In the assessment of rubber materials, hardness testing gives is insight into their performance and suitability for applications. In relation to automotive parts, industrial machinery, or even consumer goods, rubber hardness is critical as it ensures reliability and longevity. This article focuses on durometer measurements which are widely used for rubber hardness evaluation. You will learn the measurement process, its importance, and most significantly, all its steps. It is my hope that everyone grasps the importance of this testing method as they reflect on material quality and selection.

What Is The Standard Test Method For Rubber Hardness?

The standard test for rubber hardness is the durometer test which is further elaborated in ASTM D2240. This method uses the durometer instrument to measure indentation resistance of a certain material. The process requires applying certain force on the material to indent using a dome shape tip, then reading the value from the scale which ranges 0 to 100. Different Shore scales, such as Shore A or Shore D, are used and with softer materials like rubber, Shore A is preferred. With this method, accuracy, consistency, and repeatability for evaluations is achieved.

Overview of ASTM D2240 and its significance

ASTM D2240 outlines a standard procedure for evaluation of hardness of materials with a durometer. This standard serves as a benchmark in the quality assurance system to evaluate and ensure mechanical properties of elastomers, polymers, and thermoplastic materials. It helps in sure classification of materials based on their resistance to deformation which relates directly to how they perform under specific operational conditions. The specification describes, among others, the Shore A and Shore D which cater for flexible rubbers and elastomers, and harder plastics and polymers respectively.

The precision and reproducibility of measurements along with the defined conditions under which tests are performed is a notable feature that sets ASTM D2240 apart. Certainty in the measurement process stems from uniform control of indentor shape and size, force application, hold time, and measurement environment. These features make the Standard more useful in the automotive, aerospace and medical device industries where accurate measurement of material hardness is necessary for operational and safety reasons. Following ASTM D2240 will guarantee that there is no divergence from global industry standards, aid in development of new solutions, and foster uniformity in material use among international supply chains.

What does the d2240 standard involve?

The ASTM D2240 standard defines the steps to determine the hardness of flexible materials like rubber, elastomers and some polymers. It uses an instrument called a durometer which measures the depth of a mark left on a material due to a certain load placed upon it. The standard divides the different types of hardness measurement into scales like Shore A and Shore D which are made to suit different materials rigidity. Shore A is familiar with softer materials like rubber while Shore D deals with harder plastics.

The procedure needs to observe a number of requirements like specimen thickness, surface smoothness, force, and time. Accuracy is often dependent on durometer calibration and maintenance standards which are provided in ASTM D2240. Also, other factors such as temperature and specimen servicing outside the scope of the standard are critical for capriciousness reasoning which these standards seek to eliminate. This level of detail makes the results consistent which are essential for benchmarking, material choice, and competitive assessment in many industries.

Key parameters in the standard test method for rubber

The standard test method for rubber, like any other form of orthotic devices, has a few critical elements that needs to be followed to ensure accurate and consistent hardness measurements. Some of these elements are the use of accurate durometer for rubber hardness testing, tools like indenters with proper shapes, application of forces rate, and waiting times. As an example, an environmental condition that is important for testing is the temperature. The temperature needs to be controlled and maintained between 23°C ± 2°C to avoid variances in performance due to temperature. Preparing the test specimens is no less important than the primary procedure. For example, parallel uniform thickness (in this case not less than 6mm), and smooth, cleans surfaces help to provide more reliable readings. Also, there is a standard that defines the conditions under which measurements are made. For example, all measurements must be made on a base that is not distorted and non-deforming flat to prevent errors in the measurements such as distortion. Together, these parameters form the primary basis for reliable and reproducible data which enable analysis with minimal error around the true value.

How Is Shore Hardness Measured?

A durometer is a device designed to measure ‘shore hardness’, which is the resistance of materials to indentation. The device has an indenter which measures the material put under a consistent force. Measurement of depth from the indentation is checked and marked on a scale of 0 to 100. Common scales are Shore A which measures softer materials while Shore D measures harder substances. Smooth surfaces, right angle contacts, and time control are necessary to take accurate measures

Understanding the shore hardness testing process

Shore hardness testing processes are also focused on maintaining conditions for measurements as well in this case frame of reference compliance. The focus of this section is marking the edges of the material as well as keeping it flat for further testing without applying any force. The setup should be meeting the goal outline for standards of industry like ASTM D2240 and its circumference including temperature and material surface layering.

Soft elastomers, rubbers, and foams should be tested using the Shore A scale durometers with special care to avoid deformation from excess force or pressure. On the other hand, thermoplastics and harder polymers are classified as rigid materials and are tested using the Shore D scale durometer requiring a coarser tip.

Reading measurements requires several checks to be done across the material to get precise variations for averaging. However, no matter how many times the material is sampled, it cannot be tested on an unstable surface thinner than the material itself to prevent bottoming out, as this will compromise data integrity.

Different types of durometers used for measurement

|

Type of Durometer |

Description |

Key Features |

Applications |

|---|---|---|---|

|

Shore A Durometer |

Measures softer materials |

For flexible rubber and elastomers |

Automotive tires, shoe soles |

|

Shore D Durometer |

Measures harder materials |

Designed for rigid plastics and hard rubbers |

Industrial parts, hard thermoplastics |

|

Shore OO Durometer |

Measures very soft materials |

Common for gels and foam materials |

Sponges, soft foam, gel wrist pads |

|

Shore OOO Durometer |

Ultra-soft material measurement |

Enhanced sensitivity for soft polymers |

Silicone gels, ultra-soft elastomers |

|

Shore C Durometer |

Primarily for medium-hard rubbers |

Bridges the gap between Shore A and D |

Rubber rollers, medium-density rubbers |

|

Shore 00 Durometer |

For exceptionally soft substances |

Similar to Shore OOO, more specialized |

Soft gels, lightweight foams |

|

Shore E Durometer |

Wider scale for hard elastomers or plastics |

Provides precise scales for harder materials |

Heavy-duty rubber, high-density foams |

|

Shore M Durometer |

Thin materials testing |

Used for thin elastomer sheets |

Rubber sheets, thin film products |

How to interpret durometer hardness results

To provide an accurate assessment of hardness properties, the inter-relation of the material being tested and the hardnes durometer scale applied greatly impacts the results. This is true in the case of scale designed to accommodate specific classes of elastomers, being Shore 00 for gel-like or foam materials, while Shore A is slighter softer elastomers, and Shore D captures the hardest plastics or rigid structural materials.

When looking at values, greater durometer readings mean a material is more resistant to indentation and rigid, while softer and more flexible is indicated by lower readings. For exact comparisons, processes like temperature, force application, and material thickness need to be uniform across all tests. Differences in any of these factors can distort the data’s reliability. Reliability is also affected by the choice of durometer scale, so careful selection is needed to avoid error. Following the proper calibration procedures for the measuring device increases accuracy along with obedience to the testing protocols provided. Adherence to the calibration procedures specified maximizes accuracy in the measuring device’s readings.

What Are The Different Hardness Scales For Rubber?

The rubber hardness can be gauged using three primary durometer scales depending on the use of the material:

- Shore A Scale: This is used for soft, flexible rubbers such as elastometers, tires and seals. Also, it measures moderate hardness materials.

- Shore D Scale: Focused on harder rubbers or plastics such as rigid thermoplastics and tough elastomers.

- Shore O Scale: Applied to very soft rubbers or gels which need measurement of very low hardness values with precision.

Using each scale requires the appropriate type of durometer instrument which aligns the intended properties of the material. It is important that the correct scale is chosen to achieve accuracy in measurement and meaningful results.

Exploring shore A and shore D scales

Although, Shore A and Shore D scales are the most common approaches to measure the hardness of a material, each caters to different materials and hardness states. Shore A scale is largely focused on soft to medium hard materials comes out to be more flexible elastomers, rubber and silicons. The scale’s hardness values are usually within 10A to 95A, 10A being soft gel and 95A approaching hard plastic-like rigidity.

Conversely, the Shore D scale is meant for harder composites such as rigid plastics, vinyl, and hard rubbers. Shore D starts where A ends, ranging from approximately 30D on moderately hard materials and going all the way to 90D which is exceptionally tough, almost rigid.

The difference between the two scales is also seen in the testing approach. Shore A durometers use a softer spring loading mechanism and a blunt indenting needle, whereas higher spring force with a sharp indenting point is used on Shore D durometers. These characteristics make each scale unique and aids in delivering accurate assessments of material properties regardless of the field.

Comparison of hardness scales for various materials

|

Hardness Scale |

Material Types |

Measurement Range |

Typical Applications |

Key Notes |

|---|---|---|---|---|

|

Shore A |

Soft plastics, rubber, elastomers |

0 to 100 |

Tires, seals, shoe soles |

Suitable for flexible materials |

|

Shore D |

Hard plastics, semi-rigid polymers |

0 to 100 |

Hard hats, plastic sheets |

Best for harder, less elastic materials |

|

Rockwell |

Metals and alloys |

Multiple scales |

Steel, brass, aluminum |

Provides depth-based hardness values |

|

Brinell |

Metals, particularly soft alloys |

Variable (HBW) |

Bearings, metal forgings |

Measures diameter of indentation |

|

Vickers |

Metals, coatings, ceramics |

Variable (HV) |

Micro-scale materials |

Precise for thin material layers |

|

Mohs |

Minerals, ceramics |

1 to 10 |

Geology, ceramics testing |

Simplified scale based on scratch resistance |

|

Knoop |

Thin coatings, small samples |

Variable (HK) |

Microstructures, thin films |

Specialized for surface hardness |

|

Shore O |

Soft foam, low-density elastomers |

0 to 100 |

Foam mattresses, sponges |

For low-density, compressible materials |

|

R Scale |

Hard thermoplastics |

Specific ranges |

Plastic pipes and containers |

Alternative for plastics measuring |

|

Barcol |

Fiber-reinforced plastics (FRP) |

0 to 100 |

Boat hulls, composite materials |

Portable with fast measurements |

Why is understanding different shore scales important?

Shore scales are vital to almost every industry, from manufacturing and construction to quality control, as these scales aid in evaluating the performance of materials, and ensuring safety, durability, and functionality. Different Shore scales aid in evaluating the hardness of different materials like plastics and flexible elastomers, each having specialized methods to test them. Engineers, for instance, rely on these scales to assess how materials will perform under stress, determine wear resistance, and fine-tune product designs. In this regard, comprehensive knowledge for these scales aids in aligning with industry benchmarks. Understanding different Shore scales ensures accurate evaluations of the material’s hardness for different use cases. If tested incorrectly, entire industrial systems would rely on malfunctioning machinery that cannot be trusted, leading to elevated operational costs and harmful environmental impacts. Every incorrect evaluation adds layers of risk that engineers are forced to accept, continuously increasing uncalculated expenses.

What Is the Impact of Vulcanization on Rubber Hardness?

The process of vulcanization aids in rubber’s hardness as it forms cross-links between individual polymer chains. Added cross-links improve the strength of the material along with the elasticity and the resistance to deformation under any given stress. The process increases durability and stability, while rubber’s stickiness and soft texture are reduced. This increased hardness assists with the mechanical performance level rise needed in tires, seals, and industrial components.

How vulcanized rubber differs from thermoplastic elastomers

The chemical composition, method of processing, and the characteristics of performance and vulcanized rubber differ with that of thermoplastic elastomers (TPEs). In the case of vulcanized rubber, it goes through an irreversible cross-linking process which leads to the formation of a three-dimensional network of sulfur bonds alongside polymer chains. The cross-linked structure results in the rubber having high resilience, thermal stability and resistance to any chemicals or degradation from the environment. On the downside, this means the material cannot be reshaped or remelted post-curing.

In contrast, thermoplastic elastomers do not use cross-linking as a means to obtain their characteristics. TPEs are physical blends, combining elastomers’ elastic traits with thermoplastics’ easy processing. Both thermoplastic elastomers and their composites can be melted and remolded several times with little reduction in quality, thus they are highly recyclable and fit for uses that require repeated or adjustable designs. On the downside, vulcanized rubbers and TPEs have a poorer mechanical strength and thermal resistance which hampers their applicability in high-endurance industrial equipments such as machinery or tires for automobiles.

The role of durometer testing in quality control

Elastomers and other polymeric materials undergo rigorous quality and consistency practices alongside durometer testing. This is known for measuring hardness and is an important property relating to performance in diverse applications. Durometer testing, utilizing Shore A or Shore D, measures resistance to indentation and output data is often measurable and precise. Shore A is preferable for softer elastomers like rubber and thermoplastic elastomers while Shore D is reserved for tougher plastics and other polymers.

To avoid unnecessary defects, manufacturers thrust accuracy-centered durometer tests within the production processes. The data gathered from such tests also relates to other metrics such as tensile strength, elongation, abrasion resistance, and more. This correlation enables a holistic grasp of how materials behave under considerable stress during operation. The reliability of automated quality control processes is further strengthened by recent advancements in digital durometer automation. This highlights the continued need for industries, spanning from automotive and aerospace to medical manufacturing, to perform durometer tests where material precision is essential for safety and durability.

What Methodologies Are Used In Hardness Testing?

Most commonly, hardness testing divides in three branches:

- Brinell Hardness Test (BHN)

This approach consists of embedding a hardened steel or tungsten carbide ball into the tested material’s surface under load guidelines. Measuring the diameter of the indentation allows calculating the hardness value, thus making this test convenient for use on metals and other coarse structured materials.

- Rockwell Hardness Test (HR)

Using a steel or diamond cone, or even a steel ball, as an indenter, Rockwell testing applies predetermined loads to make indentations. The measure of indentation depth results in swift precision verification that is seamless for metals and polymers.

- Vickers Hardness Test (VHN)

In the Vickers test, a diamond pyramid-shaped indenter is used under static load application. It is particularly useful for thin sections or small pieces since it provides accurate readings regardless of the number of material layers.

Having these methodologies perform optimally for the defined criteria of material type, material thickness, and precision, the results are dependable for measuring hardness.

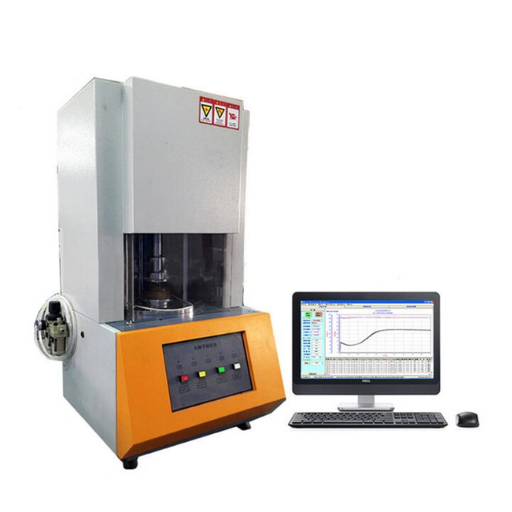

Insights into the test method for rubber property—durometer

The hardness of rubber and elastomeric materials can be evaluated using the durometer test, which is convenient and methodical. It highlights how these materials withstand compression. A usual system is with an indentor; in this case, a spring-loaded one that will penetrate the surface of the material to its predetermined measuring scales of Shore A or Shore D. Softer rubbers will typically be measured with Shore A while harder materials will be measured with Shore D.

Significant developments in durometer testing concern its standardization owing to ISO 868 and ASTM D2240 which enhance the accuracy as well as the repeatability of the measurements. Also, electronic durometers with digital output along with data storage are more accurate and efficient in analysis which makes sure that the methodology is up to par for stringent performance measures needed in automotive or aerospace industries and even consumer goods.

International standards and ISO compliance in rubber testing

Entering rigorous industry standards on repeatability, consistency, and quality verification, international bodies like ISO 37 on tensile stress-strain properties and ISO 48 on hardness testing define how rubber undergoing specific conditions should be assessed, thus detailing entire evaluation workflows. These protocols reduce variability in testing environments leading to dependable information supporting material claims for manufacturers and researchers.

Recent updates to compliance policies now include more sophisticated automated testing systems in line with ISO 23529. This standard outlines the specific procedures for the sampling, conditioning, and testing of rubbers to guarantee accuracy and repeatability. Updates to international standards enable further technological advancement, innovative research, and refinement to processes to respond to new challenges in the application of materials technology. Compliance with these standards empowers businesses to operate within highly regulated and competitive environments whilst enhancing value for money, optimization of processes, and meeting all regulatory demands on the performance and quality.

Why Is Hardness Measurement Critical For Material Performance?

Evaluating hardness is critical in additional ways such as cross checking consistent material and processing quality, estimating load stress outcomes, and optimizing design parameters tailored to specific application demands. Performing hardness testing directly aligns with quality control in meeting accuracy and compliance targets with performance ratings. The outcome material also tested effectively in meeting demands during its intended lifecycle while maintaining optimal performance standards.

Effects of hardness on rubber applications

Scrolling through different types of industrial rubbers, one critical aspect that stands out among the rest is the industry’s hardness. It is known that hardness on an industrial scale determines the performance of rubbers in general, however, the multi-faceted nature of its application joints both the sensitivity and variability of rubbers performance. The scale for measuring hardness ‘Shore’, particularly it’s A scale provides the most convenience measuring stretchable rubbers. For rubbers that are meant to serve different functions, workstation rigidity, wearing properties, and slipage resistance are necessary. Thus, having a shore A scale reading above a certain level that is meant for a certain purpose, i.e., wiper blades, is a necessity.

Softened grades of rubbers on the other hand allow for more slipping as well as improved compression in comparison to harder grade rubbers. This is highly important while dealing with particular components such as gaskets which increase performance through leak prevention and shock absorption. When looking at various factors impacting performance shape, failure rate, and robustness, an ideal rubber’s shape must incorporate softening treatment for increased absorption as well as application-specific ratio without a hardness requirement dictated by a minimum threshold stiffness. For example, focused investigations state to the contrary that softening and adding fillers might increase function and not allow the retaining forces to enhance damage-resistant capability, expectably resilient. Through proper balance of rubber formulation and operational demands, optimal capabilities can be achieved.

How hardness testing informs product development

Through product testing and the collection of feedback, the insights gained into the materials performance during force application provides critical information for further product development. With the comparison of certain parameters, such as the elasticity, toughness as well as the permanent deformation resistance of materials, engineers are able to estimate their workability in real life scenarios. Take the automotive domain: proper estimation of hardness of rubber parts functioning as seals or engine mounts have to ensure optimal sealing and wear resistance during mechanical loading and heating cycles. Accuracy in measuring and calculating the hardness value also helps to directly trace steps with different materials to achieve predetermined targets, which range between improving the material’s wear resistance to better its flexibility. As well, the provided data from hardness testing helps initial estimation of failure points during stress simulations, thus assuring the product is safe and reliable while improving the design.

Reference Sources

-

Improving Precision of Rubber Test Methods (1993): Focused on improving the precision of rubber hardness tests, particularly IRHD and Shore methods. Identified operator influence, temperature, load, and time as key factors affecting test repeatability and reproducibility.

-

Nonlinear Elastic Analysis of Hardness Tests (1991): Used finite-element analysis to study the relationship between IRHD values and the elastic properties of elastomers.

-

Determination of Rubber Components Influencing Hardness (2024): Explored the impact of various rubber components on hardness using statistical methods. Identified significant substances in rubber recipes that affect hardness, aiding in material optimization.

Frequently Asked Questions (FAQs)

Q: What is the durometer method for rubber property—durometer hardness?

A: The durometer method for rubber property—durometer hardness is a standardized approach used to determine the indentation hardness of rubber and elastomeric materials. It involves pressing a specific type of durometer gauge into the material and measuring the resistance to penetration.

Q: How does the ASTM D2240 test relate to rubber hardness measurement?

A: The ASTM D2240 test outlines the standard test method for determining the indentation hardness of rubber and elastomers. It specifies the equipment and procedures to ensure consistent and accurate measurements of rubber hardness.

Q: What types of rubber can be tested using the ASTM D2240 standard test method?

A: The ASTM D2240 standard test method can be applied to various types of rubber, including vulcanized or thermoplastic rubber. This versatility makes it suitable for assessing a wide range of rubber products used in different industries.

Q: What equipment is used in the ASTM D2240 test?

A: The equipment used in the ASTM D2240 test typically includes a durometer gauge, which is designed to apply a specified force to the rubber surface and measure the resulting indentation hardness. There are different durometer types, such as Shore A and Shore D, depending on the hardness scale required.

Q: What does the term “indentation hardness” mean in the context of rubber testing?

A: Indentation hardness refers to the resistance of a material to deformation when a specified force is applied. In rubber testing, it is used to quantify how hard or soft the rubber is based on the depth of indentation made by the durometer during the measurement process.

Q: Can the durometer method be used for plastics as well as rubber?

A: Yes, the durometer method is not limited to rubber; it is also applicable to various types of plastics and elastomers. The method allows for the assessment of hardness across different materials, which is essential for quality control in manufacturing.

Q: What is the significance of determining the indentation hardness of rubber products?

A: Determining the indentation hardness of rubber products is crucial for assessing their performance characteristics. Hardness can affect a product’s durability, flexibility, and overall suitability for specific applications, making it an essential factor in material selection.

Q: How does the hardness of rubber affect its modulus?

A: The hardness of rubber is directly related to its modulus, which measures the material’s stiffness. A higher hardness typically correlates with a higher modulus, indicating that the rubber will be stiffer and less flexible, which influences its performance in various applications.

Q: What factors can influence the results of the ASTM D2240 test?

A: Several factors can influence the results of the ASTM D2240 test, including the type of rubber being tested, the environmental conditions (such as temperature and humidity), and the calibration and precision of the durometer equipment used. Ensuring proper testing conditions is essential for accurate results.