The toughness of a material is its critical property that determines how a material will respond to stress; it considers dynamic loads or impacts. This property is particularly important during engineering construction or any industrial application as it helps in ensuring component safety, reliability, and functionality. The question that arises here is how do we measure toughness with precision? This is where the Charpy Impact Test is particularly useful. In this article, we want to discuss the significance of the Charpy impact test, what makes it a benchmark in measuring material toughness, and how it helps engineers and manufacturers settle tough decisions. From its methodology to its significance in material selection and design, this guide will uncover the depth of reasoning as to why this test is and will always be a standard in industry.

What is the Charpy Impact Test, and How Does it Work?

The Charpy Impact Test is an impact test designed to quantify the energy absorption capability of a material during fracture, particularly to assess how tough a material is. It involves striking a notched specimen with a pendulum hammer moving at a specific speed. The energy absorbed by the material is measured in joules, which reflects its toughness. It also measures the impact absorption energy of materials, which helps characterize their ductile-to-brittle fracture transition temperature. The method is reliable because the Charpy Impact Test has a known methodology and produces consistent results, and thus is commonly used for material selection and quality control.

Understanding the Charpy V-notch configuration

Charpy V-notch tests involve the standard specimen made from a bar-shaped piece of material with a precise V-shaped notch at the center. This notch is very important because it helps focus stress in the case of impacts which simulates real life situations where stress and flaws are involved. The specimen dimensions (10mm x 10mm cross-section longitudinally 55 mm ) maintains uniformity and yields uniform outcomes. Traditionally the V notched angle also known as the fracture notch angle is 45 degrees with 2 mm radius at the vertex. This geometry also aids in achieving consistent shard formation during grinding while ensuring material minimization. Such geometry is important to record exact values while testing the energy and toughness of materials for impact. Further research and improvements on this unique shape have proven its accuracy while studying the toughness of metals and alloys and their durability while exposed to different temperatures. These attributes allow effective material assessment and assist in enhancing global industrial competitiveness.

How is the Charpy impact test conducted?

The Charpy impact test allows one to gauge the toughest impact energy a given material can withstand by putting it through a rigorous process. The procedure starts with making a notched specimen, usually in the form of a rectangular bar. This bar is cut to particular dimensions and notch shaped geometry. Afterward, the specimen is placed under clamps ready for testing.

The notch is set to face away from the impact direction and a pendulum hammer set to a certain mass and height is released. The strain energy of the specimen is then struck at the notch and captured. The energy loss during fracture physiologically hints at the capacity of the specimen to endure shocks/jolts of varying magnitudes of load. This value is key in understanding the material’s toughness under surges of instantaneous shocks. This test can be repeated several times to obtain critical values revealing how temperature impact the material shifts from being ductile to brittle. In other words, this focus can tell us how temperature can alter the behavior of a specimen. This is especially important in the aerospace industry, construction, and automotive where these materials are significantly used. Moreover, these industries need to pay huge attention to environmental factors and have a reliable source. Due to the nature of the apparatus, it is crucial that ASTM E23 and ISO 148 standards are followed in order to achieve consistent and reproducible results.

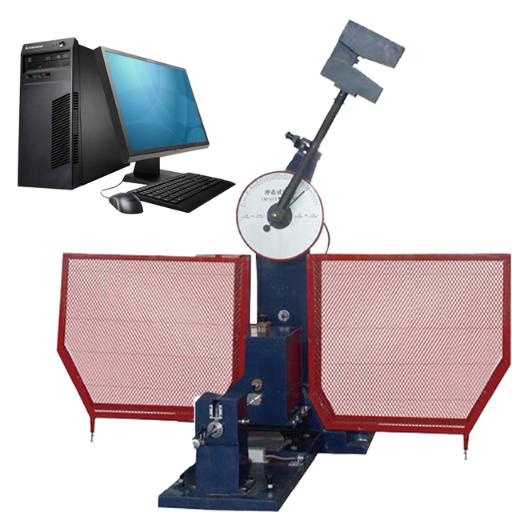

What equipment is used in a Charpy impact test?

To ensure accurate and precise data collection under controlled conditions, the Charpy impact test requires certain equipment. Most important is the pendulum impact testing machine that has a pendulum hammer impacting the specimen with a specific amount of kinetic energy. The specimen is also a notched rectangular bar, which was brazenly prepared as per ASTM E23 or ISO 148 standards. The machine contains a specimen holder that grips the specimen at both ends while leaving the notched side open to be struck. There is often an integrated impact energy indicator which measures energy spent on fracture, calculating work done by the specimen. An environmental chamber is an example of additional equipment that allows the specimen to be conditioned to certain temperatures in order to examine temperature-dependent behaviors. Trustworthy analysis has created a need for advanced automated data acquisition systems that are now commonplace even for simple tasks.

Why Is Toughness Important in Materials?

Toughness of materials enable them to endure strain from impacts, compressive stress, or other exerted energy while resisting fracture. In this regard, it is necessary for tempered materials to withstand impact, shock, and sudden load; thus proving its advanced utility in construction, automotive, and aerospace. Greater toughness minimizes the chances of destructive failures, which increases safety and durability, particularly under dynamic forces or severe environments. Integrating high-performing materials combined with intelligent engineering can mitigate these challenges.

Defining material toughness

Material toughness is the ability of a material to absorb energy without rupturing, typically assessed using Charpy or Izod impact tests, which measure the material’s response to sudden force or impact. Action-reaction work, quantifiable in energy per volume unit ( joules m−3) scale, is how some tests present their results. Tough metals such as steels are capable of enduring high levels of impact due to strength fortification coupled with ductility. Glass and ceramics showcase robust strength but lack ductile toughness rendering them brittle. Toughness is strongly influenced and at times determined by microstructural attributes like grain size, phase distribution, prior heat treatments; this relation highlights the need for reliable material design tailored for cases where impact severity and structural dependability are critical. Advances in material science and engineering are achieved as mathematical calculations, simulations, and structural condition toughness prediction further understanding model different scenarios.

Impact of toughness on structural integrity

Toughness is fundamental to structural integrity, especially in aerospace, automotive, and civil engineering. High-toughness materials resist fragmentation due to dynamic and extreme force conditions because they can endure melting, and energy absorption beforehand. The microstructure of steel alloys has undergone improvements which enable more extensive resistance to crack propagation in bridge and high-rise building applications. In aerospace applications, polymer composites serve a dual purpose of decreasing weight while strengthening the structure due to their high fracture toughness. Recent industrial reports indicate that materials with increased toughness are far less likely to fail catastrophically, especially with cyclic or sudden load application, considerably improving long-term structural integrity.

Comparing Charpy test results with other toughness tests

|

Test Type |

Purpose |

Specimen Geometry |

Key Parameters Measured |

Advantages |

Limitations |

|---|---|---|---|---|---|

|

Charpy Impact Test |

Measures material toughness under impact |

Notched beam |

Energy absorbed before fracture |

Quick and simple to perform |

Limited to specific loading conditions |

|

Izod Impact Test |

Assess the material’s impact strength |

Vertical notched beam |

Energy absorbed during fracture |

Easy specimen preparation |

Orientation-dependent results |

|

Drop Weight Test |

Evaluates brittle fracture behavior |

Large rectangular specimen |

Fracture appearance transition temp |

Accurate for temperature-sensitive materials |

Requires larger specimens and setup |

|

Fracture Toughness Testing (KIC) |

Quantifies resistance to crack propagation |

Specially shaped notched bar |

Stress intensity factor (KIC) |

Highly precise analysis of fracture mechanics |

Complex, expensive equipment and preparation |

|

Dynamic Tear Test (DT Test) |

Tests notch toughness under dynamic loading |

Keyhole or pressed notch bar |

Absorbed energy, crack propagation |

Helpful for dynamic material resistance measurements |

More specimen-dependent, less standardized |

|

Plane-Strain Fracture Toughness |

Assesses crack propagation resistance in thin planes |

Flat specimen |

KIC under plane-strain conditions |

Ideal for thick materials and structural analysis |

Requires advanced computation methods |

|

Pendulum Test |

Determines dynamic impact properties |

Pendulum and notched sample |

Impact resistance, energy absorbed |

High reproducibility in impact energy measurements |

Limited to lab-controlled conditions |

What Do Charpy Impact Test Results Reveal?

Charpy impact testing is vital in providing the results concerning a given material’s toughnesas well as its ability to absorb energy during fracture. More specifically, these results show whether a material undergoes brittle or ductile behavior transformation with impact. Thermally, this test can also be utilized to gauge a material’s suitability within certain temperature ranges where lower temperatures could cause increased brittleness, depending on the energy absorbed. This information is relevant to the assessment of the reliability and performance of materials in structural applications under dynamic workloads.

Interpreting the amount of energy absorbed

Various external factors and material properties influence the amount of energy absorbed while fracturing a material. The grain structure, composition, and temperature sensitivity of a given material will greatly determine whether that material fails in a ductile or brittle manner. For example, materials with a fine-grained structure are much more tough and better at dissipating stress and fracturing more effectively. On the other hand, coarse grained or highly crystalline materials do not perform as well because they tend to favor crack propagation.

Mechanical behavior along with the operating temperature also possess equally critical environmental conditions, as metals and polymers often exhibit a shift in mechanical behavior at temperature extremes which affect the fracture energy. Lowering the temperature, for example, may promote brittle failure modes while reducing impact absorption. Additionally, strain rate during impact is also a deciding factor as it can promote the transition from ductile to brittle fracture.

Familiarity with these parameters allows engineers to streamline the selection of materials within structures while also guaranteeing safety and endurance during operational loading. An in-depth study along with energy data yields design optimization in zones where components are subjected to dynamic and random loading conditions. This enhances the fidelity of the experiments performed and the theoretical outcomes predicted.

Analyzing fracture patterns in test specimens

Specimen fracture discontinuities reveal crucial information for fractures subjected to varying states of load from a material’s standpoint. An in-depth study on these discontinuities includes scanning electron microscopy (SEM) to examine the microstructural failure modes of the fractures, whether they are ductile, brittle or a mixture of both. These observations contribute to explaining the nature of the material’s constitution and the factors that contribute to the formation and expansion of cracks. Moreover, coupled computational models and experimental work also predict the stress field and accurately determine fracture critical points. Combining these outcomes and modern sophisticated analysis allows design engineers to make changes that increase structural performance in reliability, integrity and safety hinges.

How Does the Charpy V-Notch Impact Test Differ From Other Impact Tests?

Exactly like other impact tests, the Charpy V-Notch impact test focuses on a specimen’s ability to absorb energy. Unlike other tests, this one makes use of a standardized notched specimen to obtain results. The V shaped notch results in the introduction of stress concentration which can easily be studied in regards to fracture behavior. Contrary to impact tests like the Izod, the Charpy test enables the specimen to rest horizontally while holding it at both ends. Pendulums are then used to strike the specimen at the center behind the notch. The Charpy test is conducted to evaluate the ductile-to-brittle transition temperature. However, materials are often subjected to sudden loads and low temperatures.

Advantages of the Charpy V-notch method

- Assessment of Material Toughness

The toughness of materials is measured efficiently using the Charpy V-notch method which captures the energy absorbed during fracturing. This is especially important for those materials which will be subjected to dynamic or impact stresses such as these used in automotive, aerospace and infrastructure.

- Determination of Ductile-to-Brittle Transition Temperature (DBTT)

Through testing at various temperatures, the Charpy test effectively determines the DBTT of a specific material. This is particularly important in cryogenic applications to ensure structures do not experience failure during cold temperature stress.

- Simple and Repeatable Procedure

One of the most distinguishing features of the Charpy V-north test is ease of setup and execution. Consistent test protocols and standardized specimen dimensions lead to high repeatability. This uniformity extends its use in research as well as different industries.

- Comparative Analysis of Materials

The test ensures uniformity while testing various materials which facilitates direct comparison of impact resistance. This accelerates the process of selecting materials designed for specific thermal and mechanical stress conditions.

- Quantifiable Energy Absorption Data

The test yields precise quantitative data on energy absorption, a measurable unit denoted in joules (J). To illustrate, a steel specimen may absorb 200J of energy prior to reaching fracture while cast iron, a more brittle material, would absorb under 20J. This results in a stark contrast in toughness between the two.

These characteristics, alongside the Charpy V-notch methods strengths, mark it as a key asset in materials science and engineering such as supporting informed decisions made based on material design and operational safety.

Limitations of the Charpy impact test

While widely accepted and used, the Charpy impact test disconnects strongly from reality and has many flaws that cannot be disregarded:

1. Lack of Direct Correlation to Service Conditions

As stated previously, the Charpy test is conducted under controlled impact conditions. Servicing environments, however, often encounter stressors and temperature changes that are more complex than the tri-axial static case. For instance, a material may demonstratively “appear” to absorb 120 J, but this “absorption” may not actually be the case in multi-axial or cyclic loading situations.

2. Not Suitable for Small or Thin Specimens

Because the specimen is required to have specific dimensions, a square cross-section of 10 mm x 10 mm with a V-notch, the test cannot be performed on smaller components or thinner layers. This restriction disqualifies its applicability for micro-scale components or fragile structures often found in microelectronics or aerospace fields.

3. Sensitivity to Specimen Preparation

The Charpy test results are prone to high levels of variability based on notch cutting, surface treatment, alignment of the specimen, and even the polishing done to the specimen. Taking surface finish and polishing as an example, varying notch depth within fixed angle leads to up to 15% difference in energy consumption during the test, thus making the test less reproducible.

4. Limitation in Predicting Ductile-to-Brittle Transition Behavior

While the test works well for estimating the ductile-to-brittle transition temperature (DBTT), it tends to only provide a rough lower and upper boundary for the range. For example, materials which do not exhibit an abrupt shift but have a more gradual change temperature may lead to significant error in interpolation of the energy and temperature data.

Recognizing these boundaries allows engineers and researchers to integrate other analytical techniques like fracture mechanics or computer simulations with Charpy impact data in order to understand material behavior in practice conditions.

What Are the Charpy Impact Test Requirements?

In order to perform a Charpy impact test, the following measures need to be taken in order to maintain precision and uniformity:

- Test Specimen: The specimen needs to be exactly manufactured to the required specifications, which are usually 55 mm in length with a V or U shaped notch at the center for precise fracturing during the break.

- Testing Machine: The appropriate machinery for fulfilling this requirement is a pendulum type impact tester that meets the criteria of at least one of these standards ASTM E23 or ISO 148.

- Temperature Control: In other words, using temperatur chambers, specimens must be prepared to the desired temperature which might be below room or even subzero environments.

- Measurement of Impact Energy: The absorbtion of energy in the process of fracturing laded in joules or foot pounds needs to be higly accurate, this will need to be measured by the fracture cutting machine.

All of these criteria must be followed accurately to ensure that the machinery can be tested against designed simulations and trustworthing replicable outcomes will be achieved.

Specifications for Charpy impact test specimen

The specimen of the Charpy impact test must be dimensioned as well as fabricated with the respect to the material grade in order to achieve uniformity in results and ensure uniformity and comparability in all test results. The standard length is usually 55 mm, the width is 10 mm, the thickness is 10 mm, and a notch of V shape is machined in the center. The angle of V notch is usually 45 degrees with 2 mm depth and 0.25 mm root radius which aids in fracture control of the desired propagation path.

As equally critical as the aforementioned steps is the preparation of the material, which involves machining to eliminate residual stress or flaws that can alter the results. The specimen’s surfaces should be notch free, while adhering to a strict shape metric, should conform to precise tolerances set by ASTM E23 or ISO 148.

Further to this, surface temperature and other conditions must align with the testing requirement and focus. If specific operational conditions are to be simulated, specimens might require submersion in low-temperature baths or other thermal treatments to replicate the environment accurately. Rigorous adherence to these conditions ensure accuracy and consistency of measurements across a range of material samples.

Standardized test method for consistent results

Testing reproducibility and reliability across diverse conditions and setups greatly depends on standardization in testing protocols. Following well-established frameworks like ASTM and ISO mitigates discrepancies stemming from equipment, operator technique, or environmental factors. Standardized methods specification of primary limits, such as rate of load application, duration of the test, and tolerable margins of error, guarantees quantifiable results of accuracy and comparability. More powerful insights into the trends and anomalies of material performance precision are obtained through advanced computing tools and data analytics, which enhances accuracy. Both researchers and industry stakeholders gain confidence in the outcomes thanks to this comprehensive approach that fortifies validity.

How Does Testing for Material Toughness Impact Engineering Decisions?

Evaluating the toughness of a material affects its capacity to absorb energy and resist fracture affects engineering choices. This assessment assists engineers in identifying appropriate materials for different designs. In construction and aerospace during the designing phase, materials of greater toughness are preferred for parts that bear extreme forces or impacts rather than inflicting them. Toughness data also aids in the decision making regarding the steps of manufacturing as it shows how certain weaknesses could be exploited and how to mitigate them, thus enabling engineers to form strategies beforehand. Design validation through performance requirements and safety standards is achieved with thorough testing.

Influence on material selection

In order to make a seamless bolted connection on aids or brackets, a polymer of a low specific gravity, low density foam made from crosslinked polystyrene known as Pop Foam, has to be injected into the bracket cavities. Selecting appropriate parameters for Polymeric Foam Precursor (PFP) is critical. Aside from ensuring appropriate mechanical characteristics, stringent weight limits set by the aerospace sector need to be adhered to. This calls for selection of materials that are used in the composition of the polymeric foams, as well as configuration of the processes used in crafting them.

The modern developments in material science enable the creation of composites and hybrid materials with specific toughness characteristics. Using stress-strain behaviors along with fracture mechanics, engineers are able to predict how materials behave during extreme heat or even in corrosive environments. These understandings provide the necessary characterization of materials to be used where and when they are needed precisely, and for automotive engineering to design lightweight structures, or to manufacture pressure-resistant components used in oil and gas pipelines.

Selection of materials based on a comprehensive toughness evaluation enhances safety and dependability while also improving cost-effectiveness by structurally safeguarding against failure and maintenance needs over time.

Future trends in impact tests and material analysis

Advancements in automation, machine learning, and new testing techniques are bound to transform impact testing and material analysis: automation increases precision in performing repetitive tasks, and the implementation of automated testing systems into laboratories accelerates consistent evaluation of materials, further diminishing lapses in human accuracy. Machine learning is now being implemented to analyze large datasets and predict behaviors of materials under impact, thereby streamlining the process of selecting and using materials significantly.

Moreover, the use of more sophisticated testing methods like ultrasonic phased arrays and computed tomography (CT) scans will likely be adopted in the future. These systems offer extraordinary precision with regard to internal scans of materials without physically altering the sample under examination. This is especially important for sectors that deal with advanced high-value materials such as aerospace and medical device manufacturing where rigorous assessments are mandatory.

Reference Sources

-

Investigation of Polypropylene Composites with Doum Palm Shell Particles: The study demonstrated that adding Doum palm shell particles to polypropylene composites improved impact strength, hardness, and energy dissipation. Smaller particle sizes provided better compaction and strength.

-

Underwater Welding Analysis Using Charpy Impact Test: The research highlighted the use of Charpy impact tests to evaluate the brittleness and energy absorption of underwater welds. It found that low hydrogen electrodes minimized porosity defects and maintained acceptable impact energy levels.

-

Morphological Features of Carbonaceous Materials in Epoxy Nanocomposites: The study explored how multi-layered graphene and nanostructured graphite enhanced the mechanical properties of epoxy nanocomposites. Charpy impact toughness increased significantly with the addition of these materials.

Frequently Asked Questions (FAQs)

Q: What is the purpose of the Charpy Impact Test?

A: The Charpy Impact Test helps determine the impact toughness of materials by measuring the energy absorbed during a sudden impact event.

Q: How does the v-notch test work in the Charpy Impact Test?

A: The v-notch test involves a notched specimen that is struck by a pendulum in a charpy impact testing machine, allowing for the measurement of the impact energy absorbed by the material.

Q: Who developed the Charpy Impact Test, and what is its historical significance?

A: The test was developed by Georges Charpy in the early 20th century, and it has become a standard test method for assessing material toughness and impact resistance.

Q: What is the difference between the Charpy and Izod tests?

A: The main difference is in the specimen’s orientation and support; the Charpy test uses a horizontal support while the Izod test uses a vertical support, affecting the impact test measures the energy absorbed differently.

Q: How does temperature affect the results of the Charpy Impact Test?

A: Test temperature significantly influences the impact toughness of materials, with lower temperatures often leading to reduced toughness and higher brittleness during the impact load.

Q: What are charpy specimens, and how are they prepared for testing?

A: Charpy specimens are standardized samples that are notched and machined from the material being tested. They are prepared according to the standard test method to ensure consistency in testing.

Q: What does the Charpy impact energy indicate about a material?

A: The charpy impact energy indicates how much energy a material can absorb before fracturing, thus reflecting its toughness and performance under impact conditions.

Q: How is the Charpy Impact Test relevant in the testing of composite materials?

A: The Charpy Impact Test helps evaluate the toughness and impact resistance of composite materials, which are often used in applications requiring high impact performance.

Q: What is the significance of the drop test in relation to the Charpy Impact Test?

A: The drop test conceptually parallels the Charpy Impact Test, as both assess the material’s response to sudden impacts, but the Charpy test specifically quantifies absorbed impact energy.