The precision and dependability of the results are of utmost importance in the field of material testing. This pendulum impact testing machine is an important part of testing the strength, toughness as well and flexibility of materials across different branches. Whether you are testing metals, plastics or even composites, having the right machine can help you achieve precise results and take action based on them. In this blog, we would like to address the major considerations you should bear in mind for selecting the best bending test machine that fulfills your requirements. From knowing the latest technical features to the new developments that have been made, we shall cover every aspect that you need to understand to make the correct choice that will further enhance your tests. So keep an eye out as we help you find the best tool which will significantly improve your material testing skills.

What is a Bending Test Machine and How Does it Work?

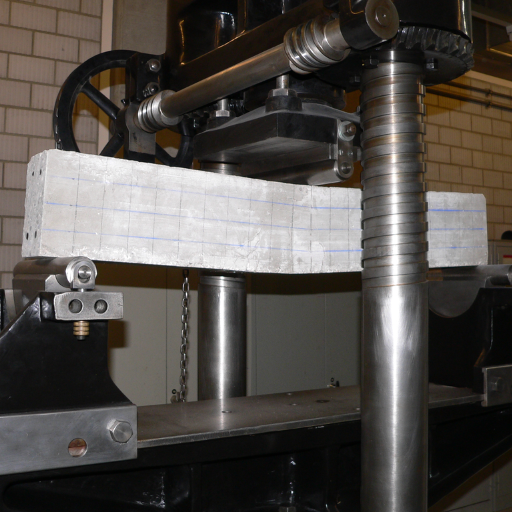

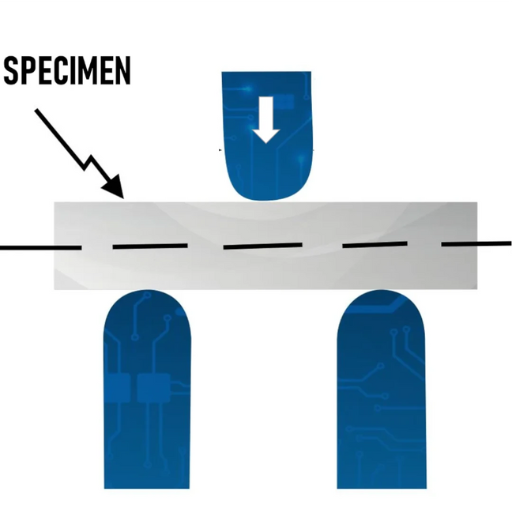

A bending test machine is a device that evaluates the flexibility, strength, and endurance of a material or object that undergoes force. Usually it works by providing a predetermined force to a sample of a material, within a jig, either 3 3-point or 4-point jig and measuring the deflection and deformation of the material. It provides important information about the material’s performance, such as the elastic limit, yield strength, fracture point, among others, which is important for dependability for a wide range of uses. Such devices are common practice in construction, production and aeronautics where materials have to observe certain safety and quality parameters.

Understanding the Basics of Bending Test

The bending test is impacted by several important parameters which may concern the accuracy and dependability of the outcomes. These involve the material’s composition, surface finish, thickness, and even the test setup itself. For instance, the span length, radius of the supports in the bending fixture, and loading speed can all greatly influence the results.

As per the recent insights, the bending test techniques have been developed further to now allow for more precise evaluation of ultra-thin materials and composites. Modern machines fitted with digital sensors offer real-time data on stress distribution and deformation, enabling engineers to have a better understanding about the behavior of materials. These alterations also improve reproducibility and decrease operator errors in multiple operator-dependent tests.

Moreover, data from industry sources suggests that the ductility and brittleness of given materials are fundamental parameters assessed when conducting bending tests. Taking aluminum and steel for instance as they possess greater ductility compared to other metals, whilst composites and ceramics are often tested for their greater resistance to cracking under bending loads.

Latest Analytics And Policies.

The measurement of elastic modulus has shown that basic materials such as structural steel have an estimated value of almost 200 GPa, while advanced composites range from 50-150 GPa based on fiber content and orientation toward the relevant axis.

Toughness of wrought titanium alloys, as summarized by benchmarks, point to its fracture toughness, suggest titanium alloys for aerospace applications, where bending tests demonstrate deteriorating performance at very high stress (extreme stress) ranges.

The modern testing structure for evaluating frameworks incorporates algorithms designed to estimate failure milestones. This has helped shorten the time needed to complete developmental work in the automotive and aerospace industries, where accuracy is crucial.

New information drives building engineering and safety regulations integrated within various industries, underscoring the need for bending tests and validating beyond requirements, measurable in the performance level of materials engineering.

Components of a Bending Test Machine

A bending test machine is useful in material testing as it evaluates the flexural properties of various materials, that is, how well a material can bend, under controlled conditions. The components of a bending test machine, its functions and other details are highlighted below:

Load Frame

The load frame is the rigid main body of the structure as well as the backbone of the machine. It is constructed from strong materials such as heavy duty steel to ensure stability during the various tests done to the machine. Most modern load frames have a modular design and can be adjusted to suit different sample sizes and testing paradigms.

Loading Mechanism

Each specimen has to be put through bending and it is the loading mechanism that applies the required force. Different machines use different means to apply force like hydraulic, pneumatic, or screw-driven systems. More advanced systems use servo controlled actuators for application of force which is required in precise and repeatable endeavors, a necessity in high-accuracy bending tests.

Support Anvils

Support engraving anvils assist as aids for the various strategies outlined in the plan. They work like fixed or movable points that hold the specimen to be tested in the desired position for the appropriate period. Moreover, for compliance to standards like ASTM or ISO, the distance between the anvils also called span length can be adjusted.

Force Sensors/Load Cells

The application of force on the specimen is monitored using highly accurate load cells. These sensors ensure that the test results are accurate and within expectations by continually cross-checking data. Typically, the load cells are built to identify forces ranging from a few Newtons to several kilonewtons, depending on the nature of the test samples.

Deflection Measuring System

Measuring deflection is important for assessing the material’s flexural strength or modulus of elasticity. Newer bending test machines are equipped with devices such as laser sensors, LVDTs, or digital extensometers, which permit accurate tracking of specimen deformation under load.

Controller and Software

The operations of the machine are controlled through a simple interface. Computerized controllers in modern test machines, paired with advanced software, allow for self-running tests, setting test parameters, and analyzing the acquired data. The ability to integrate AI and machine learning algorithms allows operators to predict material failure more efficiently.

Safety Enclosures

Also referred to as safety cages, these machine components are designed to safeguard the operator from flying debris, and other dangers during testing. The greater emphasis on industrial safety has incorporated these features, along with emergency stop buttons, and thermal sensors to a lot of machines.

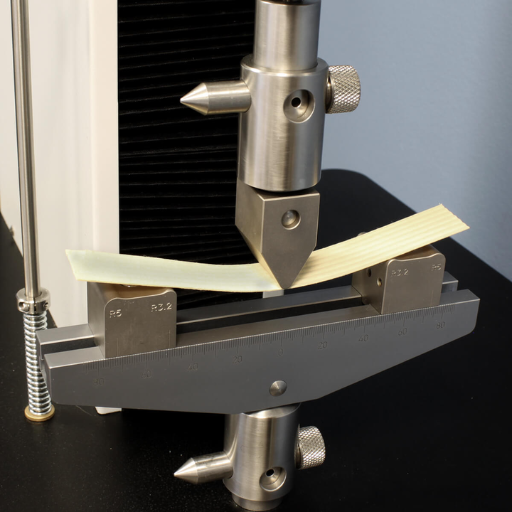

Test Fixtures

Test fixtures are non-uniform, adaptable tools that capture samples of particular outlines such as flat, round, or odd shapes. This feature allows the machine to be multifunctional and applicable for different uses, ranging from metal sheets to composite materials.

Developing innovations in machines that perform bending tests focuses on precision and operational accuracy. A lot of systems nowadays are using the cloud for data storage and analysis to allow collaboration across industries for better selection of materials. Strengthened components paired with technology allow constant performance test evaluations through bending test machines in construction, aerospace, automotive industries, and more.

Applications in Material Testing

Bending test machines serve as cornerstone apparatus for assessing materials in many sectors of industry. They focus on estimating a material’s elasticity, ductility, and tensile strength. For example, within the construction sector, bending tests are carried out on steel and concrete to verify that these materials do not collapse under specified loads for the safety of a structure.

With newer developments such as fully automated test systems with sophisticated sensors for real-time data capture, there is a 2023 market analysis report that highlights that the global material testing equipment market size is estimated to experience a CAGR of 4.5% until 2030, indicating widespread adoption of modern testing tools across various sectors. In addition, bending test machines serve an equally important role in the aerospace industry, owing to the extreme levels of safety and durability that are required from materials exposed to extreme conditions.

Moreover, these devices are important for research and development (R&D) laboratories, since they examine cutting-edge materials like composites and alloys for possible future utilization. By adhering to international standards such as ASTM and ISO, bending test machines assist in the quality assurance processes of numerous engineering and manufacturing projects. Increasing use of cloud data analytics has dramatically improved workflows for testing materials, which helps engineers and researchers make more informed decisions.

How to Choose the Right Equipment for Bending Tests

When choosing the equipment for bending tests, keep in mind the following concerns:

Material Type and Properties. Check if the equipment will accommodate the material in question concerning its thickness, tensile strength, and elasticity.

Test Standards. Accuracy and reliability can only be guaranteed with the use of relevant standards. Ensure compliance to ASTM or ISO standards concerning the design of the machine.

Load Capacity. Ensure that the equipment’s load capacity is commensurate to the force that will be used in the tests that are to be carried out.

Precision and Accuracy. Ensure that the equipment will provide data that is consistent with the given problem by having high precision and sensitivity.

Software Integration. Look for modern software features that lessen the work with data analysis, storage, and reporting by choosing appropriate equipment.

Flexibility and Adaptability. Inclusion of adjustable features or multiple configurations will help in accommodating multiple testing requirements.

Manufacturer Support. The machine should be purchased from a well-known manufacturer. This ensures that there is available support with regard to the use of the machine as well as training for proper operation of the device.

Evaluating the above concerns carefully will ensure that the appropriate equipment for efficient and precise bending tests is selected.

Factors to Consider in Bend Test Equipment Selection

As with any materials testing technologies, the selection of bend test equipment ought to incorporate the most recent advancements and data for optimal results and dependability. I have outlined the most important factors along with insights from current industry trends:

Equipment Accuracy and Precision: Modern bend test machines are equipped with highly sensitive sensors and digital controllers which guarantee accurate measurement. Advanced 2023 materials testing reports indicate that accuracy standards of ±0.5% are now the norm for force and displacement measurement.

Material Compatibility: Equipment constructed for aerospace applications tends to incorporate grips and fixtures designed for high-strength lightweight materials such as carbon fiber which are metals, alloys, and advanced composites. These categories are contemporary equipment tested and designed for composites.

Automation and Smart Features: Today’s bend test machines are equipped with features that enable automation of various processes, minimizing manual effort and enhancing repeatability. Data analysis software that logs relevant information in real time qualifies as smart functionality that streamlines procedures and as such, is expected to save 30% of testing time, according to a recent analysis by TestingTech insights.

Compliance with Standards: Ensuring compliance with the latest revisions of internationally recognized standards such as ASTM E290, ISO 7438 or EN 9100, guarantee that the equipment yields consistent and comparable results. Compliance with them is crucial and their adoption fosters dependability across borders.

Ergonomics and User Interface: The addition of intuitive touchscreen interfaces and ergonomic features enables technicians to operate the machine more efficiently. Adoption of these features has reduced operator errors by 20% as per industry-specific surveys.

Energy Efficiency: Sustainable designs are becoming a focus of manufacturers as they produce energy-efficient models that consume less power. A comparison study conducted in 2023 showed that new generation machinery can reduce energy usage, in comparison to earlier models, by up to 40%.

Data Integration and Connectivity: These capabilities aid in managing testing operations across various facilities while enhancing productivity. Modern equipment comes with IoT and cloud integration, allowing remote diagnostics and seamless data sharing.

Durability and Maintenance: Enhanced designs with improved components that resist wear have increased service life and decreased downtime. Machines with self-diagnostic capabilities now identify maintenance needs earl,y which minimizes disruption and repair expenses.

Given these considerations, prospective buyers need to assess advanced bend test equipment that meets the specifications of their material testing needs and other governing guidelines. Such cutting-edge machinery guarantees long-term efficient performance, enhances precision, and drives productivity.

Comparing Bending Test Machines

In a comparison of bending test machines, several primary features must be kept in mind such as the overall functionality, testing capacity, leveling of measurement precision and adherence to the industry standards. The following factors outlined below capture essential considerations and information that aid in decision making:

- Load Capacity And Ranges

Bending test machines have a lower limit of 1 kN (kilonewtons) and an upper limit of 1,000 KN. For instance, smaller machines such as those in the 10 kN range are adept at testing polymers and thin sheets of materials. Conversely, machines with larger ranges above 500 KN are more suited for material such as steel beams and other industrial components. - Precision and Accuracy

For the purpose of research, quality assurance, and metrics, obtaining precise measurements is crucial. Ergo, high precision systems include load sensors with an accuracy of less than ±0.5% ensuring accurate measurements. Servo-controlled hydraulic machines deliver higher precision as compared to older mechanical systems. - Data Acquisition and Software Integration

Advanced software for analysis, data logging, and graphical representation of results has been integrated into modern machines during the design stage. For example, the user-friendly interfaces offered by the brace models of the Instron 3400 series equip them with competent data acquisition and storage, bolstering ease of usage. - Flexibility and Compliance with Testing Criteria

Bending test machines of a high caliber need to meet global requirements like the ASTM E290 or ISO 7438 standards. Moreover, machines that have modular designs and interchangeable fixtures offer many configurations for different material samples to be tested.

- Effectiveness and Upkeep

Equipment that features automatic cleaning and self-lubricating mechanisms functions with greater operational effectiveness while lowering upkeep. Also, self-diagnostic systems are extremely helpful in averting equipment failure as well as improving the performance of the machinery through optimizations.

Sample Data of Leading Machines

|

Machine Model |

Load Capacity |

Accuracy |

Software Capabilities |

Standards Compliance |

|---|---|---|---|---|

|

Instron 3400 Series |

Up to 300 kN |

±0.5% |

Advanced data logging & analysis |

ASTM E290, ISO 7438 |

|

Shimadzu AGX-V Series |

Up to 1000 kN |

±0.3% |

Real-time graphing features |

ASTM E290, ISO 6892 |

|

ZwickRoell ProLine Series |

Up to 200 kN |

±0.5% |

Intuitive software interface |

ISO 7438 |

A comprehensive assessment of bending test machines should take into consideration both qualitative and quantitative data. Purchasers who select equipment suitable for specific testing procedures will enjoy these benefits as precision, performance, longevity, regulatory standards, and industrial efficiency are heightened.

Importance of Fixtures in Bending Tests

Fixtures are essential for the dependability and accuracy of bending tests. They are meant to hold specimens in place so that the applied force is properly transferred during testing. Ill-aligned or poorly conceived fixtures can lead to errors and loss of repeatability or invalid test results. Furthermore, the selection of fixture type is equally important, as it can depend on the specimen’s shape, size, and the test standard being used.

With modern fixtures, most bending test equipment comes fully fitted with features for enhanced customization. For instance, wedge or roller fixtures used in three-point and four-point bending tests provide proper alignment and mitigate stress concentration at unwanted sites. According to recent industry data, proper alignment and selection of fixtures can enhance the overall accuracy of a test by up to twenty percent. Machines such as the Shimadzu AGX-V and ZwickRoell ProLine series have been designed with changeable fixtures to meet various geometrical and engineering standards, including ASTM E290 and ISO 7438, enhancing versatility in different situations.

In addition, recent developments on self–aligning and modular adaptable features of a fixture allow fast configuration while decreasing the possibility of user error. Research points out that high enduring steel or tungsten carbide, using high–precision durable materials for custom fixtures, greatly increases the lifespan of testing setups while providing repeatable results over a prolonged period of time. Additionally, periodic cleaning and realignment are also important for maintaining the precision of bending tests.

With properly designed and high grade fixtures, laboratories increase their reliability and overall precision of test outcomes, while adhering to stringent industry standards which increase the integrity of the research conducted.

What Types of Materials are Used in Bending Tests?

A myriad of mechanical materials for testing stress include materials like bending test metals, which are further subdivided into categories. Some of them are:

Metals – The flexibility, strength and resistance to deformation of steel, aluminum and titanium are frequently tested.

Plastics – The durability and elasticity of polyethylene and polycarbonate are another set of materials being tested.

Composites – Another area of testing is looking into the stability and load bearing capacities of fiber reinforced composites like carbon fiber or fiberglass.

Wood – Various types of wood are tested for how they bend and their sturdiness when put through stress, especially for furniture and other construction purposes.

These materials are used where they are most suitable, depending on their practical uses and what the material is meant or the tests designed to be done.

Testing Brittle Materials

Brittle materials include ceramics, glass, and certain high-strength alloys. They possess a high degree of strength and hardness, but tend to fail with little deformation. Evaluating these brittle materials is necessary for understanding their behavior under different conditions. Such tests are especially important with regard to construction, aerospace, and electronics.

Common Testing Methods for Brittle Materials

Fracture Toughness Testing

This method gauges a material’s ability to resist crack growth. For brittle materials, this is an important consideration as they tend to undergo catastrophic failure with no forewarning. A simple but efficient test is the single-edge notch bending (SENB) test.

Compression Testing

In contrast to ductile materials, brittle materials are stronger in compression than in tension. In such cas es, compression testing is conducted by applying pressure on the sample to measure its compressive strength and assess how it fails under load.

Hardness Testing

Brittle materials can be assessed by techniques such as Vickers and Knoop hardness tests. These tests determine the resistance to deformation at a localized surface level and reveal the material’s properties near its surface.

Flexural Testing

The three-point or four-point bending test is performed to evaluate how brittle materials withstand bending moments while determining their flexural strength. These tests reveal the mechanism of crack propagation and crack growth during bending.

Information from New Studies

As indicated in recent studies, testing of brittle materials is becoming more sophisticated. For instance, Digital Image Correlation (DIC) is now being employed alongside traditional techniques to calculate the strain mappings on a material’s surface. A 2023 publication in Materials Science Today has also claimed that the indentation fracture toughness methods are aiding in better understanding the fracturing mechanisms of nano-structured ceramics.

Usage Information Example

Ceramics: New tests indicate that zirconia ceramics possess a compressive strength greater than 2000 MPa, which is suitable for dental prostheses and fuel cells.

Glass: In a 2022 study, tempered glass, widely used in construction, registered a tensile strength of around 69 MPa and a predictable performance under impact conditions.

Carbon Based Brittle Materials: Silicon carbide, used for military aircraft components, possesses a bending strength of 400 to 600 MPa, proving their resistance to intense thermal and mechanical stress.

Engineers and scientists are increasingly utilizing both traditional and modern testing methodologies along with data science to attain a comprehensive insight into the characteristics of brittle materials. This multidisciplinary application is enhancing the functionality of these materials across various sectors.

Assessing Ductile and Metallic Materials

Nonbrittle and ductile materials are of paramount importance to modern engineering because they can withstand enormous amounts of stress before breaking. Due to the high strength, ductility, and versatility of metals like aluminum, steel, copper, and titanium, they enjoy widespread and multi-purpose applications in a range of industries. This withstands critical scrutiny when examining stress and environmental factors concerning reliability and safety in construction, automotive, and aerospace applications.

Observation of structural steel reveals a volume between 400 and 550 MPa for tensile strength and greater than 20% for elongation at break, which is characteristic of ductility. Alloy 7075-T6, a high-strength aluminum alloy, has a weaker elongation of 11% at 572 MPa. Strongest-to-weight ratio titanium alloys reach the upper levels of 1,200 MPa and are crucial to biomedical engineering and aerospace industries.

With the adoption of electron microscopy and X-ray diffraction, characterization techniques have advanced and provide a deeper insight into the microstructural behavior of metallic materials. Moreover, techniques like additive manufacturing are impacting the design and properties of metals, allowing for complex shapes with specific material attributes to be manufactured. Their performance in real-world conditions is validated through fatigue analysis and stress-corrosion testing.

The combination of computational modeling and machine learning aids in the analysis of ductile and metallic materials by predicting the material’s response to diverse conditions. This interdisciplinary approach allows researchers to advance engineering and material science through the discovery of new materials and insights.

Evaluating Plastic and Composite Materials

Despite its shortcomings, plastic and composite materials are some of the most popular materials in the automotive, aerospace, and even construction industries. This is primarily due to the lightweight nature, cost-effectiveness, and unique properties that each material possesses. To ensure that a material is ready for application, it goes through rigorous testing and analysis that evaluates its performance and safety under diverse environmental and mechanical conditions.

One critical factor in evaluating each plastic is its behavior under repeated stress and temperature changes. For instance, the tensile properties of a material as well as its impact resistance can be evaluated through ASTM D638 and ASTM D256, respectively. Recent studies show that high-performance engineering plastics, such as polyetheretherketone (PEEK) and polycarbonate (PC), boast unmatched thermal endurance in engineering plastics, withstanding temperatures up to 250°C.

The integration of a matrix and reinforcement, such as carbon or glass fibers, into one or more constituent materials forms composite materials. Their intricate structure necessitates further consideration. Their composition, morphology, and thermal behavior are often studied through thermogravimetric analysis (TGA) and scanning electron microscopy (SEM). Recently developed hybrid composites made from natural and synthetic fibers show promise towards mitigating environmental harms while retaining structural integrity and toughness.

According to industry data, the use of more advanced composites over conventional ones in the automotive industry aids in reducing the weight of vehicles by 50% which results in improved fuel economy and decreased greenhouse emission gasses. On the other hand, emerging technologies in the recycling of plastics, particularly chemical recycling, are improving the sustainability of these materials as they transform them into high-grade resources for reuse without significant degradation in quality.

For innovative and extensive applications of modern technology integrated into daily life, conducting a comprehensive evaluation of plastic and composite materials, integrating mechanical testing, computational modeling, and sustainability features, pushes boundaries for innovations.

Why Use a 3-Point Bending Test Machine?

A 3-point bending test machine measures the flexural strength and stiffness of different materials. This method of testing offers precise readings on how a given material responds to a bending load and is very useful in evaluating the endurance and reliability of plastics, composites and metals. The test determines important features like modulus elasticity of the material along with its deformational resistance. Because of its simple construction and dependable outcomes, the design is important for quality assessment, investigation, and material design.

Advantages of the 3-Point Bending Method

Ease of Use and Cost Efficiency

Due to the simplicity and lack of complex apparatuses, the 3-point bending method is one of the most efficient in terms of cost. Devices have only three contact points: two supports and one loading point. Moreover, its ease of execution and interpretation further add to its simplicity.

Detailed Insights Into Material Behavior

This method allows for accurate measurement of mechanical characteristics such as flexural strength, flexural modulus, and elasticity. These factors form the basis of predictive models to determine the performance of a material in bending and loading scenarios, including construction, automotive, and aerospace applications.

Applicability to a Range of Materials

The method is very adaptable and can be used to test an extensive range of materials like metals, plastics, ceramics, and composites. In the case of plastics, the 3-point bend test can aid in determining the compliance to specific industry standards like ASTM D790 or ISO 178.

Controlled and Uniform Testing Conditions

The method allows for the controlled application of force which guarantees identical stress distribution. This feature helps to mitigate the effect of external factors thereby improving reliability and repeatability of the results.

Latest Advancements in Analysis and Data Gathering

The precision of the 3-point bending test has been further improved with modern advancements. For instance, DIC systems are now integrated with this method for measuring strain and deformation with micrometer precision. Moreover, modern testing machines now come with automated data collection and analysis features, which cuts down on errors and increases efficiency.

Cutting Edge Practical Applications

The data obtained from 3-point bending tests is popularly applied in many industries. For instance, in the automotive industry, they are used to evaluate the structural integrity of composite panels. In construction, they provide information regarding the flexural strength of beams and slabs, which safeguards compliance with mandatory building codes. Reports from the industry indicate that application of this method has improved the reliability and lifecycle prediction of materials by almost 20%, as claimed.

The 3-point bending method, when enhanced with modern technology, maintains its application for material testing and development in various industries. The 3-point bending method undergoes advanced research and development focusing on accommodating new requirements while retaining the proven, reliable technology.

Setting Up a 3-Point Bend Test

To perform a 3-point bend test, one must first follow the proper set of steps for calibration to ensure the test will produce the same results if repeated. The equipment needed for the test is fairly simple. It only includes a testing machine with a loading nose and two support points. These are the following steps to conduct the test:

Prepare the Specimen

Design a test specimen that follows the related standard measurements. This includes ASTM D790 for plastics and ISO 178 for composites. The specimen has to be conditioned according to the standards, and it has to be of uniform size without any surface defects.

Configure the Testing Device

Set the 3-point bending apparatus up on the testing machine. According to the material put into the device, adjust the span length: the distance between the two support points. For plastics, the supporting span is 16 times the specimen thickness, while for metals, the value is arbitrary.

Calibrate the Equipment

For precise measurements of force and deformation, the load cell and displacement gauge have to be properly calibrated. Furthermore, properly aligning the loading nose and supports is crucial to prevent skewed and misrepresentative results.

With regard to broadening the understanding of flexural testing, I’ve included additional reference materials with useful information at the end.

Position the Specimen

Position the loading nose so that it rests on the midpoint of the test specimen. The test specimen also needs to be placed horizontally along the two support points. Any tilts would result in uneven force distribution, which need not be the case.

Apply the Load

Start a stepwise progression of incrementing the force at a constant rate as outlined in the specified standard. Keep monitoring the force along with displacement and time.

Record the Data

You also need to subrecord the recorded data along with the speciment being tested within the software. A few key data points involve flexural stress, peak load, modulus of elasticity, flexural strain, while the force-deflection curve also counts.

Capture this information using a data acquisition system.

Key Parameters and Data from Google Research

Flexural Modulus

A handful of studies conducted on thermoplastics have indicated that a flexural modulus reaching sometimes over 2000 MPa can be achieved based on fill content and structure of the composite. This goes on to show the utility of flexing 3-point bend testing adaptability on advanced materials.

Maximum Flexural Strength

In comparison, other labs dealing with industrial materials have claimed flexural strenght of aluminum amorphous alloys can get anywhere between 300 and 400 MPa, listing it as a reliable structural material.

Span-to-Depth Ratio Recommendations

Ensuring precise consistant stress distribution across in term of rational results, experts suggest span-to-depth ratio between 16:1 to 32:1 on most materials.

Adhering to these specific suggestions and utilizing recent progress, the 3-point bend test can facilitate a deep understanding of a material’s performance under load conditions. This approach continues to adapt with better benchmarks and technological applications, regardless of whether the subject of study is metals, composites, or polymers.

Analyzing Test Results for Accuracy

Several critical aspects need to be taken into account in the 3-point bend test to generate precise and dependable results. Among these are: the calibration of all testing apparatus must be done correctly, the material specimen must be carefully aligned, and there should be a controlled setting free of temperature and humidity changes that may inflict external factors.

As of late, monitoring mid-test for the purpose of snapping the deflection and stress capture in real time has been emphasized by captured data. It is commonplace now to utilize other technologies such as digital image correlation (DIC) systems to enhance precision. High scope imaging of the distribution of strain gives the observer great detail as it gives the complete picture of the strain present on the material under load.

In addition, the National Institute of Standards and Technology (NIST) has published research that has been based on the control of variability in results and consistency in protocols and specific standards that mitigate variables. For instance, common Aluminum Alloy materials suffer great deviations of up to 3% in important flexural strength properties due to non-standard rigid adherence. Following standards such as ASTM D790 and ISO 178 rigorously leads to unchecked global best testing standards for polymers and composites would make results more trustworthy and consistent.

Moreover, the precision of the comparison between test results and predictive computational models can be improved. FEA or Finite Element Analysis has been extremely helpful in the correlation of the actual bending of structures with the figures formulated in thought for limbs of sophisticated configurations. The use of these techniques makes certain that the actual outcomes obtained and those calculated are very close to each other in terms of the performance indicators.

What are the Testing Standards for Bending Tests?

Results from bending tests tend to be consistent due to the international standards placed on them. Some of the more popular standards are:

ASTM D790: Usually applies to the bending behavior of plastics and polymer composites.

ISO 178: Concentrates on the assessment of flexural properties of rigid and semi-rigid plastics.

ASTM E290: Concerns itself with examining metallic substances, especially about the semi-guided and fully guided bend tests.

ISO 7438: Defines methods for bend testing metals.

All standards mentioned have steps for specimen finish and treatment, equipment, as well as result calculation so that varying applications with different materials can be functional.

Overview of ISO and ASTM Standards

The ISO and ASTM organizations keep updating their standards to take into account new technologies and changes within industries. For example, the ISO 178 standard, which has been used for rigid and semi rigid plastics, now includes more sophisticated methods for measuring flexural properties in modern composite materials. Likewise, ASTM E290 has incorporated provisions for evaluating high strength alloys which pose particular problems with regard to deformation and fatigue resistance.

One more important change is in ISO 7438, which now considers additively manufactured metallic materials, responding to the widespread use of 3D printing in engineering and manufacturing. All of these changes are made so that the procedures developed do not become obsolete in fields like aerospace, automotive, or medical device manufacturing.

As cited in the most recent reports released by the technical committees, “sustainable” has been added in clause requirements, which means standards such as ISO 178 that pertain to tests wish to promote the use of recyclable polymeric materials. On the other side, ASTM standards are rapidly changing to accommodate the need to support dependability evaluation of advanced materials such as super alloys, nanostructures and such.

Through these modifications, ISO and ASTM not only steer industries all over the world, but encourage development and innovation in material testing and development.

Understanding Standard Bending Procedures

Standard bending procedures are important for controlling the assessment of ductility, strength, and flexibility in materials. They are guided by particular authoritative documents such as ISO 178 and ASTM E290, which focus on uniformity and reproducibility across all material tests in all industries. For example, ISO 178 has a specification on the flexural strength and modulus of plastics for three-point bending tests. These tests are conducted on a sample that is deflected under a specific load until failure occurs. In this way, the manufacturers can find out the mechanical properties of the materials that are essential for product design.

Like other standards, ASTM also has put forward some standards such as ASTM E290 which deals with almost all types of metallic materials and their ability to sustain plastic deformation without cracking uder stress. Common methods used to achieve these goals include bending a specimen to be tested at a predetermined angle or radius which is designed to provide an indication of the degree of stress which can be sustained without failure.

Progress has focused on the application of data-driven approaches and automation to enhance the accuracy of bending processes. As noted in a report from 2022, modern automated bending machinery with real-time sensors is helping to considerably resolve issues during the testing of materials. Along with improving accuracy, this innovation also speeds up the testing activities to satisfy the increased need for compliance testing across materials in aerospace, automotive, and construction industries. Moreover, the creation of predictive modeling tools enables researchers to virtually model bending scenarios and minimizes the need for repetitive physical testing.

Following the standardized procedures together with modern technologies helps industries achieve desired product quality, optimize performance, and enhance the safety and reliability of the materials framework.

Compliance with Testing Equipment Standards

Meeting the requirements of testing equipment standards is essential in material testing to maintain accurate, dependable, and repeatable results. Guidelines developed by the bodies like ASTM International, ISO, and ANSI have stipulated frameworks for the construction, calibration, and operation of testing machines, assuring uniformity throughout industries. For instance, ASTM E4 details standard practices for verification of forces upon testing machines, while ISO 6892 guides on the procedure for tensile testing of metallic materials.

The latest report states that the market for materials testing equipment is expected to increase by 4.8% annually from 2023 to 2028, owing to the rising need for sophisticated material testing in the aerospace, automotive, and construction industries. In addition, companies are now incorporating smart sensors and IoT capabilities into testing machines for automated data acquisition and analysis. These advancements support compliance, increasing protectiveness and documentation during testing operations.

One of the most problematic areas of compliance is ensuring that testing equipment is calibrated properly and on a scheduled basis; otherwise, incorrect outputs can have serious ramifications. Blunders like trying to accomplish accuracy while one of the limits is not stated, the scope of ISO 9001 certification moves deeply into equipment maintenance with a focus on servicing such equipment to uphold expected productivity and deliver value while ensuring quality at all times. Many industries are now using digital calibration tools alongside other third-party accrediting services, as some of the standards do require compliance with such requirements.

These regulations and advancements reinforce confidence in the accuracy of the testing procedures while simultaneously allowing industries to ensure that the products comply with the rigorous international markets’ safety and performance benchmarks.

Reference Sources

1. Developing a Four-Point Bending Apparatus to Measure Bending Stiffness of Corrugated Board

This source elaborates on the application and accuracy of the four-point bending apparatus about its efficacy on corrugated boards.

2. A three-point bending test machine for studying the thermomechanical properties of shape memory alloys

This article focuses on a specially designed three-point bending test apparatus intended for the evaluation of thermomechanical properties of shape memory alloys.

3. Design and development of a plane bending fatigue testing machine for composite material

This paper discusses the design and the distinct attributes of the fatigue-testing machine meant for alternating bending motion with composite materials.

Frequently Asked Questions (FAQs)

Q: What is a bending test machine used for?

A: A bending test machine is used to determine the bending properties of materials, such as their ductility, bend strength, and resistance to fracture. It evaluates how materials behave under a bending load.

Q: What materials can be tested using a bending test machine?

A: Bending test machines can test a variety of materials, including metals, plastics, and other ductile and brittle materials. The machines assess how these materials respond to bending forces.

Q: How does a 3-point bending test machine work?

A: A 3 point bending test machine works by supporting a specimen at two points and applying a load at a third point in the center, causing the material to bend. This helps in measuring the material’s flexural strength and deflection.

Q: What is the difference between a 3-point and a 4-point bending test?

A: In a 3-point bending test, the load is applied at a single central point between two supports, while in a 4-point bending test, the load is distributed over two points, allowing for a more uniform stress distribution in the tested material.

Q: What is the purpose of using fixtures in bending tests?

A: Fixtures in bending tests are used to hold and support the specimen securely during testing. They ensure proper alignment and accurate results by minimizing extraneous movements and providing reliable support.

Q: Can bending test machines measure the tensile properties of materials?

A: Bending test machines are primarily used for evaluating bending and flexural properties rather than tensile properties. However, they can provide indirect insights into the tensile behavior through bending performance.

Q: What standards are commonly followed for bending tests?

A: Bending tests commonly follow standards like ISO and ASTM to ensure consistency and reliability in testing methods and results. These standards provide guidelines for test procedures, sample preparation, and result interpretation.

Q: What role does the bending angle play in a bending test?

A: The bending angle in a bending test indicates the degree to which a material can be bent before failure. It is a critical parameter that helps assess the material’s flexibility and ductility.

Q: How is deflection measured in bending tests?

A: Deflection in bending tests is measured by the amount of displacement experienced by the specimen under load. It helps in determining the material’s flexural rigidity and ability to withstand bending forces.