Road construction is an intricate process that demands the precise integration of materials, engineering techniques, and quality controls to ensure durability and performance. Central to this process are geotextiles—critical components used to enhance soil stabilization, drainage, and erosion control. However, the effectiveness of geotextiles depends heavily on their quality and resilience, which is where geotextile test fixtures come into play. These fixtures are essential tools that assess the mechanical and physical properties of geotextiles to ensure they meet the rigorous demands of modern road construction. This article explores the pivotal role of geotextile test fixtures in elevating infrastructure standards, shedding light on their testing methods, significance in material selection, and their impact on long-term project success. Through this discussion, readers will gain a deeper understanding of how these testing systems contribute to the development of safer, more reliable roads.

How Do Geotextile Test Fixtures Work?

Geotextile test fixtures work by providing a controlled environment to measure the performance and durability of geotextile materials under various conditions. These fixtures simulate real-world stresses such as tension, compression, puncture, and shear to evaluate key properties like tensile strength, permeability, and resistance to deformation. The tests ensure that the geotextile meets required specifications for its intended application, such as soil stabilization or erosion control, and helps engineers select materials that offer optimal performance and longevity in infrastructure projects.

Types of Geotextile Tests and Their Purposes

Geotextile tests can be broadly categorized into mechanical, hydraulic, endurance, and filtration tests aimed at evaluating factors such as strength, durability, water flow, and separation efficiency.

|

Test Type |

Purpose |

Key Parameter |

|---|---|---|

|

Tensile Test |

Measures tensile strength. |

Strength |

|

Puncture Test |

Evaluates puncture resistance. |

Durability |

|

Permeability Test |

Assesses water flow rate. |

Water Flow |

|

CBR Push Test |

Tests resistance to soil puncture. |

Load Capacity |

|

Filtration Test |

Checks filtration efficiency. |

Separation |

|

UV Resistance |

Evaluates UV durability. |

Longevity |

|

Abrasion Test |

Determines wear resistance. |

Wear |

This table summarizes essential geotextile tests, aligning their purposes and key evaluation parameters to facilitate material selection for diverse applications.

Using a Test Machine for Accurate Results

To ensure accurate results when using a test machine, it is essential to follow standardized procedures and account for specific technical parameters associated with each test. Below is a concise explanation of the parameters involved in the listed tests:

- Water Flow Rate (Hydraulic Conductivity): The machine should measure the volumetric flow of water through the geotextile under specific gradients. Parameters include gradient (e.g., 1.0), temperature (20°C as standard), and sample dimensions (e.g., 200mm x 200mm).

- CBR Push Test (Puncture Resistance): Apply a calibrated piston load vertically until failure. Key parameters include piston diameter (50mm), displacement rate (50mm/min), and final load capacity (kN).

- Filtration Test (Permeability Efficiency): Assess flow rate under controlled gradients while measuring the retention of soil particles. Standard parameters include particle size distribution, water head (e.g., 100mm), and test duration (30 minutes).

- UV Resistance Test (Exposure Durability): Expose samples to UV light under controlled conditions per ISO 4892 standards. Parameters include exposure intensity (0.76 W/m² at 340nm), cycle duration (e.g., 100 hours), and ambient temperature (50°C).

- Abrasion Test (Surface Resistance): Employ a rotary abrasion machine to simulate wear and tear. Parameters include rotational speed (e.g., 60 cycles/min), applied load (e.g., 2.5N), and duration (e.g., 500 cycles).

Precise machine calibration and adherence to standards, such as ASTM or ISO protocols, guarantee reliability and reproducibility in test outcomes.

Understanding Tensile Strength and Puncture Resistance

Tensile Strength refers to the maximum amount of tensile stress a material can withstand before breaking. It is a crucial parameter in assessing the durability and performance of materials under tension. Typically measured in megapascals (MPa), tensile strength is determined using standardized methods like ASTM D638 for polymers or ASTM A370 for metals. This property highlights a material’s ability to resist elongation and deformation, making it a vital factor in structural applications, manufacturing, and product design.

Puncture Resistance, on the other hand, evaluates a material’s ability to withstand penetration by sharp objects. This property is essential for materials used in protective applications, such as gloves, packaging, and membranes. Testing methods often involve applying a gradually increasing force to a defined probe until penetration occurs, with results measured in terms of maximum force (Newtons) required for puncture. Standards like ASTM F1342 or ISO 13996 define the protocols for puncture resistance testing, ensuring consistency in evaluating materials.

Understanding both tensile strength and puncture resistance allows for the appropriate selection of materials for specific applications, ensuring optimal balance between flexibility, durability, and protective performance.

How Do Geotextile Tests Ensure Quality and Durability?

Geotextile tests ensure quality and durability by evaluating critical properties such as tensile strength, elongation, permeability, puncture resistance, and abrasion resistance. These tests, conducted in accordance with standardized protocols like ASTM and ISO guidelines, measure the material’s performance under specific stressors and environmental conditions. By assessing parameters like load-bearing capacity and filtration ability, these evaluations help determine the geotextile’s suitability for applications such as soil stabilization, erosion control, and drainage systems. Comprehensive testing ensures that geotextiles meet project requirements and remain reliable over their intended lifespan.

Common Geotextile Test Methods

Common geotextile test methods include wide-width tensile testing, grab tensile testing, puncture resistance, tear resistance, permittivity testing, and UV degradation testing.

|

Test Method |

Purpose |

Parameter |

|---|---|---|

|

Wide-width tensile |

Measures tensile strength |

Load (kN/m) |

|

Grab tensile |

Evaluates handling strength |

Force (N) |

|

Puncture resistance |

Tests resistance to puncture |

Force (N) |

|

Tear resistance |

Assesses resistance to tearing |

Force (N) |

|

Permittivity testing |

Determines water flow ability |

Rate (s⁻¹) |

Role of Test Machines in Assessing Geotextiles

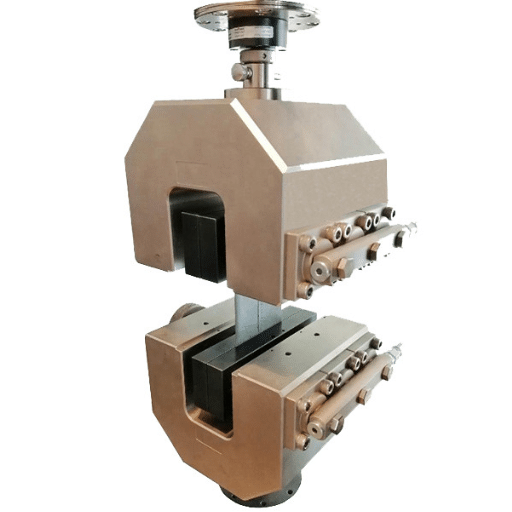

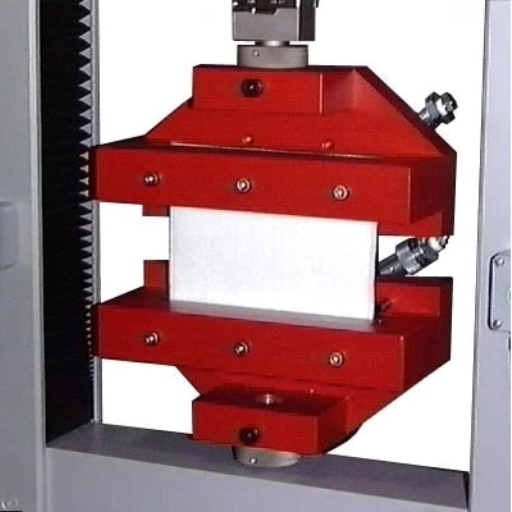

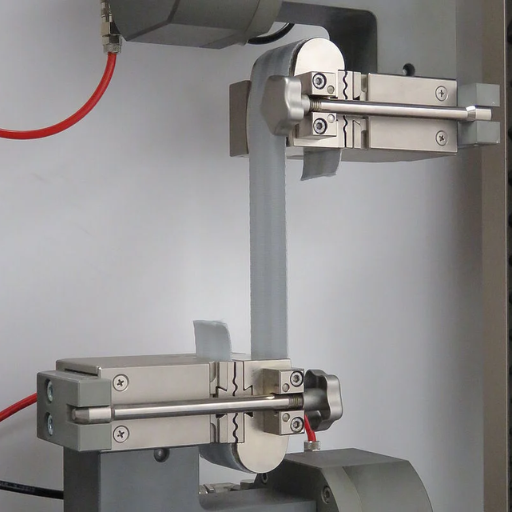

- Universal Testing Machines (UTM): Used to perform tensile, compression, and puncture tests with high precision, ensuring accurate assessment of a geotextile’s mechanical properties.

- Permittivity Testing Apparatus: Specialized equipment designed to evaluate the water flow rate through geotextiles, critical for assessing drainage and filtration efficiency.

- Tear Testing Machines: These machines accurately test the tear strength of geotextiles, crucial for determining their durability under field conditions.

- Puncture Resistance Testers: Devices that measure a geotextile’s resistance to puncture or penetration, simulating real-world stresses in construction applications.

- UV Aging Chambers: Simulate prolonged exposure to ultraviolet radiation to analyze the effects of weathering on geotextile materials, aiding in understanding long-term durability.

Importance of Tensile and Puncture Resistance Tests

Tensile and puncture resistance tests are essential in assessing the mechanical performance and durability of geotextiles under various field conditions. Tensile strength evaluates the material’s ability to withstand forces that might stretch or elongate it, providing critical data on its load-bearing capacity. This is particularly important in applications such as road stabilization and retaining walls, where geotextiles must endure tension without failure. Puncture resistance, on the other hand, measures the material’s capacity to resist penetration by sharp objects—a crucial parameter in construction environments where geotextiles may come into contact with debris or aggregate materials.

Key Technical Parameters:

1. Tensile Strength (ASTM D4595 or ISO 10319):

-

- Typical Range for Geotextiles: 10 to 400 kN/m (varies depending on woven or non-woven type)

- Test Conditions: Constant rate of elongation (e.g., 50 mm/min).

- Elongation at Break:

- Range: 10% to 80%, depending on material flexibility and design.

- Indicates the geotextile’s ability to deform without rupture.

- Puncture Resistance (ASTM D6241 or ISO 12236):

- Force to Puncture: 500 to 3000 N based on geotextile type and thickness.

- Test Conditions: Pressure applied through a steel rod or similar pointed object.

These tests not only confirm that geotextiles meet specific project requirements but also contribute to a predictive understanding of long-term performance under mechanical and environmental loads. Properly measured and documented tensile and puncture resistance ensure the reliability and efficiency of geotextiles in practical applications.

Why Are Geotextile Test Fixtures Essential?

Geotextile test fixtures are essential because they provide standardized and controlled methods for evaluating the mechanical properties and durability of geotextile materials. These fixtures ensure accurate measurement of parameters such as tensile strength, puncture resistance, and elongation under varying conditions, which are crucial for determining material performance in real-world applications. By replicating field stresses in a laboratory setting, test fixtures help predict long-term behavior under loads, environmental factors, and project-specific demands, ultimately ensuring the safe and effective implementation of geotextiles in engineering projects.

Ensuring the Quality of Geotextile Material

To ensure the quality of geotextile material, it is essential to assess and verify key technical parameters through standardized testing methods. The following parameters should be evaluated to confirm material suitability:

- Tensile Strength (ASTM D4595)

The tensile strength should meet or exceed the requirements for the intended application. Typical values range from 10 kN/m to 200 kN/m, depending on whether the geotextile is used for reinforcement, separation, or drainage.

- Elongation at Break (ASTM D4632)

Elongation levels between 10% and 60% indicate adequate flexibility, balancing strength and adaptability to ground movement.

- Puncture Resistance (ASTM D4833)

A minimum puncture resistance of 200 N is recommended for materials subjected to sharp aggregates or construction equipment loads.

- Permeability (ASTM D4491)

Geotextile permeability values (k) should be within the range of 10⁻³ to 10⁻¹ cm/s to enable adequate water flow while preventing soil migration.

- UV Resistance (ASTM D4355)

The material should retain at least 70% of its original tensile strength after 500 hours of UV exposure, ensuring durability in outdoor installations.

- Aperture Size / Filtration Opening (ASTM D4751)

Aperture sizes should be appropriately matched to the soil particle distribution, typically ranging from 0.1 mm to 1.0 mm, depending on soil type and project requirements.

By systematically verifying these parameters, engineers can ensure that the selected geotextile meets performance criteria and is suitable for safe, long-term application in civil engineering projects.

Understanding the Purpose of Geotextile Testing

The primary purpose of geotextile testing is to confirm the material’s suitability for specific engineering applications by evaluating its physical, mechanical, and hydraulic properties. This ensures optimal performance under varied environmental and load conditions. Key objectives include assessing filtration efficiency, drainage capability, tensile strength, and resistance to puncture or tear. Accurate testing enables engineers to design systems that effectively control erosion, reinforce soil structures, and prevent contamination or clogging within drainage systems. By aligning testing methods with standard protocols such as ASTM and ISO requirements, geotextile materials can be reliably certified for durability, compatibility with project specifications, and long-term stability in demanding field conditions.

Enhancing Geotextile Filtration and Drainage Capabilities

To maximize filtration and drainage performance of geotextiles, it is essential to consider their key technical parameters, including pore size (O50), permeability (k), and permittivity (ψ). Pore size, often measured as the apparent opening size (AOS), determines the material’s ability to retain soil particles while allowing water to pass through. Typical AOS values for effective filtration range from 0.1 mm to 0.5 mm, depending on soil gradation.

Permeability reflects the ease with which water flows through the geotextile, typically expressed in units of cm/s. For high-performance filtration, permeability should exceed that of the surrounding soil, frequently falling between 1 × 10⁻⁴ cm/s and 1 × 10⁻² cm/s. Permittivity, defined as the permeability normalized by geotextile thickness, ensures water flow uniformity and is generally recommended to be greater than 0.1 s⁻¹.

To enhance drainage performance, engineers commonly select nonwoven geotextiles due to their higher water flow rates compared to woven alternatives. Selecting geotextiles with high tensile strength (ranging from 10 to 25 kN/m) ensures durability under stress, making them suitable for demanding applications such as retaining walls, subsurface drainage, and erosion control. Adhering to standards such as ASTM D4491 for water permeability and ASTM D4751 for pore size evaluation ensures reliable performance and long-term stability in complex infrastructure projects.

What Are the Testing Methods Used for Geotextile Material?

Several standardized testing methods are employed to evaluate the performance and quality of geotextile materials. These include:

- Tensile Strength Testing (ASTM D4595): Measures the material’s strength when subjected to tension, ensuring it meets the mechanical requirements for specified applications.

- Water Permeability Testing (ASTM D4491): Assesses the rate at which water can flow through the geotextile, critical for drainage and filtration applications.

- Pore Size Distribution (ASTM D4751): Determines the apparent opening size (AOS) of the material, which defines its filtration characteristics.

- Burst Strength Testing (ASTM D3786): Evaluates the ability of the geotextile to withstand sudden localized pressure.

- UV Resistance Testing (ASTM D4355): Examines the material’s degradation when exposed to ultraviolet light, reflecting its durability under prolonged sunlight exposure.

By adhering to these testing standards, geotextile materials can be validated for their intended functions, ensuring reliability and long-term sustainability in engineering applications.

Understanding Tensile Testing and Its Importance

Tensile testing is a fundamental mechanical test that evaluates a material’s ability to resist tension until failure, providing critical data for design and analysis in engineering applications. The process involves applying a controlled tensile force to a specimen and measuring various parameters such as tensile strength, elongation, yield strength, and Young’s modulus. These metrics offer insights into the material’s elastic and plastic behavior, making it possible to determine its suitability for specific applications.

This test is of paramount importance in industries such as construction, aerospace, and manufacturing, where materials are subjected to significant stress during their operational lifetime. For example, tensile strength assists in selecting materials that can withstand specific loads without deforming or breaking, while elongation indicates flexibility. Furthermore, tensile testing adheres to precise standards set by organizations like ASTM and ISO, ensuring consistency and reliability of the results. By understanding these properties, engineers and designers can optimize product performance, improve safety, and reduce structural failures.

Evaluating Puncture Resistance in Geotextiles

When evaluating puncture resistance in geotextiles, I focus on standardized test methods like ASTM D4833 to ensure accurate and comparable results. This test involves subjecting a geotextile sample to a concentrated load using a metal probe until puncture occurs, enabling precise measurement of the force required. Puncture resistance is critical for applications where geotextiles are exposed to sharp objects or uneven surfaces, as it directly impacts durability and functionality. By examining factors such as material composition, thickness, and tensile properties, I can determine the most suitable geotextile for the intended application, ensuring long-term performance and reduced risk of material failure.

The Role of Universal Testing Machine in Quality Assurance

- Tensile Strength Testing: The Universal Testing Machine (UTM) evaluates the tensile strength of materials by applying controlled tension until failure, ensuring that products can withstand the required stress in real-world applications.

- Compression Testing: The UTM conducts compression tests to determine a material’s ability to resist compressive forces, which is essential for assessing the structural integrity of components under load.

- Flexural Testing: By measuring the flexural or bending strength, the UTM helps identify how materials perform under bending loads, ensuring suitability for applications involving stress variations.

- Elongation and Ductility Measurement: The UTM accurately measures the elongation and ductility of materials by tracking deformation before fracture, helping manufacturers optimize material formulations for desired flexibility.

- Adherence to Industry Standards: The UTM ensures compliance with established industry and international standards by providing reliable data on mechanical properties, contributing to product certification and regulatory approval.

What Is the Purpose of Geotextile Testing in Road Construction?

Geotextile testing in road construction serves to evaluate the performance and durability of geotextile materials under various conditions to ensure they meet design specifications. These tests assess key properties such as tensile strength, filtration efficiency, permeability, and resistance to environmental degradation. The purpose is to confirm that the geotextile will effectively reinforce soil, provide drainage, prevent erosion, and enhance the overall stability and longevity of road infrastructure. This ensures the material complies with industry standards and performs reliably in its intended application.

Enhancing Road Durability with Geotextile Tests

Geotextile testing is an essential procedure in modern road construction to ensure long-term performance and stability. These tests evaluate the material’s mechanical and hydraulic properties to guarantee optimal functionality in diverse environmental conditions. Key assessments include tensile strength testing to measure the ability to withstand stretching forces, permeability tests to ensure adequate water flow management, and puncture resistance tests to assess robustness under load stresses. Additionally, filtration efficiency testing determines the geotextile’s capacity to retain soil particles while allowing water to pass through, which is critical in preventing clogging and erosion.

The importance of geotextile tests extends to mitigating common road failure issues such as uneven settling, subgrade weakening due to water infiltration, and surface cracking. By conducting rigorous laboratory analyses and adhering to ASTM or ISO standards, engineers can select materials tailored to specific project requirements. Combining technical expertise with targeted geotextile applications fosters not only the durability but also the sustainability of road infrastructure.

Assessing Erosion Control and Permeability

When assessing erosion control and permeability, I analyze how efficiently the geotextile can prevent soil displacement while allowing water to pass through. This involves testing its filtration capability to ensure fine soil particles are retained without clogging while maintaining adequate drainage. Furthermore, I evaluate the material’s strength and durability in various environmental conditions to confirm its long-term effectiveness in stabilizing the soil and managing water flow.

The Role of Geotextiles in Aggregate and Soil Stabilization

- Erosion Control: Geotextiles effectively mitigate soil erosion by stabilizing the surface and preventing the displacement of soil particles caused by water or wind forces.

- Separation: These materials serve as a barrier between different layers of soil or aggregate, preventing intermixing and maintaining the structural integrity of the layers.

- Filtration: Geotextiles allow water to pass through while retaining fine soil particles, promoting proper drainage systems and reducing the risk of soil migration.

- Reinforcement: By distributing loads across a larger area, geotextiles enhance the structural stability of soil, providing additional strength to roadways, foundations, and other engineered structures.

- Drainage Facilitation: Acting as a conduit for water, geotextiles improve the drainage capacity within a system, helping to reduce water pressure in soil and prevent waterlogging.

Reference Sources

- Importance of Geotextile in Road Construction – Ocean Geosynthetics

- Importance of Geotextiles in Road Constructions & Types – Aimil

- Geotextiles as Separation Layers in Highway and Road Construction – MnDOT

- Test Methods of Geotextiles – Textile Sphere

- Top Test Fixtures in China

Frequently Asked Questions (FAQs)

Q: What are the different types of geotextiles used in road construction?

A: In road construction, the main types of geotextiles are woven geotextiles and non-woven geotextiles. Woven geotextiles are made by weaving fibers together, offering high strength and are used for reinforcement. Non-woven geotextiles are made from bonded fibers and are typically used for filtration and separation.

Q: How do woven geotextiles provide reinforcement in road construction?

A: Woven geotextiles provide reinforcement by offering high tensile strength, which helps stabilize soil layers and prevent shifting. This reinforcement is crucial for maintaining the integrity of the road structure, especially in areas with weak soil characteristics.

Q: What is the importance of geotextile test fixtures in determining the properties of the fabric?

A: Geotextile test fixtures are essential for assessing the properties of the fabric, such as strength, permeability, and durability. These tests ensure that the geotextile products meet the necessary standards for construction projects, providing reliable reinforcement and filtration.

Q: How do non-woven geotextiles differ from woven geotextiles in their application?

A: Non-woven geotextiles differ from woven geotextiles in their application by being more suited for filtration and separation purposes due to their permeable nature. They are often used to allow the flow rate of water while maintaining separation between different soil layers.

Q: Why is material testing important for geotextiles in road construction?

A: Material testing for geotextiles is important to ensure that the geosynthetic materials used can withstand the demands of the construction environment. Tests such as tensile testing machine and grab testing help determine the strength of the material and its suitability for specific applications.

Q: How does geotextile fabric contribute to slope stability in road construction?

A: Geotextile fabric contributes to slope stability by reinforcing the soil and preventing erosion. It acts as a stabilizing layer that holds the soil in place, reducing the risk of landslides and embankment failures.

Q: What role do geosynthetics play in the construction industry?

A: Geosynthetics play a crucial role in the construction industry by enhancing the performance and longevity of infrastructure projects. They are used for reinforcement, filtration, drainage, and separation, contributing to the overall stability and durability of construction projects.

Q: How does the weave of geotextiles affect their performance?

A: The weave of geotextiles affects their performance by influencing their strength, permeability, and flexibility. Woven fabrics generally provide higher strength and are used for reinforcement, while non-woven fabrics offer better filtration and separation capabilities.

Q: Can geotextiles be used in conjunction with other geosynthetics like geogrids?

A: Yes, geotextiles can be used in conjunction with other geosynthetics like geogrids to enhance the overall performance of construction projects. Combining different geosynthetics can provide comprehensive solutions for reinforcement, drainage, and separation.

Q: What are the common materials used in the production of geotextiles?

A: Common materials used in the production of geotextiles include polypropylene and polyester. These materials are chosen for their durability, strength, and resistance to environmental factors, making them suitable for various construction applications.