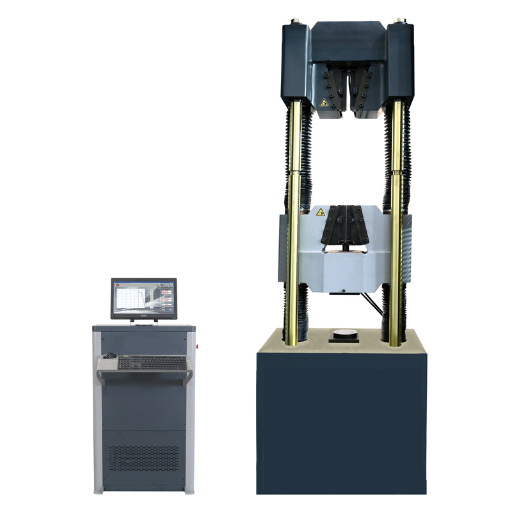

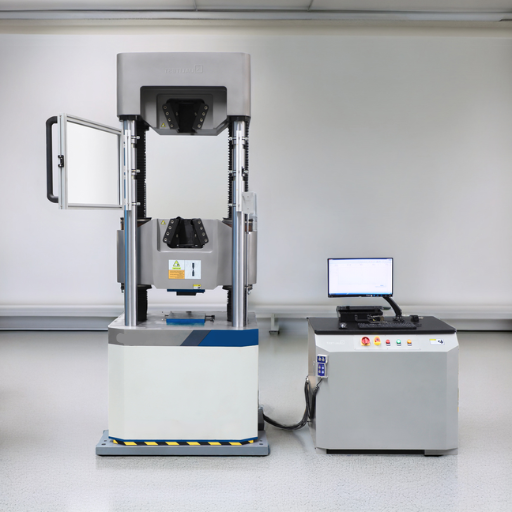

Universal Testing Machines (UTM) are essential devices in the field of material testing, providing precise and reliable insights into the mechanical properties of various materials. These machines are engineered to perform critical testing procedures, including tensile, compression, and flexural strength evaluations, making them indispensable across industries such as manufacturing, construction, and aerospace. Understanding the purpose and functionality of a UTM is vital for professionals seeking to ensure the integrity and performance of materials in demanding applications. This article will explore the core functions of UTM machines, their significance in quality assurance and research, and how they contribute to advancing material innovation in modern engineering.

How Does a Universal Testing Machine Work?

A Universal Testing Machine (UTM) operates by applying controlled force to a test specimen to evaluate its mechanical properties. The machine consists of a loading frame, grips or fixtures to hold the specimen, a drive system to apply force, and sensors to measure key parameters. During testing, the UTM applies tension, compression, or bending forces to the material while recording data such as load, elongation, and deformation. This information is then used to determine critical properties like tensile strength, yield strength, and elasticity, ensuring materials meet required performance standards.

What is the Working Principle of a UTM?

The working principle of a Universal Testing Machine (UTM) is based on precise application and measurement of mechanical forces to evaluate the physical properties of materials. The UTM operates by securely holding a material specimen within its grips or fixtures, ensuring that it is properly aligned to avoid inaccuracies during testing. Once the sample is set, the machine’s drive system—generally powered by a motor or hydraulic actuator—applies a controlled force, which may include tension, compression, flexural, or shear loads, depending on the test being conducted.

Simultaneously, highly sensitive sensors and load cells integrated within the UTM measure parameters such as the applied force, the elongation of the specimen, and associated deformations. These measurements are transmitted to a data acquisition system in real time for analysis. The stress versus strain relationship is then plotted to derive key material properties including tensile strength, modulus of elasticity, yield point, and fracture toughness. Modern UTMs are equipped with advanced electronics and software that enhance precision and facilitate automated testing, making them indispensable tools for material evaluation across industries like construction, aerospace, and automotive manufacturing.

How Is Force Applied in a Universal Testing Machine?

Force in a Universal Testing Machine (UTM) is applied via a highly controlled mechanical or hydraulic mechanism. The system typically consists of a load frame with moving crossheads driven by a lead screw (in mechanical systems) or a hydraulic piston (in hydraulic systems). The applied force is transferred directly to the test specimen through fixtures or grips, ensuring uniform distribution to prevent premature failure.

Technical parameters involved include:

- Load Capacity: Ranges from 1 kN to 3000 kN, depending on the UTM model and application.

- Crosshead Speed: Adjustable between 0.001 mm/min to 1500 mm/min for precise control during testing.

- Strain Rate: Typically controlled within 0.0001 to 0.1 s⁻¹ for standard materials testing.

- Accuracy: Load cells are calibrated to meet international standards (e.g., ASTM E4 or ISO 7500-1), ensuring force measurement accuracy within ±0.5%.

The combination of these parameters allows UTMs to apply force consistently and precisely across a variety of material testing scenarios.

What are the Components of a UTM Machine?

A Universal Testing Machine (UTM) is composed of several essential components that work in harmony to perform accurate and reliable material testing:

- Load Frame: The structural frame supports the entire machine and provides a stable platform for testing. It typically consists of two vertical columns and a movable crosshead.

- Crosshead: This adjustable component moves up or down during testing to apply tensile or compressive forces to the specimen.

- Load Cell: A highly sensitive device that measures the applied force with precision. It is often calibrated to meet standards like ASTM E4 or ISO 7500-1 to ensure accuracy.

- Grips and Fixtures: These elements securely hold the test specimen in place. Specialized grips are available for different types of materials and testing methods, such as wedge grips for tensile testing or compression platens for compressive tests.

- Actuator or Drive System: Powered by either hydraulic or electromechanical systems, the actuator facilitates the controlled movement of the crosshead.

- Extensometer: This optional accessory measures the strain on the test specimen by tracking elongation or deformation under load.

- Control System: The hardware and software interface allows the operator to set test parameters, monitor performance, and analyze data in real time. Modern UTMs often use advanced software for automation and reporting.

- Safety Features: Protective shields, overload protection mechanisms, and emergency stop buttons ensure safe operation during testing.

Each component plays a vital role in the machine’s functionality, making it a versatile tool for various material testing applications.

What Tests Can Be Performed on a Universal Testing Machine?

A Universal Testing Machine (UTM) is capable of performing a wide range of mechanical tests to determine material properties. Common tests include:

- Tensile Testing: Measures a material’s strength, elongation, and ultimate breaking point under uniaxial tensile stress.

- Compression Testing: Evaluates how a material behaves under compressive loads, determining properties such as compressive strength and elasticity.

- Flexural Testing: Analyzes a material’s ability to withstand bending forces, often used for materials like beams and slabs.

- Shear Testing: Determines the shear strength of a material, evaluating its response to parallel forces.

- Peel, Tear, and Adhesion Testing: Assesses the strength of bonded layers or the tear resistance of flexible materials.

- Creep and Relaxation Testing: Measures the deformation behavior of a material under sustained load or stress over time.

- Hardness Testing (via add-ons): Evaluates surface hardness using various hardness measurement techniques.

These tests make the UTM a versatile instrument for applications across industries like construction, manufacturing, and materials research.

What Is a Tensile Test and How Is It Conducted?

A tensile test is a fundamental mechanical test used to determine the tensile properties of materials, including their strength, ductility, and elasticity. This test involves subjecting a material sample to a controlled tensile force until it fails, allowing for precise measurements of its reaction to stress. The test is typically conducted on a Universal Testing Machine (UTM), utilizing grips to securely hold the sample while a steady, uniaxial pulling force is applied.

The primary steps involved in conducting a tensile test are as follows:

- Preparation of the Specimen: The material is shaped into a standardized test specimen, often in a “dog-bone” or rectangular shape, as specified by industry standards such as ASTM E8 or ISO 6892, ensuring consistent and repeatable measurements.

- Setup in Testing Machine: The specimen is carefully mounted between the grips of the UTM. Proper alignment is essential to ensure uniform force distribution along the length of the material.

- Application of Load: The UTM gradually applies a uniaxial tensile force to the specimen at a controlled rate. Instruments monitor stress (force per unit area) and strain (elongation per unit length) in real time.

- Data Collection: The machine records key parameters such as ultimate tensile strength (UTS), yield strength, total elongation, and the material’s Young’s Modulus (elastic modulus).

- Failure and Analysis: The test ends when the specimen fractures. The final data plots a stress-strain curve, providing detailed insights into the material’s mechanical properties and behavior under tension.

This method is widely implemented across industries, including aerospace, construction, automotive, and materials development, to ensure materials meet safety and performance requirements. Advanced testing often integrates digital extensometers and real-time data analysis for enhanced precision.

How Is a Compression Test Different from a Tensile Test?

Compression tests and tensile tests differ in terms of force direction, specimen behavior, stress type, and mechanical properties analyzed.

|

Key Parameter |

Compression Test |

Tensile Test |

|---|---|---|

|

Force Direction |

Applied inward |

Applied outward |

|

Specimen Shape |

Compressed, shortened |

Stretched, elongated |

|

Stress Type |

Compressive stress |

Tensile stress |

|

Primary Goal |

Measure compressive |

Measure tensile |

|

Failure Mode |

Buckling/cracking |

Fracture/rupture |

|

Applications |

Structural integrity |

Material strength |

What Other Types of Tests Can a UTM Conduct?

A Universal Testing Machine (UTM) can conduct shear, flexural, bend, fatigue, peel, adhesion, and cyclic tests, in addition to compression and tensile tests.

|

Test Type |

Force Applied |

Purpose |

Stress Type |

Key Use |

|---|---|---|---|---|

|

Shear |

Lateral |

Assess shear strength |

Shear |

Joint evaluation |

|

Flexural |

Bending |

Measure flexural strength |

Bending |

Beam/rigidity |

|

Bend |

Bending |

Determine ductility |

Bending |

Flexibility |

|

Fatigue |

Cyclic loading |

Estimate fatigue life |

Cyclic |

Durability |

|

Peel |

Peeling force |

Evaluate layer separation |

Tensile |

Bond analysis |

|

Adhesion |

Pulling/loading |

Check adhesion strength |

Tensile |

Coatings |

|

Cyclic |

Recurrent loads |

Analyze cyclic performance |

Various |

Repetitive load studies |

Why Is Material Testing Important?

Material testing is critical for ensuring the quality, durability, and safety of materials used in various applications. It provides valuable data on a material’s mechanical, thermal, and chemical properties, enabling engineers and scientists to predict how materials will perform under specific conditions. This process helps to identify potential weaknesses, improve product designs, and ensure compliance with industry standards. Additionally, material testing aids in validating the selection of materials for specific uses, thereby minimizing risks of failure and enhancing overall reliability in real-world applications.

How Does Material Testing Ensure Quality Control?

Material testing ensures quality control by systematically examining and evaluating the properties of materials to verify that they meet the required specifications and industry standards. This process identifies defects, inconsistencies, or weaknesses in raw materials and finished products, thereby preventing malfunctions or failures during operation. Techniques such as tensile testing, hardness testing, and impact resistance testing are employed to assess mechanical properties, while chemical analysis ensures material compositions are within acceptable limits. By incorporating rigorous testing protocols, manufacturers can maintain consistent production quality, adhere to regulatory requirements, and enhance the durability and reliability of their products in real-world applications.

What Role Does a UTM Machine Play in Determining Mechanical Properties?

A Universal Testing Machine (UTM) plays a critical role in accurately measuring and evaluating the mechanical properties of materials under various loading conditions. By applying controlled tensile, compressive, or flexural forces, a UTM provides essential data such as ultimate tensile strength (UTS), yield strength, elongation, and modulus of elasticity. These parameters are crucial for understanding the performance of materials in different applications.

Key features of a UTM include load cells with capacities ranging from a few newtons to several hundred kilonewtons, ensuring flexibility for testing a wide spectrum of materials. The machine operates with precise control of load application (commonly within ±1% accuracy) and displacement rates, adhering to standard testing protocols like ASTM, ISO, or DIN. The integration of advanced software allows for real-time data acquisition, analysis, and graphical representation, enhancing the reliability and repeatability of results.

By utilizing a UTM, industries can validate material quality, optimize designs, and ensure compliance with engineering specifications, making it an indispensable tool in material science and engineering research.

How to Choose the Right UTM for Your Needs?

When selecting a Universal Testing Machine (UTM), it is essential to evaluate key factors to match the system to your specific application requirements. Start by determining the type of tests (e.g., tensile, compression, flexural) and the maximum load capacity needed, as these dictate the machine specifications. Ensure compatibility with the materials you will test, including grips, fixtures, and environmental chambers if required. Consider the accuracy class of the UTM, which indicates measurement precision, and prioritize machines that meet relevant international standards like ASTM or ISO. Additionally, assess the software for data acquisition and analysis capabilities, ensuring it is user-friendly and supports your reporting needs. Finally, evaluate long-term considerations such as service support, calibration, and the machine’s scalability for future testing demands.

What Factors Should Be Considered When Selecting a Universal Tester?

- Load Capacity: Evaluate if the machine will achieve dead weight criteria, both safety and precision, for all your testing applications.

- Testing Speed and Range: Validate that the tester offers worthy control of speed and range for your material testing.

- Accuracy and Precision: Verify the accuracy class of the UTM in the bounds of international standards like ASTM or ISO so that it can be relied on for measurement.

- Versatility: Decide on a machine which has multilateral capabilities to accomplish tensile, compression, flexure, and shear testing.

- Grip and Fixture Options: Ensure that they can accept changeable grips and fixtures for complement sample shapes and materials along with sample geometries.

- Software Features: Assess the software for ease of use, data acquisition, and reporting features, while ensuring compatibility with required analysis methods.

- Build Quality and Durability: Evaluate the mechanical design, materials, and construction to ensure long-term reliability under rigorous use.

- Service and Support: Consider the manufacturer’s reputation for customer support, availability of spare parts, and reliable calibration services.

- Scalability and Upgradability: Check if the machine is expandable or upgradable to meet future testing requirements.

- Compliance with Standards: Ensure the UTM adheres to all relevant industry standards applicable to your testing workflows and certifications.

How to Determine the Range of Universal Testing Machines Suitable for Your Tests?

To determine the range of universal testing machines (UTMs) suitable for my tests, I first define the types of materials and test modes required, such as tensile, compression, or flexural testing. Based on this, I calculate the maximum force capacity needed, ensuring it exceeds the material’s ultimate strength to avoid overloading. I also assess the dimensions of my test specimens, ensuring the machine’s grips and fixtures are compatible. Furthermore, I prioritize machines that meet essential accuracy and compliance standards for my industry, like ASTM or ISO certifications. By analyzing scalability options and support services, I ensure the machine can adapt to future needs while being backed by reliable maintenance and calibration resources.

What Are the Common Challenges in Using a Universal Testing Machine?

One common challenge is ensuring proper specimen preparation and alignment, as improper setup can lead to inaccurate results or equipment damage. Another issue is maintaining accurate calibration over time, which is critical for reliable data but requires regular checks and certifications. Additionally, users may encounter difficulties with software interfaces, such as configuration errors or data interpretation challenges. Compatibility between machine fixtures and varying specimen types can also pose a problem, especially for non-standard tests. Finally, environmental factors like temperature or vibration can affect test outputs, requiring controlled conditions for precise measurements.

What Are the Common Errors During Testing Process?

- Calibration Errors: Failure to properly calibrate the equipment can lead to inaccurate measurements and unreliable results. Regular calibration protocols are essential to maintain accuracy.

- Operator Error: Incorrect setup of the testing apparatus, improper handling of specimens, or misinterpretation of results can introduce significant errors. Adequate training and standard operating procedures are crucial to mitigate these issues.

- Software Configuration Issues: Errors in configuring testing software, including incorrect parameter settings or incompatibility with equipment, can result in flawed data or process interruptions.

- Specimen Preparation Mistakes: Improper preparation of specimens, such as incorrect dimensions, alignment, or surface conditions, can adversely affect the consistency and validity of results.

- Fixture Misalignment: Poor alignment of fixtures or inappropriate fixture selection for non-standard tests can lead to uneven application of forces, compromising the test integrity.

- Material Defects: Pre-existing defects or inconsistencies in the test material can introduce variability that is not representative of the intended testing conditions.

- Environmental Interference: Uncontrolled environmental factors, such as fluctuating temperature, humidity, or vibrations, can disrupt measurements and introduce noise into the results.

- Data Interpretation Errors: Misinterpretation of output data, whether due to human error or software limitations, can lead to incorrect conclusions or invalid reporting.

- Lack of Preventive Maintenance: Failure to perform regular maintenance on testing equipment can result in wear and tear affecting performance, reliability, and accuracy over time.

- Overloading of Equipment: Exceeding the recommended capacities of the testing machine can damage the equipment and skew results, requiring strict adherence to operational limits.

How to Troubleshoot Machine Work Issues?

When troubleshooting machine work issues, I follow a systematic approach to identify and resolve the problem efficiently:

- Inspect the Equipment for Physical Damage: I start by visually examining the machine for any noticeable signs of wear, damage, or misalignment. This step helps quickly identify if external factors are affecting performance.

- Review Operational Logs and Settings: I check the machine’s logs and configurations to verify that it is running under the correct operational parameters. Misconfigurations or unauthorized changes are often a cause for issues.

- Calibrate the Machine: If performance deviations are noticeable, I ensure the equipment is calibrated according to the manufacturer’s specifications. Proper calibration is critical for accuracy and consistency.

- Perform Preventive Maintenance: I verify that regular maintenance tasks, such as lubrication or component replacements, have been accurately carried out. Neglecting these can often lead to machine malfunctions.

- Test Under Controlled Conditions: I perform tests with a controlled input to determine if the issue persists under standard conditions. This helps isolate whether the problem is with the equipment or external variables.

- Consult the Manufacturer’s Manual or Support: If I am unable to resolve the issue, I refer to the machine’s technical manual or reach out to the manufacturer’s support team for expert guidance.

By following this structured process, I consistently identify root causes and implement solutions effectively, minimizing downtime and ensuring operational reliability.

What Safety Measures Should Be Taken?

When it comes to safety measures, I prioritize proper risk assessment and adherence to standard operating procedures. I always wear the required personal protective equipment (PPE), such as gloves, goggles, or ear protection, based on the specific task. Before starting any work, I ensure all equipment is in safe working condition and de-energized if necessary. I consistently follow lockout/tagout procedures to prevent accidental start-up of machinery during maintenance. Additionally, I stay up to date with safety training and protocols to mitigate risks and maintain compliance with industry standards.

Reference Sources

-

Wikipedia: Universal Testing Machine – Provides an overview of UTM’s applications, including tensile, compressive, and other mechanical tests.

-

Aimil Blog: What is Universal Testing Machine – Explains the importance and working procedure of UTM machines.

-

Quora: What is a Universal Testing Machine? – Discusses the mechanical properties tested by UTM machines.

-

Instron: Tensile Testing Machines – Focuses on tensile testing and its significance in material testing.

-

Top Universal Testing Machine in China

Frequently Asked Questions (FAQs)

Q: What is a UTM machine?

A: UTM or Universal Testing Machine is a testing device which evaluates the tensile and compressive strength of materials like metals, plastics and polymers.

Q: How does a UTM machine operate?

A: The machine’s operation entails the application of force on a specimen and measuring its response which enables tensile and compression tests, among other evaluations.

Q: What types of tests can a UTM machine perform?

A: UTM machines are capable of performing a wide range of tests including tensile strength testing, compression testing, and peel tests.

Q: What materials are suitable for testing using a UTM machine?

A: Testing metals, plastics, polymers, and several other materials can be done using a UTM machine.

Q: In which industries is a UTM machine commonly used?

A: UTM machines are used in various industries, including research and development, to ensure the strength and quality of materials.

Q: What are the advantages of using a UTM machine?

A: The advantages of using a UTM machine include reliable test results irrespective of the many tests performed on the materials, and ensuring the strength of the materials through detailed testing solutions.

Q: How can I ensure the safety of my UTM?

A: Safety can be ensured by regular maintenance, using appropriate test fixtures, and monitoring system performance through system monitoring and user management.

Q: What is the importance of test duration in UTM testing?

A: Test duration is crucial as it can affect the accuracy of the test data and ultimately the reliability of the testing solution.

Q: How does a UTM machine measure test data?

A: The machine measures test data by recording the response of the material under test to the applied force, which helps in determining test results.

Q: What is the range of UTM machines available?

A: Machines range from small benchtop units to large floor-standing models, catering to different test requirements and material types.