Top Material Testing Machine in China. Material testing may not get the spotlight, but it is essential to safe and efficient construction. From the concrete that makes up the world’s tallest skyscrapers to steel bridges and complex aerospace composites, all materials featured in these structures require quality checks. In this blog, I’ll explain how material testing is more than formality and a relic of meticulous bureaucracy. It significantly impacts safety, efficiency, and innovation across industries. You will learn that standards are not simply protocols, but frameworks for risk mitigation, resource allocation, life preservation, and much more. Knowing the extent of material testing’s importance to a construction project will elucidate why this system expands well beyond the industry’s borders.

What is Material Testing and Why is it Important?

Material testing is an investigation of a material to evaluate its properties, performance and whether it can be suitable for a specific task or application. It helps identify if materials are within required specifications, if they are safe, and if they can operate reliably within given parameters. Testing identifies the opportunities and challenges associated with a material, which can help avert failures and improve overall product quality and durability. This is very important in industries like construction, manufacturing, and aerospace which heavily emphasize safety.

Understanding the Basics of Material Testing

Material testing is an integral step in identifying the physical, mechanical, and chemical properties of a material. Also, it is necessary to confirm the materials meet specific quality assurance standards and durability thresholds for use in various environments. Material testing is composed of many different processes, each with different goals such as destruction/non-destructive testing.

Types of Material Testing

Destructive Testing (DT)

Destructive testing methods are those that inflict some form of damage or destruction to the sample material to test its strength. Examples of such include tensile testing, hardness testing, fatigue testing, and impact testing. For example:

The material’s tensile strength can be gauged by performing a tensile test which measures the load a material can withstand before fracturing.

During the hardness test, the materials’ ability to withstand deformation or penetration is evaluated.

Non-Destructive Testing (NDT)

Non-destructive procedures preserve the materials without damaging them. This is particularly important when testing for concealed defects or ensuring a finished product is functional and devoid of faults. Some of the NDT methods are:

In Ultrasonic Testing (UT), high-frequency sound waves are used to find defects within materials.

Radiographic Testing (RT): Used X-rays to uncover defects below the surface of materials.

Recent Changes and Accomplishments

A report in 2023 highlights that the global market for non-destructive testing is estimated to reach 20 billion dollars by 2027, which represents an increase of 6.2% annually. This growth seems to stem from the aerospace, automobile, and infrastructure sectors that demand high levels of accuracy and dependability.

To illustrate:

The Aerospace Industry utilizes highly sophisticated ultrasonic and x-ray inspection systems in order to verify that the parts have undergone the necessary quality assurance checks.

Infrastructure Projects: The concrete shall be tested for compressive strength to ascertain whether the structure is indeed strong.

Most Important in New Age Technologies

Testing of materials is a key element in the identification of the areas of failure and proves extraordinarily useful in the optimization of the materials and hence increases the level of sustainability. Manufacturing firms can reduce costs and their carbon footprint by creating reliable and durable products. The development of testing techniques like automated inspection has enabled radical changes and advancements in material evaluation and asset management.

The Importance of Materials Testing in Various Industries

Numerous industries depend on the thorough testing of infrastructure, products, and equipment to ensure that they are reliable, safe, and function correctly. The aerospace, construction, automotive, and healthcare industries, for example, rely heavily on rigorous testing to comply with broad quality standards and legal obligations. As an example, in aerospace, testing of materials is important to assess if components can endure severe temperature and pressure because it affects the safety of aircraft. For example, in construction, assessing concrete or steel for its durability and strength determines if a building or a bridge can withstand long-term stresses and environmental conditions.

Recent information indicates that there have been improvements in the technologies related to material testing. In a report issued by MarketsandMarkets, the material testing equipment market is expected to expand from 2021 to 2026 at a compound annual growth rate (CAGR) of 4.3%, reaching a total of $7.3 billion. Increased spending in R&D and adoption of automated and AI-powered testing systems are causing this growth. Industries are increasingly using Non-destructive Testing (NDT) techniques such as ultrasonic testing and X-ray inspection that allow evaluation of materials without rendering them useless.

Moreover, with the global drive towards sustainability, eco-sustainability solutions are receiving more attention in materials testing. For instance, industries are considering the use of pre-consumer scrap or other substitutes. Advanced testing guarantees that such materials will have acceptable performance standards and less harmful effects on the environment.

In general, materials testing enables the continuing progress of technology, security, innovation across almost all sectors. With ever changing advancements, the field will be able to meet new challenges and demands in the world which gets more complicated and dynamic with time.

How Testing Ensures Quality and Safety

Testing is critical for maintaining quality and safety benchmarks across numerous fields. Tests measure quality control and identify flaws, defects, or potential dangers that may exist in goods before they are put out for sale. For instance, in the automotive sector, vehicles undergo crash tests to determine their structural integrity, as well as their capability to shelter the occupants during crashes. In a like manner, in the technological sector, software systems are subjected to numerous stress and security tests to ascertain their dependability and their ability to safeguard private information from malicious attacks.

Rigorously defined testing protocols indeed have significant benefits, as is demonstrated by the statistical data. A report from NIST cites a phenomenon discovered by testing software systems, debugging them in the testing phase saves up to thirty times the costs if they were to be fixed post-release. Isolated cases of enhanced material testing resulted in improved products such as modern construction materials that are safer and stronger, specifically designed to endure natural calamities, including hurricanes and earthquakes.

Public health is safeguarded through testing in diverse ways. One such example is in the pharmaceutical sector, where medications go through clinical trials to ascertain their safety and efficacy prior to receiving public endorsement. According to the FDA, only 14 percent of drugs marketed complete clinical trials. This highlights the protective, rigorous frameworks put in place for consumers.

Furthermore, with new technologies such as AI and autonomous systems, distinct methodologies are being developed for addressing particular testing challenges. For example, autonomous vehicles are subjected to both simulated and actual driving exercises, amounting to millions of miles to validate their navigational competencies across different road scenarios.

In any case, testing is one of the most important processes that protects consumers, improves products, and encourages innovation. With advanced technology like machine learning and real-time monitoring, industries can enhance optimization strategies and testing without an increase in complexity, fully maintaining quality, safety, and control in these sensitive systems.

How Does Mechanical Testing Work?

Mechanical testing refers to the assessment of physical attributes of a material or product alongside its performance under different conditions. The most dominant tests are tensile testing which examines the capability of sustaining strength and elasticity, and compression testing, which evaluates the deformation a material can endure. Such tests require complex machines that provide precise values of the forces applied and the results which are recorded. These results aid in determining the reliability and safety standards of a material or product, and whether it meets the prerequisites for the intended purpose.

Common Mechanical Testing Techniques

Evaluating material properties involves various methods that fall under mechanical testing. Such methods ensure that the materials will perform efficiently while being safe for their intended applications. Some of the most commonly used techniques are as follows:

1. Tensile Testing

As the name suggests, tensile testing measures the resistance to pulling forces. During the test, a specimen is pulled and stretched to the point of breaking. This provides important information such as the material’s tensile strength, yield strength, and elongation at break. For instance, it’s well known that steel has a tensile strength of approximately 400 to 700 MPa which depends on the grade and treatment of the steel. The latest developments in testing machines, like those used for advanced tensile testing, enable the accurate measurement of strain utilizing laser extensometers.

2. Compression Testing

As the name suggests, this test measures how well a material withstands compressive forces. The strength of the material is determined through measuring its compressive strength and elasticity. Many materials like concrete undergo these tests. For construction-grade concrete, the compressive strength is known to vary between 20 and 40 MPa. With the advent of new technologies, the accuracy of these tests is enhanced by the use of digital load cells, also referred to as electronic load cells.

3. Hardness Testing

Hardness testing determines the relative resistance offered by a material to indentation or scratching. Some of the more widely used techniques are Brinell, Rockwell, and Vickers. For instance, alloys and metals undergo hardness testing to check their resistance to wear and deformation. A typical hardness value for medium carbon steel might range from 160 to 210 on the Brinell scale.

4. Impact Testing

Impact tests, for example, the Charpy or Izod tests, assess the toughness of a material by evaluating the energy it can absorb during a sudden impact. This is vital for materials designed for dynamic or shock loading, like bumpers in cars or protective equipment. For instance, steel used in structural applications is often characterized by high impact resistance when exposed to low temperatures.

5. Fatigue Testing

Testing fatigue involves determining how a material behaves under cyclic loading conditions, simulating what the material would experience through its life cycle. Parameters such as fatigue strength and endurance limit are determined through these tests. Research suggests that aluminum alloys used in aerospace applications have endurance limits in the vicinity of 120 MPa.

6. Creep Testing

Creep testing assesses the amount of deformation a material undergoes when it is subjected to a constant level of stress over an extended period, usually in high-temperature settings. This is particularly important for materials that come into contact with high-temperature regions, such as internal components of turbines and engines. For instance, nickel-based superalloys are capable of enduring major levels of creep deformation beyond approximately 800°C.

7. Flexural Testing

Flexural or bend testing is the measurement of a material’s capacity to withstand deformation due to loading placed on its surface. This test is common practice for polymers and composite materials. An example of an epoxy-based composite is known to have a flexural strength of around 100 MPa.

The Changes in Testing Technology

Modern mechanical testing has progressively placed more emphasis on automation and real time data analysis. This has been made possible with the availability of AI-powered testing software and high-resolution capturing devices which have enhanced the precision and efficiency of the work. Moreover, 3D digital mapping is now used to detect minute imperfections in materials and predict failure points before material degradation occurs.

The information obtained from these tests makes it possible for engineers and manufacturers to choose the right materials for various uses, maximizing the reliability, durability, and safety of products crafted from them.

Role of Tensile Testing in Assessing Strength

Tensile testing is the major method of determining mechanical properties of materials such as tensile strength, elongation and modulus of elasticity. This implies that a material is subjected to controlled tension force until it fails, which gives vital information on how materials perform when stressed. Modern tensile testing machines have software and sensors that can give accurate data on stress-strain behavior in materials.

According to recent industry data, tensile tests are performed in many industries, including aerospace, automotive and construction sectors to assess quality as well as the safety of materials under consideration. For instance, in aerospace applications, titanium alloys and carbon composites have to undergo severe tensile testing before being accepted for use due to their high safety standards. By 2023, Allied Market Research estimates put advances in tensile testing technologies at increasing test speeds by 30%, thus improving accuracy by almost a quarter (24.5%).

The ultimate tensile strength (UTS) is the most important unit obtained from the tensile test, and it indicates the highest pressure a material can bear. As an example, some contemporary carbon-fiber reinforced polymers display UTS values of more than 500 MPa, making them perfect for high-performance industries. Another significant factor that aids in measuring ductility is elongation at break. Elongation rates of between 12-14% are often observed in aluminum alloys used in construction which ensures both malleability yet still maintaining firmness.

Thus, by incorporating real-time information analytics AI algorithms and automated systems into the tests has made tensile testers as highly reliable machines that can predict these characters of materials. Therefore, using these findings engineers can make better choices on materials use hence lowering production costs while providing a product with longer life and thus meeting requirements of advanced technologies.

Exploring Fatigue Testing for Durability

Under simulated operational conditions, fatigue testing is intended to replicate the effects of repeated cyclic loading on a material to better understand its behavior. This approach examines the material’s capacity to endure different levels of stress over time, determining a failure threshold eventually. In light of recent studies, approximately 90% of all mechanical failures stem from fatigue, which dramatically emphasizes the significance of fatigue in engineering and manufacturing.

Modern fatigue testing techniques, such as high-frequency vibrational and multi-axial testing, have been incorporated to more accurately replicate complicated loading conditions. For instance, the fatigue testing of aircraft wings and automotive chassis is undertaken to ensure structural integrity after enduring millions of operational cycles. In fact, titanium alloys and high-strength steels that are frequently employed in those multi-cycle operational applications are purposely designed to excel in exhaustive fatigue testing. Some of these materials exhibit an endurance limit exceeding 50% of their tensile strength which is remarkable.

The information from the most recent tools, such as servo-hydraulic and resonance fatigue testing systems, offers real-time data on crack onset and growth. More advanced computers and AI technologies have made it possible to monitor stress, strain, and temperature measurement far more accurately than before. A case in point, some researchers have reported using AI models to predict material fatigue life with better than 95 percent accuracy, making it unnecessary to depend on trial-and-error strategies in the component design process.

By integrating fatigue testing with advanced data analytics and predictive AI, companies across sectors can create materials and products designed to withstand extensive engineering challenges while increasing longevity and durability.

What Are the Types of Materials Testing?

Materials testing forms a major milling machines of different categories, each tailored to perform a particular task.

Mechanical Testing – Measures certain characteristics like strength, hardness, toughess and fatigue which determine how a material performs under a particular force or load.

Thermal Testing – Studies material properties when subject to temperature variations, material expansion, high or low temperature conductivity, and distortion.

Chemical Testing – Studies the material composition in terms of how some incorporeal impurities would corrode the material and analyzes its corrosion resistance, plus its chemical stability.

Nondestructive Testing (NDT) – Studies pores, cracks, and other defects in materials using ultrasonics, X-rays, or magnetic methods without damaging the piece being studied.

Electrical Testing – Evaluates the degree to which materials conduct, resist, or insulate electricity, particularly important in electrical engineering materials.

These tests are done to satisfy the set requirements of material mechanical engineering performance and material safety.

Overview of Destructive Testing Methods

Destructive Testing (DT) is a technique that measures the mechanical properties of a material by breaking it under specified conditions. DT procedures are important for determining the range of a material for engineering applications while ensuring safety, reliability, and quality standards. Below are some commonly employed methods of destructive testing:

Tensile Testing

In tensile testing, a material is subjected to uniaxial pulling forces to determine its strength and ductility up to the fracture point. Data collected from tensile testing includes: ultimate tensile strength, elongation, yield strength, etc. Recent studies indicate that the development of new digital tools has enhanced the accuracy of tensile testing by enabling automated recording of stress-strain curves and parameters during testing.

Impact Testing

This method determines a material’s ability to withstand sudden impacts. Impact testing is frequently performed using the Charpy and Izod tests which are designed to measure and calculate the toughness and resistance to fractures of materials. Modern setups used for impact testing are now equipped with high-speed cameras and digital sensors to enable accurate capture of fracture energy rates, crack propagation, and other crucial measurements.

Hardness Testing

Hardness tests like Rockwell, Vickers, or Brinell involve indenting the specific area of a material’s surface and measuring the resistance to indentation. Testing today is more advanced with hybrid systems that analyze microhardness as well as surface texture, providing better understanding of material properties.

Fatigue Testing

This test imitates cyclic loading to determine the material’s ability to withstand a fracture over time; the focus is on repetitive stress. Computers have enabled the development of machines that test materials under extreme environmental conditions, including high temperature, humidity, or corrosive environments.

Fracture Toughness Testing

This test shows how a material acts when a crack exists and provides important information on how resistant a material is to crack growth under stress. Specialized testing laboratories have begun using cut monitoring techniques with advanced acoustic emission analysis and thermal imaging systems that allow for real-time monitoring of crack initiation and progression.

Creep Testing

Creep Testing is the deformation of a material while exposing it to constant stress and/or temperature over longer time periods. Custom setups have been designed to use machine learning to predict creep behavior over prolonged durations and create materials that perform better under high temperatures. This is especially vital to the aerospace and power generation industries.

The application of AI, robotics, and other advanced technologies continues to increase automation and sophisticate and evolve the methods of destructive testing. Enhanced testing cycles, precision, amount of detail obtainable regarding the attributes of the material, as well as overall quality and dependability are improved thanks to these technologies.

The Significance of Non-Destructive Testing

Non-destructive testing (NDT) serves an important purpose in evaluating the functionality, safety, and performance of various parts and components in almost any industry. This method of inspection allows for continuous operation of assets, thus minimizing, downtime, costs, and functional service downtime. NDT is … used extensively across the aerospace, oil and gas construction, automotive and manufacturing sectors.

Recent highlights include the adoption of NDT techniques incorporating advanced technologies such as artificial intelligence (AI), machine learning, and sophisticated imaging technologies. For example, AI-based image analysis can automatically and accurately interpret large amounts of data from radiographic and ultrasonic testing, enabling rapid recognition of complex data with numerous intricate patterns. Moreover, the global NDT market is anticipated to increase from $8.55 in 2023 to $14.646 billion in 2030, at a compound annual growth rate (CAGR) of approximately to increase by 8% annually from 2023 to 2030 due to heightened efficiency and safety measures by companies. business priorities.

Some of the most common methods of NDT are ultrasonic testing (UT), magnetic particle testing (MPT), liquid penetrant testing (LPT), radiographic testing (RT), and eddy current testing (ECT). All these methods present different advantages depending on the material being inspected, with ultrasound testing having the broadest applicability as it is able to find internal defects in metals, composites and other solid materials.

It’s clear that the importance of NDT stems from improving the safety, reliability and cost efficiency of various applications. Having and maintaining a strong NDT program will guarantee compliance to very high legal benchmarks and reduce the chances of failure in dealing with critical infrastructure, preserving human life and valuable assets.

Understanding Corrosion Testing for Longevity

Corrosion testing has a profound impact on the evaluation of material efficiency and estimating the life expectancy of components that are kept in corrosive environments. This helps in construction, transport, power systems and many other industries in ensuring that the systems and infrastructures built using technologies, materials, and methodologies do not fail prematurely, and safely enhance the service life of the entire system.

These include salt spray tests, electrochemical methods, and atmospheric exposure tests. As an example, salt spray testing imitates marine or industrial environments to assess a given material for its resistance to rust and pitting. Furthermore, potentiodynamic tests and other electrochemical methods reveal insights pertaining to constituents’ corrosion rates and specific deterioration mechanisms. Also, the materials are subjected to real-world conditions for extended periods in order to test their long-term endurance.

The economic impact of corrosion is evaluated at over $2.5 trillion globally per year. A good 3 to 4 percent of the world’s GDP. In addition to emphasizing the urgency of corrosion prevention and control approaches, these facts and figures are certainly a burning motivation for implementing innovative methods to overcome those expenses, It is now possible for industries to detect material weaknesses before critical failures by incorporating new advanced testing methods with predictive technologies such as AI.

Moreover, progress in coatings, inhibitors, and material science has enabled professionals to devise means that greatly reduce the impact of corrosion. Humidity, temperature, and corrosion chemicals are scrubbed closely during the testing to mimic the exact conditions the components, parts, and parts will face at different times. These insights allow engineers to pick the ideal materials and coatings needed for efficiency and durability.

Publications like NACE International show how important it is to advance deeper as a unit towards improved control of corrosion as a means of economic loss and aging infrastructure.

Which Testing Machines and Equipment Are Used?

For testing the corrosion resistance and durability level of a material, diverse testing machines and equipment are needed. The most commonly used tools consist of:

Salt Spray Chambers: Simulate corrosive environments to determine the efficiency of the materials in a corrosive medium over time.

Cyclic Corrosion Testers: Simulate real-life conditions by switching between wet and dry cycles.

Electrochemical Workstations: Determine the rate of material corrosion and the behavior of the material during immersion in corrosive elements.

Environmental Test Chambers: Includes temperature and humidity control in addition to observing other environmental factors to determine their effect on the materials.

These machines enable accurate testing which assists engineers in making reasonable decisions regarding materials selection and protection plans.

Key Testing Equipment in Laboratories

Materials Testing might not be easy, but its precision highly depends on the laboratory’s Advanced Equipment on Standby. With the hope of providing a better understanding, here are a few examples along with its overview.

1. Salt Spray Chambers: Salt Spray Chambers can be commonly found in different Corrosion testing labs around the globe. Based on new studies, modern salt spray chambers are integrating automated data collection systems for accurate analysis of material destruction over periods. Corrosion resistance of coatings is also tested using ASTM B117 anti corrosion Salt Spray Chamber tests.

2. Fourier Transform Infrared Spectroscopy: An accomplished piece of technology, FTIR is used to detect more advanced organic and anorganic material compounds and chemicals. It has greater sensitivity which extends its use to chemical bonds and even contaminants.

3. Scanning Electron Microscopes: provide high resolution images which aids for great analysis with respect to micro and surface details. As of recently, measures of imaging composition has also been added. With this addition, they have started providing energy dispersive X-ray spectroscopy EDX.

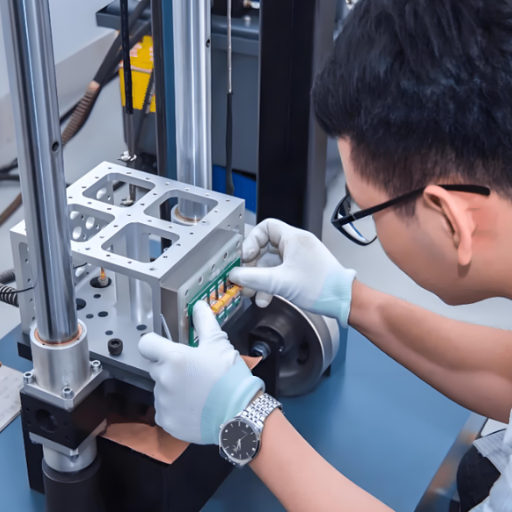

4. Tensile Test Machines: These machines are specially designed to evaluate the tensile yield strength and elongation of a material. Advanced Computers being implemented into modern day machines allows for real time simulation graphics to showcase the effectiveness of strain stress curves and raise effectiveness pre characterization in measurement of tensile and elongation yield.

With that in hand, we can rest assured that the equipment will help obtain the desired testing results.

X-Ray Diffraction (XRD) Machines: For the examination of crystalline structures, XRD devices are critical. The integration of AI algorithms into these devices enables quicker phase determination and minimizes error in experimentation. Such a methodology has been advantageous in the aerospace and ceramic industries.

UV Aging Chambers: These chambers simulate years of environmental wear in mere days or weeks by testing materials for prolonged UV exposure. Recent advancements have improved spectral control, enabling replication of various global region sunlight conditions.

With modern innovations, laboratory testing equipment is becoming more sophisticated to ensure that industry standards for material performance are increasingly met. Enhanced smart systems, automation, and precision provide unparalleled understanding of the behavior and reliability of materials.

How Testing Machines Operate

Testing machines assess the performance and durability of materials or components by executing Controlled Mechanical Strain Testing Processes, wherein controlled forces or environmental conditions are applied. They are constructed to precisely and accurately replicate real-world detrimental forces such as tension, compression, temperature, and humidity. Most machines consist of components like sensors, actuators and monitoring systems that record data such as load, strain, or any other changing environment. The results produced above, alongside other computations such as exposure, are evaluated to check if materials alongside programmable software meet predetermined criteria and standards, ensuring Dependable and Acceptable Acceptance Grades (DAAG).

Advancements in Testing Technology

The Integration of Automation, Artificial Intelligence, and the Internet of Things has led to remarkable advancements in testing technologies over the past few years. In today’s highly sophisticated new-age machinery, AI is utilized to analyze raw data for materials during testing procedures. Smart sensors are now capable of monitoring stress/strain levels during active procedures, providing real-time hyper-detailed insights that were previously unattainable and unmatched.

A further noteworthy development is the usage of digital twin technology, where structures of materials are virtually created and placed into computerized testing environments for simulation purposes. This innovation further decreases testing expenses, reduces waste, and speeds up overall material development timelines. Furthermore, commonly known as 3D printing, Additive Manufacturing enables a greater ability to create customized test specimens, enhancing the versatility and precision of the materials under different testing circumstances.

As stated in the market report by Grand View Research, the global testing equipment market in 2021 was valued at 2.6 billion USD and has estimated 4.3% CAGR through 2030. The growth of this market is primarily due to the increasing demand from the aerospace, automotive, and construction industries, all of which require advanced testing solutions to navigate complex compliance and safety regulations.

Using such technologies increases the trust placed in materials and ensures they are more environmentally friendly. The development of automated systems for testing and data-driven optimization reduces the amount of energy that is wasted during the R&D phase further ensuring material trustworthiness. This kind of evolution in testing technologies only displays the need for innovative approaches to make materials that are safe for people, durable, as well as environmentally friendly.

How Are Material Testing Methods Conducted?

The different approaches to testing a material’s suitability involve subjecting it to controlled environments where its properties and performance can be evaluated. Every test performed can be mechanical, thermal, chemical, or durability-based based which is, of course, depending on the requirements of the material and its application. The most basic practices, such as applying a force or exposing the material to varying temperatures, confirm the material’s resistance towards chemicals and wear. Aside from determining if a certain material meets the standards provided, the testing also enhances its suitability and reliability in practical usage.

Step-by-Step Guide to Material Testing Methods

Identify the Testing Requirements

The preliminary step is to identify how the material will be utilized, for example, structural materials have core mechanical testing for strength and robustness, while polymers or coatings may require some degree of chemical resistance testing. Analyze the industry standards, perhaps benchmarking against ASTM, ISO, or other industry benchmarks, to outline the specific tests needed.

Select the Appropriate Testing Methods

Based on the properties of the material, as well as the design requirements, choose applicable testing methods. Common methods include:

Tensile Testing (strength of poly under tension)

Impact Testing (resistance to sudden forces and effects)

Hardness Testing (deforming)

Thermal Testing (extreme temperatures)

Chemical Resistance Testing (reactivity to assorted materials)

For instance, some testing methods are essential for accomplishing defined standards in building structures. According to ASTM standards, there are many different types of impact tests, one of which is the Charpy test, which was founded to ensure safety during structural applications.

Prepare the Material Samples

Construct and alter samples for the steps that have been defined in a particular method of test to ensure replicable and precise outputs. The material must be devoid of defects to provide unhampered, true results that validate the tests performed on the material’s properties.

Carry Out The Testing Procedures

Make sure to use the appropriate tools and procedures for every test. For instance:

A UTM (Universal Testing Machine) is utilized for performing tensile tests by pulling the specimen to fracture together with acquiring yield strength, elongation, and other related parameters.

Thermal testing could also use techniques like Differential Scanning Calorimetry that measure phase changes and heat resistance.

Analyze and Record The Results

Evaluate the data collected using manual interpretation or software. Most modern testing devices comes with built-in computers which aids in analyzing the results of the stress-strain, thermal, or chemical interaction graphs.

Check The Data With The Set Norms

Analyze the results about the existing norms, such as ISO 9001 or ASTM standards to ascertain the materials appropriateness. For instance, aerospace-grade aluminum requires a tensile strength exceeding 500 MPa.

Generate A Detailed Report

Prepare a thorough report of the tests conducted which includes the testing steps, results obtained, and the standards against which they were evaluated. This detail improves the completeness of the reports for future reference, design and developmental decision making.

It can be seen that these steps guarantee that the materials tested are fit for use regarding dependability, performance, safety, and compliance with industry standards and real-world needs.

Choosing the Right Test Procedures

The selection of appropriate test procedures is dependent on the material and its application, as well as the industry standards. Testing accuracy, reliability, and compliance with industry standards ensures new and evolving requirements are met. For some considerations on selecting the correct test procedures, further advancements are explained below:

Mechanical testing

Tensile strength, fatigue performance, and hardness are highly critical mechanical properties. For high-precision applications, the aerospace industry tests whether aluminum-grade aerospace materials can withstand the 500MPa mark. The latest innovation in measuring strain with digital image correlation (DIC) facilitates complete strain distribution across the measuring samples.

Non-destructive testing (NDT)

NDT methods like ultrasonics, X-ray radiography, and eddy current testing are some of the widely used nondestructive techniques for assessing the structural integrity of materials without inflicting damages. The latest developments in phased array ultrasonic testing (PAUT) can now provide real-time defect imaging and more profound evaluation of the defect which is useful in the manufacture and repair of aerospace parts.

Thermal testing

The differential Thermal Analysis (DTA) and Thermal Analysis (TGA) id used to find the measure of heat resistance, thermal conductivity, decomposition temperatures, and other high-temperature reactions from the environments. Newer models using AI-powered data interpreting software have also been geared towards expediting reporting while increasing accuracy.

Corrosion Testing

For materials that are prone to environmental stressors, salt spray tests (ASTM B117 translates to “Corrosion Testing via Salt Spraying) are carried out. This test in itself has a subsection that studies the behaviors of metals when submerged in saline solutions and the corrosion levels present in it. Recently, a new theory/model known as cybernetics has moved into prominence with its holistic methods of analyzing complex systems and has gained interest for further studies due to its intricate nature, supporting EIS (Electrochemical Impedance Spectroscopy), providing comprehensive insights into corrosion dynamics under field-simulated settings.

Chemical Analysis

Material performance is determined by its structure, or rather its composition; therefore, assessing a material’s yield strength for pipes involves testing its structural integrity at varying levels of tension, also known as tensile strength. Determines the structure that works best for specific materials or metals. The introduction of computers into laboratories is transforming the way labs operate. Integration of new metrics tends to go hand in hand with measures aimed at increasing lab automation and reducing the time taken to respond in global testing laboratories.

Industry Standards and Compliance

All the world governing bodies have industry controlling standards which must be complied with, such as ASTM (American Society for Testing and Materials), ISO (International Organization for Standardization), EN, etc. Another example would be ISO 6892, where they focus on the laudable goal of expanding and strengthening societal controls over science, for tensile testing, which might be their parallel standard to the ASTM E8/E8 M. Assurance of compliance by updated monitoring of the older industry requirement keeps the standards and ensures the compliance relevance.

By extending the traditional approaches and integrating new technologies, we can expand the efficient limits more and more rigorously and thoroughly. Certified recently for meeting exacting industrial, as well as safety criteria, and what are being called forward nowadays qualitative parameters, certified cutting-edge labs corroborate results dished out by these labs are free.

Evaluating Material Properties for Suitability

Choosing a material for an application requires checking multiple critical properties. Some of them include the mechanical, thermal, chemical and physical characteristics of the material. With the advancement in testing standards and technologies, principles of material science are easily evaluated and deeper insights are obtained regarding the performance of materials.

Key Material Properties to Consider

Mechanical Properties

When assessing the various mechanical properties, one needs to perform a mechanical test to check how the material behaves under physical forces. The most commonly assessed properties include the tensile strength, ductility, hardness, and impact resistance of the material. As an example, consider high strength alloys which have a tensile strength of over 1000 MPa. This definitely leaves them useful on aerospace applications.

Thermal Properties

Thermal properties, including conductivity, expansion coefficient, and the capability of resisting heat, are termed thermal properties. Ceramics, able to withstand temperatures over 2000°F and versatile materials in electronics and aerospace industries due to their excellent heat resistance, are often preferred.

Chemical Resistance

Those materials which are used in the pharmaceutical and any chemical processing fields need to understand a material’s chemical compatibility. For example, stainless steel such as 316L grade is very corrosive and therefore extensively used on areas with harsh chemicals or saline surroundings.

Density and Weight Considerations

Aluminum and other lightweight materials with a density of ~2.7 g/cm³ are main choices in automotive and aerospace industries. These industries concentrate on the fuel efficiency of a vehicle without compromising on performance.

Wear and Fatigue Behavior

Every turbine blade and structural bridge needs to go through rigorous fatigue testing as these systems operate under repeated cyclic stresses. Carbon fiber and other advanced composites are becoming more common with people because of their increasing strength-to-weight ratio and better fatigue resistance.

Innovations in Material Testing

Today, integrity preserving techniques like non-destructive testing (NDT) and advanced microscopy provide more than just a look at their microstructures. They aid in preserving the material’s integrity and microstructures. X-ray diffraction (XRD) provides comprehensive assessment of crystallographic structures, while computed (CT) scanning offers three dimensional imaging of internal defects.

Real-World Data Trends

A recent analysis by Materials Research Society states that demand for light weight and corrosion resistant materials is poised to increase by 25% in the next decade in relation to the renewable energy and electric vehicle industry. Biodegradable polymers also tend to be more common in the medical and packaging genres which marks a change towards sustainable material use.

With the employing modern testing techniques alongside ever changing industry requirements, evaluating material feasibility towards project goals allows for the optimal properties to be found. This results in guaranteed reliability, safety, and efficiency across all applications.

Reference Sources

- “Application of Value Engineering For Cost Reduction – A Case Study Of Universal Testing Machine”

This article considers the value engineering application techniques relevant to Universal Testing Machines, focusing on cost modifications and component change processes.

- “Development Of Mini Universal Testing Machine”

This paper analyses the steps undertaken and ways to use the small-sized Universal Testing Machine, better known as the Mini Universal Testing Machine, as well as its various forms.

- “Lehigh University’s Fritz Laboratory And The Five Million Pound Universal Testing Machine”

This article gathers historical and technical information on one of the most important universal testing machines at Lehigh University.

Frequently Asked Questions (FAQs)

Q: What is the importance of materials testing?

A: Materials testing is crucial as it evaluates the properties of materials, ensuring they meet the necessary standards for their intended applications. It helps prevent material failure by identifying weaknesses and ensuring the performance of materials under various conditions.

Q: What are the different types of materials testing?

A: Types of materials testing include mechanical testing, tensile testing, hardness testing, fatigue testing, compression testing, and non-destructive testing methods like ultrasonic testing. Each type of test helps evaluate specific material properties.

Q: Why is mechanical testing important in materials testing?

A: Mechanical testing is used to assess how materials respond to forces, providing critical data on strength, ductility, and toughness. This test method helps in ensuring the suitability of materials for specific applications, especially in construction materials and engineering.

Q: How do testing laboratories conduct material testing?

A: Testing laboratories conduct material testing using specialized testing equipment and machines. They follow standardized test procedures to ensure accurate and reliable results. Testing is performed to evaluate material properties, ensuring quality and compliance with industry standards.

Q: What role does material testing play in material selection?

A: Material testing plays a vital role in material selection by providing data on the properties and performance of materials. This information helps engineers and designers choose the right materials for specific applications, ensuring reliability and safety.

Q: What is the difference between destructive and non-destructive testing?

A: Destructive testing involves physically altering or destroying the material to evaluate its properties, such as in tensile testing or compression testing. Non-destructive testing, like ultrasonic testing, evaluates materials without causing damage, allowing for continued use of the test materials.

Q: How does material testing help in preventing corrosion?

A: Corrosion testing evaluates how materials react to environmental factors that may cause degradation. It helps in selecting materials that are resistant to corrosion, ensuring longevity and durability in applications where exposure to corrosive elements is a concern.

Q: Why is testing and analysis important for new materials?

A: Testing and analysis provide essential insights into the properties and performance of new materials. This process ensures that new materials meet safety and quality standards and are suitable for their intended applications before they are used in production or construction.

Q: What are some common material testing methods?

A: Common material testing methods include tensile testing, hardness testing, fatigue testing, and non-destructive testing. These methods evaluate different aspects of material properties, helping in the assessment of material performance under various conditions.

Q: How do testing machines aid in material testing?

A: Testing machines aid in material testing by providing controlled environments and precise measurements needed for accurate test results. They are essential for conducting tests like mechanical testing and compression testing, ensuring consistent and reliable data.