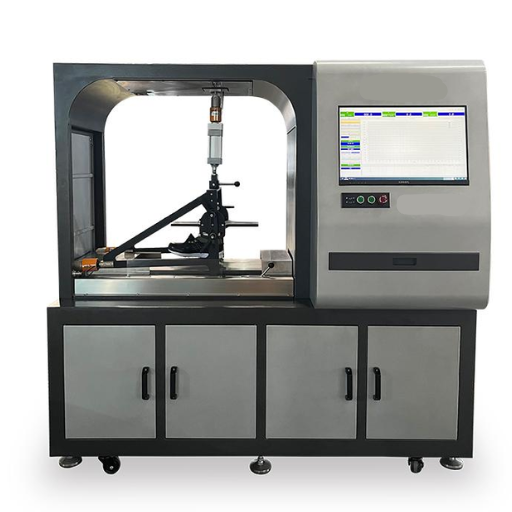

Footwear testing machines play a pivotal role in ensuring the quality, durability, and performance of footwear products before they reach consumers. With the footwear industry constantly striving to meet high standards and consumer expectations, these machines provide an essential means of verifying material integrity, comfort, and resilience under real-world conditions. This article explores the critical role of footwear testing equipment in the quality assurance process, highlighting the various types of machines used, their applications, and the value they bring to manufacturers and end-users alike. Whether you’re a footwear designer, quality control professional, or industry enthusiast, understanding these tools is crucial to navigating the intersection of innovation and reliability in footwear production.

What Is a Footwear Testing Machine?

A footwear testing machine is a specialized device designed to evaluate the performance, durability, and safety of footwear under various conditions. These machines simulate real-world stresses such as bending, abrasion, impact, and compression to ensure that the footwear meets industry standards and customer expectations. By replicating common wear scenarios, footwear testing machines help manufacturers identify potential weaknesses and improve overall product quality, ensuring reliability and compliance with regulatory requirements.

Key Components of Footwear Testing Equipment

- Compression and Flex Testing Mechanism

This component evaluates the durability and flexibility of footwear soles under sustained stress. It applies a specific force to mimic the pressure exerted during walking or running. Typical parameters include a compression force range of 0-50 kN and a flexing frequency of 125 ± 5 cycles/min.

- Abrasion Resistance Tester

Abrasion testers measure the wear resistance of outsoles and upper materials by simulating constant friction. Key specifications may include a rotational speed of 40 ± 2 rpm and an applied load of 500-1000 g, ensuring a precise assessment of surface endurance.

- Impact Testing System

This system tests the footwear’s ability to withstand sudden impacts, crucial for safety and high-performance shoes. The mechanism generally utilizes a falling weight or pendulum with an adjustable impact energy range of 5-50 J.

- Slip Resistance Testing Platform

To assess traction and prevent accidents, this platform measures the coefficient of friction on various surfaces. Common technical parameters include a load of 25 ± 5 kgf and surface angles adjustable up to 45° for incline tests.

- Waterproofing and Hydrolysis Testing Chamber

Designed to test the moisture resistance of footwear, this chamber subjects shoes to high humidity, water immersion, or hydrolysis simulations. Parameters typically involve temperatures ranging from 25°C to 65°C and variable humidity levels up to 98%.

- Tensile Strength Tester

This component evaluates the breaking strength of materials used in footwear construction, such as leather and textiles. Standard force ranges are from 0-10 kN, with elongation measurements up to 300%.

By integrating these components into the testing process, manufacturers can ensure comprehensive assessment and compliance with relevant technical standards, ultimately guaranteeing product performance and longevity.

How Does a Testing Machine Work for Shoes?

A testing machine for shoes operates by simulating real-world conditions to evaluate the performance, durability, and safety of footwear. It involves multiple testing modules explicitly designed for various parameters. For instance, the machine may use cyclic loading to assess wear resistance or motion simulators to replicate walking and running. Components such as tensile testers measure the strength and elongation of materials, while compression systems scrutinize sole impact resistance under pressure. Each test adheres to standardized protocols, ensuring reliability and consistency in results. Data collected helps manufacturers optimize materials and designs to meet quality and regulatory standards effectively.

The Role of Footwear Testing Machines in Quality Control

1.Assessment Silhouettes Construction Machines Tests: Footwear testing machines analyze the construction of removable soles such as concord and other stress causing components to check if they endure prolonged use.

2.Slip resistance testing: Through varying environmental and surface conditions, these machines test the slip resistance of the soles to improve safety and function.

3.Cushioning and Impact evaluation: The compression and rebounding of the footwear are measured, testing the level of cushioning and shock absorption, vital to the footwear and critical to the lessenable force on the body’s joints.

4.Flexibility and Bending Resistance: Repetitive bending of boots is takes place aboard a pivoting for deck hatch which helps assess foot wear flex resistance, comfort and longevity.

5.Environmental Resistance Analysis: Machinery applying erosive decaying actions simulate hair dryer blower flames, jack bore striking, hammer dulcimation, faucet hurling water, and oven frying to analyze if footwear withstands hostility.

How Do Testers Ensure the Quality of Shoes?

Testers ensure the quality of shoes through a rigorous series of assessments focused on durability, comfort, and performance. They utilize advanced mechanical and environmental simulation tools to identify potential weaknesses, such as material fatigue, insufficient traction, or reduced flexibility. Laboratory tests for wear resistance, impact absorption, and environmental stress factors provide a comprehensive understanding of a shoe’s capability. Additionally, quality assurance protocols involve both automated and manual inspections, ensuring defects are identified and rectified before mass production. This meticulous process guarantees that the final product meets industry standards and user expectations.

Types of Footwear Testing Methods

There are several types of footwear testing methods, including abrasion resistance, slip resistance, flex durability, tear strength, impact absorption, seam strength, and water resistance. These tests evaluate various performance parameters to ensure footwear safety, comfort, and durability.

|

Test Type |

Key Parameter |

Description |

|---|---|---|

|

Abrasion Resistance |

Durability |

Measures the wear and tear from repetitive friction or contact with surfaces. |

|

Slip Resistance |

Traction |

Evaluates grip and stability on various surfaces to prevent slipping. |

|

Flex Durability |

Flexibility |

Tests the material’s endurance under repeated bending and flexing. |

|

Tear Strength |

Strength |

Assesses the material’s ability to resist tearing under stress or force. |

|

Impact Absorption |

Cushioning |

Determines the footwear’s capacity to absorb shocks and reduce impact forces. |

|

Seam Strength |

Integrity |

Measures the robustness of seams to withstand tension and stress. |

|

Water Resistance |

Waterproofing |

Tests the footwear’s resistance to water penetration or absorption. |

The Importance of Abrasion Tester in Shoe Testing

The abrasion tester plays a critical role in ensuring the durability and longevity of footwear materials. By simulating repetitive frictional forces that occur during regular use, this tool provides measurable data on the wear resistance of fabrics, leathers, and other materials used in shoe manufacturing. Assessing abrasion resistance is essential to maintaining product quality and meeting industry standards, as it directly correlates to how well shoes can withstand prolonged usage under various conditions.

Key Technical Parameters of Abrasion Testing

- Load Applied: Typically ranges from 5 to 10 N, ensuring accurate simulation of real-life wear conditions without excessive force.

- Abrasion Cycles: Standard test cycles range from 5,000 to 25,000 revolutions, depending on the expected usage level and material type.

- Surface Finish: Abrasion testing often involves abrasive papers or specific textured surfaces standardized for reproducibility (e.g., grit size P220 or P400).

- Test Speed: Standard rotational speeds for the tester usually fall between 30–70 rpm to mimic natural friction rates.

- Abrasion Index: Outcome is measured in terms of weight loss (mg) or thickness reduction (mm), providing quantitative insights into material degradation.

By incorporating the abrasion tester into shoe testing protocols, manufacturers can confidently validate their materials for both functional performance and customer satisfaction, ultimately minimizing premature failures and improving the product’s lifecycle.

Understanding Compression Tests for Safety Shoes

Compression testing for safety shoes is a critical evaluation process designed to measure a shoe’s ability to withstand heavy loads without compromising the safety of the wearer. This test specifically assesses the protective toe cap and observes the deformation or failure under a predefined compressive force. Standards like ASTM F2413 and EN ISO 20345 dictate the benchmarks for acceptable performance, ensuring that the safety footwear is compliant with industry regulations.

The process involves placing the safety toe cap under a compressive load, where calibrated machinery applies a set force incrementally until failure or deformation thresholds are reached. Key parameters recorded include the maximum compressive force endured (typically measured in kN) and the residual clearance offered inside the toe cap post-deformation. For workplace safety, thresholds are established, such as the ability to withstand forces up to 15 kN or higher based on the designated protection rating, offering adequate resistance against crushing injuries.

By utilizing standardized compression tests, manufacturers can ensure that safety shoes meet both regulatory demands and real-world challenges, safeguarding users in hazardous environments such as construction, manufacturing, and heavy industry. This robust validation process not only enhances worker safety but also reinforces consumer trust in the reliability and durability of the footwear.

Why is Footwear Testing Equipment Crucial for the Industry?

Footwear testing equipment is essential for ensuring that products meet industry standards for safety, durability, and performance. By rigorously evaluating materials and finished products through specialized testing processes, manufacturers can identify potential defects, ensure compliance with regulatory requirements, and enhance product reliability. This not only minimizes risks for end-users but also helps manufacturers maintain a competitive edge by delivering superior-quality footwear that aligns with consumer expectations and industry benchmarks.

Benefits of Using Footwear Testing Equipment

- Enhanced Product Quality: Footwear testing equipment ensures that all materials and finished products meet stringent quality standards, resulting in durable and reliable footwear for consumers.

- Regulatory Compliance: By utilizing advanced testing equipment, manufacturers can verify that their products align with international safety and performance regulations, reducing the risk of penalties and recalls.

- Improved Consumer Safety: Testing processes identify potential hazards, such as slipping, abrasion, or material failure, creating safer products that protect end-users in various environments.

- Operational Efficiency: Automated and precise testing methods streamline quality control processes, reducing manual errors, saving time, and lowering production costs.

- Competitive Advantage: Consistently delivering high-quality, tested footwear helps brands build trust with customers and solidify their position in the market as providers of premium products.

Impact of Testing Equipment on Shoe Manufacturing

Testing equipment plays a pivotal role in ensuring the durability, safety, and performance of footwear during the manufacturing process. By simulating real-life stressors and conditions, manufacturers can accurately assess the quality and reliability of their products. Below are key areas where testing equipment impacts shoe manufacturing, combined with corresponding technical parameters:

- Material Performance Analysis

Advanced testing equipment, such as tensile testers, assesses the strength and elasticity of materials used in the upper, outsole, and midsole. For instance, material tensile strength is tested at forces typically ranging from 10 N to 50 N/mm², depending on the material type. This ensures the components meet the required standards for wear and tear resistance.

- Abrasion and Slip Resistance

Abrasion testers evaluate the lifespan of materials by subjecting them to repeated friction. Slip resistance testing equipment, compliant with standards like ASTM F2913 or ISO 13287, measures the coefficient of friction (COF), where typical acceptable values often range between 0.3 and 0.6 for safety and comfort assurance.

- Sole Flexing Resistance

Flexing machines simulate continuous bending to test midsole and outsole durability. Most testing methodologies involve flexing the sole over 30,000 cycles at various angles (usually 90-120 degrees) to identify potential failures such as cracking or material degradation.

- Waterproofing and Breathability Testing

Equipment such as hydrostatic pressure testers determines the waterproof capacity of footwear materials by applying water pressure, generally ranging from 0.1 to 1.0 MPa depending on product specifications. Additionally, breathability meters quantify moisture vapor transmission rates (MVTR), with preferred values exceeding 10,000 g/m²/day for premium performance footwear.

- Compression and Impact Resistance for Safety Footwear

Testing equipment measures the ability of safety shoes to withstand heavy loads and impacts. For instance, compression resistance assessments are typically conducted with forces up to 200 Joules to mimic workplace hazards. These tests ensure compliance with safety certifications such as ASTM F2413 or EN ISO 20345.

- Environmental Simulation Tests

Climatic chambers replicate extreme conditions such as high temperatures, humidity, and UV exposure to study material performance over time. For example, UV resistance equipment often irradiates footwear with 340 nm wavelength light to test color and material endurance.

By integrating precise, automated testing equipment into production workflows, manufacturers not only enhance product quality but also maintain compliance with international standards, fostering greater consumer trust.

Choosing the Right Tester for Your Needs

When choosing the right tester for my needs, I focus on three critical factors. First, I evaluate the specific materials and performance characteristics that require testing, such as abrasion resistance or UV durability, ensuring the tester aligns with industry standards like ASTM or ISO. Next, I consider the operational requirements, including automation capabilities, software integration, and overall ease of use, to streamline workflows and improve accuracy. Lastly, I assess the long-term value, balancing cost with reliability, calibration support, and manufacturer reputation to ensure consistent, dependable results over time.

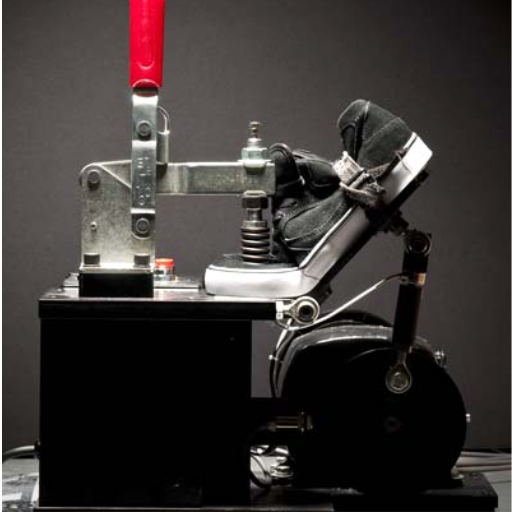

What Role Does the Bennewart Flex Tester Play in Footwear Testing?

The Bennewart Flex Tester plays a critical role in assessing the flexibility and durability of footwear materials under repeated bending conditions. By simulating the mechanical stress experienced during usage, this device evaluates the resistance of soles and other components to cracking, separation, or structural failure. The data obtained ensures compliance with industry standards and provides insight into product longevity, aiding manufacturers in developing high-performance footwear that meets both functional and durability requirements.

Application and Function of Bennewart Flex Tester

- Evaluating Flex Resistance: Measures the ability of materials to withstand repeated flexing motions without exhibiting cracks, splits, or other structural failures.

- Durability Testing: Assesses the long-term durability of footwear components, ensuring they meet specific performance requirements under prolonged mechanical stress.

- Material Selection: Aids manufacturers in identifying the best materials for production by analyzing their resistance to dynamic deformation.

- Quality Assurance: Ensures that products comply with established industry standards and specifications, fostering customer satisfaction and reliability.

- Product Development and Innovation: Provides critical data to support innovation in product design, enabling the development of advanced materials with superior endurance and flexibility.

Comparing Bennewart Flex Tester with Other Flex Testing Machines

The Bennewart Flex Tester, along with other prominent flex testing machines like the Ross Flex Tester, the Bally Flex Tester, and the De Mattia Flex Tester, are commonly used to assess the flexibility and endurance of materials under repeated stress conditions.

|

Parameter |

Bennewart |

Ross Flex |

Bally Flex |

De Mattia |

|---|---|---|---|---|

|

Application |

Rubber |

Rubber |

Leather |

Rubber |

|

Standards |

ISO, ASTM |

ISO |

ISO |

ISO, ASTM |

|

Speed (rpm) |

Adjustable |

Fixed |

Fixed |

Adjustable |

|

Test Cycles |

High |

Medium |

Medium |

High |

|

Material Size |

Large |

Medium |

Small |

Medium |

|

Durability |

High |

High |

Moderate |

High |

|

Output Data |

Quantified |

Basic |

Visual |

Quantified |

|

Adjustability |

High |

Low |

Low |

Medium |

How Do Shoe Testing Machines Measure Tensile Strength and Elongation?

Shoe testing machines measure tensile strength by applying a controlled uniaxial force to a sample until it breaks. The process often involves gripping the material securely at both ends and increasing the load at a constant rate to determine the maximum force the material can withstand. This is vital for assessing a shoe’s resistance to tearing under stress.

For elongation measurement, the machines calculate the percentage increase in the sample’s length relative to its original length during the tensile test. This data is critical for understanding the flexibility and deformation characteristics of the shoe material under stress, contributing to evaluations of durability and performance standards. These measurements comply with industry-specific protocols such as ISO 3376 or ASTM D5034 to ensure consistent and accurate results.

Understanding Tensile Testing in Footwear

Tensile testing evaluates the mechanical characteristics of footwear and its components and materials by measuring strength, elasticity, and stiffness. A controlled force is applied until failure occurs, and in doing so, the material’s tensile strength, elongation at break threshold, and modulus of elasticity can be determined. This is crucial with regard to forecasting a material’s behavior under stress and evaluating its appropriateness for distinct purposes in footwear design and manufacturing.

Commonly employed standards, including ISO 3376, ASTM D5034, and ASTM D638, outline the methodologies for conducting tensile tests, ensuring uniformity and precision in measurements. The insights gained from tensile testing help manufacturers select materials that enhance the durability, comfort, and structural integrity of footwear, meeting both industry specifications and consumer expectations. By systematically uncovering a material’s mechanical behavior, tensile testing ensures that products maintain performance and safety standards across their intended lifespan.

Evaluating Elongation and Its Impact on Shoe Durability

Elongation, a critical parameter in material science, refers to the extent to which a material can stretch or deform under tensile stress before breaking. Its evaluation is vital in determining the suitability of materials used in footwear construction. Materials with high elongation percentages, often measured in compliance with standards such as ASTM D638 or ISO 37, exhibit better flexibility and resistance to cracking under repeated stress, contributing to enhanced durability. For instance, elastomers used in midsoles typically demonstrate elongation values ranging from 250% to 900%, depending on formulation. Conversely, materials with low elongation are better suited for structural components requiring rigidity and dimensional stability, such as shoe shanks.

The impact of elongation on shoe durability lies in its ability to absorb and adapt to forces generated during walking or running. Over time, a balance between sufficient elongation and tensile strength ensures the material can endure cyclical loading without permanent deformation or failure. Excessive elongation, however, may lead to material fatigue and reduced structural integrity, emphasizing the need for precise material selection and testing to align with performance requirements.

Reference Sources

-

SATRA – Footwear Testing, Research, and Consultancy: Offers comprehensive testing, production efficiency solutions, and technical consultancy for the footwear industry.

-

AMETEK Test – Recommended Test Machines for Footwear Testing: Provides details on advanced footwear testing machines and standards.

-

ZwickRoell – Fatigue Tests on Shoe Soles: Focuses on fatigue tests for shoe soles, material development, and quality control.

-

NuShoe – Footwear Inspection Quality Control Tips: Offers insights into effective footwear inspection and quality control practices.

-

Top Footwear Testing Machine in China

Frequently Asked Questions (FAQs)

Q: What is the purpose of footwear testing machines?

A: Footwear testing machines are used to test various properties of shoe materials and finished footwear, ensuring quality assurance. These machines help test the impact resistance, flexibility resistance, and penetration resistance of shoes, among other attributes.

Q: How does a tensile testing machine function in footwear testing?

A: A tensile testing machine is used to test the tensile strength and elasticity of footwear materials. It assesses how much strain a material can withstand before breaking, which is crucial for ensuring the durability of shoe components.

Q: What is a din abrasion tester and how is it used?

A: A din abrasion tester evaluates the wear resistance of different materials used in footwear. It assesses the abrasion resistance which is important in determining the life span of shoe soles and upper parts of the shoe.

Q: How is compression set tested in footwear materials?

A: Compression set is tested by evaluating the decrease in thickness a material experiences after it has been subjected to a constant load. This measurement is critical pertaining to the level of comfort and the functionality of the foam and rubber materials in the footwear.

Q: What are some footwear testing equipments mainly used for color matching?

A: Color matching equipments mainly used in footwear testing include spectrophotometers and colorimeters. These devices assess the color fastness and yellowing resistance of shoe materials to ensure consistent and accurate color reproduction.

Q: How is the ross flexing test conducted on shoe materials?

A: The ross flexing test is used to test the flexibility resistance of shoe materials by subjecting them to sole through reciprocating flexing movements. This test helps determine the material’s ability to withstand repeated bending without cracking or breaking.

Q: What role does a peel tester play in footwear testing?

A: A peel tester is used to test the adhesion strength between different layers or components of a shoe. This test ensures that the sole, upper, and other parts of the shoe remain securely bonded under various conditions.

Q: Why is density important in footwear material testing?

A: Density is an important parameter in footwear material testing as it affects the overall weight and comfort of the shoe. Testing for density helps in selecting materials that provide the right balance between durability and lightness.

Q: What is the significance of penetration resistance testing in footwear?

A: Penetration resistance testing is crucial for assessing the safety features of footwear, especially for industrial and safety shoes. This test is used to test the impact resistance of shoe materials against sharp objects, ensuring wearer protection.