The Universal Testing Machine (UTM) has revolutionized material testing by delivering accuracy and flexibility through dependable systems for engineers, researchers, and manufacturers to assess the mechanical characteristics of different materials. In addition to tests like measuring tensile strength, compressive forces, or bending resistance, the vertical pillar construction, automotive industry, and aerospace industry would not function effectively without the UTM across all of its branches. This blog will detail the core functions of a Universal Testing Machine, emphasize its irreplaceable role in maintaining quality assurance and product integrity while safeguarding structural reliability, discuss product innovations through exposure to the workings of materials and detail formulation derived from positive and negative stresses, fracture mechanisms, and internal material movement, and the role such devices play in innovation advancement through design and accuracy.

What is a Universal Testing Machine and How Does it Work?

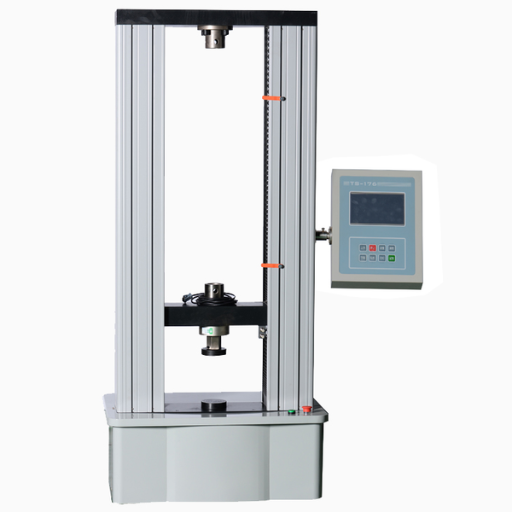

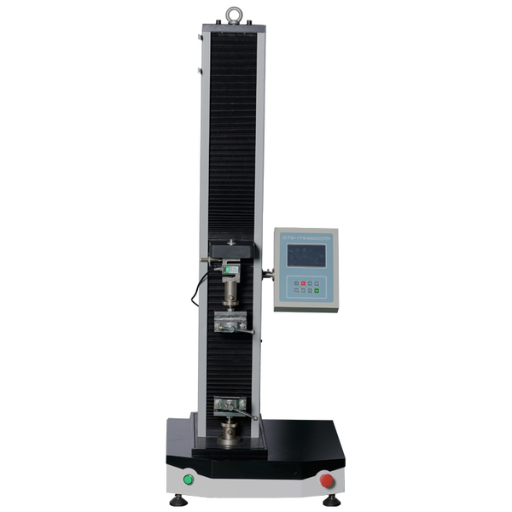

Like all equipment, a universal testing machine (UTM) has designated operating, limiting, and force zones. It evaluates the mechanical properties of materials under a variety of activities and assesses tensile, compressive, and shear strengths. The machine consists of key components such as a loading frame, crossbar, force transducers, grips, fixtures, and specimen holders.

On the UTM’s operation, hydraulics and electromechanical systems provide a controlled force while simultaneously measuring the material’s response with precision sensors. This data is then processed and presented with advanced algorithms, revealing insights that guarantee compliance with regulatory standards and bolster further innovation and development initiatives.

What are the main components of a UTM?

A Universal Testing Machine (UTM) has several primary parts which work collaboratively to provide seamless tests. These include:

- Load Frame

The load frame is the main structure of the UTM’s axial alignment systems, or at least it’s the most important one regarding structural stability. It usually takes the form of two vertical columns joined by crossheads, and it should also be robust to musculoskeletal injuries.

- Crosshead

The crosshead is the elevators that go up and down with the columns, and it may be park manually or automatically. Its movement is essential for control of strain, as it can move to apply tension or compressive forces to the specimen.

- Load Cell

The load cell is one type of very sensitive transducer called strain gages featuring very specific characteristics in relation to its measuring range. It transforms a given force’s mechanical representation into an electrical signal and needs to respect certain standards of precision including within set limits.

- Grips or Fixtures

Grips or fixtures are utilized to ensure that the specimen is securely held in position during testing. These components may include wedge grips, pneumatic grips, or specialized fixtures, tailored for testing specific shapes or properties of the material.

- Drive System

The application of force can be generated by a drive system either electromechanically or hydraulically. For high force requirements, a hydraulic system would be appropriate, while precision, lower force tests would use an electromechanical system.

- Control and Data Acquisition System

With this system, users can define the parameters of the test and track real-time data from the test’s sensors. Modern UTMs utilize advanced software for controlling the testing processes, data acquisition, and post-test detailed evaluation, ensuring compliance with all testing requirements.

- Extensometer

An extensometer automatically measures strain on a specimen and its deformation with great precision. It aids in the determination of certain material characteristics such as its modulus of elasticity as well as its elongation.

In assuring reliable and standardized material testing in diverse industries, every component has a specific function to fulfill the precision and performance standards of modern Ultrasonic Testing Machines (UTMs).

How does the testing system function?

As with any material testing system, the UTM is built around the application of precision measurements of force to a specimen. As with any specimen, it is first fixed securely within the grips of the Universal Testing Machine (UTM). The machine subsequently applies a specific force: one of tension, compression, bending, or shear, corresponding to the selected test. Each step of the process, including the application of tension through a load cell, extensometer, or strain gauge measures deformation, is done with precision.

The use of specific machine software coupled with digital controllers facilitates the real-time collection, processing, and analysis of data, which gives important information on how a material behaves under tests circumstances. This enables capturing critical mechanical attributes such as industry compliant tensile strength, yield strength, modulus of elasticity, and elongation.

What types of tests can be performed using a universal testing machine?

Universal testing machines (UTMs or Universal Testing Machines) are more than just specific devices to execute certain actions; they are multifunctional devices that can perform diverse mechanical tests on materials to assess their behavior under varying conditions. Some of the more commonly performed tests include tensile and compression testing. In tensile testing, a material is subjected to uniaxial pulling force until it fails, and during this process, the material’s strength and elongation are measured. We also perform compression testing which focuses on the assessment of a material’s compressive properties. Copper materials which are used in electrical power generation also undergoes UTMs for flexural testing to measure their bending properties as well as their elasticity modulus.

Shear testing is yet another important applied research area, which aims to measure the amount of force a material can withstand when subjected to sliding parallel to itself, while peel and adhesion testing give information on the strength of the bond between two substrates. Furthermore, UTMs allow sophisticated fatigue testing to examine failure mechanisms resulting from cyclic loading, and also fracture toughness testing to assess how much a material can withstand crack propagation. With the addition of some auxiliary configurations, these machines can also perform specialized tests such as hardness testing which increases their versatility for use in aerospace and construction as well as biomedical engineering.

What are the Applications of Material Testing with a UTM?

Using a Universal Testing Machine (UTM) for material testing helps in assessing and obtaining the mechanical properties of the material. Testing processes include tensile tests for the determination of strength and elasticity, compression tests for evaluation of load versus resistance, and flexural tests for the assessment of boring properties. In addition, UTMs are widely used in the quality control phase of production to check whether the performance of a material is in compliance with the standards set out for that specific material. These tests are important in the aerospace, automotive and construction industries in order to guarantee safety, strength and compliance with engineering requirements.

How is a UTM machine used in quality control?

Universal Testing Machines (UTMs) ensure the quality control of materials through their functionality by verifying mechanical properties of materials against a set standard. Furthermore, these machines measure mechanical properties of materials including tensile strength, compressive strength, and elongation, along with modulus of elasticity. During the quality control evaluation, specific specimens are tested under simulated realistic loading conditions to quantify stress. The results are then compared against set requirements to check if the material passes the evaluation. Take the aerospace industry for example; UTMs are employed to evaluate composite materials for tensile properties to ascertain their suitability for high-load applications. In construction, these machines determine compressive strength of concrete for primary structures to guarantee the integrity of a structure. Standards-based tests and calibrated measurements gathered through the use of UTMs lead to helpful conclusions, which aid various industries to ensure the required reproducibility, improve safety, and minimize the chances of failures.

What role does the universal tester play in research and development?

The ULTs hold a vital role in the field of science and engineering, providing complete characterization of materials to accelerate the innovation processes. With ULTs and controlled environments, researchers are able to analyze mechanical properties including fatigue, tensile strength, elasticity, and a myriad of other mechanical properties. UTMs are helpful in producing sophisticated materials and components, especially in the aerospace, automotive, and biotechnology industries, by simulating commendable stress during the processes. Tests done through UTMs further aid in supporting theoretical modeling, improving formulations, and refining product designs due to the high precision and repeatability these tests provide. Through fundamental research as well as applied technologies, the UTs are critical as they provide rich data from various testing conditions.

What types of materials are commonly tested with a UTM?

|

Material Type |

Description |

Common Tests Performed |

Key Parameters |

|---|---|---|---|

|

Metals |

Ferrous and non-ferrous alloys |

Tensile, compression, shear |

Yield strength, elongation, hardness |

|

Polymers |

Thermoplastics, thermosets, rubbers |

Tensile, impact, creep |

Stress-strain, deformation rate |

|

Composites |

Carbon fiber, glass fiber, aramid |

Flexural, tensile, interlaminar |

Maximum load, failure mode |

|

Ceramics |

Oxides, nitrides, carbides |

Compression, fracture toughness |

Compressive strength, modulus |

|

Wood and Timber |

Hardwood, softwood, engineered wood |

Flexural, compression |

Elastic modulus, shear strength |

|

Textiles |

Fabrics, yarns, threads |

Tensile, tear resistance |

Strength, elongation at break |

|

Adhesives |

Epoxies, polyurethanes, cyanoacrylates |

Shear, peel, tensile |

Bond strength, adhesion properties |

|

Concrete |

Concrete cylinders, beams, slabs |

Compressive, flexural testing |

Compressive force, elastic modulus |

|

Powders |

Metal powders, polymer powders |

Compaction, tensile |

Compressibility, granular behavior |

|

Biomaterials |

Bone, cartilage, medical implants |

Compression, fatigue |

Biomechanical properties, endurance |

|

Elastomers |

Natural rubber, synthetic rubber |

Tensile, tear, relaxation |

Elasticity, tensile strength |

What Type of Tests Can Be Conducted Using a Universal Testing Machine?

A Universal Testing Machine (UTM) is a universal device which can carry out and is capable of multiple mechanical tests to evaluate the characteristics of the materials. The most common tests conducted include:

- Tensile Testing: It uses uniaxial pulling force to determine material failure, yield and tensile strength , as well as elongation.

- Compression Testing: Evaluating compressive deformation metrics, strength and materials distortion within given loads.

- Flexural Testing: Addresses specific material parameters like flexural rigidity and bending strength focused on slabs or beams.

- Shear Testing: Measures shear parameters like strength and resistance of the material to shear forces.

- Fatigue Testing: Evaluates the resistance and endurance of a material through repetitive cyclic load application.

- Tear and Peel Testing: Measures elastomer and adhesive forces of separation, determining the tensile strength of peeling apart or tearing materials.

Due to its versatility, the UTM is able to handle different kinds of materials and regions of application such as metals, polymers, biomaterials, and elastomers which require accurate and uniform evaluation.

What is a tensile test?

A tensile test is a form of mechanical test conducted to determine the tensile properties of materials. It involves the application of a uniaxial force to a specimen until fracture occurs so as to measure the response of the specimen to the force applied. Critical parameters such as ultimate tensile strength (UTS) , yield strength , elongation, and modulus of elasticity are measured in tensile testing. These parameters help in assessing the material’s mechanical and structural response to deform under tension.

The process usually employs a standardized sample geometry, like a dog-bone shaped specimen, to maintain consistency and accurate measurements throughout the testing procedure. During the evaluation, parameters such as load and elongation are measured which yields a stress-strain curve illustrating important material qualities and features. Tensile tests are crucial to assure function in relation to a material’s design during breach verification, quality assurance, and material innovation processes for many industries including civil, aerospace, and manufacturing sectors. Moreover, they help determine conformity to worldwide standards perceiving international regulations such as ASTM D638 and ISO 527.

How is a compression test performed?

A compression test evaluates how a material responds to compressive forces in addition to determining the compressive strength, modulus of elasticity, and yield strength. The test starts with a specimen which is usually cylindrical or cubical shaped made to specific norms like ASTM E9 or ISO 604 relevant in terms of material and its application. The specimen is then located between the two parts of a compression testing machine.

In testing, a uniform compressive force is applied at a controlled rate, usually measured in force per unit area (pounds per square inch, psi) until the specimen either deforms or fractures. The test captures the force and deformation data in real-time, producing a stress-strain curve which reflects key mechanical attributes of the material. The accuracy of the test is defined by a number of primary parameters: specimen preparation, testing apparatus alignment, apparatus setup, and equipment calibration. Compression testing is common in construction and engineering for evaluating metals, plastics, concrete, and composites to determine if they can endure compressive forces without structural failure.

What are shear tests and how are they conducted?

Shear tests are primary methods of assessing a material’s capacity to resist some force that will tend to cause sliding failure along a defined geometrical plane, especially in applications involving dominant shear stresses. These tests determine shear strength, shear modulus, or ultimate shear stress by applying two equal but opposite parallel forces on a material. Most tests are performed under standardized guidance such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization).

The process usually consists of fixing a material specimen in a special shear fixture that applies uniform shear forces. The incremental loading associated with fracturing the specimen is recorded is applied in steps. The uniaxial, biaxial, and more intricate shear loading patterns reproduce real-world scenarios. Shear test variations include single-lap shear, double-lap shear, or punch shear, depending on the material and the evaluation purpose. This information is critical for aerospace, mechanical engineering, and construction industries where they need to understand the shear behavior for the rational design and safety of the structure dealing with such stress.

What are the Key Features of a Universal Testing System?

- Versatility

A universal testing system can conduct tensile, compression, bending and shear tests which make it applicable to different materials and for various purposes.

- Precision and Accuracy

With the integration of modern load cells and extensometers, these systems measure forces, material behavior, displacements, and precision mechanics with unparalleled accuracy.

- Customizable Test Fixtures

The system allows for particular fixtures and specimen grips to support different material configurations and dimensions, customizing tests to precise specifications.

- Automated Data Acquisition

Universal testing systems are outfitted with modern software which enables real time data collection and analysis with effortless visualization and generation of results.

- Wide Load and Speed Range

From low-force delicate polymers to high-strength alloys, these systems span a wide operating range of forces, speeds, and testing scenarios.

What safety features should a UTM have?

Material testing requires the use of Universal Testing Machines (UTMs) and to guarantee the safety of the operator and the tests, the machines must be designed with suitable protective devices. Below is safety features every UTM must be equipped with.

- Overload Protection

These devices also serve as protective mechanisms to the machine and test samples as they cease operations when the loading exceeds the maximum limit of the machine. For instance, contemporary systems apply safety features for measuring force and will terminate testing when 110% of the rated capacity is reached.

- Interlocked Protective Enclosures

Safety boxes with interlocks not only ensure safety, but they also restrict human contact with mobile parts of the machine during the testing procedure. The enclosure must be securely closed for the test to begin thus ensuring safety and preventing accidental contact.

- Emergency Stop Button

Strategically located emergency stop buttons enable operators to halt processes immediately in the case of a problem. This feature reduces the likelihood of injuries to personnel as well as damage to equipment resulting from mechanical, software failures, or human errors.

- Software-Driven Safety Protocols

Automated machine control software maintains a preset testing parameters and is able to suspend the machine in cases of excessive displacement, sudden load drops, or sample failure. In addition, a reliable system captures these events for subsequent analysis.

- Load Cell and Sensor Calibration Alerts

UTMs should proactively notify system operators to reset load and set cells, and other relevant sensors to prevent accruing erroneous test results from repeated use which pose testing risks. Some automated systems issue prompts based on time, usage, or both.

UTMs must be configured with proper safety procedures alongside the capability to capture precise and dependable results. Sustaining both operator well-being and operational excellence hinges on complying with such requirements.

What is the significance of the load cell in testing?

In materials testing, the load cell is one of the most important elements because it acts as the primary sensor which measures force. It makes it possible to measure tensile, compressive and shear forces during a test with precision by converting mechanical force to an electrical signal. The precision and response of the load cell impacts the test data reliability. Thus, the test data’s material properties of strength, elasticity, and durability depend on the test reliability. Today’s load cells are equipped with state-of-the-art strain gauge configurations, making use of high-class materials which enhances their resistance to external factors. In addition, load cells must adhere to calibration procedures to ensure maintained accuracy as well as compliance with specified industry requirements. To these records, the load cell has an essential function in ensuring material assessments in industries such as aerospace, construction, and manufacturing are accurate.

What is the Importance of Test Results in Material Testing?

The outcomes achieved in material testing is imperative for ascertaining pertinent information regarding the precision, resilience, and safety of the materials in consideration. The information gathered helps to check if the materials to be used actually comply with the predetermined requirements and particular intricacies. Precise test results are needed to anticipate any potential problems, foresee the way a material will react to different conditions, and inform design decisions. Compliance with the benchmarks will secure risks, reinforce performance, and guarantee the materials tested are reliable to their intended uses.

How are test parameters determined?

Evaluation of the material’s properties must be done simultaneously with the material’s application purpose; industry requirements, intended use, and product specifications should always be factored in when determining test parameters. This step starts with determining the physical and environmental factors or the mechanical and chemical processes that the material will undergo and the conditions it will be subjected to over its lifetime. Standards organizations such as ASTM International, ISO, and other norms provide exhaustive frameworks and standards for testing in many sectors. Such instructions ensure that the selected criteria will indeed model real-life scenarios.

Furthermore, empirical information collected from previous tests and performance alongside their computational modeling is integrated to refine and sculpt parameters which tailor to the material’s attributes. Conditions of loading, temperature ranges, pressure, and even time intervals are meticulously calibrated to achieve consistency and precision in test scenarios. Partnerships between engineers, material scientists, and quality control professionals deeply focus ensure all pertinent aspects that fall within the scope are addressed, thus establishing a reliable structure for determining the assessed features of the materials and compliance. The tests are systematically conducted guaranteeing that the information obtained is relevant and insightful.

What is the significance of compressive strength and tensile strength?

The compressive and tensile strength of a material are characteristics that define how a material behaves under different forces, and both are critical mechanical properties. A compressive strength entails the reduction of the volume of a solid characteristic under compressive load. This is important for construction materials like concrete where structures need to endure high vertical loads without cracking and collapsing. Counteracting rupture of a material is known as tensile strength of that material. This is important for polymer and metal based materials which must withstand forces that stretch or pull them apart without breaking.

These attributes are essential for choosing a material and designing a structure. Sufficient compressive strength guarantees stability for structures undergoing compressive loads, such as buildings and bridges. Meanwhile, tensile strength is critical for tension supporting elements such as cables, beams, and suspension systems. Engineers with accurate measurement and a proper grasp of these attributes are able to forecast performance and optimize designs tailored to each requirement, ensuring safety alongside reliability. This is crucial in construction, aerospace, automotive, and manufacturing industries.

How Do Different Materials Affect Results in Mechanical Properties Testing?

Mechanical properties testing reveals how different materials are uniquely composed and structured. This is true for metals which tend to have high tensile strength and high ductility in their plastic-shaped forms useful for load-bearing functions. Flexibility and low weight are advantages for polymers but they have lower rigidity and strength, and thus limited use in high-stress environments. Ceramics, as their name suggest, are hard and resistant to compressive forces but tend to be brittle in tension. Composites exhibit characteristics from two or more constituent materials and therefore can be designed to have greater strength, stiffness, or thermal resistance than traditional materials based on their make-up. All such material behaviors considered are important during the evaluation and testing process for precise predictions of performance in the testing versus real application scenarios.

What is the role of deformation in testing?

Material testing is guided by deformation because it offers a glimpse into the mechanical nature of materials under different types of stress and strain. Engineers and researchers are able to measure the structural integrity of a material by analyzing its deformation under various forces including tensions, compressive, shear, or even coupled forces. The elastic modulus, yield strength, and ultimate tensile strength are some of the parameters that can be accurately measured without too much complexity, thus delineating a material’s limits before failure. Inappripriate actions such as digital image correlation (DIC) or use of strain gauges perform more complex geometries, however, there are much more advanced techniques that ensure precise measurements on simpler forms. These data points are crucial for most strenuous fields such as aerospace, construction, or even medical device engineering where failure can result in dire consequences.

How does elasticity impact material performance?

Elasticity characterizes a material’s behavior under mechanical pressures like stress, particularly its ability to recover to its original configuration after undergoing change. An allocation of a material’s stiffness and flexibility is given by the modulus of elasticity, known as Young’s modulus. Steel exemplifies a material with a high modulus of elasticity and rigidity, while rubber demonstrates a low modulus and flexibility. Many industries rely on the equilibrium of materials elasticity, one example being automotive engineering where suspension elements must be elastic enough to mitigate impacts yet remain intact. In the example of medical devices, stents demonstrate how the adaptive nature of materials elastic behavior enables their use within the constantly changing environments of the body. For engineers, having the right understanding and models of elasticity aid in defining and optimizing relevant materials for their specific use in durability and performance.

Reference Sources

-

Universal Transverse Mercator (UTM) system: This article discusses the UTM system’s grid-based approach for accurate mapping and navigation, commonly used in surveying and geospatial analysis.

-

UTM Codes in Digital Strategy: This resource explains UTM codes (Urchin Tracking Module) used in digital marketing to track URL performance in Google Analytics.

-

Tracking UTM Tags in App Store URLs: This StackOverflow discussion focuses on using UTM tags for tracking user sessions in app stores.

Frequently Asked Questions (FAQs)

Q: What is a Universal Testing Machine (UTM)?

A: A Universal Testing Machine, also known as a materials testing machine, is a device used to test the tensile and compressive strength of materials. It can apply a controlled force to a test specimen to determine its mechanical properties.

Q: What are the primary applications of UTMs?

A: UTMs are used in various testing applications, including tensile testing, compressive testing, and bending tests. They are essential for evaluating the strength of materials, ensuring they meet industry standards, such as ASTM and ISO.

Q: How does the control system in a UTM work?

A: The control system in a UTM regulates the machine work, allowing for precise force application and monitoring of the test duration. This ensures accuracy and repeatability in the results obtained from different tests.

Q: What types of materials can be tested using a UTM?

A: A UTM can be used to test a wide range of materials, including metals, plastics, and composites. It is particularly effective for assessing the tensile strength of materials under various loading conditions.

Q: What is the importance of standard tests in UTM operations?

A: Standard tests, such as those defined by ASTM and ISO, ensure that the results obtained from a UTM are consistent and comparable across different materials and testing environments. This is crucial for quality assurance in manufacturing.

Q: Can a UTM perform both tensile and compressive tests?

A: Yes, a UTM is designed to perform both tensile and compressive tests. This versatility allows it to assess the behavior of materials under different types of mechanical forces.

Q: What is the significance of the tensile strength of materials?

A: The tensile strength of materials is a critical property that indicates how much load a material can handle before failing. Understanding this strength helps in selecting appropriate materials for various engineering applications.

Q: How does a UTM ensure accuracy and repeatability in testing?

A: A UTM ensures accuracy and repeatability through its advanced control systems and calibration processes. Regular maintenance and adherence to testing protocols also contribute to reliable results.

Q: What factors influence the test duration in UTM tests?

A: Factors influencing the test duration include the material to be tested, the test method employed, and the machine’s settings. Some materials may require longer test durations to accurately measure their strength and properties.

Q: What role does the test specimen play in UTM testing?

A: The test specimen is the material sample that is subjected to testing in a UTM. Its dimensions and properties must be carefully prepared according to standard guidelines to ensure valid test results.