Geotextiles have become an indispensable component in modern engineering and construction, providing innovative solutions to challenges related to soil stabilization, drainage, filtration, and erosion control. However, the effectiveness and durability of geotextiles are highly dependent on their quality and performance, which is why robust testing methods are critical. This guide aims to demystify the various testing techniques used to evaluate geotextiles, offering a detailed exploration of their applications, standards, and performance criteria. Whether you’re a civil engineer, project manager, or a professional in the construction industry, this article will equip you with the knowledge needed to understand the key metrics, methodologies, and assessments that ensure geotextile materials meet project-specific demands. Prepare to dig into the technical intricacies of geotextile testing and uncover the science behind their real-world functionality.

What Is Astm and How Does It Relate to Geotextile Testing?

ASTM, or the American Society for Testing and Materials, is an international standards organization that develops and publishes technical standards for a wide range of materials, including geotextiles. These standards ensure quality, consistency, and performance across products and applications. For geotextiles, ASTM defines specific testing methodologies to evaluate critical properties such as tensile strength, permeability, puncture resistance, and durability. By adhering to ASTM standards, engineers and professionals can confidently assess whether a geotextile meets the necessary requirements for its intended use, maintaining project reliability and safety.

Understanding the Role of ASTM in Testing of Geotextile Material

ASTM plays a critical role in ensuring standardized evaluation of geotextile materials, particularly in assessing their suitability for various civil engineering applications. The organization provides precise testing protocols designed to measure key technical parameters, ensuring consistency, reliability, and safety. Below are the critical parameters and their corresponding ASTM testing methods:

- Tensile Strength and Elongation (ASTM D4632): Evaluates a geotextile’s resistance to tensile forces, reflecting its capability to withstand applied stresses without failure.

- Permeability (ASTM D4491): Measures the ability of the geotextile to allow water flow perpendicular to its plane, critical for drainage and filtration functions.

- Puncture Resistance (ASTM D4833): Assesses the material’s resistance to perforation, crucial for durability under stress from sharp objects or uneven surfaces.

- Apparent Opening Size (AOS) (ASTM D4751): Defines the pore size distribution to ensure proper filtration while preventing soil migration.

- Ultraviolet (UV) Resistance (ASTM D4355): Tests the material’s resistance to degradation caused by exposure to sunlight, ensuring long-term durability in exposed installations.

- Burst Strength (ASTM D3786): Evaluates geotextile resistance to hydraulic forces, essential for applications under high water pressure.

These testing methods ensure that geotextiles meet design and operational requirements for applications such as erosion control, soil stabilization, and drainage systems, ultimately contributing to the integrity and success of engineering projects.

Key ASTM Standards for Geotextile Tests

The following ASTM standards are pivotal in determining the performance and applicability of geotextiles in engineering and construction projects:

- ASTM D4751 – Standard Test Method for Determining Apparent Opening Size of a Geotextile: This test establishes the nominal maximum opening size (pore size) in geotextiles, which is critical for filtration and separation applications.

- ASTM D4491 – Standard Test Methods for Water Permeability of Geotextiles by Permittivity: This standard evaluates the geotextile’s ability to pass water under specified conditions, essential for drainage and hydraulic flow performance.

- ASTM D4632 – Standard Test Method for Grab Breaking Load and Elongation of Geotextiles: It measures tensile strength and elongation properties, crucial for assessing durability and mechanical stability under tensile loads.

- ASTM D6241 – Standard Test Method for Static Puncture Strength of Geotextiles and Geotextile-Related Products Using a 50-mm Probe (CBR Plunger Test): This method evaluates puncture resistance, vital for geotextiles used in road construction and subgrade reinforcement.

- ASTM D5035 – Standard Test Methods for Breaking Force and Elongation of Textile Fabrics (Strip Method): Aims to determine the fabric’s strength over its length and width to assess stress resistance in various applications.

These standards allow engineers to select and verify geotextiles that meet specific project demands, optimizing safety, functionality, and longevity in structural and environmental engineering contexts.

Importance of ASTM D6241 and ASTM D4632 in Geotextile Assessment

ASTM D6241 – Standard Test Method for Static Puncture Strength of Geotextiles and Geotextile-Related Products (CBR Test): This standard evaluates a material’s resistance to static puncture under a concentrated load, enabling the assessment of its suitability in applications requiring puncture resistance. The test determines the maximum force (kN) and corresponding displacement (mm) under controlled conditions, critical for designing stable and durable geotechnical projects.

ASTM D4632 – Standard Test Method for Grab Breaking Load and Elongation of Geotextiles: This method focuses on the grab tensile properties of geotextiles, including tensile strength (N) and elongation (%). It is particularly valuable for understanding a material’s response to uniaxial stress, assisting in the evaluation of load-bearing capacity and flexibility of geotextiles in field conditions.

Both standards provide quantifiable data essential for selecting geotextiles that meet project-specific environmental, structural, and stress-related performance criteria. By defining precise technical parameters, these tests enable engineers to predict long-term performance and ensure compliance with safety and durability requirements.

How is the Tensile Strength of Geotextiles Measured?

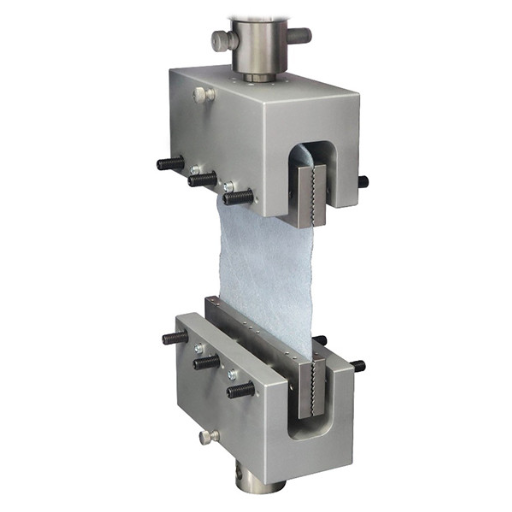

The tensile strength of geotextiles is measured through standardized testing methods, most commonly ASTM D4595 and ASTM D5035. These methods involve the application of controlled tensile forces to geotextile specimens under specified conditions until failure occurs. Key parameters such as ultimate tensile strength, elongation, and stress-strain behavior are recorded. ASTM D4595 assesses wide-width strips to eliminate edge effects, providing data more representative of field performance, while ASTM D5035 evaluates narrower specimens for specific applications. Both methods contribute to a comprehensive understanding of a geotextile’s mechanical properties and suitability for intended uses.

Overview of Tensile Test Methods for Geotextiles

To comprehensively evaluate the tensile properties of geotextiles, ASTM D4595 and ASTM D5035 serve as widely recognized standards, each catering to different testing requirements. ASTM D4595 specializes in measuring the tensile strength of wide-width geotextile strips. By using specimens with controlled dimensions, it minimizes edge effects and simulates real-world performance under uniform stress, offering highly reliable data for field applications such as soil reinforcement and load distribution.

Conversely, ASTM D5035 addresses the tensile properties of narrower fabric specimens. This method is especially applicable for lighter geotextiles or projects where edge conditions are critical, though it may not provide the same field-representative outputs as ASTM D4595. Specimens are clamped and subjected to tension to determine breaking force and elongation at failure, which are critical factors for quality control and material consistency.

By combining insights from both methods, engineers and researchers can achieve a robust assessment of geotextile performance, ensuring that the material’s strength and durability align with the required project specifications, whether for infrastructure, drainage, or erosion control applications.

Procedure for Tensile Properties of Geotextiles Using a Wide-Width Strip

The procedure for determining the tensile properties of geotextiles using a wide-width strip involves several critical steps to ensure accuracy and compliance with standards. First, the geotextile specimen is prepared by cutting it to the specified dimensions, ensuring that the fabric’s structure and integrity remain unaffected. The specimen is then clamped in the testing machine’s grips, ensuring even distribution of force and avoiding slippage.

Next, the testing machine, calibrated to the required specifications, applies a uniaxial tensile force at a constant rate of extension. The load and elongation data are continuously measured until the specimen reaches its breaking point. These measurements, including peak load and elongation at failure, are recorded to evaluate the material’s tensile strength and deformation characteristics.

Finally, multiple specimens are tested to account for variability, and the results are analyzed. This ensures the geotextile’s performance aligns with project requirements, offering reliable data for engineering applications.

Evaluating Elongation and Tensile Strength with Universal Testing

To evaluate elongation and tensile strength using universal testing, I would follow a systematic process centered on precision and repeatability. First, I would prepare standardized specimens according to relevant ASTM or ISO guidelines to ensure consistent testing conditions. Then, I would use a universal testing machine equipped with appropriate grips and load cells to apply a uniaxial tensile force. During testing, strain measurements would be captured, typically with an extensometer or a similar device, to accurately determine elongation. The data would allow me to analyze tensile strength, yield strength, and elongation at break, ensuring all results are evaluated against the specific performance criteria of the material.

What Are the Procedures for Puncture Resistance Tests on Geotextiles?

Puncture resistance tests on geotextiles typically follow standardized methods such as ASTM D4833 or similar protocols. The procedure involves securing the geotextile specimen in a testing fixture while a standardized probe or pin is applied at a consistent rate of penetration perpendicular to the material surface. The test determines the force required to puncture the geotextile. Load and displacement measurements are recorded during the test. These data are used to evaluate the material’s puncture resistance, which is critical for assessing its suitability in applications requiring durability against mechanical forces.

Exploring Methods for Determining Puncture Resistance of Geotextiles

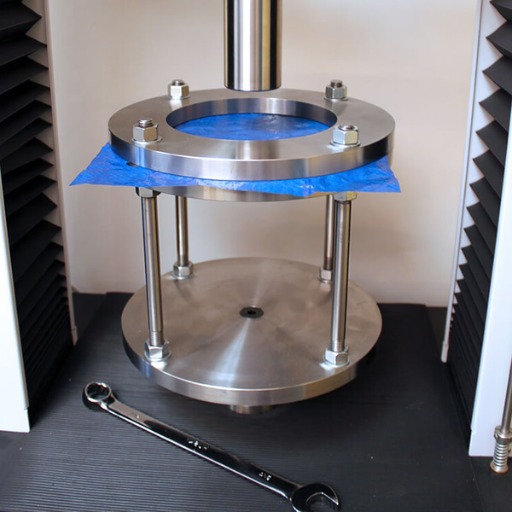

To accurately determine the puncture resistance of geotextiles, several standardized test methods are employed. Among the most widely used is the ASTM D6241 test, also known as the Static Puncture Test (CBR Test). This method evaluates the geotextile’s resistance to puncture by pressing a plunger with a defined diameter (usually 50 mm) through the material at a specified displacement rate, typically 50 mm/min. Key technical parameters recorded during the test include:

- Maximum Force (kN): The peak force exerted on the material before puncture occurs.

- Displacement at Peak Force (mm): The distance the probe penetrates when the maximum force is reached.

- Energy Absorption (J): The total work done during puncture, calculated from the force-displacement curve.

Additionally, the EN ISO 12236 method is often applied in international settings, following similar principles to the ASTM D6241 standard with minor variations in probe specifications and displacement rates. Proper sample conditioning, including temperature and humidity control, ensures repeatability and reliable results. These methods provide critical data for comparing geotextile performance in applications requiring mechanical robustness.

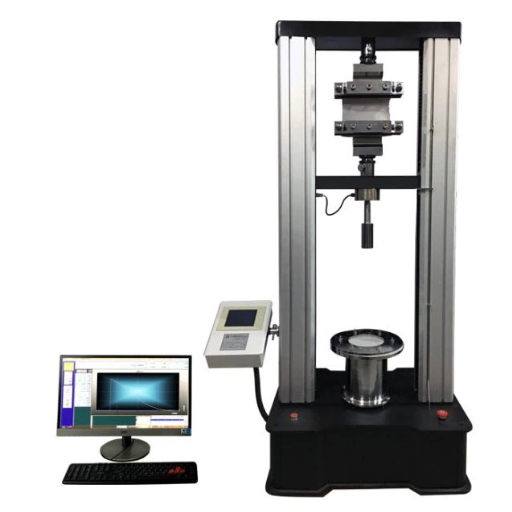

Key Equipment for Puncture Testing in Geotextile Materials

Puncture testing of geotextile materials requires precision equipment to ensure accurate and repeatable measurements. The primary apparatus includes:

- Universal Testing Machine (UTM)

The Universal Testing Machine is equipped with a calibrated load cell capable of accurately measuring force. It must be compatible with a circular steel probe, typically designed to match the dimensions prescribed by standards such as ASTM D6241 or EN ISO 12236, where the probe diameter is 50 mm. The machine should allow a controlled displacement rate, such as 50 mm/min, as commonly specified. Adjustable grips or clamps are used to securely fix the geotextile specimen without slippage during testing.

- Circular Steel Probe

The probe used in puncture tests must adhere to precise specifications to ensure uniform application of force. For example, ASTM D6241 specifies a 50 mm diameter probe, while the ISO 12236 standard may allow small variations. The probe must be constructed from highly durable materials such as stainless steel to avoid deformation under repeated loading conditions.

- Test Frame and Specimen Clamping System

A robust test frame is vital to hold the geotextile material in place during puncture testing. The clamping system must provide uniform specimen fixation around the target area to prevent tearing or movement that could compromise the data. Typically, the clamping rings have inner diameters of 150 mm to 200 mm, accommodating standard sample sizes.

- Environmental Control System

Accurate testing requires temperature and humidity-controlled environments matching the conditions under which geotextiles will be deployed. Standard recommendations suggest conditioning the samples at 21°C ± 2°C and 65% ± 5% relative humidity for a minimum of 24 hours prior to testing.

- Data Acquisition and Analysis Software

Advanced puncture testing relies on integrated software to record force-displacement data. These systems provide real-time visualization, automated calculations for peak puncture resistance, and detailed output graphs. They ensure compliance with technical standards by minimizing human error during data processing.

This equipment framework ensures compliance with international testing protocols and allows engineers to evaluate geotextile puncture resistance with high precision and consistency.

Comparing Puncture Strength Across Geotextile Fabrics

Various geotextile fabrics, including woven, non-woven, knitted, and composite types, exhibit distinct puncture resistance characteristics based on their material properties and construction methods.

|

Fabric Type |

Strength |

Elongation |

Thickness |

Material |

|---|---|---|---|---|

|

Woven |

High |

Moderate |

Thin |

Polypropylene |

|

Non-Woven |

Moderate |

High |

Thick |

Polyester |

|

Knitted |

Low |

High |

Thin |

Polyethylene |

|

Composite |

Very High |

Moderate |

Varied |

Hybrid |

This table highlights the puncture resistance (strength), elongation capacity, and physical characteristics of different geotextile fabric types to aid in selecting the appropriate material for specific engineering applications.

How Do Geotextile Test Systems Function?

Geotextile test systems function by evaluating the mechanical and hydraulic properties of geotextile materials under controlled conditions. These systems measure parameters such as tensile strength, puncture resistance, permeability, and elongation to assess material performance. Tests are conducted using specialized equipment, including tension testers and permeability apparatus, to replicate real-world stresses and interactions with soil, water, or other materials. The results provide critical data for determining suitability in various engineering applications, ensuring durability, reliability, and compliance with technical standards.

Components and Setup of Geotextile Test Systems

A geotextile test system comprises specialized instruments and equipment designed to evaluate key performance metrics such as tensile strength, puncture resistance, and hydraulic properties. The primary components include a universal testing machine equipped with grips for tension and compression tests, a permeability testing apparatus to measure water flow through the fabric, and a bursting strength tester to assess resistance to localized pressure. Additional elements, such as load cells, strain gauges, and temperature-controlled environments, may be integrated depending on the specific testing parameters.

The setup requires precise calibration and alignment of equipment to ensure accurate readings, adhering to standards such as ASTM D4595 for tensile properties or ASTM D4491 for permeability. Specimens are secured in designated fixtures, and testing conditions are rigorously maintained to replicate expected field environments. Data acquisition systems are employed to record results in real-time, enabling detailed analysis for compliance with engineering requirements. The careful assembly and operation of this system are crucial for producing reliable and reproducible data essential for design and material selection.

Utilizing Test Equipment for Geotextiles

Testing geotextile materials requires precise equipment and standardized methodologies to ensure accurate characterization of properties such as tensile strength, permeability, and puncture resistance. The most commonly used tests include ASTM D4595 for tensile performance and ASTM D4491 for water flow rates. Specialized fixtures securely hold specimens during testing, replicating relevant field conditions to ensure applicability of results.

For tensile strength testing, controlled tension is applied to measure the material’s response under stress, identifying its breaking point. Permeability tests, such as falling head and constant head methods, determine the geotextile’s capacity to allow water to pass through while retaining soil particles. Additionally, puncture resistance tests evaluate the material’s durability when subjected to concentrated forces.

Modern laboratories employ automated data acquisition systems to monitor, record, and analyze test outputs in real-time. Advanced software integrates these data points, producing detailed reports for compliance evaluation and optimizing material selection processes. When using test equipment, meticulous calibration and adherence to standards are essential to generate reliable results, paving the way for robust geotechnical engineering applications.

Advanced Techniques in Testing Geotextiles

Advanced techniques for testing geotextiles involve a combination of mechanical, hydraulic, and durability assessments to ensure performance under varying environmental conditions. Key procedures include tensile strength testing, which measures the material’s resistance to applied forces using standards such as ASTM D4595, and puncture resistance tests, which evaluate the ability of geotextiles to withstand concentrated pressures. Hydraulic properties are analyzed through permeability testing (ASTM D4491) to determine water flow capacity and filtration capability.

Dynamic performance tests, such as cyclic loading and accelerated aging (exposure to UV light, moisture, and chemicals), are critical for assessing long-term durability and predicting field performance. Soil-geotextile interaction is tested through pull-out resistance tests and direct shear testing to ensure stability in geotechnical applications. The integration of automated testing equipment and digital imaging techniques has further refined accuracy, enabling researchers to monitor deformation, strain distribution, and microstructural changes in real-time. These advances collectively enhance the reliability and applicability of geotextiles in infrastructure development.

Why is Reinforcement Important in Geotextiles?

Reinforcement in geotextiles is essential for improving the mechanical performance and durability of soil structures. By providing tensile strength and distributing loads evenly, reinforced geotextiles enhance the stability of slopes, retaining walls, and roadways. This reduces the risk of settlement and structural failure, particularly in applications involving weak or compressible soils. Additionally, reinforcement mitigates deformation under stress, ensuring long-term functionality and resilience of the engineered system in various environmental conditions.

The Role of Geotextiles in Soil Reinforcement

- Erosion Control: Geotextiles prevent soil erosion by stabilizing the ground surface and promoting vegetation growth, particularly on slopes and areas exposed to water flow.

- Separation: By maintaining the separation of different soil layers, geotextiles ensure the integrity of the structural foundation and prevent the mixing of materials, which could negatively affect load-bearing capacity.

- Drainage: Geotextiles facilitate water flow within soil systems, acting as a filtration layer to allow the passage of liquids while blocking soil particles, thereby improving drainage efficiency.

- Load Distribution: By evenly distributing applied loads across a broader surface area, geotextiles enhance the stability and durability of engineered structures, reducing localized stress and settlement.

- Filtration: Geotextiles provide effective filtration by allowing water to move through soil layers without losing particles, crucial in applications like retaining walls, landfills, and roadbeds.

Evaluating the Reinforcement Capabilities of Different Geotextile Types

When assessing the reinforcement capabilities of various geotextile types, it is essential to consider their mechanical properties, material composition, and specific applications. Below are the most commonly used geotextiles alongside their technical specifications and typical functions:

- Woven Geotextiles

Woven geotextiles are manufactured by weaving fibers to form a highly durable, tensile fabric. They are specifically designed for applications requiring high tensile strength and load distribution.

– Tensile Strength: Typically ranges from 20 kN/m to over 200 kN/m, depending on material and design.

– Elongation at Break: Usually less than 15%, offering low deformation under load.

– Applications: Ideal for road construction, retaining walls, and high-load-bearing surfaces.

- Non-Woven Geotextiles

Non-woven geotextiles are created through processes like needle punching or heat bonding of synthetic fibers, resulting in a fabric optimized for filtration and drainage.

– Tensile Strength: Lower than woven types, averaging between 6 kN/m and 50 kN/m.

– Elongation at Break: Ranges from 30% to 100%, making them versatile in accommodating soil movements.

– Applications: Preferred for drainage systems, landfill liners, and projects requiring separation and filtration.

- Knitted Geotextiles

Knitted geotextiles are produced using knitting techniques with synthetic yarns, combining flexibility and strength. These are specifically used in situations requiring adaptability and versatility.

– Tensile Strength: Ranges from 10 kN/m to 100 kN/m.

– Applications: Suitable for coastal erosion control and reinforcement of irregular or steeply sloped terrains.

Application of Geotextile Reinforcement in Construction

- Roadway Stabilization

Geotextiles are used to reinforce subgrade soils and prevent deformation under heavy traffic loads, enhancing the longevity and performance of roadways.

- Retaining Wall Support

They provide critical reinforcement for retaining wall structures by improving soil stability and distributing stress more evenly.

- Landfill Liners and Covers

Geotextiles act as protective layers in landfill systems, offering separation between different materials and preventing leachate migration into surrounding environments.

- Slope and Embankment Reinforcement

By stabilizing steep slopes and earthen embankments, geotextiles mitigate the risk of soil erosion and structural collapse.

- Railway Foundation Reinforcement

Geotextiles improve load distribution and prevent track deformation by strengthening the subgrade beneath railway foundations.

Reference Sources

-

Geotextile Lab Testing – Geocomp: Provides insights into industry-accepted standard test methods like ASTM D6241.

-

Geotextile Testing – TestResources: Offers details on testing machines and methods for measuring properties like tensile strength and puncture resistance.

-

GRI Test Methods – Geosynthetic Institute: Covers test methods and properties for high-strength geotextile tubes used in coastal and riverine structures.

-

ASTM D4751 – Apparent Opening Size Test Methods: Focuses on determining the apparent opening size (AOS) of geotextiles.

-

Top Test Fixtures in China

Frequently Asked Questions (FAQs)

Q: What are geotextiles and their primary functions?

A: Geotextiles are permeable fabrics used in construction and engineering projects to enhance soil stability, provide erosion control, and assist in drainage. They are primarily used to separate, filter, reinforce, protect, or drain soils.

Q: What are the common types of geotextiles?

A: The common types of geotextiles are woven and nonwoven geotextiles. Woven fabrics are made by weaving fibers together, providing high tensile strength, while nonwoven geotextiles are made by bonding fibers together, offering excellent filter and drainage properties.

Q: How is the tensile strength of geotextiles tested?

A: The tensile strength of geotextiles is often tested using a grab test, which is a tensile test method. This involves using a tensile testing machine to apply a force on a geotextile sample until it breaks. The grab test is a tensile test that evaluates the resistance of a geotextile to multidirectional force.

Q: What is the significance of the thickness of the geotextile?

A: The thickness of the geotextile is crucial as it affects the fabric’s filtration and drainage capabilities. A thicker geotextile might provide better durability and cushioning, whereas a thinner one might allow for higher flow rates through geotextiles.

Q: How are geotextiles tested for permeability?

A: Geotextiles are tested for permeability using tests such as the constant head test or the falling head test. Although constant head testing is used for soil samples, the falling head test is often preferred for geotextiles to measure how water passes through a geotextile due to its adaptability to different conditions.

Q: What role does the width of the specimen play in geotextile testing?

A: The width of the specimen is critical in testing as it ensures uniformity and accuracy in results. When using a wide-width strip specimen, the test evaluates the overall strength and elongation properties of the geotextile, which are essential for determining its suitability for specific applications.

Q: Why is acceptance testing important for geotextiles?

A: Acceptance testing is vital to ensure that geotextiles meet specific performance standards and design requirements. It involves evaluating various properties of geotextiles, such as tensile strength, permeability, and resistance, to provide design parameters that ensure the material’s reliability and effectiveness in its intended application.

Q: How does the resistance of a geotextile to environmental factors get evaluated?

A: The resistance of a geotextile to environmental factors such as UV exposure, chemical exposure, and biological degradation is evaluated through a series of standardized tests. These tests help predict the long-term durability and performance of the geotextile in different environmental conditions.

Q: Can you describe a method used to determine geotextile properties?

A: One method to determine geotextile properties is tensile testing using a tensile testing machine. This method describes a method for assessing the material’s strength and elasticity, which are critical for ensuring the geotextile can withstand the forces it will encounter in situ.