Tensile testing is a fundamental process in materials science and engineering, offering critical insights into the mechanical properties of materials. By subjecting a material to controlled tension, this test evaluates key characteristics such as tensile strength, elasticity, ductility, and ultimate breaking point. But why is this process so important? Whether you’re designing robust structural components, ensuring product safety, or adhering to industry standards, tensile testing forms the backbone of material selection and performance validation. This article dives into the reasons why tensile testing is indispensable, exploring its role in understanding material behavior, optimizing design processes, and ensuring long-term reliability. You’ll gain a deeper appreciation for how this seemingly straightforward procedure drives innovation and maintains the integrity of countless industries.

What Is a Tensile Test and How Does It Work?

A tensile test is a mechanical testing method used to determine how a material responds to forces that attempt to stretch it. During the test, a sample of the material is subjected to a controlled tensile force until it breaks. This process measures key properties such as tensile strength, elasticity, elongation, and the material’s breaking point. The results provide critical insight into the material’s mechanical behavior, helping engineers assess its suitability for specific applications.

Understanding the Tensile Test Process

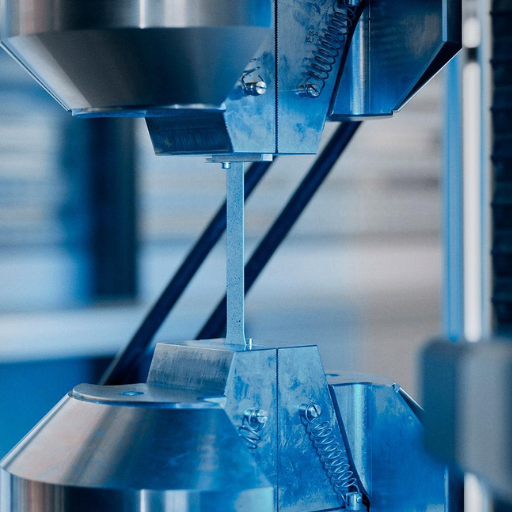

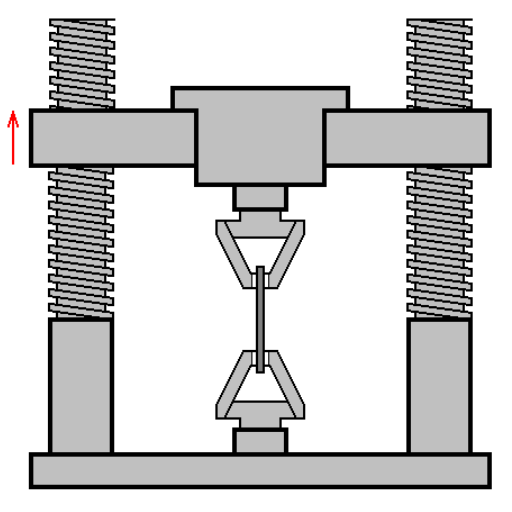

The tensile test process begins by preparing a standardized specimen, designed to ensure consistency in results. This specimen is typically clamped into a universal testing machine (UTM), which applies a uniaxial tensile force. During the test, the machine gradually increases the load at a controlled rate while simultaneously measuring the specimen’s response, including stress and strain values. Data collected often include the yield strength, ultimate tensile strength, elastic modulus, and ductility, which are critical for understanding how the material behaves under stress.

The results of the test are plotted as a stress-strain curve, a graphical representation that outlines important behavior like the elastic and plastic deformation regions, proportional limits, and the failure point. Engineers use this information to determine whether the material can endure specific operational demands and environmental conditions, ensuring reliable performance and safety in its intended application.

The Role of the Test Machine in Tensile Testing

- Load Application and Measurement: The test machine applies a controlled uniaxial tensile load to the specimen, enabling precise measurement of the material’s response under stress.

- Strain Measurement: Equipped with extensometers or strain gauges, the machine accurately records the elongation of the material, allowing for the determination of strain values as the load increases.

- Data Logging and Analysis: Modern tensile test machines are integrated with digital systems to log stress and strain data in real time, facilitating detailed analysis and the generation of stress-strain curves.

- Controlled Testing Conditions: The machine maintains highly controlled environmental and loading conditions, ensuring consistent and reproducible results for accurate material characterization.

- Specimen Failure Assessment: By continuing the load application until material failure, the machine identifies critical points such as ultimate tensile strength, yield strength, and failure strain, providing comprehensive insights into the material’s mechanical properties.

Key Tensile Properties Measured

- Ultimate Tensile Strength (UTS): This is the maximum stress that a material can withstand while being stretched before necking occurs. It serves as a primary indicator of the material’s robustness.

- Yield Strength: Yield strength marks the stress at which a material begins to deform plastically. Beyond this point, permanent deformation occurs, and it is a critical measure of a material’s durability under load.

- Elongation at Break: This property quantifies the strain a material can endure before failure, expressed as a percentage of its original length. It provides insight into the material’s ductility.

- Elastic Modulus: Also known as Young’s Modulus, this measures the stiffness of a material, representing the ratio of stress to strain in the elastic deformation range.

These properties collectively define the mechanical behavior and operational capabilities of materials under tensile forces.

Why Is Tensile Testing Important in Material Science?

Tensile testing is crucial in material science because it provides a comprehensive understanding of a material’s mechanical properties, such as strength, ductility, and elasticity. By subjecting materials to controlled tension, engineers and scientists can determine performance limits, predict behavior under stress, and identify suitability for specific applications. This data is essential for material selection, quality control, design optimization, and ensuring safety and reliability in practical use.

Evaluating Mechanical Properties of Materials

Key Technical Parameters for Evaluating Mechanical Properties

When evaluating the mechanical properties of materials, several critical technical parameters must be considered. These parameters provide essential insights into material behavior under various conditions:

- Tensile Strength (σ): Indicates the maximum stress a material can withstand while being stretched. This is a vital parameter for applications requiring high durability under tensile loads.

- Yield Strength (σy): Represents the stress at which a material begins to deform plastically. It defines the transition between elastic and plastic behavior.

- Elastic Modulus (E): Measures a material’s stiffness or resistance to deformation under stress. This is crucial for applications demanding high rigidity.

- Ductility (%elongation or %reduction in area): Evaluates the extent to which a material can deform before fracture. This factor is critical in determining material toughness and usability in dynamic conditions.

- Fracture Toughness (KIC): Quantifies a material’s ability to resist crack propagation. It is a key consideration in structural applications where failure prevention is critical.

- Hardness (measured by scales such as Rockwell, Vickers, or Brinell): Provides insight into a material’s resistance to surface deformation, wear, and abrasion.

- Fatigue Strength: Assesses a material’s endurance under cyclic loading. This property is crucial for components subjected to repetitive stress.

- Poisson’s Ratio (ν): Defines the ratio of lateral strain to axial strain in a material under loading. It helps predict deformation behavior in three dimensions.

Each of these parameters is determined through standardized testing protocols and heavily influences material-selection decisions for engineering and manufacturing applications.

The Importance of Tensile Strength in Engineering

Due to being among the most important parameters in engineering, tensile strength entails stress a material can handle before being pulled or stretched to the point of failure. This property allows, for example, the construction of components meant to withstand certain loads, verify the functionality, and check if any failures are present within the structure for various applications. Most important factors, however, remain the basic composition of constituents, the sum of forces active tending to shatter a structure, and the conditions under which a system will work.

Key Technical Parameters Related to Tensile Strength

- Ultimate Tensile Strength (UTS): Represents the maximum stress a material can withstand in tension before breaking. It is measured in units such as megapascals (MPa) or pounds per square inch (psi). UTS is a decisive factor in determining whether a material is suitable for high-load scenarios.

- Yield Strength (σy): The stress at which a material begins to deform plastically. Below this point, the material will return to its original shape when the load is removed. Yield strength is critical for predicting the behavior of materials under normal working conditions.

- Elongation at Break (%): Expresses the extent to which a material can stretch before breaking, providing insight into its ductility. This parameter is frequently included in material specifications to balance strength and flexibility.

- Modulus of Elasticity (E): Indicates how much a material deforms under elastic loading conditions. It is particularly important in applications where stiffness is prioritized, such as in aerospace or automotive components.

Applications and Implications

Engineering disciplines such as civil, mechanical, and aerospace rely heavily on precise knowledge of tensile strength for designing reliable structures and components. For instance, in bridge construction, the tensile strength of cables and steel supports determines load capacity and safety. Similarly, in aerospace engineering, materials with high tensile strength and low weight, such as titanium alloys, are preferred for optimizing performance. Proper evaluation of tensile strength ensures that materials can withstand operating stresses without failure, directly impacting durability and cost-effectiveness.

How Tensile Testing Services Enhance Product Quality

Tensile testing services play a critical role in enhancing product quality by ensuring materials meet performance standards and reliability requirements. Through the precise measurement of tensile strength, elongation, and yield properties, these services help identify material suitability for specific applications. By revealing weaknesses or inconsistencies in materials, tensile testing allows manufacturers to make informed decisions about design, production processes, and material selection. This rigorous evaluation minimizes the risk of product failure, improves safety, and supports compliance with industry regulations, ultimately leading to more durable and cost-effective products.

How to Perform a Tensile Test?

To perform a tensile test, follow these key steps:

- Specimen Preparation: Select a standardized test specimen with defined dimensions and surface quality, ensuring it represents the material being evaluated.

- Equipment Setup: Use a calibrated tensile testing machine capable of applying controlled force. Attach the specimen to the machine’s grips securely to avoid slipping during the test.

- Parameter Configuration: Input necessary test parameters such as grip separation speed, force range, and test duration as per relevant standards (e.g., ASTM, ISO).

- Test Execution: Start the test, allowing the machine to apply uniaxial tension. The specimen will deform until it fractures, while data is recorded in real-time.

- Data Analysis: Capture and interpret key metrics such as ultimate tensile strength, yield strength, and elongation. These values provide essential insights into the material’s mechanical properties.

- Documentation: Compile and report the results in compliance with industry or project-specific requirements, incorporating any observed anomalies for thorough analysis.

Preparing the Tensile Specimen

When preparing the tensile specimen, I ensure compliance with the standardized specifications outlined by relevant standards such as ASTM E8/E8M or ISO 6892. Specimens must be machined from the material stock uniformly and with precision to avoid introducing stress concentrations or defects. I confirm that gauge lengths, width, and thickness meet the specified dimensions for the material and test type, ensuring reproducibility. Furthermore, I verify that the specimen surface is free of irregularities and properly finished, as these factors can impact load distribution and test outcomes.

Setting Up the Universal Testing Machine

To set up the Universal Testing Machine (UTM), I begin by ensuring the machine and its components are properly calibrated per the manufacturer’s specifications and relevant test standards, such as ASTM E4. I confirm that the load cell and extensometer are attached securely and selected based on the anticipated load range and strain requirements of the test. Next, I carefully install the test specimen in the grips, aligning it precisely to prevent eccentric loading, which could skew results. Once the specimen is secured, I verify the test software settings, inputting the appropriate parameters such as loading rate, test type, and environmental conditions. Finally, I conduct a pre-test inspection of the entire setup to ensure reliability and safety before initiating the test sequence.

Analyzing the Tensile Test Results

Once the tensile test is complete, I review the data to determine critical properties of the material, such as yield strength, ultimate tensile strength, and elongation at break. Using the stress-strain curve generated by the test, I analyze key points, including the elastic limit and fracture point, ensuring that the results align with expected performance standards or material specifications. Any anomalies or unexpected trends are compared against the test setup to rule out procedural errors or equipment malfunctions. This detailed assessment allows me to accurately characterize the material’s mechanical behavior under applied stress.

What Are the Different Types of Tensile Testing?

Tensile testing can be categorized into several types, including standard tensile testing, true stress-strain testing, high-temperature tensile testing, axial tensile testing, and cyclic tensile testing.

|

Test Type |

Description |

Key Points |

|---|---|---|

|

Standard Testing |

Measures basic tensile properties, such as yield strength, ultimate strength, and elongation. |

Basic metrics |

|

True Stress-Strain |

Analyzes stress-strain relationships beyond the yield point for detailed material behavior. |

Detailed data |

|

High-Temp Testing |

Assesses tensile properties of materials at elevated temperatures to ensure heat resistance. |

Heat testing |

|

Axial Testing |

Applies uniaxial stress to evaluate directional strength and material isotropy. |

Directional |

|

Cyclic Testing |

Examines material performance under repeated loading and unloading conditions to assess durability. |

Durability |

Standard Test Methods for Different Materials

When it comes to standard test methods for different materials, I would approach the questions by summarizing the key aspects of each type of testing briefly:

- Tensile Testing evaluates a material’s ability to withstand axial forces before undergoing plastic deformation or fracturing. It provides critical data on tensile strength, elasticity, and elongation. This helps engineers select suitable materials for structural applications.

- High-Temperature Testing is utilized to ensure that materials maintain mechanical integrity at elevated temperatures. By simulating extreme environmental conditions, this test confirms a material’s heat resistance and performance reliability over time.

- Axial Testing, which applies uniaxial stress to a sample, is primarily used to measure strength and isotropy along a single direction. This provides insights into how a material will perform under directional loads.

These methodologies are essential tools in material science for predicting behavior, ensuring safety factors, and guiding material selection processes across industries.

Comparing Uniaxial Tensile vs. Other Tests

The primary tests for material performance comparison include Uniaxial Tensile, Compressive, Shear, Flexural, and Hardness tests. Below is a concise table summarizing key parameters and characteristics across these testing methodologies.

|

Test Type |

Key Focus |

Load Type |

Direction |

Outcome |

Material Example |

|---|---|---|---|---|---|

|

Uniaxial Tensile |

Strength |

Tensile |

Single |

Max stress-strain |

Metals |

|

Compressive |

Resistance |

Compressive |

Single |

Deformation rate |

Ceramics |

|

Shear |

Shear Force |

Shear |

Perpendicular |

Shear modulus |

Adhesives |

|

Flexural |

Flexibility |

Bending |

Multi |

Bend stress |

Polymers |

|

Hardness |

Surface |

Indentation |

Static |

Resist wear |

Alloys |

Special Considerations for Composite Materials

Composite materials present unique challenges during mechanical testing due to their heterogeneous structure and anisotropic behavior. Unlike metals or polymers, composites often consist of a combination of distinct materials, such as fibers embedded within a matrix, which necessitates specialized testing protocols. For tensile tests, it is critical to align the test direction with the principal fiber direction to achieve accurate results, as properties can vary significantly with orientation. Additionally, factors such as fiber-matrix interfacial bonding and void content must be considered, as these can influence mechanical performance.

Environmental conditions, including temperature and humidity, also play a crucial role in the testing of composite materials. High temperatures can degrade the matrix, altering load-carrying capabilities, while moisture absorption may compromise structural integrity. Thus, conditioning composites to service-relevant environments prior to testing ensures data accuracy and relevance. Furthermore, selecting proper grips and ensuring even load distribution during testing are vital to prevent premature failures at the gripping points.

Finally, regulatory standards—including ASTM and ISO guidelines—provide frameworks to ensure consistent and reliable testing of composites. Adhering to these standards ensures comparability across datasets and reliability in application-specific design decisions.

How Do Tensile Testing Machines Work?

Tensile testing machines operate by applying a controlled tensile force to a material sample while measuring its response to the load. The process begins with securely mounting the specimen between two clamps or grips to ensure even force distribution. The machine then utilizes a load frame and a crosshead that moves at a predetermined speed to elongate the material. Sensors, such as load cells, measure the applied force, while extensometers or strain gauges monitor the elongation or deformation. These measurements are recorded and translated into stress-strain data, which is analyzed to determine material properties such as tensile strength, elasticity, and ductility. The entire process is governed by precise automation and software to ensure repeatable and accurate results.

Components of a Universal Testing Machine

A Universal Testing Machine (UTM) is composed of several critical components designed to measure material properties under various conditions with precision and reliability:

- Load Frame: The load frame serves as the structural backbone of the UTM. It consists of two vertical columns and a horizontal crosshead, which can move to apply force to the specimen. The load frame is designed to withstand high forces without distortion, ensuring accurate and repeatable results.

- Crosshead: The crosshead is a movable component that applies tensile or compressive forces to the test specimen. Powered by a servo motor or hydraulic system, the crosshead’s precise positioning is essential for controlling the deformation rate during testing.

- Load Cell: The load cell is a highly sensitive device that measures the applied force during testing. It converts mechanical force into an electrical signal, ensuring accurate force readings across a wide range of material properties.

- Grips and Fixtures: Grips and fixtures secure the test specimen during the experiment. These components vary depending on the type of test (tensile, compressive, or flexural) and are designed to ensure proper alignment and minimize slippage.

- Extensometer or Strain Measurement Device: Extensometers or strain gauges are used to accurately measure the deformation or strain of the specimen. These devices are critical for determining properties like elongation and the modulus of elasticity.

- Drive Mechanism: UTMs use either hydraulic or electromechanical drive systems to control the crosshead movement. Hydraulic systems are often used for high-capacity testing, while electromechanical systems provide precise control for smaller loads.

- Control System: The control system typically includes a computer or microcontroller-based interface. It allows users to define test parameters, monitor real-time data, and analyze results through advanced software.

- Safety Features: Modern UTMs are equipped with safety features, such as limit switches, overload protection, and emergency stop buttons, to prevent damage to the machine and ensure operator safety.

- Data Acquisition and Analysis Software: The software collects data from sensors in real-time, processes the stress-strain information, and generates graphs and reports for comprehensive analysis of the material behavior.

Each component of the UTM is essential for ensuring consistent and accurate testing across a variety of materials and testing conditions. Together, these elements enable UTMs to provide reliable data for the evaluation of mechanical properties.

The Function of Grips in Testing

- Securing the Specimen: Grips are designed to hold the test specimen firmly in place to prevent slippage during testing, ensuring accurate and reliable results.

- Distributing Force Evenly: By applying uniform pressure along the contact surfaces, grips help prevent stress concentrations, which could otherwise lead to premature specimen failure.

- Accommodating Various Specimen Types: Grips are engineered to handle different shapes, sizes, and materials, allowing for versatile testing of metals, polymers, composites, and more.

- Maintaining Alignment: Properly designed grips ensure that the specimen remains aligned with the testing axis, minimizing bending stresses and improving the validity of test data.

- Withstanding High Loads: Grips are constructed with robust materials to endure the high tensile or compressive forces applied, reducing the risk of equipment damage or test interruptions.

Calibration and Maintenance of Tensile Testing Equipment

Proper calibration and maintenance of tensile testing equipment are critical to obtaining accurate and reliable results. To ensure precision, I verify that all load cells and extensometers are calibrated according to industry standards, using traceable reference materials. Regular inspections are conducted for wear and alignment issues, particularly on grips and fixtures, as misalignments can impact test data integrity. I follow manufacturer guidelines rigorously, scheduling preventative maintenance at specified intervals and replacing any components showing signs of degradation. When performing adjustments or calibrations, I document all procedures meticulously to maintain compliance and traceability, adhering to ISO or ASTM testing standards.

Reference Sources

-

Why Everyone Should Care About Tensile Testing (And How to Conduct a Proper One) – Discusses the significance of tensile testing and its proper execution.

-

What is Tensile Testing and Why is it Important? – Explains the role of tensile testing in evaluating weld performance and material strength.

-

What is Tensile Testing? – TWI – Provides an overview of tensile testing, including its purpose and applications.

-

Tensile Testing in Research and Development in 2024 – Highlights the role of tensile testing in determining material properties for research and development.

-

Top Tensile Testing Machine in China

Frequently Asked Questions (FAQs)

Q: Why is performing a tensile test important in materials science and engineering?

A: Performing a tensile test is important because it helps determine the tensile properties of a material, such as tensile strength, tensile modulus, and elongation. These properties are crucial for understanding the behavior of materials under tension and ensuring they meet specific engineering requirements.

Q: What is a tension test and what does it measure?

A: A tension test, also known as a tensile test, measures the engineering stress and engineering strain of a material being tested. It involves stretching a test piece to determine its strength, ductility, and breaking strength, providing key insights into its mechanical properties.

Q: How does tensile testing provide insights into the material being tested?

A: Tensile testing provides insights by measuring how a material responds to tension. It identifies the tensile stress and tensile strain the material can withstand before failure, helping engineers design products that are safe and reliable.

Q: Why is understanding tensile modulus significant in tensile testing?

A: Understanding tensile modulus is significant because it indicates the stiffness of a material within the elastic region. It helps engineers predict how much a material will deform under a certain load, which is crucial for applications requiring specific elastic properties.

Q: What role does tensile strength testing play in determining the strength of the material?

A: Tensile strength testing plays a critical role in determining the maximum stress a material can withstand while being stretched before breaking. This information is essential for ensuring the material’s suitability for various applications and for understanding its strength and ductility.

Q: How can tensile testing systems vary for different materials?

A: Tensile testing systems can vary based on the type of material being tested. Different materials, such as metals, polymers, and composites, may require specific testing conditions and appropriate test methods to accurately assess their properties.

Q: What is the significance of offset yield strength in tensile testing?

A: Offset yield strength is significant as it indicates the stress at which a material begins to deform plastically. Knowing this property helps engineers ensure that materials will not permanently deform under specified working loads.

Q: Why is it important to use the appropriate test method during tensile testing performed on materials?

A: Using the appropriate test method is important because it ensures the accuracy and reliability of the results. Different materials and applications require specific testing procedures to accurately measure tensile properties, which are fundamental to materials science and engineering.

Q: What are the key outcomes of tensile testing performed on brittle materials?

A: The key outcomes of tensile testing performed on brittle materials include determining the breaking strength and understanding the material’s limited ductility. This information is crucial for applications where brittle failure needs to be avoided.