Surface abrasion plays a critical role in determining the durability and long-term performance of materials, particularly in construction, engineering, and geology. For professionals in these fields, accurately quantifying the abrasion resistance of rock-based materials is essential for ensuring structural integrity and functionality in demanding environments. This blog post takes an in-depth look at the Böhmé Abrasion Tester, a widely recognized tool for evaluating surface abrasion rates in rocks and similar materials. Through a methodical exploration of its operation, key principles, and practical applications, we will uncover how this testing method enables scientists and engineers to make informed decisions about material selection and performance prediction. Whether you’re a researcher, practitioner, or student, this guide will equip you with valuable insights into understanding and leveraging surface abrasion data effectively. Stay tuned as we navigate the technical intricacies and real-world relevance of this essential testing process.

What Is the Böhmé Abrasion Test?

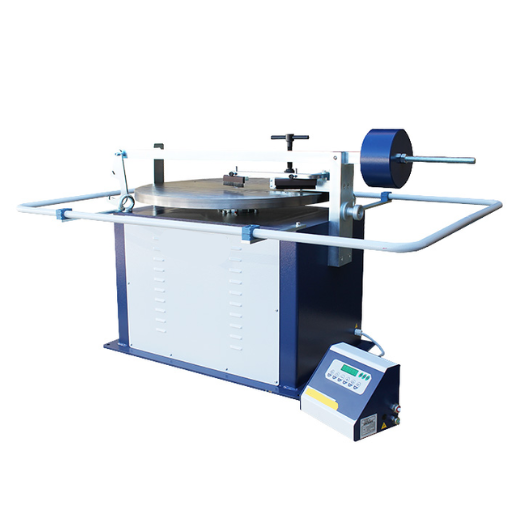

The Böhmé abrasion test is a standardized method used to measure the wear resistance of materials, particularly concrete, natural stone, and similar construction materials. It assesses the material’s ability to withstand surface abrasion under controlled conditions. The test involves subjecting a sample to abrasive forces using a rotating disk and an abrasive medium over a specified time. The resulting material loss is measured and expressed as volume loss, providing a quantifiable indicator of the material’s durability and suitability for various applications.

How Does the Böhmé Abrasion Test Method Work?

The Böhmé abrasion test method evaluates the abrasion resistance of natural stones and concrete by simulating wear under standardized conditions. A square or rectangular sample is securely placed in the testing apparatus, where it is exposed to a rotating steel disc covered with abrasive sand. The test applies a specific load, as defined by standards such as EN 14157 or ASTM C1353. After a set number of rotations, the sample’s material loss is calculated by either measuring the volume loss or the reduction in thickness. This quantifiable data enables accurate assessment of the material’s durability for practical applications, such as flooring, paving, or other high-wear environments.

Key Rock Properties Affecting Abrasion Results

- Mineral Composition

The composition of minerals within the rock significantly impacts its abrasion resistance. Harder minerals, such as quartz (Mohs hardness of 7), typically exhibit greater resistance to wear than softer minerals like calcite (Mohs hardness of 3). The proportion of harder minerals directly correlates with improved durability.

- Grain Size and Texture

Fine-grained rocks with tightly interlocking crystals tend to resist abrasion better than coarse-grained rocks. The contact points between grains also influence the material’s performance, with fine textures reducing mechanical wear.

- Porosity and Density

Rocks with lower porosity and higher density demonstrate less material loss during abrasion tests. A porosity below 5% and a density above 2.5 g/cm³ are generally indicators of high abrasion resistance.

- Cementation and Bond Strength

The quality and strength of the cementing material between grains significantly affect abrasion resistance. Well-cemented rocks, such as those with silica or iron oxide binders, often show superior durability compared to poorly cemented counterparts.

- Moisture Content

Elevated moisture levels within rock pores can reduce abrasion resistance due to weakening of internal bonds. A lower water absorption coefficient (e.g., <0.5%) is preferable for environments with high wear demands.

Understanding these parameters helps tailor material selection for specific applications, ensuring suitability under defined mechanical and environmental conditions.

Applications of the Böhmé Test in Evaluating Natural Building Stones

- Assessment of Abrasion Resistance

The Böhmé test is widely utilized to determine the wear resistance of natural building stones, ensuring their performance in high-traffic areas such as flooring and pavements.

- Material Suitability for Urban Infrastructure

By evaluating the abrasion resistance of stones, the test aids in selecting materials suitable for constructing roads, sidewalks, and public spaces that endure constant mechanical stress.

- Quality Control in Quarrying and Production

The test serves as a quality assurance measure for quarry operators and manufacturers, ensuring that extracted or processed stones meet the necessary mechanical standards.

- Comparison of Different Stone Types

The Böhmé test provides a standardized metric for comparing the durability of varying types of stones, enabling informed decision-making during the material selection process.

- Adaptation to Specific Environmental Conditions

Results from the test help determine the suitability of stones for regions exposed to harsh weather, ensuring their long-term stability and performance in varying climatic conditions.

How Is the Böhmé Test Method Conducted?

The Böhmé test method is conducted by subjecting stone samples to a controlled wear process using an abrasive material. Specifically, a stone specimen is placed onto a rotating disc covered with abrasive grit under a consistent and standardized load. The disc rotates for a pre-determined number of revolutions, simulating wear and tear. After the test, the stone specimen is measured to determine the volume or weight loss, which provides a quantitative assessment of its abrasion resistance. This method ensures precise and repeatable results for evaluating the durability of different stone types.

Step-by-Step Guide to Conducting the Abrasion Test

- Preparation of the Specimen

Obtain a stone specimen of the required dimensions as specified by the testing standard. Ensure that the surface is clean, free of dust, and any irregularities that could affect the test.

- Calibration of Testing Equipment

Ensure the abrasion testing machine is properly set up. Calibrate the equipment, including the rotating disc and the standardized load mechanism, to confirm they are functioning within the required specifications.

- Application of Abrasive Grit

Prepare the abrasive grit as per the test requirements. Distribute the grit evenly onto the surface of the rotating disc to ensure consistent application during testing.

- Mounting the Specimen

Secure the stone specimen firmly onto the designated holder on the testing machine. Verify that the specimen is aligned and positioned correctly to minimize any movement during the test.

- Setting Test Parameters

Program the testing machine with the required parameters, including the number of revolutions, load applied, and rotational speed as dictated by the standard test method.

- Execution of the Test

Start the machine to initiate the rotation of the disc. Allow the test to run for the pre-determined number of revolutions while ensuring the test is uninterrupted.

- Completion and Removal of the Specimen

Once the test cycle is complete, turn off the machine and carefully remove the specimen from the holder. Handle the specimen with care to maintain its post-test condition.

- Cleaning and Measurement

Gently clean the specimen to remove any residual abrasive debris. Measure the specimen’s dimensions, weight, or volume loss using precise measurement tools.

- Data Recording and Analysis

Document all measured data, including weight or volume loss. Analyze the results to calculate the abrasion resistance of the stone specimen in accordance with the testing method.

- Maintenance of Equipment

Clean the testing machine thoroughly after each use. Inspect the components for wear and ensure it remains calibrated for future tests.

Essential Equipment and Test Specimen Preparation

To prepare for the abrasion resistance test, I primarily use a calibrated testing machine designed for this purpose, along with precision measuring instruments like balances and calipers. Additionally, abrasive materials, such as steel balls or sand, can be required depending on the specific test standard being applied. For specimen preparation, I ensure the test piece adheres to the dimensional requirements specified in the given standard (e.g., ASTM standards). The surface of the specimen is cleaned thoroughly to prevent contamination, and I always verify uniformity in size and shape across all samples for consistent and reliable results.

Common Challenges in the Böhmé Abrasion Test

One of the primary challenges I encounter is ensuring the uniformity of the abrasive material. Variations in particle size or hardness can significantly affect the results, leading to inconsistent data that may not reliably reflect the material’s true abrasion resistance. Additionally, maintaining strict control over the applied load is critical; any deviation can skew wear rates and compromise repeatability. Humidity and temperature fluctuations in the testing environment pose another obstacle, as they can influence the properties of both the specimen and abrasive medium, potentially altering test outcomes. Lastly, ensuring the specimen meets the dimensional tolerances outlined in test standards, such as ASTM C1353, requires meticulous preparation, as any irregularity can lead to biased results or issues during the process.

How Can Artificial Neural Networks Enhance the Understanding of Böhmé Test Results?

Artificial neural networks (ANNs) can significantly enhance the understanding of Böhmé test results by identifying complex, non-linear relationships within the data that may not be apparent through traditional analytical methods. These networks can process large volumes of test parameters and results, enabling the prediction of material performance under various conditions with high accuracy. Additionally, ANNs can assist in identifying patterns or anomalies in the data, offering deeper insights into the factors influencing wear behavior. By leveraging machine learning algorithms, ANNs enable the optimization of material design and predictive maintenance strategies, thus improving the efficiency and reliability of testing processes.

Role of Data Mining Techniques in Predicting Rock Abrasivity

Data mining techniques play a crucial role in predicting rock abrasivity by enabling the processing and analysis of large datasets to identify patterns and relationships. Below are five key data mining techniques used in this domain:

- Cluster Analysis: This technique is employed to group rocks with similar abrasivity characteristics based on key parameters such as mineral composition, hardness, and texture.

- Regression Analysis: Regression models help establish quantitative relationships between rock properties (e.g., grain size, porosity) and abrasivity indices, enabling accurate predictions.

- Decision Trees: Decision tree algorithms simplify complex datasets by identifying decision rules that classify rocks based on their abrasivity levels.

- Support Vector Machines (SVMs): SVMs are used to classify and predict rock abrasivity by finding the optimal hyperplane that separates data points from different abrasivity classes.

- Principal Component Analysis (PCA): PCA reduces dataset dimensionality by identifying the most significant variables, making it easier to analyze and predict rock abrasivity efficiently.

Using Artificial Neural Networks for Better Accuracy

Artificial Neural Networks (ANNs) are highly effective in improving the accuracy of rock abrasivity prediction due to their ability to model complex, nonlinear relationships within datasets. ANNs consist of interconnected layers – an input layer, one or more hidden layers, and an output layer – that work collectively to learn patterns in the data. By utilizing activation functions such as ReLU or sigmoid, ANNs can capture intricate features that traditional methods may overlook.

Training a neural network involves providing it with labeled datasets of rock properties, such as mineral composition, grain size, and unconfined compressive strength, to identify subtle correlations related to abrasivity. Advanced techniques like backpropagation and gradient descent are used to minimize prediction errors iteratively. Furthermore, the integration of regularization techniques, such as dropout, prevents overfitting by ensuring the model generalizes well to new datasets.

The ability of ANNs to handle large and multidimensional datasets makes them superior when analyzing complex geological data. Combined with pre-processing methods like normalization and feature selection, ANNs can deliver precise and repeatable predictions, facilitating better decision-making in geotechnical engineering and resource extraction processes.

Case Studies: Predicting Abrasion Resistance of Natural Stones

Accurately predicting the abrasion resistance (AR) of natural stones is critical for their selection and application in construction and engineering projects. Artificial Neural Networks (ANNs) have been employed as a robust tool for this purpose due to their ability to model non-linear relationships between input variables and AR.

Methodology and Parameters

To predict the AR, datasets comprising critical properties of stones are utilized. Key parameters include:

- Density (g/cm³): A measure of mass per unit volume, affecting durability.

- Porosity (%): Influences water absorption and structural integrity under wear.

- Uniaxial Compressive Strength (MPa): Indicates the stone’s ability to resist crushing forces.

- Quartz Content (%): Determines hardness, which is directly correlated with AR.

- Water Absorption by Weight (%): Reflects stone permeability and susceptibility to wear.

These parameters are typically subjected to preprocessing, including normalization, to improve model accuracy. ANNs with carefully optimized architectures, for example, a feedforward network with hidden layers set between 1-3 depending on complexity, are trained using datasets collected from laboratory tests.

Results and Insights

Case studies reveal that ANN models can achieve high predictive accuracy with correlation coefficients exceeding 0.90 when adequately trained. For instance, models integrating multiple stone properties alongside environmental factors such as humidity have reported prediction errors below 5%. This showcases their feasibility for practical applications, reducing the need for extensive physical testing.

By leveraging ANNs with relevant and well-characterized technical parameters, engineers can reliably estimate the abrasion resistance of natural stones, streamlining material selection and optimizing performance outcomes for various geotechnical applications.

What Are the Implications of Rock Abrasivity in Construction?

Rock abrasivity has significant implications in construction, particularly in the selection and performance of tools, equipment, and materials. High abrasivity in rocks can lead to increased wear and tear on cutting tools and machinery, resulting in higher maintenance costs and reduced operational efficiency. Additionally, it impacts the design of excavation and tunneling processes, as more robust and wear-resistant materials may be required to cope with abrasive conditions. Understanding rock abrasivity also aids in accurately determining project timelines and budgets, ensuring both safety and cost-effectiveness in construction operations.

Impact on Building Materials and Construction Costs

The abrasiveness of rocks is of high significance when choosing construction materials, as it affects their durability. A high rock abrasiveness increases the wear on any machinery and equipment used in construction. For instance, to counter these effects, drill bits and cutting tools are made from materials like tungsten carbide and hardened steel because they withstand abrasives more than most materials. On the other hand, the over-reliance on worn parts unduly raises the maintenance burden which, along with increased operational costs, becomes unsustainable.

From a financial perspective, high rock abrasivity directly correlates with increased construction costs due to the need for specialized equipment, lower productivity rates, and additional reinforcement requirements. Abrasive environments slow down excavation and tunneling speeds, increasing labor hours and fuel consumption. Technical parameters often considered when assessing the abrasivity impact include the Cerchar Abrasivity Index (CAI), where values greater than 3.0 indicate highly abrasive rock, and other indices such as the Sievers’ miniature drill test result and LCPC Abrasivity Coefficient. These metrics are essential for planning, as they determine the appropriate materials, cutting tools, and protective coatings to use, thus optimizing both cost efficiency and project durability.

Correlating Abrasion Resistance with Compressive Strength

The correlation between abrasion resistance and compressive strength is critical in understanding a material’s durability and performance under challenging conditions. Higher compressive strength often indicates a material’s ability to resist surface wear, as stronger materials tend to be less prone to abrasion. However, this relationship is not always linear and depends on factors such as mineral composition, grain size, and moisture content.

Key technical parameters for analysis include:

- Uniaxial Compressive Strength (UCS): This measures the maximum axial load a material can withstand before failure, often reported in MPa.

- Cerchar Abrasivity Index (CAI): Indicates the material’s abrasiveness, where values exceed 3.0 for highly abrasive conditions.

- Schmidt Hammer Rebound Number: Provides indirect assessment of surface hardness and compressive strength.

- Los Angeles (L.A.) Abrasion Test Value: Quantifies resistance to wear by measuring the percentage of weight loss in aggregate materials.

By integrating these parameters, it is possible to predict how compressive strength influences abrasion resistance, enabling better material selection and engineering outcomes for projects.

Assessing the Durability of Pavement and Building Stones

The durability of pavement and building stones is primarily assessed through their ability to withstand mechanical stresses, environmental conditions, and long-term wear. Key tests and methodologies include:

- Water Absorption Test – This test measures the porosity of stones, indicating their resistance to water ingress and freeze-thaw cycles, which can lead to cracking and degradation over time.

- Abrasion Resistance Test – Used for assessing the material’s capability to resist surface wear under friction or mechanical actions, such as in the Los Angeles (L.A.) Abrasion Test.

- Compressive Strength Test – Identifies stones’ ability to handle significant loads without fracturing, showcasing their suitability for structural applications.

- Weathering Test – Simulates environmental effects, including exposure to cycles of wetting, drying, and temperature fluctuations, to gauge long-term performance under climatic stressors.

By combining the results of these tests, engineers can accurately evaluate the performance characteristics of materials, ensuring proper selection for specific applications. This comprehensive approach helps maximize structural integrity, extend lifespan, and reduce maintenance costs for pavements and buildings.

What Are the Alternatives to the Böhmé Abrasion Test?

Several alternatives to the Böhmé abrasion test exist, each designed to evaluate material durability under different conditions. The ASTM C944 Rotating-Cutter Method assesses surface wear resistance using a high-pressure rotating cutter. The Los Angeles (LA) Abrasion Test, per ASTM C131/C535, is widely used for evaluating aggregate toughness and resistance through mechanical tumbling in a rotating drum with steel balls. The Taber Abraser test offers another approach, employing a rotating abrasive wheel to determine surface wear. Additionally, the Micro-Deval Test evaluates resistance to degradation through abrasion and attrition in a wet environment, making it suitable for assessing aggregates subjected to moisture. Each method provides specialized insights depending on the material’s intended application and performance requirements.

Comparing Böhmé with the Cerchar Abrasivity Test

The Böhmé abrasion test and the Cerchar abrasivity test differ fundamentally in their application, measurement method, and the type of wear or abrasion they assess.

|

Parameter |

Böhmé Test |

Cerchar Test |

|---|---|---|

|

Purpose |

Surface wear |

Rock hardness |

|

Application |

Flooring use |

Mining/drill |

|

Abrasion Type |

Surface |

Tip wear |

|

Environment |

Dry |

Dry |

|

Measurement Unit |

mm material |

CAI index |

|

Sample Type |

Flat slab |

Rock core |

Exploring Wear Resistance Tests for Different Rock Types

Wear resistance tests for different rock types include the Böhmé test, Cerchar abrasivity test, Los Angeles abrasion test, and Schimazek’s F-value test.

|

Test Name |

Purpose |

Sample |

Unit |

Type of Wear |

Environment |

|---|---|---|---|---|---|

|

Böhmé |

Surface wear |

Flat slab |

mm loss |

Surface |

Dry |

|

Cerchar |

Drill wear |

Rock core |

CAI index |

Tip wear |

Dry |

|

Los Angeles |

Aggregate wear |

Rock chips |

% loss |

Aggregate |

Dry |

|

Schimazek |

Abrasion eval. |

Rock sample |

F-value |

Abrasion |

Any |

Benefits of Using Support Vector Machine Models in Abrasion Testing

- Improved Prediction Accuracy: Support vector machine (SVM) models are highly capable of handling complex and non-linear relationships within data, leading to more accurate predictions for material abrasion characteristics.

- Ability to Handle Multi-Dimensional Data: SVMs efficiently process high-dimensional input data, making them ideal for analyzing multiple material and environmental parameters that influence abrasion.

- Robustness to Overfitting: By utilizing a regularization parameter, SVM models effectively avoid overfitting, ensuring reliable performance even with limited or noisy datasets commonly encountered in laboratory abrasion tests.

- Versatility Across Test Conditions: SVM models can adapt to varying environments and types of wear, providing consistent results regardless of the test type or material composition being analyzed.

- Reduced Computational Complexity: With the use of optimization techniques inherent in SVMs, the computational demands for analyzing abrasion tests are significantly reduced, allowing for faster processing and real-time application.

Reference Sources

-

Assessment of the method for abrasion resistance determination of sandstones on Böhme abrasion test apparatus – This article evaluates the Böhme abrasion test method for both dry and water-saturated sandstones.

-

Correlation between wide wheel abrasion (capon) and Bohme abrasion test results for some carbonate rocks – This study explores the relationship between Böhme abrasion and wide wheel abrasion test results.

-

Data mining techniques for the prediction of Bohme surface abrasion rates from rock properties – This research discusses the use of data mining techniques to predict Böhme surface abrasion rates based on rock properties.

-

Abrasion wear characterization of some selected stone flooring materials with respect to contact load – This paper examines the abrasion wear rates of stone materials under varying loading conditions using the Böhme test.

-

Top Böhme Abrasion Tester in China

Frequently Asked Questions (FAQs)

Q: What is the Böhmé Abrasion Tester and how is it used to assess rock properties?

A: The Böhmé Abrasion Tester is a device used to assess the abrasion resistance of rocks. It evaluates the wear resistance of natural stones used in construction by simulating natural wear conditions. The test helps determine the usability of wide wheel surfaces on different natural stones.

Q: Why is understanding the resistance of natural stones important in civil engineering?

A: Understanding the resistance of natural stones is crucial in civil engineering because it impacts the durability and longevity of structures. Knowing the strength properties and resistance helps engineers select appropriate materials for specific applications, reducing damage to the stone and ensuring structural integrity.

Q: How do physical and mechanical properties of rocks affect their abrasion rates?

A: The physical and mechanical properties of rocks, such as tensile strength, modulus of elasticity, and point load strength, directly influence their abrasion rates. Rocks with higher strength properties and better mechanical rock properties typically exhibit lower abrasion rates, making them more suitable for certain construction applications.

Q: What role do soft computing techniques play in assessing rock properties?

A: Soft computing techniques, like artificial neural networks, are used to assess rock properties by predicting the behavior of natural stones through artificial neural network analyses. These techniques help in modeling complex relationships between rock properties and their resistance to abrasion.

Q: How can the petrographic characteristics of rocks be used to determine abrasion resistance?

A: Petrographic characteristics, such as mineral composition and texture, provide insights into the mechanical properties of rocks. By analyzing these characteristics, one can assess the ability of rocks to resist abrasion and predict their performance in real-world applications.

Q: What is the significance of testing limestone and granitic rocks for abrasion resistance?

A: Testing limestone and granitic rocks for abrasion resistance is significant because these rocks are commonly used in construction. Understanding their strength properties and how they react under abrasive conditions helps in selecting the right material for specific projects, ensuring both durability and cost-effectiveness.

Q: How does the point load test contribute to evaluating the strength properties of rocks?

A: The point load test is used to determine the point load strength and other mechanical rock properties. It provides a quick and efficient method to evaluate the strength of rock masses, which is essential for assessing their suitability for various construction purposes.

Q: What advancements have been made in using artificial neural networks for evaluating rock abrasion?

A: Advancements in using artificial neural networks for evaluating rock abrasion include improved predictive accuracy and the ability to model complex datasets. These neural network analyses allow for better assessment of different natural stones, enhancing the selection process for construction materials.

Q: How do universities, like the University of Science and Technology, contribute to research on rock abrasion?

A: Universities, such as the University of Science and Technology, contribute to research by developing new methods to evaluate rock properties and advancing the understanding of how different factors affect abrasion rates. Their research plays a vital role in improving testing techniques and material selection in civil engineering.