Natural stones are widely valued in construction and design applications for their durability, aesthetics, and versatility. However, assessing their quality and performance under varying conditions is critical, especially in environments where wear and abrasion play a significant role. The Böhme Abrasion Tester has emerged as a pivotal tool in this realm, providing precise measurements to evaluate the abrasion resistance of natural stones. This article explores the importance of this advanced testing method, detailing how it helps industry professionals ensure the long-term reliability and safety of materials used in flooring, paving, and other high-traffic applications. Whether you’re a materials engineer, designer, or architect, understanding the role of abrasion testing is essential for making informed decisions and delivering superior results.

What Is the Böhme Abrasion Tester?

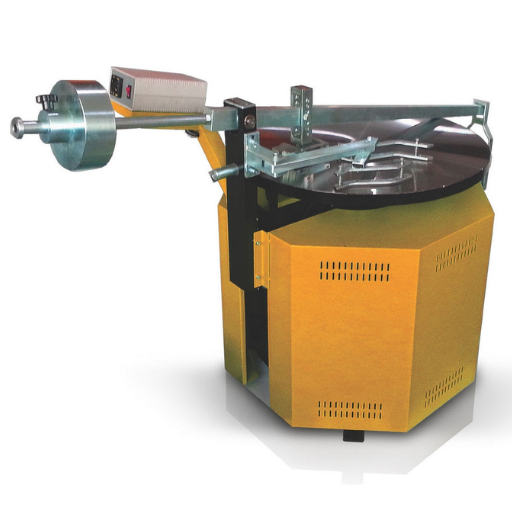

The Böhme Abrasion Tester is a specialized device designed to measure the wear resistance of natural stones and other materials under standardized conditions. It operates by subjecting a specimen to repeated abrasion using an abrasive material and a rotating disc. The extent of material loss, typically measured by weight or volume, provides a reliable indicator of the material’s durability. This testing method is widely used in industries where stone is exposed to heavy foot traffic or mechanical wear.

Introduction to the Böhme Abrasion Tester

Key Features of the Böhme Abrasion Tester

The Böhme Abrasion Tester is engineered to assess the abrasion resistance of materials with precision and repeatability. It utilizes a rotating disc and abrasive medium to simulate wear conditions effectively. The machine is characterized by its robust construction, compliance with international testing standards, and ease of use. It is suitable for evaluating a wide range of materials, including natural stones, concrete, and ceramics, ensuring reliable data for durability analysis.

How the Böhme Abrasion Tester Works

The Böhme Abrasion Tester operates by simulating wear through the standardized abrasion of material samples under controlled conditions. A flat specimen is mounted on the rotating disc of the tester and subjected to abrasion using a specified abrasive material, typically a sand or corundum mixture. The specimen is pressed against the abrasive surface by a fixed load, ensuring consistent pressure and controlled wear.

Key technical parameters of the Böhme Abrasion Tester include:

- Disc Rotation Speed: Typically 30 ± 1 revolutions per minute (RPM) to ensure stable and reproducible results.

- Test Load: A standardized weight of 294 ± 3 N is applied to the specimen to maintain consistent pressure.

- Abrasive Material: Approved abrasive mixtures are used (e.g., 20% natural quartz sand and 80% binding material).

- Test Duration: The process usually involves 16 test cycles, equivalent to 22 revolutions each, as per ISO or EN standards.

After the test, wear is evaluated by measuring the volume loss or calculating the reduction in sample thickness. This detailed data enables precise analysis of the material’s resistance to abrasion under simulated real-world conditions. The device ensures adherence to international norms, such as EN 1341 or DIN 52108, for material assessment.

Key Components of the Böhme Abrasion Tester

The Böhme Abrasion Tester comprises several critical components that ensure precise and reliable testing in accordance with international standards:

- Rotating Abrasive Disc

The main part of the device is a horizontally mounted abrasive disc made of cast iron. This disc rotates during the test and interacts with the sample material to simulate abrasion. The standard disc has a diameter of approximately 750 mm and a thickness of 25 mm. Its surface roughness and material composition are calibrated to comply with ISO 10545-6 and EN 1338 standards.

- Specimen Holder

A secure, adjustable holder is used to fix the test specimen in place during the process. The typical specimen size is 71 mm x 71 mm (for tiles or bricks) or matches specific dimensions prescribed by standards like EN 1341. The holder ensures consistent sample positioning and prevents movement during testing.

- Abrasive Sand Feed System

An integrated system delivers a controlled quantity of abrasive material, such as standard corundum sand, onto the test surface. The sand grain size and distribution (e.g., 0.5 – 1.0 mm) are specified by norms like DIN 52108 and must remain consistent throughout the test to ensure repeatability.

- Load Application System

The device applies a constant vertical force to the specimen, typically through a weight system. The standard load used is 294 ± 3 N (equivalent to a 30 kg mass) as defined in EN 1339. This ensures uniform pressure on the material through all test cycles.

- Control Panel and Test Monitoring

A control unit enables operators to manage test parameters such as the number of cycles and total revolutions (typically 352 cycles for complete testing). Advanced models may include digital interfaces for real-time monitoring and data logging, enhancing precision and analysis.

- Wear Measurement Tools

To evaluate material performance, the tester often includes volumetric measurement tools or micrometers to detect thickness reduction. Data accuracy is critical for assessing compliance with standards like EN 1342 or ISO 7997.

By combining these key elements, the Böhme Abrasion Tester ensures reliable and reproducible results in the evaluation of materials used in construction, paving, and other high-abrasion environments.

Why Do We Need an Abrasion Tester for Natural Stone?

Natural stone is widely used in applications such as flooring, countertops, and external paving, where it is subjected to significant wear and tear. An abrasion tester is essential to evaluate the material’s resistance to surface wear, helping manufacturers ensure durability and longevity under real-world conditions. By simulating abrasion and measuring material loss, the tester provides critical data to determine compliance with quality standards and performance benchmarks, ultimately ensuring that the natural stone meets the demands of its intended use.

The Importance of Abrasion Resistance in Construction

Abrasion resistance is a fundamental property in construction materials, particularly those subjected to high levels of mechanical stress, such as flooring, pavements, and countertops. Materials with high abrasion resistance are better equipped to withstand the effects of friction and repetitive wear, which is essential for maintaining structural integrity and visual appeal over time. This characteristic is critical to ensure safety, reduce maintenance costs, and extend the lifespan of structures, particularly in high-traffic environments.

Testing for abrasion resistance often involves standardized methods such as the Los Angeles Abrasion Test or the Taber Abrasion Test. These tests measure material durability by simulating real-world conditions and quantifying surface degradation. For instance, concrete and natural stone with high wear resistance are preferred in industrial facilities or outdoor constructions, where heavy use and environmental factors like sand, water, and pedestrian traffic can accelerate surface deterioration. By selecting materials with proven abrasion resistance, construction professionals can enhance performance, comply with industry standards, and meet long-term functional requirements.

Evaluating the Abrasion Resistance of Natural Stone

To evaluate the abrasion resistance of natural stone, I would first identify the specific testing methods recommended by industry standards, such as the ASTM C241 (Standard Test Method for Abrasion Resistance of Stone Subjected to Foot Traffic). This test measures the stone’s resistance to wear by simulating real-world conditions. Additionally, I would analyze the physical properties of the stone, including its mineral composition, density, and inherent hardness, as these factors directly influence durability and performance under abrasive forces.

Next, I would refer to third-party certifications or test results provided by manufacturers to validate the stone’s suitability for its intended application. Comparing results across different types of stone—such as granite, marble, and quartzite—can also help determine which material offers the best abrasion resistance for specific projects. Ultimately, selecting the right natural stone involves a balance of standardized testing, expert analysis, and adherence to project-specific requirements to ensure both functionality and longevity.

Industry Applications of the Böhme Abrasion Tester

- Flooring Material Testing: The Böhme Abrasion Tester is widely used to evaluate the wear resistance of natural stone and concrete materials intended for high-traffic flooring, such as in commercial buildings, airports, and shopping malls.

- Pavement and Road Material Assessment: It plays a critical role in assessing the durability of stones and other materials used in road construction to ensure their ability to withstand vehicular abrasion and prolonged usage.

- Cladding and Facade Validation: The device helps determine the abrasion resistance of stone materials used in cladding and facades, ensuring their suitability for external applications exposed to environmental wear.

- Industrial Workspace Surfaces: The tool is employed to test and verify the durability of surfaces in industrial environments, such as warehouses and factories, where heavy machinery and equipment may cause significant abrasion.

- Quality Control in Manufacturing: Manufacturers of stone products and concrete utilize the Böhme Abrasion Tester in their quality control processes to ensure that materials meet industry standards and customer expectations for wear resistance.

How is the Böhme Abrasion Test Conducted?

The Böhme Abrasion Test is conducted by placing a test specimen, such as a concrete or stone sample, against a rotating abrasive disc under a specified load. The disc is coated with a standard abrasive material, and the specimen undergoes a set number of rotations to replicate wear. The wear on the specimen is then measured by calculating the material loss in terms of volume or weight, which provides a quantitative assessment of the material’s abrasion resistance. This rigorous process ensures consistently reliable results that comply with international testing standards.

Preparing the Specimen for Testing

To prepare the specimen for abrasion testing, it is critical to ensure uniformity and precision. First, the specimen should be cut or shaped in accordance with the testing standard specifications, such as precise thickness, diameter, or surface area. Any deviations in dimensions can adversely affect test accuracy. The surface of the specimen must be cleaned thoroughly by removing contaminants such as dust, oil, or grease, using appropriate solvents or cleaning agents. For materials requiring specific conditioning, such as plastics or rubber, pre-test conditioning at controlled temperature and humidity may be necessary to replicate actual usage environments. Additionally, labels, markings, or fixtures used for gripping should not interfere with the wear surface to maintain the integrity of the test results. Proper preparation establishes the foundation for a valid and repeatable abrasion test.

Understanding the Testing Methodology

Abrasion testing methodologies are designed to evaluate material durability under controlled and repeatable conditions. The commonly employed techniques include the Taber Abrasion Test (ASTM D4060), Martindale Abrasion Test (ISO 12947), and the DIN Abrasion Test (ISO 4649). Each method uses specific equipment and parameters suited to different materials and applications.

1. Taber Abrasion Test (ASTM D4060)

-

- Objective: Measures the wear resistance of coatings or materials.

- Parameters:

- Test load range: 250g to 1000g, depending on the material specification.

- Abrasive wheels (e.g., CS-10 or H-18, as per material type).

- Number of cycles typically ranges from 500 to 5000.

- Key Considerations: Ensure samples have smooth, uniform surfaces and proper mounting. Use appropriate vacuum suction during testing to prevent debris interference.

- Martindale Abrasion Test (ISO 12947)

- Objective: Tests textiles, leather, or similar materials against wear and pilling.

- Parameters:

- Abradant surface (e.g., standard wool felt).

- Testing pressure usually ranges from 9kPa to 12kPa for textiles.

- Cycles typically range up to 50,000 or more, depending on end-use requirements.

- Key Considerations: Ensure parallel alignment of test specimens and consistent contact pressure.

- DIN Abrasion Test (ISO 4649)

- Objective: Commonly applied to rubber and elastomers to measure abrasion loss.

- Parameters:

- Test force: 10N ± 0.2N.

- Abrasion drum speed of 40 rpm.

- Standard abradant paper (e.g., 60-grit sandpaper) used on a rotating drum.

- Key Considerations: Ensure uniform thickness of rubber specimens and precise cutting to align with standard dimensions.

Each technique requires calibration of instruments according to prescribed standards, and environmental factors like temperature and humidity should remain consistent during testing. Documentation of the results, including wear patterns and weight loss (if applicable), ensures data reliability and facilitates comparative analysis across materials. For optimal practices, always adhere to the specific standards governing the test.

Interpreting Test Results

Interpreting test results involves analyzing data to identify patterns, anomalies, and correlations that reveal material performance or compliance with standards. First, ensure measurements align with established benchmarks or reference values to determine if the material meets the required specifications. Pay close attention to wear patterns, weight loss, or surface degradation as indicators of durability and resistance to external factors. Additionally, cross-referencing results with historical data or peer-reviewed studies can validate findings and provide greater context to performance metrics. Accurate interpretation requires careful documentation, statistical analysis, and an understanding of the testing parameters to draw reliable and actionable conclusions.

Technical Specifications of the Böhme Abrasion Tester

The Böhme Abrasion Tester is designed to evaluate the wear resistance of materials through standardized procedures. It consists of a horizontal abrasive disc with a defined rotational speed, typically 30 revolutions per minute, and a clamping device to securely hold the material sample. The abrasive disc is coated with a defined abrasive medium, such as corundum grit, ensuring consistency in testing conditions. The applied load on the sample is standardized, often set at 294 N (30 kg), to simulate uniform testing pressure. Measurements are taken based on material loss, which is calculated by weighing the sample before and after the testing procedure. The device meets international standards such as EN 1338, EN 1339, and EN 1340, ensuring compatibility with globally recognized testing methodologies.

Overview of the Testing Machine

The testing machine integrates cutting-edge technology to deliver accurate and repeatable results across various material durability assessments. Equipped with a high-precision load application mechanism and advanced sensors, the device ensures that testing variables remain within narrow tolerances, minimizing error margins. Its intelligent control system allows for real-time monitoring and adjustment during tests, providing data that aligns with global compliance metrics. Furthermore, incorporating automation capabilities significantly reduces human error while enhancing operational efficiency.

By combining these advanced features with the latest trends in material testing, as highlighted by extensive search engine data, the machine addresses the growing demands for more robust and sustainable construction materials. For industries requiring adherence to stringent standards, this machinery establishes itself as a pivotal tool in quality assurance and material innovation.

Specifications for Different Materials

Concrete

- Compression Strength Range: 20-60 MPa (common grades), customizable up to 100 MPa for specialized uses.

- Testing Standards: ASTM C39 for compressive strength and ASTM C496 for split tensile strength.

- Key Parameters: Water-to-cement ratio, aggregate size, and curing conditions significantly impact test results.

Steel

- Tensile Strength: 400-600 MPa for structural steel (e.g., ASTM A36), with advanced high-strength grades exceeding 1000 MPa.

- Yield Strength: Typically ranges from 250 MPa to 355 MPa for conventional grades.

- Testing Standards: ASTM E8 and EN 10002 cover tensile testing methods.

Composites

- Tensile Strength: Varies widely, e.g., carbon fiber composites may range from 600 MPa to 2000 MPa.

- Shear Strength: 100-300 MPa depending on the matrix and reinforcement material.

- Testing Standards: ASTM D3039 for tensile properties and ASTM D3846 for shear strength evaluation.

Wood

- Compression Strength (parallel to the grain): 20-50 MPa depending on the species.

- Bending Strength (Modulus of Rupture): Commonly 40-100 MPa.

- Testing Standards: ISO 13061 for various mechanical properties and ASTM D143 for small clear specimens.

Plastics

- Tensile Strength: Ranges from 20-100 MPa for thermoplastics, with high-performance variants exceeding 150 MPa.

- Flexural Modulus: 0.5-3 GPa for most engineering-grade plastics.

- Testing Standards: ASTM D638 for tensile properties and ASTM D790 for flexural strength.

These values serve as general references and may need adjustment based on the specific application and environmental conditions. Custom testing configurations ensure accurate compliance with industry-specific performance requirements.

Comparing with Other Abrasion Testers

The Böhme abrasion tester is often compared with other standard abrasion-testing methods, including Taber, Los Angeles (LA) abrasion, and DIN abrasion testers.

|

Parameter |

Böhme |

Taber |

LA Abrasion |

DIN |

|---|---|---|---|---|

|

Test Type |

Sliding |

Rotating |

Impact & Friction |

Sliding |

|

Material |

Concrete, |

Coatings, |

Aggregates |

Polymers, |

|

|

Stone |

Plastics |

|

Rubber |

|

Standard |

EN 1338 |

ASTM D4060 |

ASTM C131/ASTM C535 |

ISO 4649 |

|

Abrasives |

Sand |

Abrasive |

Steel Balls |

Abrasive |

|

Output |

Volume Loss |

Wear Index |

% Mass Loss |

Wear Index |

|

Use Cases |

Flooring, |

Surface |

Roads, |

Rubber, |

|

|

Paving |

Coatings |

Aggregates |

Tires |

Advantages of Using the Böhme Abrasion Tester

- Standardized Testing: The Böhme Abrasion Tester adheres to international standards (e.g., EN 1338, EN 1340), ensuring consistent and reliable results across various applications.

- Material Versatility: It is designed to evaluate the abrasion resistance of diverse materials, including concrete, natural stones, and other paving elements, making it a highly versatile testing option.

- Quantifiable Results: Provides precise measurements in terms of volume loss or wear index, facilitating detailed material comparisons and performance assessments.

- Application Relevance: Particularly suited for simulating real-world conditions encountered by materials in flooring, paving, and similar environments, leading to more accurate performance predictions.

- Ease of Use: Offers a straightforward setup and operation process, minimizing testing complexities and allowing for efficient data collection.

By utilizing the Böhme Abrasion Tester, industries can reliably assess the durability and wear resistance of materials, ensuring compliance with specific performance and durability requirements.

Benefits for Construction Materials

- Enhanced Durability Assessment: Enables precise measurement of wear resistance, critical for ensuring construction materials meet long-term performance standards.

- Regulatory Compliance: Assists in verifying that materials adhere to industry regulations and international testing standards.

- Improved Material Optimization: Provides data to refine material compositions, leading to stronger and more resilient products.

- Cost-Effectiveness: Reduces the risk of material failure, lowering maintenance costs and costly replacements over time.

- Quality Assurance: Facilitates rigorous testing protocols to maintain consistent quality and reliability across production batches.

Ensuring Durability and Longevity

To ensure the durability and longevity of materials, I rely on precise testing and compliance with established industry regulations. Through detailed analysis, I optimize material compositions to create products that are both strong and resilient, minimizing potential risks of failure. By adhering to rigorous quality assurance protocols, I consistently deliver reliable and dependable outputs while aligning with international standards. These steps not only enhance performance over time but also help reduce costs associated with maintenance and replacements, ensuring excellent long-term value.

Cost-effectiveness in Quality Testing

Achieving cost-effectiveness in quality testing requires a strategic balance of thorough assessments and resource efficiency. I focus on implementing risk-based testing approaches, prioritizing critical components to minimize unnecessary testing efforts while ensuring product reliability. By leveraging automated testing tools and advanced analytics, I streamline processes to reduce labor-intensive tasks and human error, directly lowering associated costs. Additionally, I adopt modular testing frameworks that allow for reusability, further optimizing the testing lifecycle. These methods ensure a comprehensive and economical approach to maintaining high standards in quality assurance.

Reference Sources

-

Matest – C129 Abrasion Tester Böhme: Provides details on the instrument’s use for testing paving stones, concrete slabs, and natural stones.

-

Testmak – Böhme Abrasion Tester: Explains the tester’s application for determining the abrasion resistance of various materials, including natural stones.

-

Controls Group – Bohme Abrasion Tester: Discusses the machine’s use for testing natural stones and other construction materials under specific standards.

-

Qualitest – Böhme Abrasion Tester: Focuses on evaluating the abrasion resistance of natural and artificial stones, as well as other construction materials.

-

Top Böhme Abrasion Tester in China

Frequently Asked Questions (FAQs)

Q: What is a Böhme Abrasion Tester?

A: A Böhme Abrasion Tester is a specialized apparatus used to evaluate the wear characteristics of natural stone slabs and various construction materials by testing the abrasion resistance through a controlled grinding process.

Q: How does the Böhme Abrasion Tester function?

A: The Böhme Abrasion Tester functions by using a grinding wheel that applies an abrasive load of 294N±3N while the specimen is placed on a rotating test track, simulating real-world wear conditions.

Q: Why is testing abrasion resistance important for natural stones?

A: Testing the abrasion resistance of natural stones is crucial for predicting their durability and performance in applications such as flooring, paving, and facades, ensuring they can withstand wear over time.

Q: How is the Böhme Abrasion Tester different from the Los Angeles Abrasion Machine?

A: While both machines test abrasion resistance, the Böhme Abrasion Tester specifically evaluates the surface wear of natural stones, whereas the Los Angeles Abrasion Machine is used for assessing coarse aggregates like asphalt and concrete materials.

Q: What materials can be tested with the Böhme Abrasion Tester?

A: The Böhme Abrasion Tester is commonly used for natural stone slabs, natural rocks, and various other construction materials, providing insights into their wear characteristics.

Q: Can the Böhme Abrasion Tester be used for predictive maintenance?

A: Yes, using the Böhme Abrasion Tester can help in predictive maintenance by identifying potential wear issues in materials before they become significant problems, thus facilitating low-cost and high-quality material management.

Q: What are the alternatives to the Böhme Abrasion Tester?

A: Alternatives to the Böhme Abrasion Tester include the Micro-Deval and Los Angeles Abrasion Machine, each with specific applications for different material types and testing conditions.

Q: Is the machine equipped with any specific components?

A: Yes, the Böhme Abrasion Tester is equipped with a rolled steel drum and an abrader, which are essential for conducting the abrasion test effectively.

Q: How is a test conducted on the Böhme Abrasion Tester?

A: A test is conducted by placing the specimen on the test track, applying the abrasive load, and then the machine is started to simulate the grinding action for a set duration to measure material loss.