Test fixtures are very crucial in the product development and quality assurance process to ensure reliability and performance. Functional test fixtures form the nervous system of the process where a suitable and repeatable environment tests components, assemblies, and systems. What exactly makes them so vital? And how does good design enhance their working nature? We shall hence plunge into the world of functional test fixtures, understanding their advantages, basic design principles, and why their presence is imperative for the smooth operation of all industries.

Introduction to Test Fixtures

What is a Test Fixture?

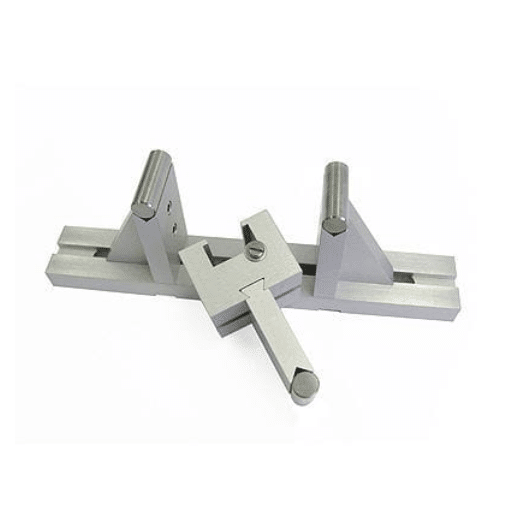

A test fixture is a mechanical or electromechanical apparatus designed specifically to hold, align, and support a test object through the course of various tests. By maintaining precise control over the test conditions, it simulates real-life conditions or applies precise forces in evaluating product performance, durability, or quality. Hence, test fixtures serve as instruments in finding the weaknesses or defects and making sure that the object conforms to the required specifications.

Force-Testing Fixtures

Force-testing fixtures are fixtures that are used to exert or apply controlled mechanical force, such as tension, compression, or shear, on a product or material. These fixtures are so important to make sure a component is structurally sound and reliable in manufacturing, aerospace, and healthcare industries.

By using force testing fixtures, engineers can measure characteristics of material strength, elasticity, and material performance when subjected to stress to find out whether the product will withstand real situations worthy to muscles.

The Role of Fixtures in Functional Testing

Force testing fixtures do great things in functional testing by ensuring consistent application and accurate measurement of different forces on objects. These fixtures give support and proper alignment and hold the specimen or product during testing to gather reliable data. It is this fixture that, when improperly handled, may allow error through misalignment, thus rendering the testing process unreliable.

- Real-life Simulation: Fixtures simulate conditions of real life in a laboratory environment

- Force Application: Enable stepwise application of tension, compression, shear forces

- Safety Compliance: Ensure manufacturers test products against regulatory standards

- Quality Assurance: Prevent failures and establish consumer goodwill

Importance in Electronic Manufacturing

Force testing fixtures are the most essential interrogatories to ensure manufacturing processes in electronic manufacturing where manufacturers strive to produce durable, reliable, and standard-compliant products. These fixtures serve manufacturers to consistently and repetitively test forces on various components in electronics, e.g., connectors, switches, circuit boards, etc.

Quality Assurance

Controlled and measured forces help learn if materials and components withstand mechanical stress in regular use, reducing risk of product failures.

Manufacturing Efficiency

Integration into quality assurance processes streamlines test procedures and cuts down production lags caused by unobserved faults.

Benefits of Using Test Fixtures

Improved Accuracy in Testing

Force testing fixtures are paramount as they work to enhance the testing process’s degree of accuracy across electronics manufacturing. Force testing fixtures secure components during testing, thereby eliminating any inconsistencies in measurement that may be caused by component movement or interference from the outside.

! Key Accuracy Benefits

- Consistent and reliable measurements across repeated tests

- Early defect detection preventing defective products from reaching market

- Accurate simulation of real-world conditions

- Enhanced design decisions based on precise testing outcomes

Enhanced Repeatability and Reliability

Force testing fixtures are important for improving repeatability and reliability in testing. Depending on the exact design of force testing fixtures, each test is carried out under exact conditions, variations being minimized and faithful to the results. This repeatability is thus important for comparing performance data of several specimens or tests and ensures increased confidence in the collected data.

| Reliability Factor | Benefit |

|---|---|

| Consistent Testing Conditions | Minimizes variations and ensures faithful results |

| Durability Design | Built for repetitive use with long-term accuracy |

| Real-Force Simulation | Tests performance under realistic usage conditions |

| Enhanced Decision-Making | Consistent results enable clear flaw detection and improvements |

Increased Safety for Operators and Equipment

Force testing fixtures help make safe environments for operators and equipment by ensuring accurately formed testing environments. Force testing fixtures hold the component securely during force application, thus avoiding any sudden movement and sudden failure that may cause injury to the operator or damage to the equipment.

Operator Safety

- Prevents sudden component movement

- Reduces injury risk from sudden failures

- Includes safety features like load limits and emergency stops

Equipment Protection

- Decreases wear and tear on test equipment

- Provides controlled testing environment

- Prolongs testing equipment lifespan

Types of Test Fixtures

Tensile and Compression Test Fixtures

Tensile and compression test fixtures are special tools used in testing the mechanical properties of materials when subjected to tension or compression. They are important in determining specific material properties, such as tensile strength, yield strength, elasticity, and compressive strength.

Tensile Test Fixtures

- Grip or clamp material steadily during stretching

- Prevent slippage and uneven stress distribution

- Ensure consistent force application along material length

Compression Test Fixtures

- Provide neat platform for compression testing

- Prevent specimen distortion or misalignment

- Maintain controlled and standardized conditions

Shear Testing Fixtures

Shear testing fixtures are integral in measuring forces of materials and their performance under stress. Setting a very specific shear force onto a specimen, the test fixture details intention for data entering or result collecting. Low-angle shearing is the one engineering process in which the engineers and manufacturers expect how their test specimen will perform under operational forces.

Key Properties Measured:

- Shear Strength: Maximum shear stress a material can withstand

- Shear Modulus: Material’s response to shear deformation

- Deformation Behavior: How materials behave under shear forces

- Standard Compliance: Adherence to ASTM or ISO guidelines

Custom Test Fixtures for Specific Applications

Custom test fixtures are force-testing tools that play a very important role in ensuring testing accuracy and validity under changing conditions. These fixtures are used to hold the specimen firmly, ensuring that all force is applied precisely, as any discrepancies in this would form variables in the test results.

| Industry | Application | Testing Focus |

|---|---|---|

| Aerospace | Turbine blades, structural fasteners | Extreme force resistance under realistic conditions |

| Automotive | Vehicle components | Crash resistance, load-bearing, durability |

| Manufacturing | Various components and assemblies | Dynamic and static condition assessment |

Designing Effective Test Fixtures

Key Considerations for Fixture Design

1. Specimen Compatibility

- Hold specimen firmly without damage

- Accommodate dimensions and tolerances

- Ensure reproducibility and reliability

- Consider modular and adjustable designs

2. Precision and Repeatability

- Yield consistent results every trial

- Minimize opportunities for error

- Maintain exact alignment with tolerances

- Ensure fixture stability during testing

3. Durability and Usability

- Survive repeated use and harsh conditions

- Easy assembly, disassembly, and adjustment

- Minimize downtime for efficiency

- Apply ergonomic principles for safety

Factors Influencing Fixture Setup

There are several critical factors affecting an effective fixture setup. One of the main factors is the type of testing required; such tests might be of mechanical stress, electrical performance, or environmental durability. That is, if you understand the purpose of testing, you will know what type of fixture should be designed and built to accomplish the set objectives with maximum functionality and accuracy.

- Testing Type Requirements: Understanding mechanical stress, electrical performance, or environmental durability needs

- Component Design Considerations: Accounting for dimensions, shape, and material properties of test subjects

- Modularity and Adaptability: Designing for various components and easy adjustments

- Operational Efficiency and Safety: Ensuring ease of assembly, ergonomic design, and user safety

Common Challenges and Solutions in Fixture Design

| Challenge | Solution |

|---|---|

| Limited Versatility | Design modular fixtures for easy reconfiguration and future scaling |

| Precision and Repeatability Issues | Use quality materials, proper alignment design, and auto-adjustment guides |

| Ergonomic and Safety Concerns | Incorporate adjustable-height features, easy-to-operate controls, and clear safety procedures |

Future Trends in Test Fixture Technologies

Automotive Industry Test Applications

In the automotive industry, test fixture technologies are used to test for functionality, safety, and compliance with the relevant standards. Test fixtures test engines, transmissions, suspension systems, and electronic controls. They simulate working conditions and therefore help find design errors or manufacturing defects before the vehicle reaches the consumer.

Electronic Component Testing Applications:

- Sensors and circuit boards for modern vehicles

- Performance testing under various environmental conditions

- Autonomous driving features and electric vehicle powertrains

- Structural integrity and material strength assessment

Automation in Test Fixture Setup

Automating testing setup results in streamlining the testing processes with the diminution of manual interventions, thus improving output. Automated systems specifically allow exact adjustments, maintain consistent testing conditions, and collect data in real-time, thereby producing reliable and reproducible results.

Automation Benefits

- Reduced manual intervention and human error

- Improved safety during material handling

- Consistent testing conditions

- Real-time data collection

Time and Efficiency Gains

- Significantly reduced test duration

- Faster development cycles

- Rapid component size adjustments

- Minimal preparation time

AI-Driven Data Analysis in Testing Processes

Force testing fixtures are essential elements to evaluate the strength, durability, and mechanical performance of materials or products. These fixtures hold the test samples in fixed positions, thus allowing for constant testing conditions and minimizing the variability caused by human factors or the environment.

AI Integration Benefits:

- Enhanced Precision and Efficiency: AI algorithms process huge volumes of test data quickly and identify patterns or anomalies with great accuracy

- Early Defect Detection: Engineers can spot potential defects or weaknesses in materials during development, reducing real-world failure instances

- Bias Elimination: AI-processed analysis eliminates human bias and ensures legitimately metric-based conclusions

- Predictive Modeling: AI systems predict material behavior under specific conditions and guide engineers toward better designs

Frequently Asked Questions (FAQ)

Q: Why are test fixtures vital to the testing of electronic devices?

Test fixtures confer on electronic devices the quality and reliability. They provide a fixed, repeatable means of electrically connecting a device under test (DUT) to a test system, so measurements and electrical tests could be made. The correct fixtures are used to verify whether the manufacturer-defined performance of his products has been achieved during the manufacturing and testing phase.

Q: How do test fixtures accommodate their specific testing requirements?

Test fixtures can be used to test differently equipped electronic devices. In-circuit test (ICT) fixtures are commonly utilized to test printed circuit boards by making contact with predetermined test points. This kind of fixture can be customized for the purpose of testing with its own special requirements that are peculiar to the DUT and, therefore, make testing very efficient.

Q: What role does test fixture design play in the manufacturing domain?

Test fixture design is of great importance with respect to manufacturing. A better test fixture can simplify test scenarios, reduce tear down time, and thereby increase production efficiencies. With DFM and DFT principles considered, the manufacturers can assure that a fixture provides an appropriate setup to carry out more tests.

Q: Can fixtures be used for multiple test methods?

Yes, fixtures can be used for different test methods: environmental and electrical. Test fixtures remain quite versatile to accommodate a range of testing situations in matters of prototype testing or high volume manufacturing, thereby ensuring that each device receives thorough evaluation.

Q: What are implicit test fixtures and their importance?

An implicit test fixture is a generic terminology for a fixture that might not be explicitly defined but is crucial for the performance validation of an electronic device. Such fixtures provide enough flexibility in the test setup so that test signals and their configuration can easily vary; thus, one setup method can service a multitude of test needs.

Q: How can test fixtures help to speed up testing?

Test fixtures speed up testing by being able to accommodate multiple tests within a single fixture, which in turn results in a reduced time required to run the various tests and thus less expenditures. This helps the manufacturers ensure their production targets are achieved while also upholding strict quality assurance standards through these rigorous testing procedures.

Q: How does working with test fixtures improve the reliability of an electronic device?

Test fixture design with the required reliability ensures that every testing scenario is fielded uniformly. While inflicting in robust test fixture designs that are suitable to high-volume manufacturing, the manufacturer is advantaged to lessen the probability of defects and ameliorate the quality of electronic devices escorted out there.

References

-

Force Testing: Purpose, Importance, Types of Testing – Xometry – Explains how force testing is used for quality control, safety, and material selection.

-

Importance of Quality Test Fixtures – Nordon – Highlights the role of test fixtures in ensuring accuracy, precision, and performance validation across various industries.

-

The Importance of Force Testing – Quality Magazine – Discusses how nondestructive force measurement techniques help evaluate materials, assemblies, and components effectively.