Manhole covers are critical components of urban infrastructure, tasked with enduring immense loads and variable environmental conditions to maintain safety and functionality. Ensuring their durability and reliability is not just a matter of routine testing but an essential requirement to meet stringent regulatory standards. This is where a manhole cover test machine becomes indispensable. Designed to simulate real-world stressors, these machines provide precise data on a cover’s load-bearing capacity, material integrity, and overall performance. This article will explore the pivotal role these machines play in material testing, shedding light on why they are a fundamental investment for industries committed to delivering superior and reliable infrastructure solutions.

What Is a Manhole Cover Test Machine?

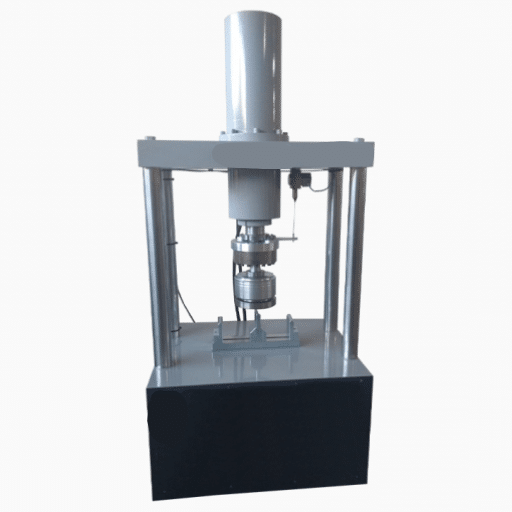

A Manhole Cover Test Machine is a specialized device used to evaluate the strength, durability, and load-bearing capacity of manhole covers. It applies controlled pressure and stress to simulate real-world conditions, ensuring that the covers meet safety and performance standards. These machines are essential for verifying compliance with industry regulations and preventing potential failures in infrastructure components.

Understanding the Testing Machine

Key Features and Components of the Manhole Cover Test Machine

The Manhole Cover Test Machine is equipped with a robust hydraulic system to apply controlled and measurable loads, capable of assessing both static and dynamic forces exerted on manhole covers during use. Advanced load sensors and digital interfaces ensure precise data collection, allowing engineers to analyze the structural integrity and performance of the materials. Many machines are designed to accommodate various testing parameters, including vertical pressure tests, bending tests, and impact resistance studies, versatile enough to meet industry standards like EN 124 or ASTM guidelines. Additionally, safety mechanisms, such as overload protection systems, are integrated to ensure consistent and reliable testing without equipment failure. The efficiency of these machines plays a critical role in maintaining infrastructure safety and meeting regulatory requirements promptly and accurately.

Role in Material Testing

- Assessing structural integrity through standardized stress and strain evaluations.

- Ensuring compliance with international standards such as EN 124, ASTM, and ISO.

- Measuring material durability under extreme conditions, including temperature variations and mechanical load differences.

- Identifying potential failure points through detailed fatigue and wear analysis.

- Conducting comprehensive impact resistance tests to simulate real-world conditions.

- Evaluating material deformation properties under controlled bending and compression scenarios.

- Supporting research and development initiatives by providing precise performance data for new material formulations.

- Facilitating quality control processes to minimize defects and ensure product reliability.

Importance of Testing for Safety

Testing plays a critical role in ensuring the safety, functionality, and durability of materials and products used in various applications. By subjecting materials to rigorous evaluations, potential failure modes can be identified and mitigated before deployment. Key technical parameters considered during testing include:

- Tensile Strength: Measures the maximum stress a material can withstand when stretched. Typical ranges vary based on material type, e.g., 250-400 MPa for structural steel.

- Impact Energy: Assesses a material’s resistance to sudden impacts, often measured using the Charpy or Izod impact test (e.g., values around 20-100 J for polymers depending on thickness).

- Hardness: Evaluated using standardized scales such as Rockwell or Brinell, determining resistance to surface indentation, e.g., Brinell Hardness 200-250 for medium carbon steel.

- Fatigue Limit: Identifies the stress level below which a material can endure repeated loading without failure (e.g., ~50% of ultimate tensile strength for metals).

- Deformation Characteristics: Monitored under bending, torsion, or compression to ensure materials perform as expected under load.

These parameters ensure that materials meet safety and performance standards, reducing the risk of catastrophic failure and enhancing product reliability in real-world applications. Comprehensive testing enables proactive identification of weaknesses, supporting innovations and maintaining high safety benchmarks.

How Does a Testing Machine Work?

A testing machine operates by applying controlled forces to a material or component to measure its response under specific conditions. It typically consists of a load frame, a drive mechanism, sensors, and a data acquisition system. The load frame holds the specimen securely while the drive mechanism applies forces, such as tension, compression, or torsion, at calibrated rates. Sensors measure parameters like load, deformation, or displacement, while the data acquisition system records and processes this information in real-time. The results help determine material properties, such as strength, elasticity, or failure points, ensuring precision and consistency in testing outcomes.

Components of a Manhole Cover Test Machine

- Load Frame

The load frame provides a rigid and stable structure to securely hold the manhole cover during testing. It is designed to withstand high forces without deformation and typically features adjustable fixtures to accommodate various sizes and shapes of covers.

- Drive Mechanism

The drive mechanism delivers controlled forces, such as compression or static loads, to simulate real-world conditions. This includes hydraulic or electromechanical actuators capable of applying forces up to 100 kN – 500 kN, depending on the test requirements.

- Load Cells

High-precision load cells measure the force applied to the manhole cover with minimal error. These sensors typically operate within a range of ±1% accuracy to ensure reliable data collection.

- Displacement Sensors

Displacement sensors monitor deformation or deflection of the manhole cover during loading. Linear Variable Differential Transformers (LVDTs) or similar devices are commonly used, offering resolutions in the range of 0.01 mm – 0.1 mm.

- Data Acquisition System (DAQ)

The DAQ system records and processes real-time information from load cells and displacement sensors. It is equipped with interfaces for graphical analysis and customizable test configurations, ensuring efficient data management and reporting.

- Control Unit

The control unit regulates the actuation process, allowing for precise settings such as load rate, duration, and maximum force. It is vital for automating test sequences and ensuring repeatability.

- Protective Enclosure

A safety enclosure shields the operator from potential hazards, such as fragments from cover failure. Transparent polycarbonate panels or reinforced steel housings are commonly used.

- Calibration System

An integrated or external calibration system ensures periodic verification of sensors and actuators, maintaining compliance with industry standards like ASTM A30 or EN 124.

Principles of Compression and Load Testing

Compression and load testing are fundamental procedures in material and structural analysis, aimed at determining the strength, deformation, and failure properties of materials or components under specific loads. These tests are governed by standardized processes to ensure consistent results and compliance with industry norms.

- Compression Testing

Compression testing involves applying a gradually increasing compressive force to a material specimen until it deforms or fractures. This type of test is essential for evaluating materials such as metals, polymers, or concrete. Key metrics obtained include compressive strength, modulus of elasticity, and deformation behavior under load. Test setups typically require a universal testing machine (UTM) equipped with compression platens or fixtures designed for the specimen’s geometry. ASTM and ISO standards, such as ASTM E9 or ISO 604, guide the protocols for accurate testing.

- Load Testing

Load testing ensures that structures or components can bear expected operational loads safely without failure. This process is crucial for validating the performance of bridges, beams, and industrial equipment. Load is systematically applied, often replicating real-world conditions, to measure deflection, stress, and strain. Data from load tests confirm compliance with safety margins and help identify weaknesses. Standards like ASCE 7 and EN 1990 specify requirements for load testing procedures.

Both testing methods rely on precise instrumentation, such as strain gauges and load cells, to collect data with high accuracy. Proper calibration of testing equipment and adherence to international standards are critical for obtaining reliable and reproducible results.

Understanding Hydraulic Systems

Hydraulic systems operate based on Pascal’s principle, which states that pressure applied to a fluid in a confined system is transmitted undiminished in all directions. These systems consist of components such as a hydraulic pump, fluid reservoir, valves, actuators (e.g., cylinders or motors), and pipelines. The pump generates the required pressure by moving fluid from the reservoir into the system, enabling mechanical work. Actuators convert the hydraulic energy into kinetic or linear motion, depending on the application.

A critical advantage of hydraulic systems is their ability to produce high force and precise motion control in compact designs. However, regular maintenance is essential to prevent issues such as fluid contamination, leakage, or pressure loss, which can impair performance. These systems find applications in industries ranging from aerospace and automotive to construction machinery, underscoring their versatility in delivering controlled power efficiently.

What Are the Benefits of Using a Manhole Cover Test Machine?

Manhole cover test machines provide a reliable and efficient method for evaluating the structural integrity and durability of manhole covers under varying load conditions. These machines ensure compliance with industry standards by simulating real-world stress scenarios, thereby minimizing the risk of failure in the field. Additionally, they help reduce maintenance costs by identifying potential defects early, allowing for timely corrective actions. Their precision and repeatability enhance the quality assurance process, making them an indispensable tool for manufacturers and testing facilities.

Ensuring Precision and Accuracy

Precision and accuracy in testing equipment depend on multiple factors, including design specifications, calibration protocols, and environmental conditions. To achieve optimal performance, it is essential to regularly calibrate machines using traceable standards, which ensures that measurements remain consistent and within acceptable tolerances. Advanced technologies such as digital sensors and automated control systems have further enhanced the ability to minimize systematic and random errors. Additionally, maintaining a controlled testing environment—free from excessive vibration, temperature fluctuations, and humidity—can significantly improve measurement reliability. Regular audits and compliance with ISO 17025 standards for calibration and testing strengthen the equipment’s reliability, ensuring consistency across applications and reinforcing the integrity of results.

Improving Reliability of Manhole Covers

Key Factors for Improving Reliability of Manhole Covers

To improve the reliability of manhole covers, several technical parameters and considerations must be addressed:

1. Material Selection: The choice of material significantly influences durability and load-bearing capacity. Common options include:

-

- Ductile Iron: High tensile strength (minimum 420 MPa) and excellent impact resistance.

- Composite Materials: Lightweight, corrosion-resistant, and non-conductive, ideal for specific applications.

- Steel Reinforcements: Added to enhance structural integrity for high-traffic areas.

- Load Class Compliance (per EN 124 standards):

- Class A15: For pedestrian-only areas, supporting a load of up to 1.5 tons.

- Class B125: Suitable for sidewalks and light traffic zones, supporting up to 12.5 tons.

- Class D400: Designed for roads and highways, supporting up to 40 tons.

- Anti-Slip Design:

- The surface must incorporate patterns with a friction coefficient above 0.6 to reduce slipping hazards under wet conditions.

- Corrosion Resistance:

- Use of protective coatings, such as hot-dip galvanization or epoxy resin applications, offers extended resistance to environmental damage.

- Secure Fitting and Locking Mechanisms:

- Ensuring precise tolerances (±0.1 mm) and implementing tamper-proof locking systems prevents dislodgement and unauthorized access.

- Maintenance Protocols:

- Routine inspections every 6-12 months to detect wear, cracks, and corrosion.

- Load-testing during preventive maintenance cycles to verify compliance with operational demands.

These measures, combined with strict adherence to quality standards and real-world testing scenarios, can substantially enhance the reliability and safety of manhole covers across diverse applications.

Enhancing Stability and Safety

To ensure optimal stability and safety of manhole covers, several key strategies must be implemented:

1. Material Selection: Utilizing high-strength materials such as ductile iron ensures durability under heavy loads while maintaining resistance to cracking and corrosion. Advanced composite materials are also becoming popular for their lightweight and non-conductive properties, enhancing both functionality and worker safety.

- Precision Engineering: Manhole covers must be designed with tight tolerances to ensure a secure fit within frames. Anti-slip surface designs enhance traction, reducing the risk of accidents, while locking mechanisms prevent dislodgement due to external forces or unauthorized tampering.

- Load Standards Compliance: Adhering to international standards, such as EN 124 or ASTM A48, guarantees that the covers are rated for specific load classifications, ensuring they can withstand dynamic stresses in traffic-heavy environments.

- Maintenance Practices:

- Regular inspections are critical for identifying structural wear, deformation, or misalignment.

- Implementing real-time monitoring systems with embedded sensors can detect anomalies, such as physical displacement or environmental stresses, improving proactive maintenance schedules.

- Applying corrosion-resistant coatings extends the product’s lifespan in environments with high moisture or chemical exposure.

- Integration of Smart Technologies: Incorporating IoT (Internet of Things) capabilities, such as sensors that monitor stress, vibration, and temperature, provides real-time data to optimize performance and preemptively address structural concerns.

Investing in these measures creates a robust strategy to enhance the longevity and safety of manhole cover systems while mitigating risks in urban and industrial environments.

How Does the Testing Machine Ensure Compliance with Standards?

The testing machine ensures compliance with standards by conducting precise and repeatable evaluations of manhole cover systems under controlled conditions. It simulates real-world forces, such as load-bearing capacity and impact resistance, to determine whether the materials and design meet the required specifications. Advanced sensors and data logging features provide accurate measurements, enabling detailed analysis and verification against international standards such as EN 124 or AASHTO M306. This rigorous testing process ensures that the covers are capable of withstanding operational demands while maintaining safety and durability.

Role of Certification and Inspection

- Compliance with Standards: Certification and inspection processes ensure that products adhere to established international, national, or industry standards, guaranteeing their safety, quality, and performance.

- Quality Assurance: By conducting thorough inspections, manufacturers can identify and address any defects or inconsistencies, maintaining high standards of production.

- Risk Mitigation: Regular inspections minimize the likelihood of failures or hazardous incidents by identifying potential issues before products are deployed or installed.

- Regulatory Approval: Certification demonstrates compliance with legal and regulatory requirements, facilitating market access and preventing potential legal liabilities.

- Consumer Confidence: Certified and inspected products instill trust among end-users, as these processes validate the reliability and durability of the goods or systems in question.

Adherence to Industry Standards

Adhering to industry standards ensures that products and systems meet established benchmarks for safety, quality, and performance. I understand that these standards are often set by authoritative organizations and serve as a framework for consistency and reliability. By complying with such standards, I can enhance product interoperability, reduce risks associated with failures, and maintain compliance with regulatory requirements. Furthermore, leveraging standards allows me to align with best practices, ensuring that my work supports both innovation and global competitiveness.

Testing in Accordance with Guidelines

Testing in accordance with guidelines ensures that my processes meet established benchmarks for quality, safety, and performance. By following these frameworks, I can systematically evaluate outcomes, identify potential flaws, and implement corrective actions as necessary. This disciplined approach not only supports regulatory compliance but also fosters consistent results, enhances user trust, and mitigates risks associated with non-conformance.

What Are the Types of Materials Tested Using a Manhole Cover Test Machine?

Different types of materials tested using a manhole cover test machine include cast iron, ductile iron, composite materials, concrete, and fiberglass.

|

Material |

Description |

Key Strength |

Durability |

|---|---|---|---|

|

Cast Iron |

Traditional metal used |

High |

Long-Lasting |

|

Ductile Iron |

Modified iron alloy |

Flexible |

High |

|

Composite |

Lightweight polymer |

Corrosion-Free |

Moderate |

|

Concrete |

Cement-based material |

Heavy Load |

High |

Testing on Cast Iron and Steel

Testing cast iron and steel manhole covers involves evaluating their strength, load-bearing capability, and durability under simulated real-world conditions. The tests are conducted using a manhole cover test machine to adhere to industry standards, such as EN 124 or AASHTO specifications. Below are the key parameters and results:

1. Load-Bearing Capacity

-

- Cast Iron: Demonstrates a static load-bearing capacity of up to 40 tons, making it suitable for heavy traffic zones.

- Steel: Exhibits a higher tensile strength, supporting static loads exceeding 50 tons. This makes it applicable for extreme industrial environments.

- Impact Resistance

- Cast Iron: Moderately resistant to impact due to its brittle nature, measured with a Charpy impact test, typically ranging from 10–20 J.

- Steel: Superior impact resistance, with Charpy impact values between 40–70 J, depending on alloy composition.

- Corrosion Resistance

- Cast Iron: Susceptible to rust and degradation in high-moisture environments unless treated with protective coatings.

- Steel: Stainless steel alloys provide corrosion resistance, although standard carbon steel requires galvanization or coating for improved durability.

- Thermal Properties

- Cast Iron: Shows reduced thermal conductivity, performing well in environments where heat exposure is moderate.

- Steel: Possesses higher thermal conductivity, which may necessitate insulation under high-heat conditions.

These tests underline the application-specific benefits of both materials. Cast iron is advantageous for its affordability and shear compressive strength, while steel offers enhanced versatility and robustness for specialized industrial applications.

Analyzing Composite Materials

Composite materials are engineered from two or more constituent materials with significantly different physical or chemical properties. The combination results in a material that exhibits superior characteristics compared to its individual components. Commonly, composites consist of a matrix, which binds the material together, and a reinforcement component that provides strength and rigidity.

Properties and Applications

Composite materials are valued for their high strength-to-weight ratio, corrosion resistance, and design flexibility. For instance, carbon fiber-reinforced polymers (CFRPs) are frequently used in aerospace and automotive industries for their lightweight yet durable properties. Similarly, glass-reinforced polymers (GRPs) are widely used in construction and marine applications due to their impact resistance and versatility.

Key Advantages

- Mechanical Performance: Composites exhibit enhanced strength, stiffness, and fatigue resistance compared to traditional materials like metals or ceramics.

- Thermal and Chemical Resistance: Many composite materials can withstand high temperatures and are resistant to environmental degradation, making them ideal for harsh conditions.

- Customization: The combination of different matrix and reinforcement materials allows for tailored properties to suit specific application needs.

Challenges

Despite their advantages, composites pose challenges, including high production costs, complex manufacturing processes, and difficulties in recycling. These barriers are significant in industries prioritizing cost efficiency and sustainability, although ongoing research aims to address these limitations.

By leveraging these characteristics, composite materials are transforming modern engineering, offering solutions that traditional materials cannot achieve. Their adoption continues to grow as advancements in production techniques improve cost-effectiveness and recyclability.

Evaluating Concrete and Cement

Concrete and cement are fundamental materials in construction but serve distinct purposes. Cement acts as the binding agent in concrete, a composite material made from cement, water, sand, and aggregates. While cement provides the adhesive strength, concrete delivers structural durability and flexibility for large-scale projects.

Key differences include their composition and usage. Cement alone is prone to cracking and is unsuitable for standalone applications, whereas concrete’s combination of materials grants it enhanced compressive strength and weather resistance. Furthermore, concrete’s curing process, which involves the chemical reaction between cement and water, is critical in achieving its final strength and longevity. Modern advancements have also introduced variations such as reinforced concrete and eco-friendly cements, addressing performance and environmental requirements.

Both materials play crucial roles, with cement being integral to producing concrete, the backbone of infrastructure development worldwide.

Reference Sources

-

Petersen Products: Manhole & Underground Utilities Testing Solutions – Discusses tools for detecting leaks and structural flaws in manhole covers, ensuring compliance with industry standards.

-

TCR Engineering: Expertise in Precast Manhole Cover Testing – Highlights the importance of testing manhole covers for extreme loads, tampering resistance, and accident prevention.

-

Polieco: Manhole Cover Certifications – Provides information on compliance with the EN 124:2015 standard for manhole covers in vehicular and pedestrian areas.

- Top Manhole Cover Testing Machine in China

Frequently Asked Questions (FAQs)

Q: What is a Manhole Cover Test Machine?

A: A Manhole Cover Test Machine is a specialized device used for conducting tests on manhole covers to evaluate their strength and durability under various conditions. It simulates real-world scenarios to ensure the materials used can withstand demanding conditions.

Q: Why is a Manhole Cover Test Machine essential for material testing?

A: It is essential because it provides accurate and reliable testing results, ensuring that manhole covers meet safety standards. The machine uses advanced testing techniques to assess the bearing capacity and residual deformation of various materials under hydraulic loading conditions.

Q: How does the testing software enhance the performance of the Manhole Cover Test Machine?

A: The testing software enhances performance by allowing for digital control and precise force measurement. It provides a comprehensive data analysis, enabling users to customize and adjust the tests for specific requirements.

Q: What role does the piston play in the Manhole Cover Test Machine?

A: The piston is crucial for applying hydraulic force during tests. It ensures uniform pressure distribution over the sample, which is necessary for accurate flexural and compression testing.

Q: Can the Manhole Cover Test Machine perform tests on similar products?

A: Indeed, additional works like drainage covers and other infrastructure project elements can be tested with the machine because of its adaptable versatility of design and superior control adjustment features.

Q: What are the benefits of using a servo system in the Manhole Cover Test Machine?

A: Results of the tests can be obtained from the machine with the use of a servo system, which guarantees precision, and reliability, and employs a uniform application of force to the workpiece. With these conditions, accurate test results will surely be achieved.

Q: How does the hydraulic oil and hose system function in the machine?

A: The hydraulic oil and hose system is responsible for transmitting power to the piston, allowing for smooth and controlled hydraulic loading. This system is essential for performing accurate strength tests on manhole covers.

Q: What makes the Manhole Cover Test Machine easy to use?

A: Its user-friendly interface, automatic settings, and graphic displays make it easy to operate, even for those with minimal training. The machine’s design ensures straightforward adjustments and quick setup for various tests.

Q: How does the Manhole Cover Test Machine cater to the global market?

A: By providing a measurement system that adheres to international standards, the Manhole Cover Test Machine meets the varied requirements of the global market, ensuring compatibility and reliability in different regions.