material sample while the actuator which can be hydraulic or electromechanical, controls the crosshead’s movement. The ensuring the proper application of force is maintained at all times.

Suitable Fixtures and Grips – This sample of material to be tested is gripped securely by various types of grips, namely wedge grips and various other specialized fixtures depending on the test type which can be compression, tension, or flexural tests.

Test Procedure:

The sample of the material is set between the grips or fixtures.

The actuators dictate the crosshead position to apply a preset load or displacement.

While Op-2 Extensometers mounted on the load frame record the strain, the load cell continuously captures the corresponding force being applied.

For example –

Measurement and control system software integrated with the UTM manages data collection, display, and analysis in real time. That’s why it is possible to generate:

Material properties, such as elasticity, yield strength, and ultimate tensile strength, which can be calculated from the resulting stress-strain curves obtained during testing.

Supported conclusions can be provided as explicit numerical and graphical reports aiding in research, quality checks, and even the development of new products.

Thanks to the comprehensive nature of modern UTMs equipped with digital control systems, versatility is no longer a concern. Providing a burst of new capabilities such as data processing at speeds up to 1,000 Hz to capture detailed behavior of material alongside bolts of reliability gained from machines like the Instron 5960 Series that offer automatic calibration and error detection.

Driven by the evolution of advanced technologies like robotic testing, adaptable software, and the demands posed by industries ranging from aerospace to goods testing, UTMs are being revolutionized into powerful devices.

What are the key components of a universal test machine?

A universal testing machine (UTM) is composed of several systems such as precision, accuracy, and reliability, that can overshoot or underestimate the marker accuracy of the tests performed and is a versatile system for material testing. Below are the primary components of a UTM, along with their functionalities:

Load Frame

Heavy-duty testing machines contain the main frame which is the load frame of the UTM. The housing arms are responsible for supporting all other components, and they must endure the various forces that are exerted and applied. Traditionally, it has two vertical columns which are further categorized under a cut that serves as a crosshead operating under the moving dynamic to impose the strain. Steel or aluminum are the materials best fit to provide the load frames with maximum construction strength and skeletal endurance will resulting in durability and stability.

Load Cell

The apply electrical signal which is transformed alerts that informs the system of the represented action of as a bond which helps record the fractures in the extremity of the force load sensor and of every measure buttress. Modern load cells are highly sensitive and accurate, with some capable of measuring forces from as low as 1 N to over 1,000 kN, depending on the machine’s capacity.

Crosshead and Actuator

The crosshead is the most mobile part, which creates the force on the specimen to be tested. Its movement is usually executed by an actuator of some kind, which could be a hydraulic, a servo-electric, or a pneumatic depending on the kind of machine. For example, Servo-electric systems are widely used because of their energy saving features and accuracy.

Grips and Fixtures

Grips and fixtures serve to keep the material specimen firmly fixed during the testing process. Different types of grips,如或Orthopedic type pneumatic grips or specialized attachments, are available based on the material being used and the type of test to be performed. More sophisticated grips with the ability to adapt to certain unconventional shapes are more accurate with delicate samples, thus providing better testing accuracy.

Extensometers

Extensometers are used to determine the amount of deformation or strain that has taken place on a member under load over time. Optical non-contact systems and new cameras with Laser tracking systems and video tracking systems, and nowadays it is possible to use non-contact methods to take measurements of specimen, Advanced non-contact optical extensometers are used which offer high-accuracy strain measuring capabilities.

Control and Data Acquisition System

This system controls the UTM, which allows the user to set the parameters of the test, control test speed, the force to be applied, the change of position, and other values. It captures and assesses the results of the test in the process. Most modern UTMs have accompanying highly specialized software to perform complex data processing, graphing, reporting, and even automation of these tasks.

Test Software

A testing software allows the pre-programming of test procedures to be compliant with standards set by governing bodies like ASTM or ISO. This guarantees that tests are always uniform, repeatable, and adapted to particular needs. Furthermore, some systems have features such as AI-enabled predictive analytics and error detection algorithms.

Motor or drive System

The crosshead movement is equally to the operation of a motor or drive system. For example, Servo motors are common because of their accuracy and highly controlled motion, which is crucial for everything from displacement increment testing to variable speed testing.

Safety Features

The safety of the operator is one of the areas that is given a lot of attention in modern Universal Testing Machines. The machines are equipped with emergency stop buttons, load limits, and even protective shields which minimize risk during testing.

Environmental Chambers (Optional)

UTMs can have these chambers for testing materials under specific temperature and humidity conditions. These chambers enable testing under extreme temperatures or humidity levels, providing real-world conditions for advanced material analysis. Typical ranges can include temperatures from minus eighty degrees Celsius to over three hundred degrees Celsius depending on the type of the chamber.

Tensile testing, compression testing, flexural testing, and fatigue testing are just a portion of the wide range of material tests that can be done using a universal test machine after combining interrelated parts. UTMs are continually optimized, and because of that, they provide more versatility, precision, and multifunctional use across several industries.

What types of tests can a UTM machine perform?

The Universal Testing Machines (UTM) are created to manage a wide range of tests to determine the mechanical properties and behavior of a material. Following is a list of the most important tests that can be performed by a UTM machine with explanations.

Tensile Testing

This is arguably one of the most popular uses of UTM. Tensile testing analyzes and records the reaction of a material to tensile (pulling) forces. The test will provide additional important data on tensile strength, elongation, and young’s modulus. The test is particularly important for calculatin elasticity and ductility of materials which is crucial for aerospace and construction and even manufacturing.

Compression Testing

This test, as the name suggests, applies compressive forces to a material to determine how it behaves under crushing loads. Compression testing identifies the compressive strength, yield strength, and deformation characteristics of materials. It is especially useful in materials like concrete, metals, and even ceramics under compressive forces.

Flexural (Bend) Testing

Flexural tests determine the amount of deformation that a material can resist when forced to bend. The amount of flexural strength and flexural modulus is measured by the UTM using three-point or four point bending. This type of test is particularly critical for brittle materials such as composites and even plastics and wood.

Fatigue Testing

Fatigue testing consists of constant application of cyclic loads to analyze the endurance and life of a material or component concerning changing stress levels. This test is especially important for materials that operate in dynamic or vibrating environment which includes automotive and structural components.

Shear Testing

Shear testing evaluates the ability of a material to resist forces that cause sliding layers to move relative to one another. This type of test is important for glue, stoppers and other materials which are used in construction where high shear strength is required.

Hardness Testing

While less frequently performed on basic UTMs, advanced models can execute hardness tests, measuring the material’s strength and resistance to indentation in a given force, giving some insight into the material’s strength and susceptibility to wear.

Peel, Adhesion, and Tear Testing

Adhesive and adhesive bond assessment through peel and adhesion testing is within the reach of UTMs. Complementary to polymer and fabric materials, tear resistance is another important test.

Creep and Stress Relaxation Testing

For a prolonged period with constant material load, UTMs enable creep tests, measuring deformation over a period with constant stress, and relaxation tests which assess the decrease in stress under a constant strain.

Data Validity

The tensile strength of structural steel generally falls between 400 and 550 MPa, depending on the testing methods used.

The compression strength of concrete ranges from 20 to 40 MPa, although ultra-high performance concrete may exceed 150 MPa.

Fatigue life estimates suggest some high-strength aluminum alloys can endure up to 10 million cycles at 50% ultimate tensile strength.

Optimizations of Universal Testing Machines (UTMs) are currently being implemented to include automated data collection, real-time data analytics, and specific environmental controls. These advances guarantee Home UTMs will yield precise and consistent results across numerous testing types. With their flexibility, UTMs serve as essential devices in the research and development, quality control, and product design and development activities of various sectors.

Exploring the Compression Testing Machine

A Compression Testing Machine is utilized for evaluating the mechanical strength of materials under compressive loading. It assesses maximum compressive strength, deformation, and failure pressure level. These devices find application in construction, manufacturing, and materials science for testing metals, concrete, plastics, etc. These machines ensure that materials and components made from them are safe and perform well.

What is a compression testing machine used for?

This type of machine is made for evaluating how materials withstand compressive loads and their weakening effects due to pressure. These machines are adaptable for assessing the performance of materials under a load which considers quality control and safety assurance. Typical usage includes assessment of concrete, brick and mortar which is very important for determining if these materials will be structurally sound. For example, concrete is said to possess a compressive strength of 20 MPa for residential buildings and over 40 MPa for high-performance constructs.

Compression testing machines are also employed extensively in the testing of metals, polymers, and composite materials to characterize their deformation and failure mechanisms. More advanced models can accurately capture elastic modulus, yield strength, and fracture of the material. For instance, in the automobile industry, the compression testing is used to evaluate the under-tested realistic expository conditions for parts like springs and pistons to assess their endurance for real-world use.

Current models of compression testing machines are equipped with modern technologies like digital load controllers and data analysis software. Innovations such as automation of stress-strain diagrams, peak force capturing, and many others are positively impacting decision-making processes in the advanced sectors like aerospace, construction, and materials engineering. The machines gather important information that aids engineers and researchers in the design and development of various industrial structures.

How to measure compressive strength with a CTM?

When measuring compressive strength with a Compression Testing Machine (CTM), there is a specific method employed that ensures consistent results. The following procedures are recommended:

Sample Preparation

Accurately prepare the specimen such as cubes or cylindrical samples as per the standard dimensions figure by industry’s governing bodies like ASTM and IS codes.

In concrete standard practice, cubes are manufactured to the dimensions of 150 mm x 150 mm x 150 mm. Care should be taken that the sample is clean and unsoiled.

Sample is meant to be cured for a specific amount of time which in this case is usually 7 or 28 days for concrete so adequate hydration and strength testing conditions need to be present.

Machine Setup

Always remember to check that the CTM meets the calibration requirements dictated by industry operating procedures before commencing.

At this time, confirm that everything regarding load cells, sensors, software systems, and all other components is working for precision accuracy.

Set-up of the Sample

Carefully place the sample at the center of the lower platen of the CTM as this makes the sample less susceptible to eccentric loading.

Tilting the upper platen can result in tilted loading; therefore, it is important to do it with care.

Testing Procedure

Ensure to start the load application at a uniform rate as recommended by requisite standards, such as (1.25 ± 0.05 MPa/s according to IS 516).

Pay attention to the digital display or system software for verification purposes.

Result Documentation

Record the maximum load or peak force the sample can sustain before either cracking or crushing takes place.

Apply the following equation to determine the compressive strength:

Compressive Strength = Maximum Load / Cross-sectional Area

As in the example of a cube specimen with a face of dimensions 150 mm x 150 mm, loaded to the value of 675 kN:

30 MPa = 675,000 N / 150 mm x 150 mm.

Result Analysis

Make certain that all design compliance standards are met alongside the calculated compressive strength.

Pay attention to trends or any unusual results, particularly when multiple specimens are tested.

Safety Precautions and Routine Maintenance

Put on personal protective equipment (PPE) before operating the machine, as safety should come first.

Ensure that the CTM is cleaned and maintained regularly for optimal performance and operational longevity.

Parameters Resulting in Inaccuracy

Curing. Improper curing conditions increase the chances of not accurately measuring strength because hydration greatly affects concrete’s strength.

Sample Measuring. Be sure to measure all samples accurately, as their dimensions will affect the results; even a small deviation makes a difference.

Machine Calibration. Ensure the machine is calibrated to promote the credibility of test results.

Measuring compressive strength using a CTM is important in construction, material testing and quality control. Following the engineers ensures that buildings are safe and materials are used effectively.

What are the mechanical testing capabilities of a CTM?

A compression testing machine is used to assess the mechanical properties of construction and engineering materials. This is done by subjecting them to a compressive force. It has applications in construction, aerospace, material research, and manufacturing to meet safety and operational benchmarks.

Testing Compressive Strength: A compression testing machine is used to determine the compressive strength of concrete, ceramics, metals, and composites. The CTM applies an incrementally controlled load until it determines the upper limit of compressive force a material can withstand. This is done right before the material fails.

Testing Flexural Strength: CTM’s assess deflection under load for bending beams, slabs, and other structural components to determine the flexural strength.

Shear strength testing: Some CTMs are designed to measure shear strength by exerting a shear force on the surface of the material. This is important in determining the strength of composites when analyzing interlayer adhesion and fault resistance.

Stress-Strain Evaluation: When a CTM is used with extensometers and digital measuring systems, it can provide detailed stress-strain data. This in turn helps in calculating measuring devices from picometers to terameters. Important mechanical properties calculated through this precise measurement are Young’s Modulus, Poission’s Ratio, and ductility. Cyclic Loading Tests: Cyclic compression tests can be performed using CTMs to replicate real-world conditions by subjecting materials to repetitive loading and unloading cycles. This is essential for the study of fatigue failure of metals and polymers.

High Temperature Compression Testing: CTMs can be equipped with microwave or infrared heating units on the spindles, allowing for testing materials at elevated temperatures. This simulates operational high-heat environments encountered in aerospace and industrial activities.

According to the data from recent technological advancements, there is an increasing prevalence of integrating CTMs with IoT and automated systems. Such additions enable tighter control, data gathering, and analysis, making the systems more reliable and less prone to human mistakes. An example of this is seen in modern digital CTMs which provide real-time graphical feedback of the force applied against the displacement of the specimen, resulting in further understanding of material behavior.

CTMs are important for the development of materials used in the construction of bridges, skyscrapers, and the latest aerospace technologies. Through advanced robotics, their reliability to ensure safety, durability, and performance are greatly improved.

Comparing Tensile Test and Compression Test

The tension and compression tests are two distinctly different tests that evaluate the strength of materials using opposite forces.

Tensile Test – Evaluates the amount of tension a material can endure. Crushing a specimen up to the point at which it splits into two pieces allows for the evaluation of tensile strength, elongation, Young’s modulus and bearing rigidity. It certifies how much force can be applied to a material before it starts to deform.

Compression Test – Evaluates how a certain material performs under the application of compressive force. Checking to see at which point a specimen can be squished until deformation or failure occurs measures how much compressive strength, elasticity, and buckling resistance the specimen possesses.

All examples help for the selection of materials in respect to their most useful applications like the difference between load bearing structures and tesion bearing components.

Differences in testing equipment for tensile and compression tests

Equipment for performing tensile and compression tests is custom-made for each case to measure different behaviors of materials under diverse forces. Andres were made with separate equipment to provide unforeseen mechanical characteristics of the material, each test uses unique equipment that reflects distinct design purposes.

Tensile Test Equipment

A specimen needs to be pulled apart to perform a tensile test. This type of test is often performed using a universal testing machine (UTM) with clamps or grips holding the sample at both extremes. Important parts of the system are:

Load Cell: Measures the Ultimate test.

Extensometer: Monitors and measures the parts elonagtion and strain through particled to the degree of interfermation in ultra precise manner.

TEnsile Fixtures Pull will hold the restraining parts of the tensile grips and pull part so that applies pulling of the material imparted is applied uniformly.

Besides, it’s common for the software applicable in performing tensile tests to provide real-time analysis of stress of the specimen and deliver curves which assist in stress value defined in ultimate tensile strength, yield, sustaining and elastic modulus.

Compression Testing Units

In terms of mechanics, compression tests involve pressing a specimen between two plates or platens and determining how it behaves under compressive forces. A UTM’s base generally serves as the testing machine’s platform, while the base also features additional parts like:

Compression Platens: Smooth and rigid surfaces that apply uniform compressive forces to the material.

Displacement Sensor: Measures the degree of deformation of the specimen due to compression.

Load Capacity Adjustment: Increased machine capacity is often mandatory for stronger materials like metals or dense composites.

Equipment Variation as a Differentiating Factor

Gripping Vs Platen Mechanism Difference:

Tension tests utilize grips or wedge fixtures to pull specimens.

Compression utilizes flat plates or platens to compress.

Force Direction:

Tension force is applied in uniaxial pulling to the machine, while compressive force is exerted in uniaxial form in a compression test.

Range and Sensitivity:

Emphasis on extending devices and strain data makes elongation measuring the primary concern in tensile equipment.

Compression setups emphasize the opposite and need to have high load capacities because of the forces they may encounter.

Design of the Specimens:

Tensile test specimens are usually designed with a cross-section of a dog bone. This configuration makes certain that the samples break within the gauge’s length.

The shape of compression specimens is generally more uniform, either cylindrical or cubical, to withstand uneven stress distribution.

Modern Innovations

Newer systems can improve both accuracy and power automation with material testing equipment. Modern systems now utilize:

Digital Controllers and Sensors for the application of force and signal for data capture.

Video Extensometers which provide strain measurement without physical contact during tensile tests.

AI Integration which allows for predicting the material’s properties from previously conducted tests.

The most recent studies (quote Instron and MTS) pointed out that tensile and compression testing methods have been primary in the capture of data within the aerospace, construction, and manufacturing industries. For instance, carbon fiber reinforced composite, an aerospace grade material, undergoes tensile strength testing to evaluate its ability to withstand tension. Compression testing evaluates the material’s buckling behavior in structural components.

How do tensile and compression tests differ in application?

Tensile And Compression Tests are very different in their methods which helps derive other use cases in mechanical performance evaluation of a material. Each has a different way of applying stress and measuring strain.

The application of tensile testing begins with determining the stretching behavior of the material in value terms. The most critical properties defined with such tests include tensile strength, elasticity, ductility and ultimate tensile strength (UTS). As an example, the construction industry applies tensile testing for checking the performance of steel rebars and cables in suspension bridges because they need to make sure that those materials will withstand pulling forces. It helps estimate the risk of failure in future applications. Recent analyses, including those done on aerospace materials, indicate that titanium alloys exhibit a UTS of about 1000 MPa or more which puts them in the category of materials that can be used for frames in aircraft where there is a substantial amount of stress.

On the contrary, Compression tests target the application of a squeezing or pressing force on the material. Those tests become very crucial in any form of structure that endures compressive loads including pillars, beams and any material used in the foundation in civil engineering. Data on advanced concrete mixes recently subjected to compression testing indicate that their compressive strengths exceed 40 MPa which gives them credibility in terms of stability and resistance to buckling under heavy loads. Blending the outcomes from these tests will enable industries to pick materials tailored toward particular difficulties. As an example, carbon fiber composites might be used by aerospace manufacturers for components with high tensile requirements while titanium alloys are used for components that both tensile and compressive forces act on.

What are the typical testing procedures for each test?

In order to maintain accuracy and dependability, all testing procedures associated with evaluation of materials must follow set techniques. Further down are the latest trends relating to testing processes and comprehensive guidelines for tensile and compressive strength tests.

Tensile Strength Test

Preparation of the Specimen: A sample material is fabricated according to accepted criteria which are based on standardized guides like ASTM D638 for plastics or ASTM E8/E8 M for metals.

Mounting the Specimen: The material is fastened into the grips of a UTM so that the specimen does not move out of position.

Application of Load: The machine exerts a unilateral, steady pull on the specimen at a regulated speed until it breaks. The high loading speed also complies with the material’s standard requirement. METALS FOR INSTANCE, UTM’S 5 MM/MIN. The machine starts to fracture the sample at a calculated positive pressure.

Collection of Data: Throughout the process, stress and strain are measured via the UTM and a stress-strain curve is generated. The ultimate tensile strength (UTS), yield strength, and elongation at break are important numerical values acquired from this curve, along with many others.

Analysis of Results: Insights into the capability of a material to endure tension are offered by processing data through modern software designed for graphical representation of materials. Precise and automatic measurement tools, namely sensors, are built into many contemporary UTMs making them more reliable.

Compressive Strength Test

Preparation of the Specimen: Concrete structures are shaped into prisms or cylinders, along with test samples placed into cubes. These geometric shapes are set by particular standards like ASTM E9 and ASTM C39.

Placement in the Compression Machine: The specimen is placed precisely in the center of the compression testing machine to avoid uneven distribution of force on the specimen.

Application of Load: For concrete, an increment of 0.25 MPa/s is added, but these rates depent on the materials in question. Typically, the load is provided in a steadily increasing manner, using compression as the method.

Recording Deformation: The sensors which are already in place track displacement, and systems follow the processes continuously, ranging until failure to achieve the data which is required.

Result Interpretation: To compute the compressive strength, the value of the maximum load divided by the cross-section area of the specimen is calculated, and mapped by employing digital image correlation DIC technology to mark logically along failure modes, to provide more accuracy and precision.

Latest Advances in Testing

High-Precision Instruments: With AI prediction for failure before segment defeat, the usability and dependency have increased greatly, transforming material analysis for compression testers and Ultra Testing Machines (UTMs) dramatically.

Sustainable Testing Practices: Their purpose is to lessen the waste produced during the test, by expanding the use of eco-friendly sample preparation materials, disengaging the damaged parts of the specimen left intact to be reused later.

Data Technology updates – All-in-one data management systems which record results and integrate with simulation tools are being adopted by laboratories.

Innovations and procedures need to be controlled for accurate evaluation of material behavior under tensile and compressive stresses which ensure applicable usage across numerous industries.

The Role of Hydraulic Systems in Testing Machines

Due to the accurate and controlled application of force, hydraulic systems are highly advanced in the testing industry. They use pressurized fluid to generate the needed force which is useful for doing tensile, compressive, and even fatigue tests. Their great results and constant accuracy guarantee reliable results, which are vital for assessing material properties. Also, because hydraulic systems maintain smooth force application and can manage heavy loads, they are widely applied in different industrial testing situations.

How do hydraulic systems enhance mechanical testing?

The use of hydraulics in mechanical testing encourages accuracy, control, forceable action, and reproducibility, all necessary in assessing material strength and endurance. This is why hydraulic systems have such extensive applications across various materials such as metals, composites, and plastics. For instance, modern hydraulic testing systems can apply forces in the range of thousands of kilonewtons which applies to large structural works such as bridges and aircraft components.

The recent outbreak of smart technologies has led to the incorporation of digital monitoring and control into hydraulics technology, enhancing precision. Data recording modifications, changes in the software algorithms, and control system interfaces allow the researchers to study the stress-strain characteristics with more detail. Industry research estimates that within the digital hydraulic systems, the variability in testing reduces by as much as 20%, increasing the reliability of data about the evaluation of material performance.

Furthermore, the smooth and precise application of force ensures accuracy, reducing the impact of mechanical vibrations or other undefined factors that can disrupt fatigue testing systems for real-world operational stress duplication on materials. This characteristic of continuously supporting cyclic load strengthens the versatility of hydraulic systems. The advancement of technology alongside these features has established them as an essential component of modern mechanical testing systems.

What are the benefits of hydraulic systems in UTMs and CTMs?

The incorporation of hydraulics brings irreplaceable benefits to Universal Testing Machines (UTMs) and Compression Testing Machines (CTMs) ,making them critical components in the testing of materials. One of the advantages is their precision in delivering high force capabilities, enabling the testing of materials with different strength levels, from fragile specimens to robust industrial components. With the capability to apply forces from a few hydraulic kilonewtons (kN) up to thousands of kN, hydraulic technologies outperform others in load generation and control.

Moreover, precision force control contributes to minimal vibrations and consistent pressure application, ensuring accurate and repeatable test results. Studies show that the force variability with which hydraulic actuators work is nothing more than 1%, which is ascribed to the wide range of testing conditions hydraulic actuators are subjected to. This is optimal for fatigue, tension, compression, and cyclic testing.

Additionally, they are reliable under extreme conditions. Cost-effective in the long run despite the initial investment. They endure extreme shock and sustained heavy loads while maintaining high efficiency. This endurance reduces maintenance costs and guarantees durability over long-term taxation.

The recent development of servo-hydraulic systems has increased the adaptability of hydraulic machines because of their programmable control of load application. For instance, advanced load sensors and digital control interfaces equipped to hydraulic machines can offer real-time monitoring that can further enhance data testing accuracy and precision.

Also, the addition of energy-efficient hydraulic pumps and hydraulic fluid control systems has increased the ecological sustainability of these machines by lowering power consumption while still maintaining high testing standards. Industry studies suggest that upgraded hydraulic systems can guarantee a 30 percent decrease in energy consumption, resulting in a positive impact both economically and environmentally.

Due to their remarkable strength, precision, dependability, and versatility, hydraulic systems have maintained their position as an essential part of Universal Testing Machines (UTMs) and Compression Testing Machines (CTMs), ensuring continued support for resource material testing and analysis.

Choosing the Right Testing Solutions for Your Needs

Once you start outlining the requirements regarding testing solutions, begin by selecting the tests that correspond to the materials and properties you wish to examine. Determine the testing standards for the capacity and value of the machine’s precision, classifying the tests as tensile, compression, or fatigue testing. Check the measurement tool against your industrial standards and the flexibility of its uses. Select the best fitting solutions from reputed manufacturers who emphasize accuracy, structural integrity, and energy conservation. Last but not least, validate that the machinery has reliable technical and maintenance support to properly sustain its value throughout its life.

Factors to consider when selecting testing equipment

Accuracy and Precision

Measurement error needs to be within a minimum range to achieve accuracy and precision. All levels of testing require these attributes to be accurate and reliable. Make sure that your equipment checks all levels of accuracy. Research states that advanced testing machines have an accuracy of around 0.5 percent or closer, which makes the data dependable.

Ease of Use and Automation

Check equipment with touch interfaces and operation-enhancing features. Modern testing machines are designed with software add-ons, touch displays, and automated test cycles, lessening the amount of manual work needed in the process and adding value to productivity. For instance, in comparison to older systems, newer automated tensile testing machines can save a substantive amount of time, up to 40 percent.

Range and Versatility

Assess the device’s upper and lower limits. Greater machines are those with higher ranges of force and those that can test multiple materials, including metals, polymers and composites. Recent multi-functional innovations range from tensile to compressive and impact testing and can switch seamlessly.

Compliance with Industry Standards

Make sure the equipment has met or is certified to given international and local standards – ISO, ASTM, EN, and even custom standards – set for a specific some industry. Following these enables industries to be assured with consistency and credibility in results. This is crucial for aerospace and automotive industries.

Integrating Data Systems for Reporting

Some machines have data integration meaning that they can collect, analyze, and compile data in such a way that it is simple to use. Their cloud based systems or LabView Software also allow for Test Result Sharing, where test results can be viewed and monitored remotely. This increases transparency and efficiency.

Warranty and Service Costs

For expensive testing devices, long-term dependability is crucial. The more expensive option is always slower with maintenance and repair, so try finding one with a stainless steel frame and wear-resistant parts. Sometimes, cost is justified, such as in recent industry analysis studies that say maintenance indeed decreases system breakdowns by up to 60%.

Social Responsibilities

It is clear that there is a growing demand to incorporate sustainability into the design and construction of testing machines. Modern systems that have low power consumption and/or energy recovery mechanisms can reduce total energy consumption by up to 25%, assisting companies in their environmental goals.

Evaluating testing equipment from this perspective allows organizations to harness changes in technology while guaranteeing performance and strategic investment.

How to determine the appropriate load capacity?

The analysis of appropriate load-bearing capacity is paramount for the equipment to function effectively, safely, and within its operational constraints. These are the major points that should be remembered.

Knowing the Requirements of the Load

Always begin by determining the greatest load that the equipment will need to endure during the periods of maximum activity. This includes both static loads (not changing and consistent weights) and dynamic loads (fluctuating or moving weights). An example would be the need posed by the stored goods and the movement for force exerted by motion. A rough estimate is always advised, considering from 20 to 25 percent safety margin over the calculated maximum load, else for unaccounted fluctuations or growth in the future.

Material characteristics and limits of stress

Think of the equipment’s material properties, for instance, the elasticity of the material’s tensile storage, endurance, etc. It is established that some materials such as carbon steel and reinforced composites, are capable of holding very high levels of stress. Typically, carbon steel can withstand stress levels of greater than 250 megapascals (MPa), making it popular in industrial settings.

Industry Standards and Safety Codes

Check the ASME (American Society of Mechanical Engineers) and ISO guidelines to locate the equipment type’s recommended load capacity. Most of these standards utilize safety coefficients to provide a wide margin of operational safety.

Simulations and Testing

Make use of simulation software and other available load testing tools. Modern programs can simulate the equipment’s performance under a variety of load conditions accurately. For example, Finite Element Analysis (FEA) tools can assist in identifying the weak points in the design structure before actual installation.

Energy and Performance Optimization

If energy efficiency is the focus, consider the power and mechanical work needed to manipulate the loads. Recent studies recommend that retrofit energy optimization on existing equipment tailored to specific loads reduces energy usage by as much as 10-15% and extends operational life.

Practical estimates of expected loads, material analyses, industry standards, and advanced technological testing allow companies to determine sensible values for their operational risks and load capacity while minimizing risks and maximizing longevity.

What are the best practices for using a tensile testing machine?

To follow the best practices for maintaining tensile testing machines in good working condition, their accuracy should not be compromised alongside the results achieved. Detailed recommendations from recent insights follow below:

Calibrate the Machine Regularly

It is essential to conduct periodic calibrations to achieve proper precision within the relevant force measurements. Current practices in the industry set a baseline of at least once a year calibration or after considerable use of the tensile testing machines. Compliance with other requirements such as ASTM E4 and ISO 7500-1 is guaranteed through proper calibration.

Understand the Material Being Tested

Comprehensive understanding of material characteristics that such as the tensile strength, elastic modulus, and elongation properties is critical. This greatly aids in choosing relevant test methods, ensuring all relevant settings in the machine are adjusted, guaranteeing results are attained without deviation.

Check for Proper Alignment

Inevitably, the specimen might come in misalignment which can lead to measurement inaccuracies in the test and uneven stress distribution to the material subjected to testing. Proper alignment of the grips and fixtures is critical to avoid incorrect results.

Use High-Quality Specimens

Test specimens must be prepared according to the relevant standards, some being ASTM D638 for plastics and ASTM E8 for metals. Test accuracy and repeatability are highly disrupted by rough edges, dimension inconsistency, and other specimens’ defects

Monitor Environmental Conditions

Temperature and humidity, among other environmental factors, can have an impact on test results, especially on materials that are more susceptible to environmental exposure. For instance, ASTM D3039 recommends an environment controlled for temperature at 23 ± 2°C for the testing of composites. Sensitive materials should be tested in climate-controlled rooms.

Document and Analyze Data Thoroughly

For optimal documentation, use contemporary tensile testing machines equipped with data harvesting software. Stress-strain curves can be readily generated and automated systems enhance the level of analysis to be conducted, thus improving the reliability of tests performed.

Perform Routine Maintenance

Load cells, grips, and fixtures should be checked frequently for any wear and tear. Moving components require lubrication and any worn parts should be replaced immediately to avert damage to the machine.

Training and Operator Competence

Ensure operators are trained to use the machine properly and interpret generated results accurately. Inadequate training tends to use with the machine severely compromises the quality of data generated.

Following these guidelines allows companies to better their processes of tensile testing while simultaneously stabilizing performance and meeting established standards.

Reference Sources

- Examining Compressive Strength of Concrete Structures by UTM

This paper highlights the application of UTM and CTM in measuring compressive and tensile strengths, enabling comparisons.

- Research on the Effect of Bamboo as a Reinforcing Material in Concrete

This work combines the results of tensile, compressive, shear, and bond tests using UTM and CTM and compares them with a detailed analysis.

- Study on The Assessment of Durability of Concrete Structures

This research also incorporates discussions of UTM and CTM concerning the chemical reactions that affect the durability of concrete.

Frequently Asked Questions (FAQs)

Q: What is a universal test machine (UTM)?

A: A universal test machine (UTM) is a testing equipment used to evaluate the mechanical properties of various materials through different tests such as tensile test, compression test, and flexural test. It can assess the tensile strength, compressive strength, and other characteristics of materials.

Q: How does a UTM differ from a CTM?

A: A UTM is designed for a variety of tests, including tensile, compression, and flexural tests, allowing for comprehensive material testing. Conversely, a Compression Testing Machine (CTM) is specifically focused on measuring the compressive strength of materials, primarily used for concrete and metals.

Q: What tests can be performed using a UTM?

A: A UTM can perform multiple tests, including tensile tests, compression tests, flexural tests, and shear tests, providing a versatile solution for material testing requirements.

Q: What is the significance of tensile testing using a UTM?

A: Tensile testing using a UTM helps in determining the tensile strength, elongation, and deformation of materials under controlled force, which is crucial for assessing their mechanical properties and performance in various applications.

Q: What are the key components of a UTM machine?

A: The key components of a UTM machine include the load frame, load cell, crosshead, grips and fixtures, and a control panel. These components work together to perform precise material testing.

Q: How does the hydraulic system in a UTM function?

A: The hydraulic system in a UTM provides the controlled force required for testing by moving the crosshead, which applies load to the test specimen. This system ensures accurate and consistent results during mechanical testing.

Q: What kind of materials can be tested using UTM and CTM?

A: A UTM can test a wide range of materials, including metals, plastics, and composites, for various mechanical properties. A CTM is primarily used for testing the compressive strength of materials like concrete and metals.

Q: Why is quality control important in material testing?

A: Quality control in material testing ensures that materials meet specific standards and performance criteria, which is essential for safety, reliability, and compliance in industrial applications.

Q: How does a UTM machine working process differ for tensile and compression tests?

A: In a tensile test, the UTM pulls the specimen to measure tensile strength and deformation, while in a compression test, it applies a compressive force to determine the material’s compressive strength and behavior under load.

Q: What role does testing software play in UTM operations?

A: Testing software in UTM operations facilitates test control, data collection, and analysis, allowing for efficient and accurate evaluation of the mechanical properties and performance of materials.